Patents

Literature

41results about How to "Increase heat absorption rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

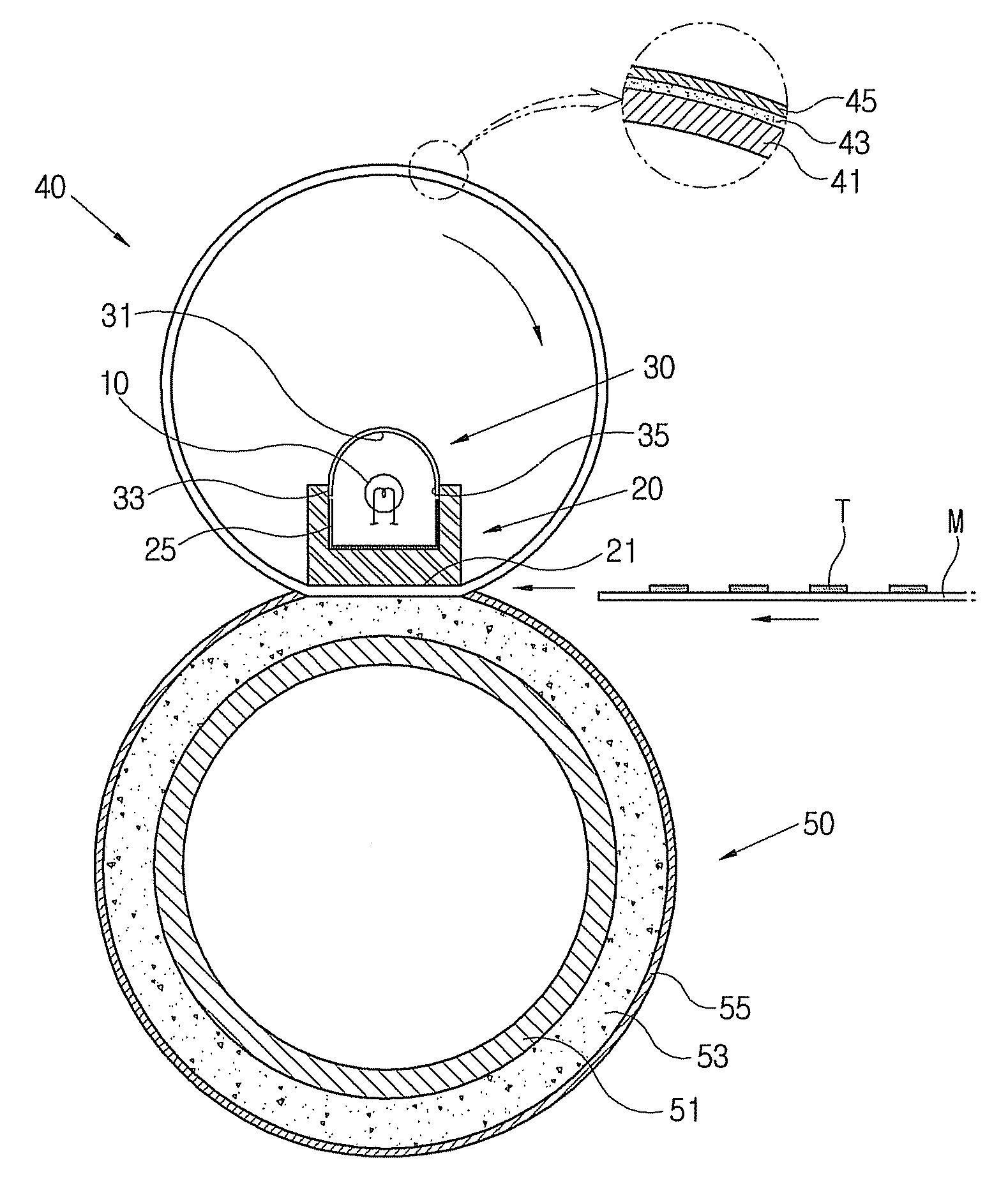

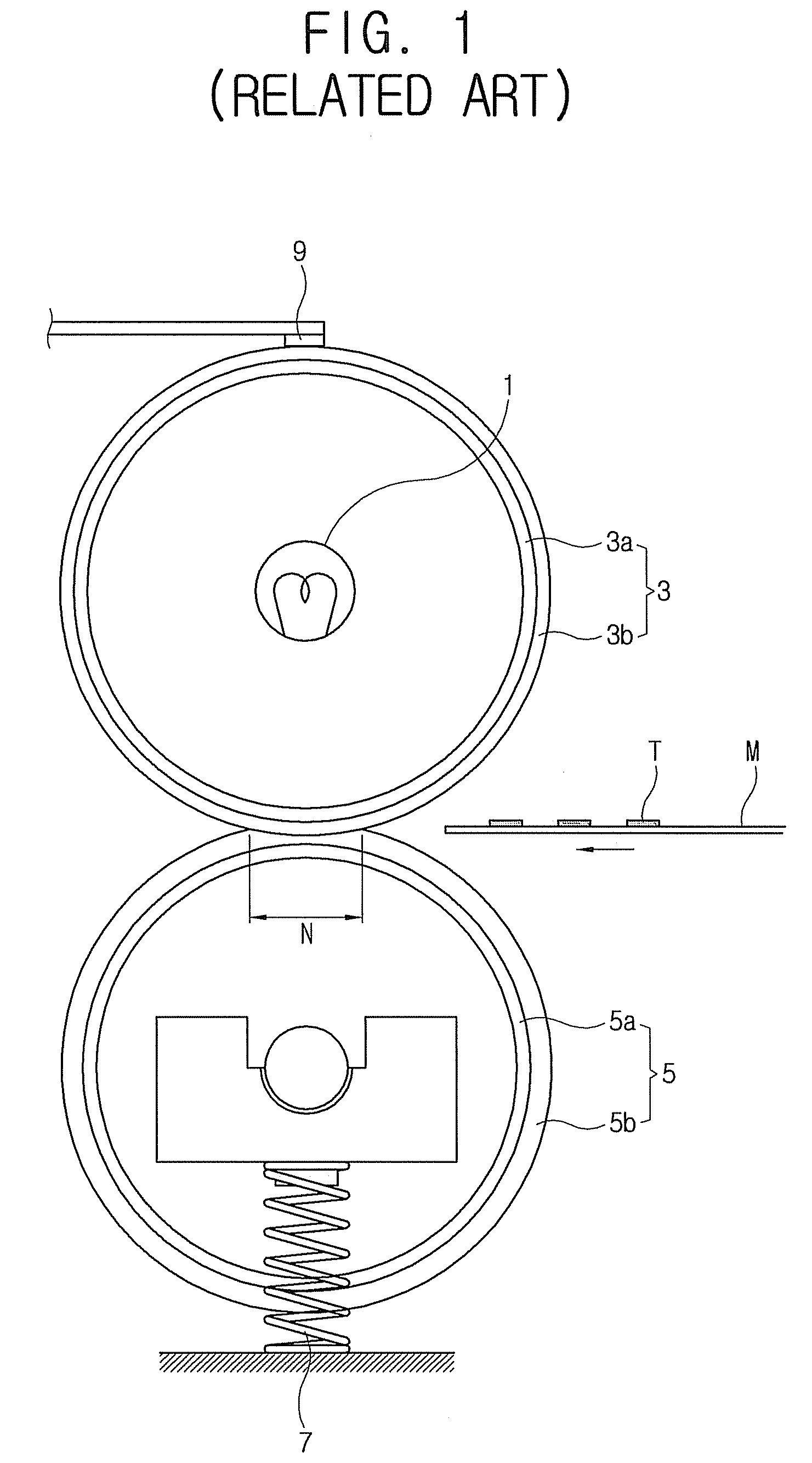

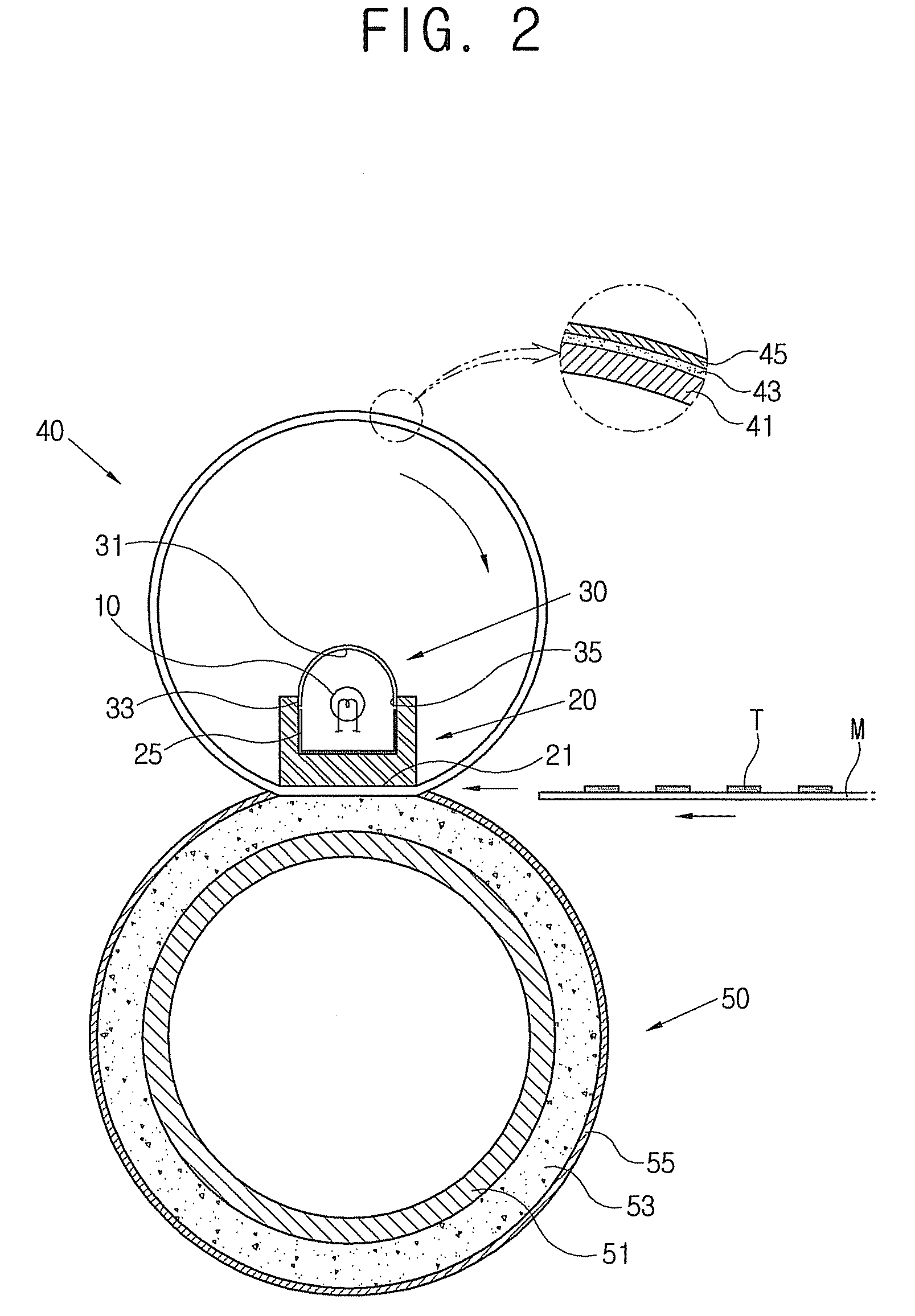

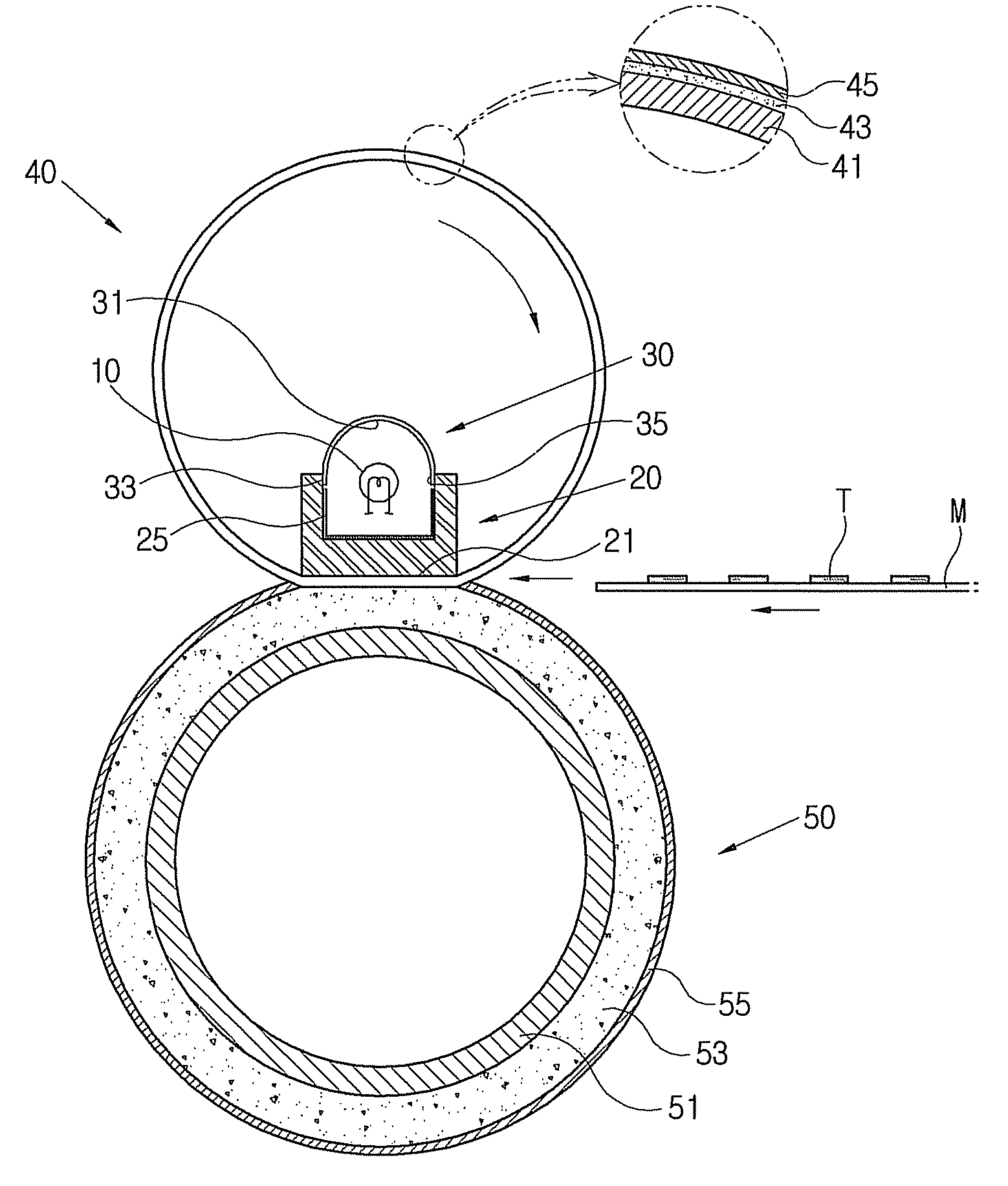

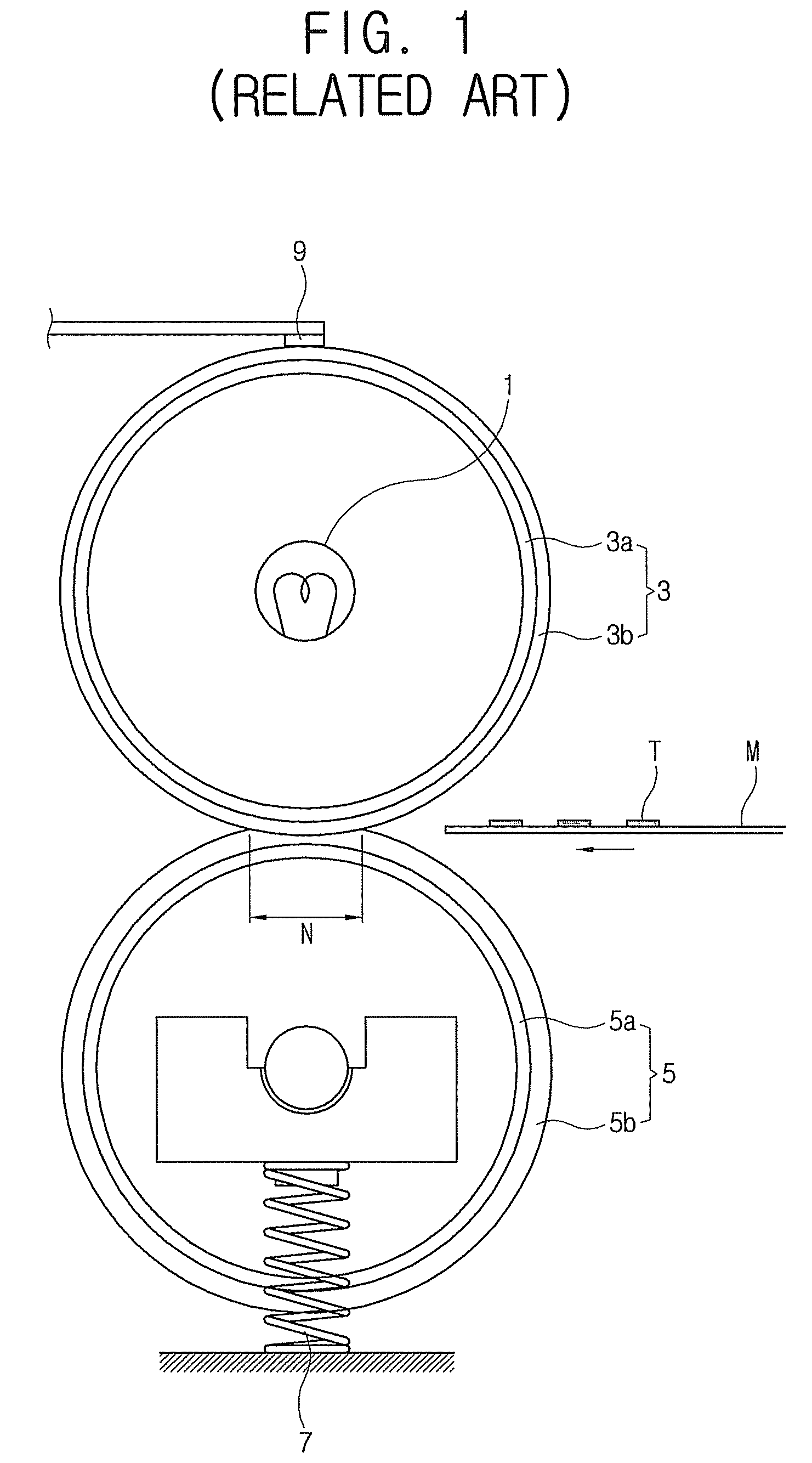

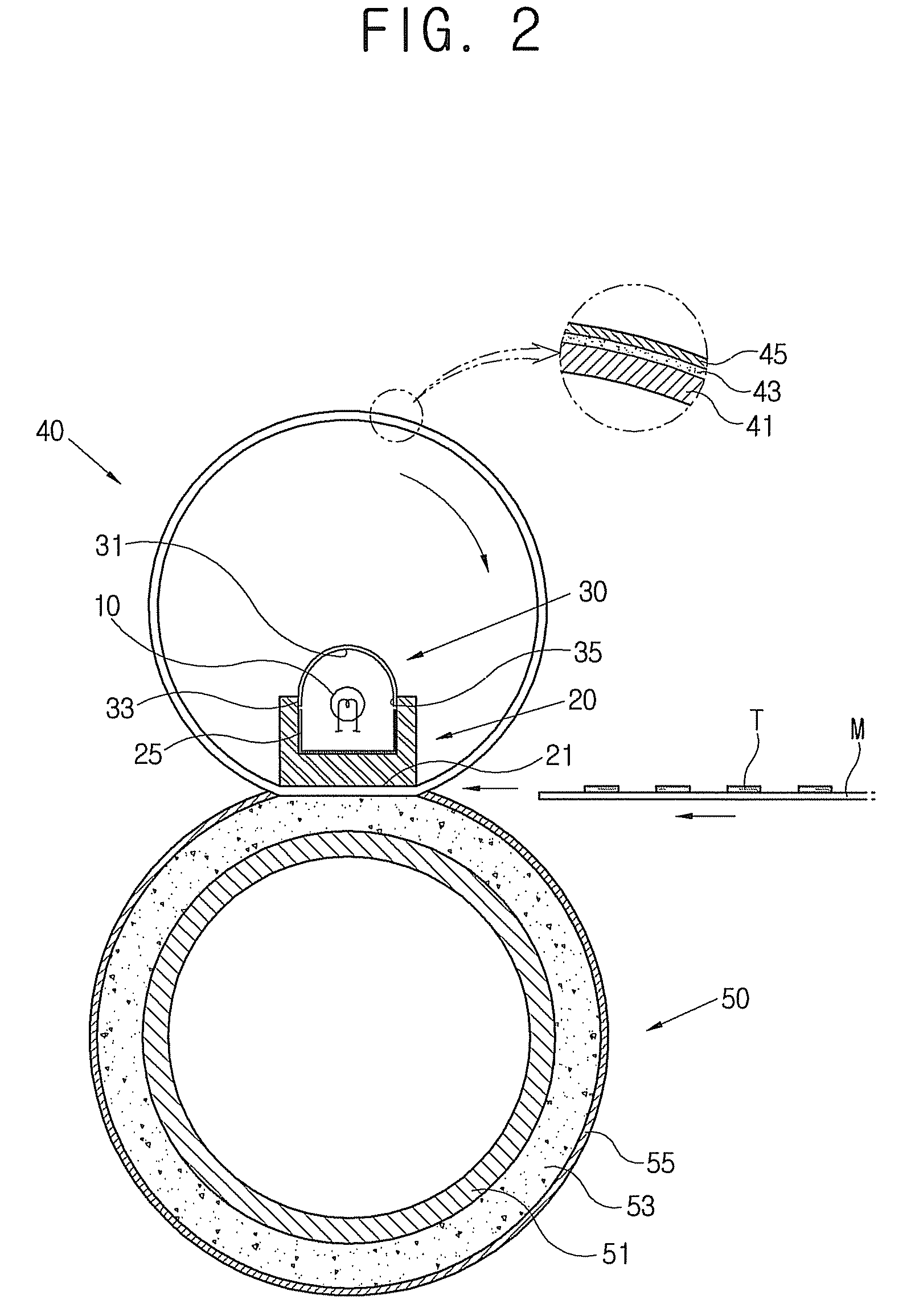

Fusing unit and image forming apparatus using the same

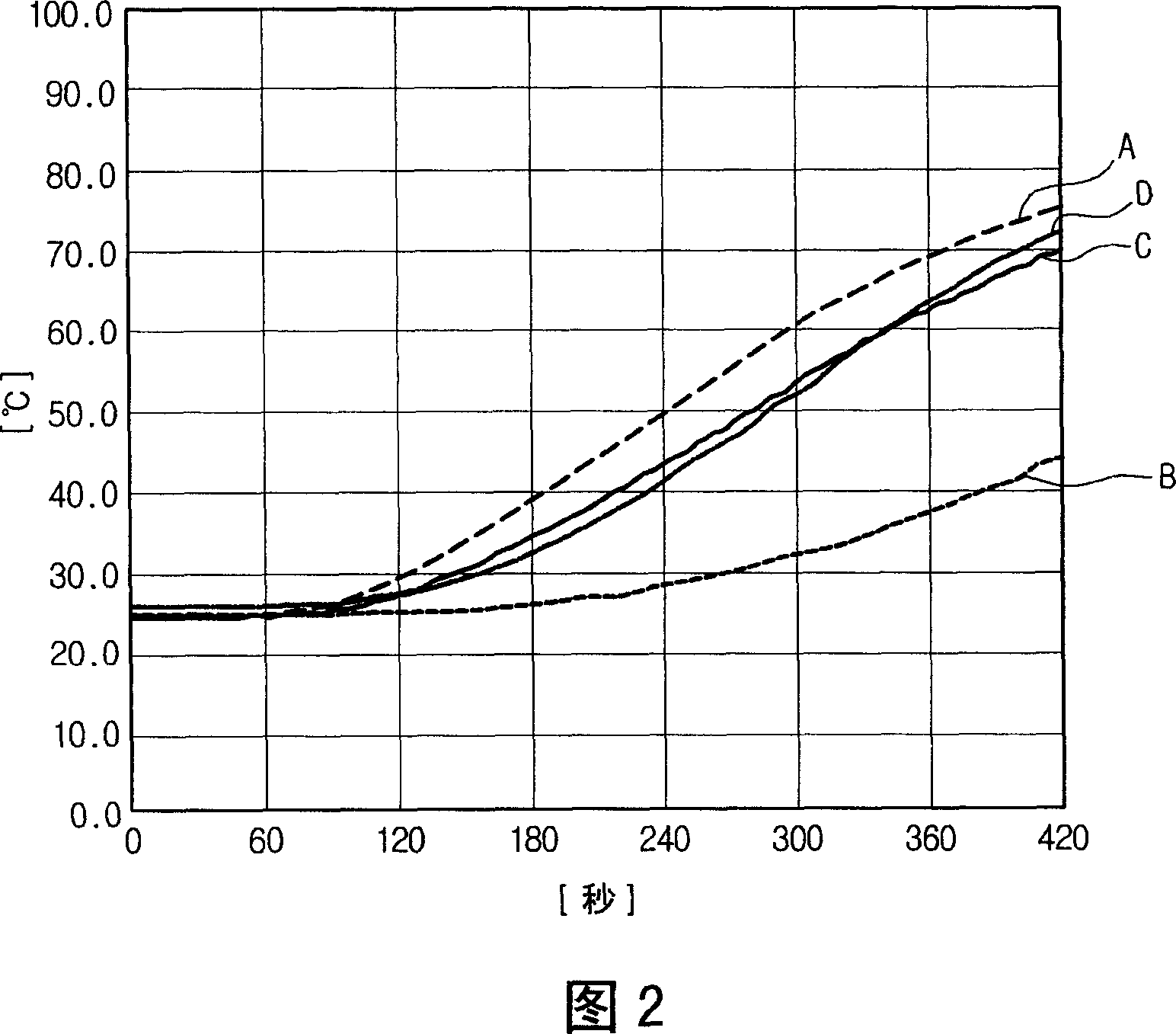

ActiveUS20080199231A1Secures fusing stabilityImprove heating efficiencyElectrographic process apparatusImage transferImage formation

Owner:HEWLETT PACKARD DEV CO LP

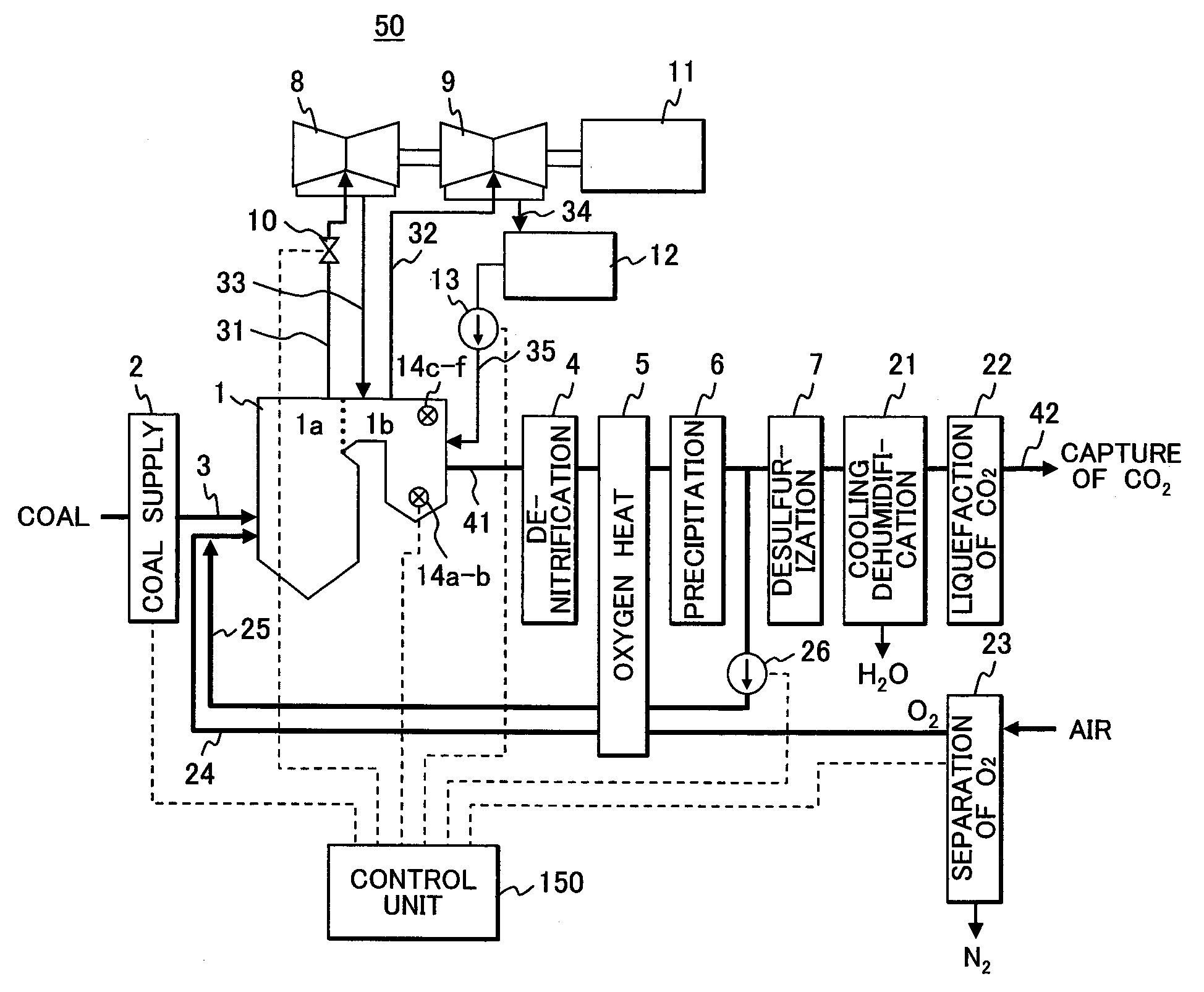

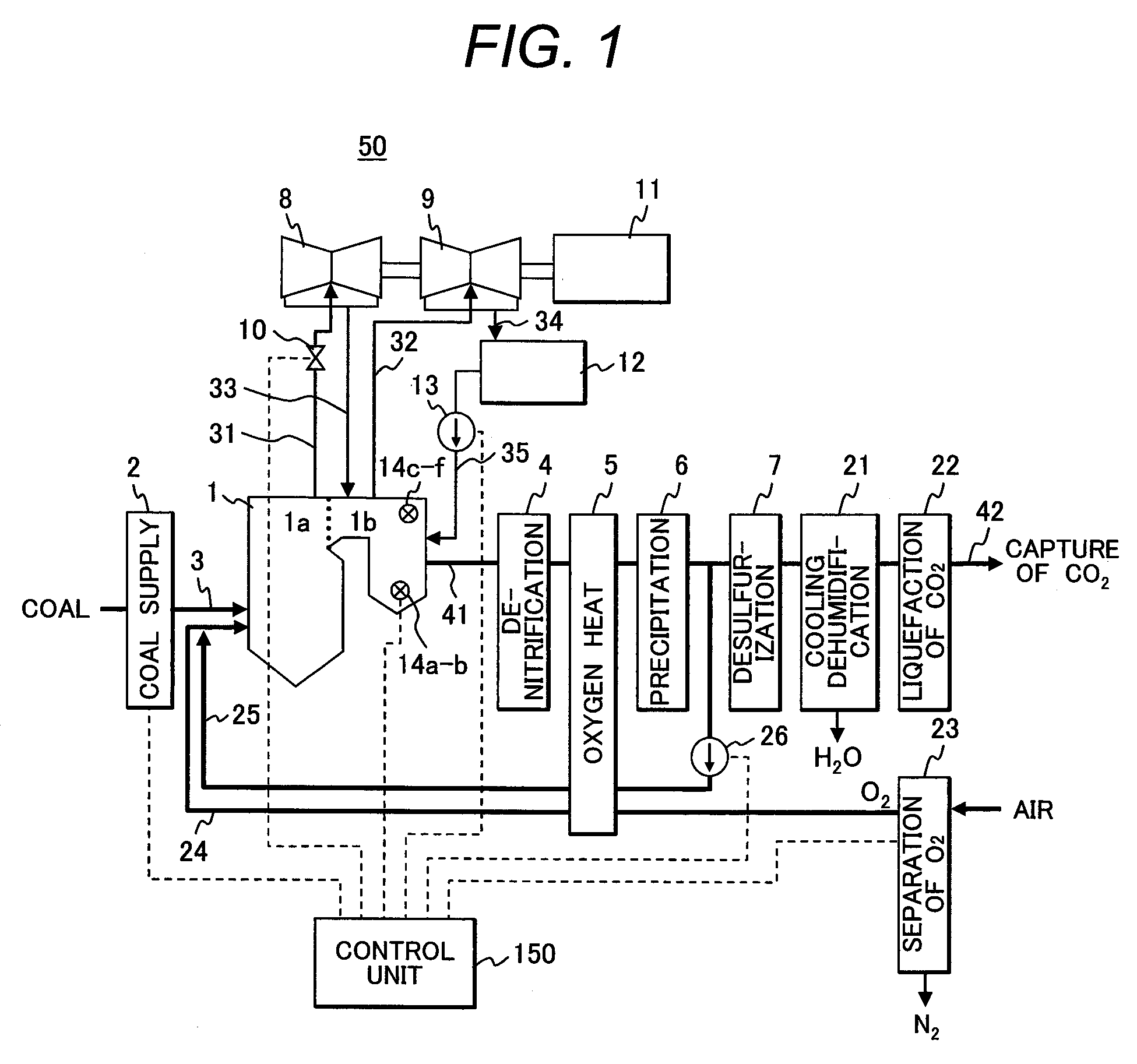

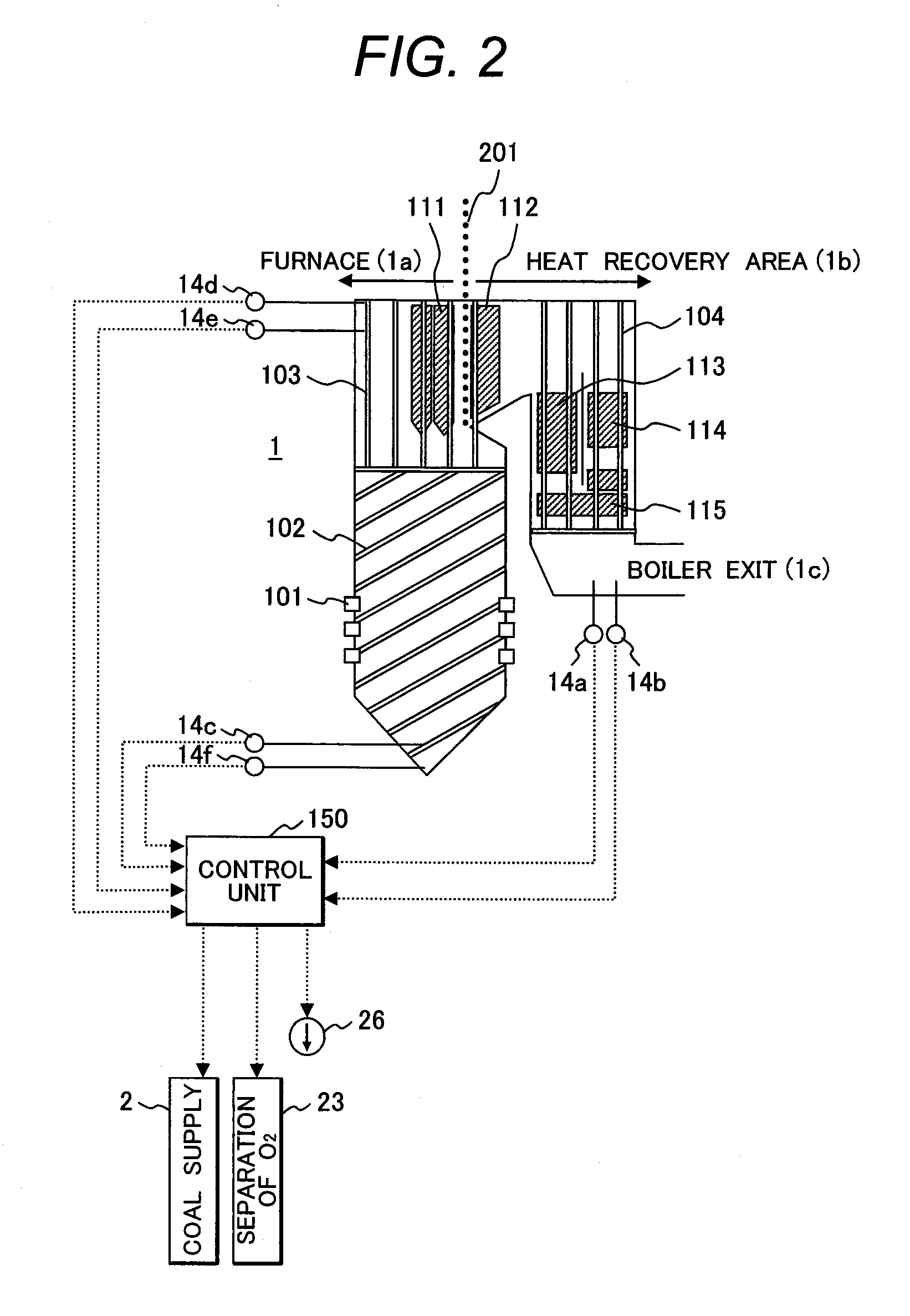

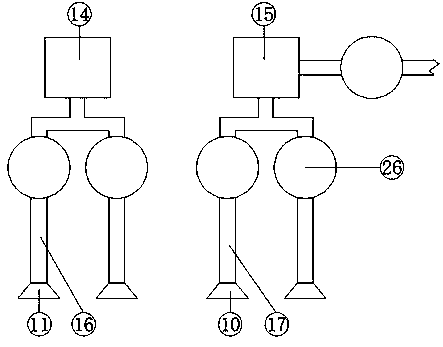

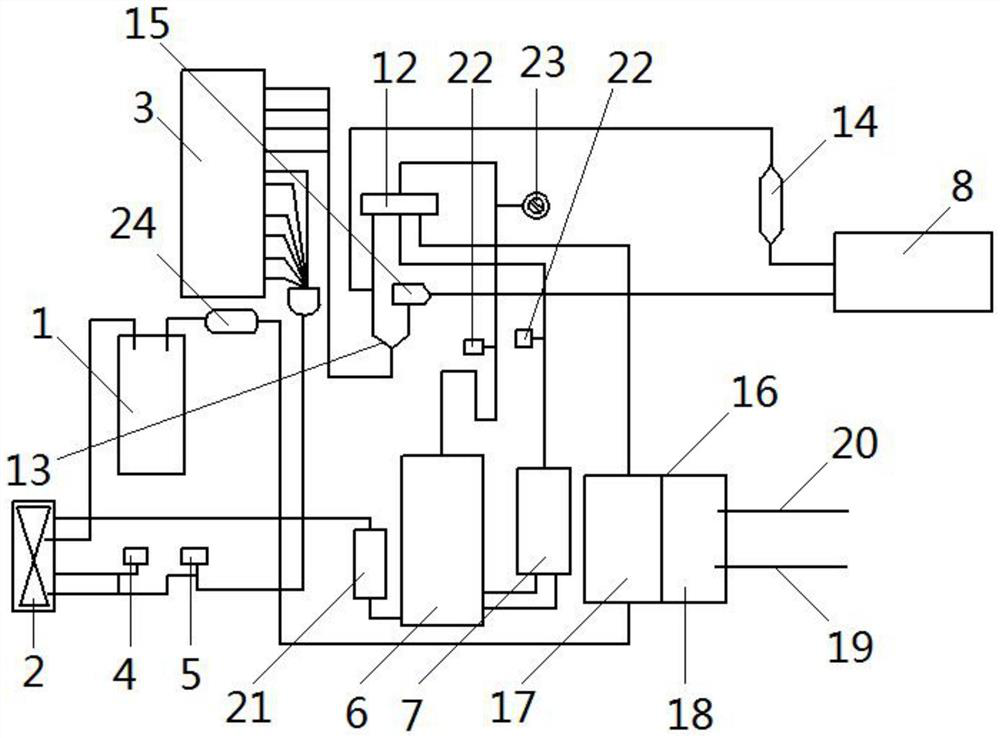

Oxyfuel Boiler and Control Method for Oxyfuel Boiler

InactiveUS20110011315A1Guaranteed uptimeExpense required can be suppressedFuel supply regulationFluegas recirculationProcess engineeringAir separation

An oxyfuel boiler structured so as to mix oxygen separated from air with a part of exhaust gas branched from exhaust gas discharged from the boiler for generating vapor and supplying to a vapor demand facility by burning coal fuel, and supply the mixed gas to the boiler as an oxidizing gas for burning the coal, wherein an air separation unit for separating air and manufacturing oxygen from air, an oxygen supply system for leading the oxygen manufactured by the air separation unit to the oxyfuel boiler, a recirculation system for leading a part of exhaust gas branched from the exhaust gas discharged from the oxyfuel boiler to the oxyfuel boiler, and a recirculation fan for supplying the exhaust gas to the recirculation system are installed, respectively.

Owner:HITACHI LTD

Fusing unit and image forming apparatus using the same

ActiveUS7890040B2Increase in sizeSecures fusing stabilityElectrographic process apparatusImage transferImage formation

Owner:HEWLETT PACKARD DEV CO LP

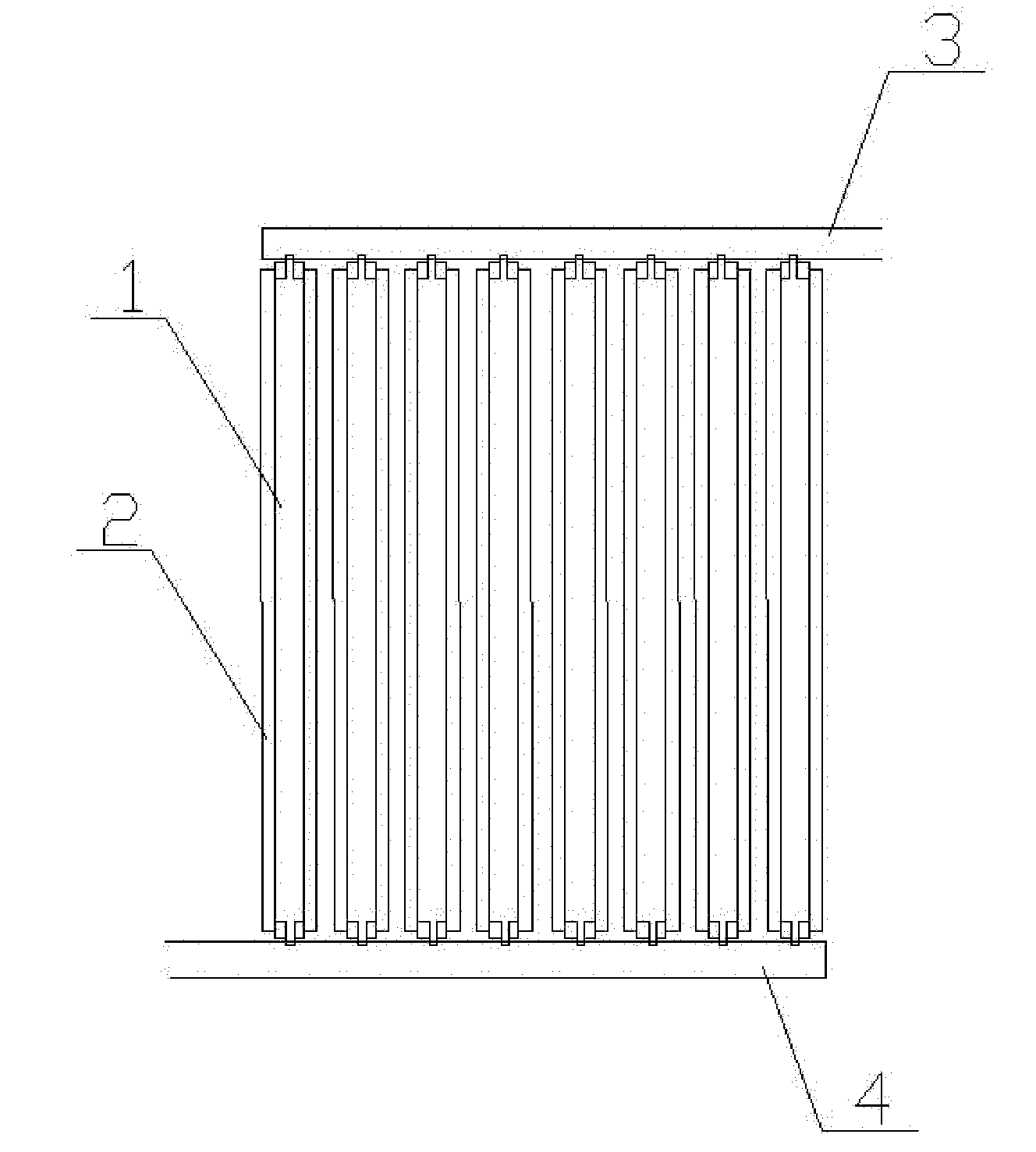

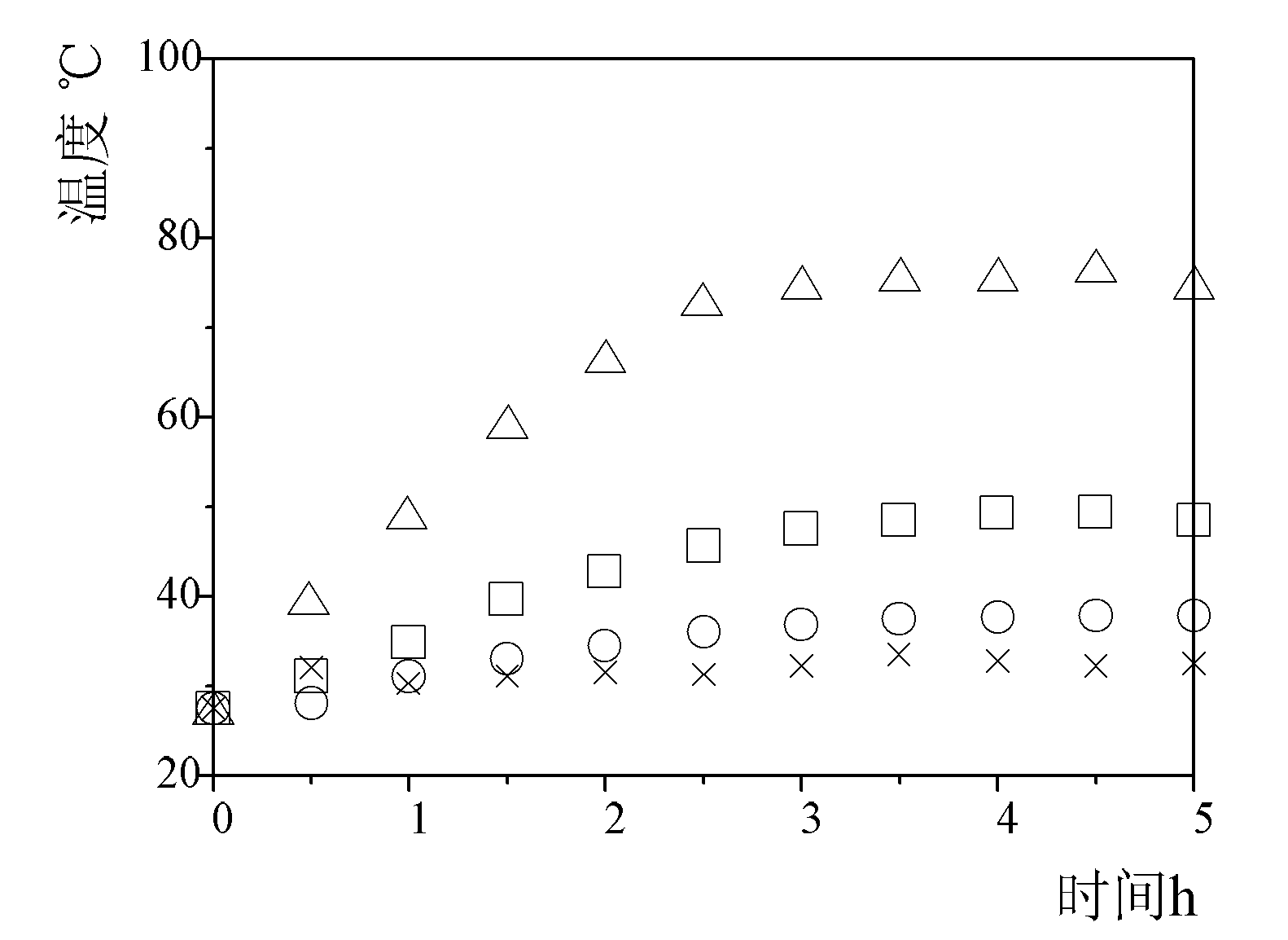

Nano-fluid direct absorption type solar heat collector

ActiveCN101915459AImprove heat collection efficiencyImprove thermal conductivitySolar heating energySolar heat devicesThermal energyNanoparticle

The invention relates to a nano-fluid direct absorption type solar heat collector, in particular to a solar heat collector, which solves the problems of great heat loss and low heat collection efficiency of the conventional heat collectors. The nano-fluid direct absorption type solar heat collector of the invention comprises N vacuum pipes, N reflecting mirrors, a first heat insulation communicating pipe and a second heat insulation communicating pipe, wherein the N vacuum pipes are arranged in a row; one open end of each vacuum pipe is communicated with the first heat insulation communicating pipe through a rotary joint respectively, while the other end is communicated with the second heat insulation communicating pipe through the rotary joint respectively; the first communicating pipe is communicated with a water outlet; the second heat insulation communicating pipe is communicated with a water inlet; one reflecting mirror is arranged below each vacuum pipe respectively; working medium in each vacuum pipe comprises a fluid substrate; nanoparticles are also added into the working medium in each vacuum pipe; and N is an integer more than 2. The solar heat collector is used for converting solar energy into heat energy.

Owner:HARBIN INST OF TECH

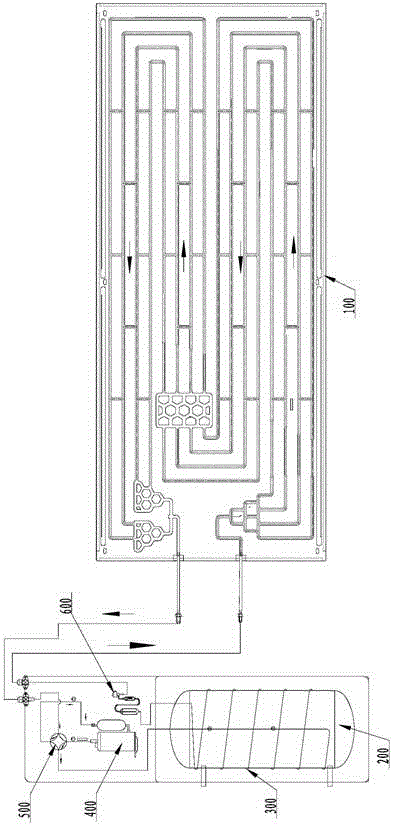

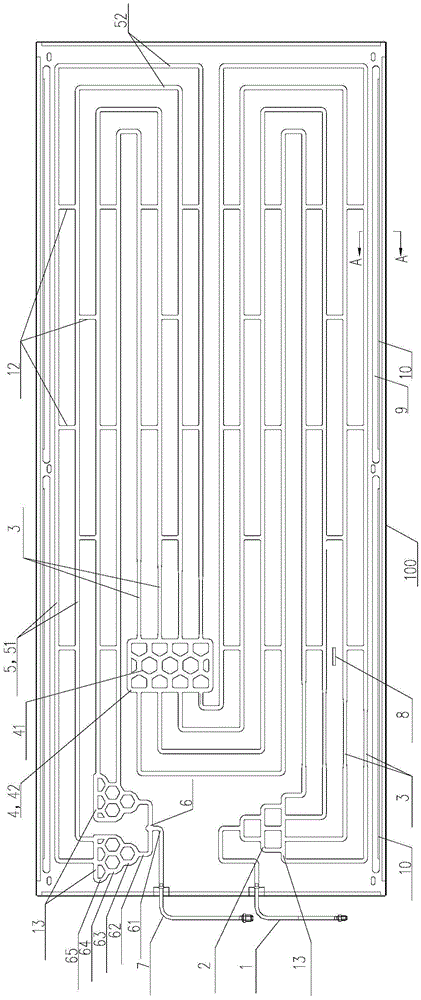

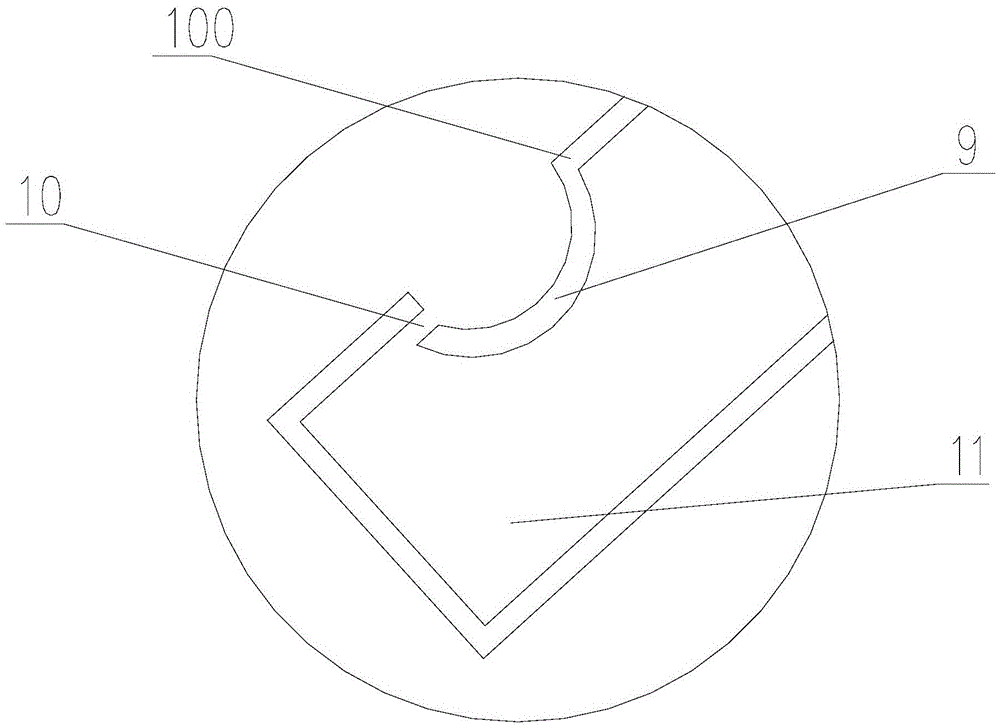

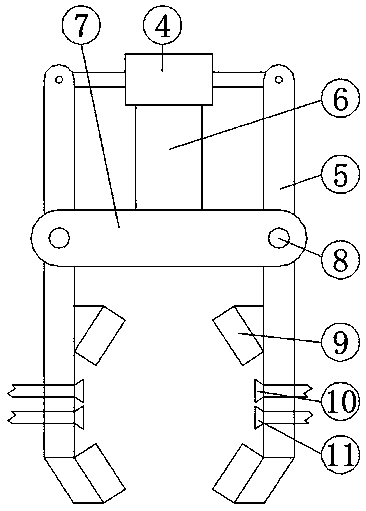

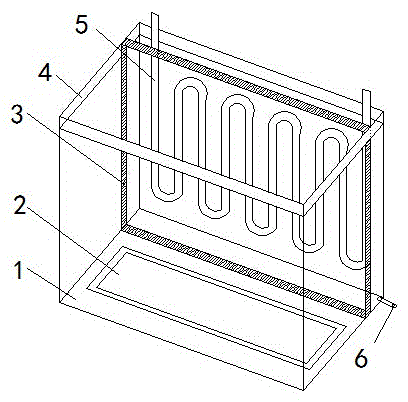

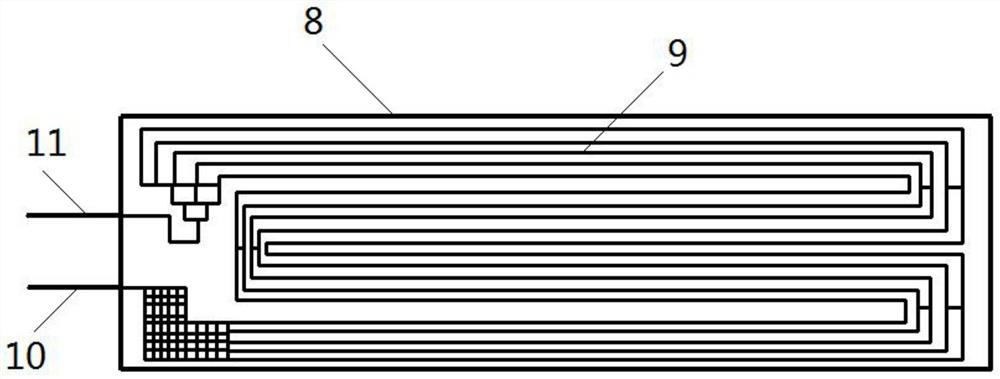

Solar heat pump huffing evaporator and water heater

InactiveCN106468493AImprove board utilizationIncrease heat absorption rateSolar heating energyFluid heatersTree shapedRefrigerant

The invention relates to a solar heat pump huffing evaporator and a water heater. The evaporator is formed by pressing and huffing two plates; multiple heat exchange runners are arranged on the evaporator in parallel; an inlet of the evaporator is communicated with inlet ends of all the heat exchange runners by tree-shaped shunting runners; the middle parts of all the heat exchange runners are communicated with a honeycomb-shaped gathered shunting runner; and outlet ends of all the heat exchange runners are communicated with an outlet of the evaporator by a tree-shaped gathered runner. As the above runners are arranged on the evaporator, a refrigerant flowing through the puffing evaporator is totally vaporized, the panel utilization rate of the evaporator is prominently increased, and the heat sucking speed of the evaporator is accelerated; and meanwhile, the flowing speed of the refrigerant in the runners of the evaporator is controlled to be within a reasonable range, the problems of whole vibration and noise, caused by too fast flowing speed change of the refrigerant, of the evaporator are overcome. Meanwhile, the evaporator is simple in structure, prominent in effect and suitable for application and popularization.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

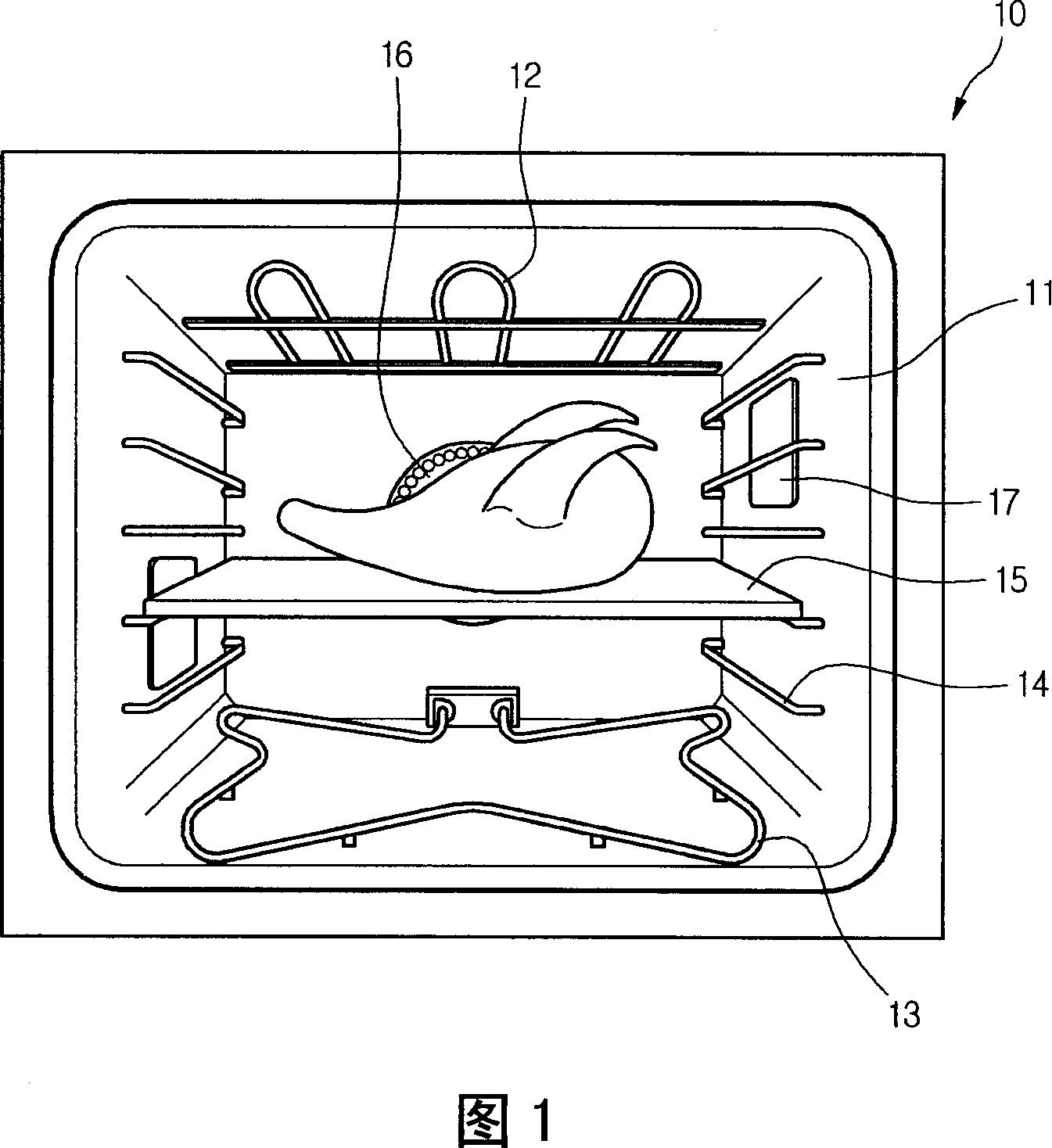

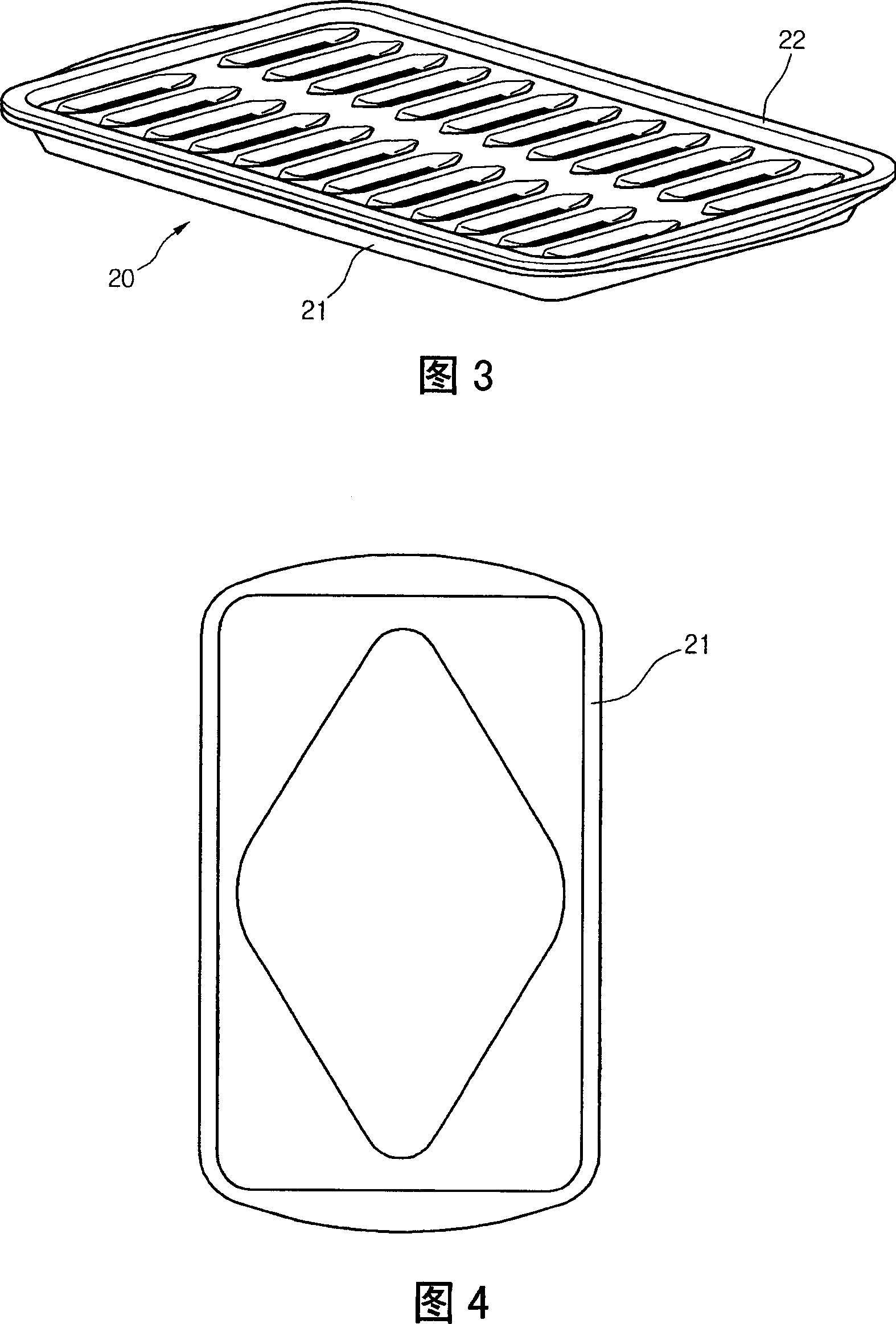

Electric oven

InactiveCN1979002AIncrease heat absorption rateSpeed up cookingDomestic stoves or rangesStoves/ranges shelves or racksAbsorption rateMechanical engineering

Provided is an electric oven. The electric oven includes a cavity defining a cooking chamber, a heater mounted in the cavity and a tray member on which food is loaded, the tray assembly being slidably inserted into the cavity and plated to enhance heat absorption rate.

Owner:LG ELECTRONICS INC

Nano cermet solar heat-absorption coating material and preparation method thereof

ActiveCN106752915AImprove thermal conductivityExcellent solar absorption performanceAnti-corrosive paintsRadiation-absorbing paintsHeat conductingDistillation

The invention relates to a nano cermet solar heat-absorption coating material and a preparation method thereof. The coating material is prepared from the following components in parts by weight: 40-50 parts of organic silicon resin, 2-7 parts of curing agent, 11-12 parts of absorbent, 2-4 parts of absorbing enhancer, 33-45 parts of aid, 13-17 parts of cermet material and 7-13 parts of heat-conducting material. The absorbent is doping-modified nano titanium dioxide. The preparation method sequentially comprises the following steps: constant-temperature pressurization reaction, reflux reaction and reduced pressure distillation reaction. Compared with the prior art, the doping-modified nano titanium dioxide is used as the absorbent and matched with the absorbing enhancer, so that the coating material has excellent solar absorptivity. The cermet material and heat-conducting material with photocatalytic mobility are adopted to widen the solar absorption range and enhance the heat-conducting property of the coating material, so that the coating material has the advantages of longer service life, mild technological conditions for reaction and low production cost, and can easily implement industrial production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

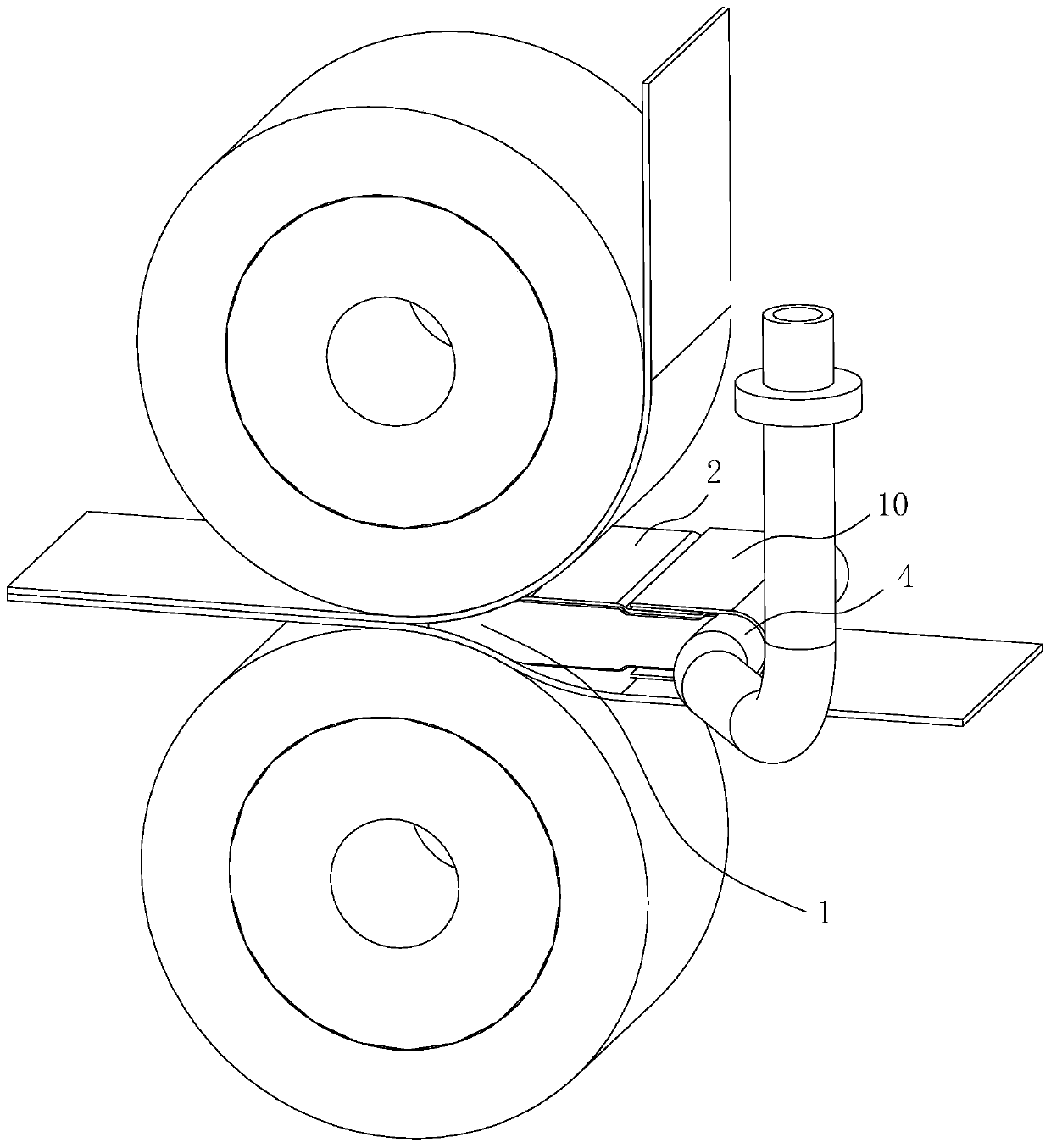

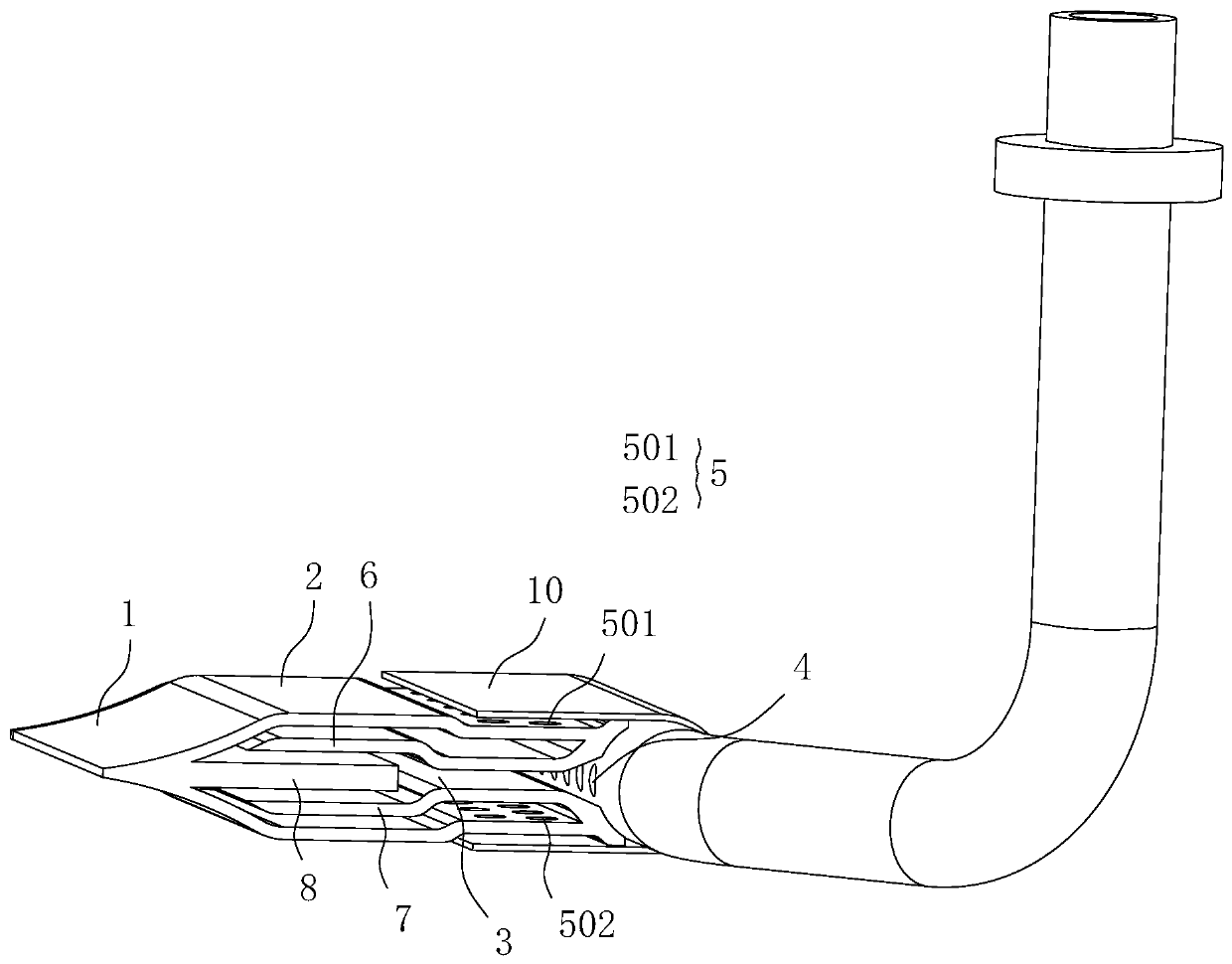

Air blowing hot wedge and heating method and using method thereof

The invention belongs to the technical field of hot melting welding, and particularly relates to an air blowing hot wedge and a heating method and a using method thereof. The air blowing hot wedge comprises a hot wedge body, wherein the hot wedge body comprises a welding part and a heated part, the heated part is hollow to form a hot air cavity, and the hot air cavity is provided with an air inletend and an air outlet end; and the welding part receives heat conducted by the hot air cavity so that two to-be-welded materials penetrating through an inlet of a pressurizing part of a hot air welding machine can be subjected to hot melting welding. According to the heating method, the air blowing hot wedge is adopted, and the heating method comprises the following steps that air heated from theoutside penetrates into the hot air cavity from the air inlet end and is discharged through the air outlet end to form a hot cycle; and in the circulating operation process of hot air, the heat of the hot air is conducted to the welding part of the air blowing hot wedge so that the two to-be-welded materials can be subjected to hot melting welding through the welding part. According to the air blowing hot wedge and the heating method and the using method thereof, the welding heat is obtained through heat conduction, the hot air is not directly blown to the materials, the heat output is concentrated, the materials are prevented from being wrinkled and deformed, the bright edges of the periphery are prevented from being welded, and the welding quality is high; and the size is small, the heat transmission is high, and the welding efficiency is high.

Owner:CHANGZHOU RUFA MACHINERY CO LTD

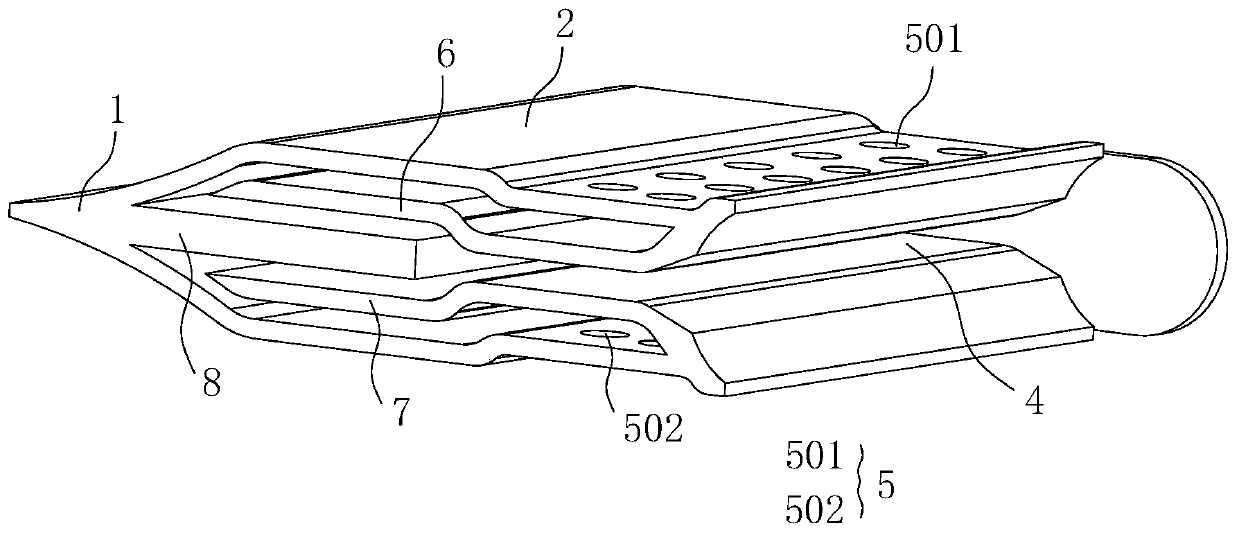

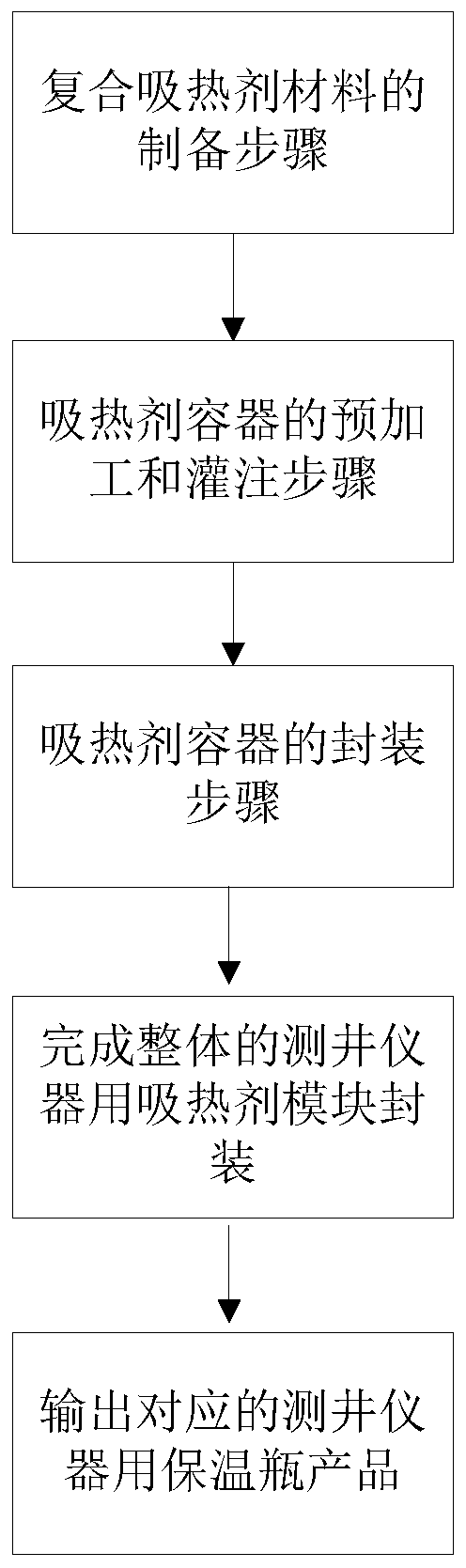

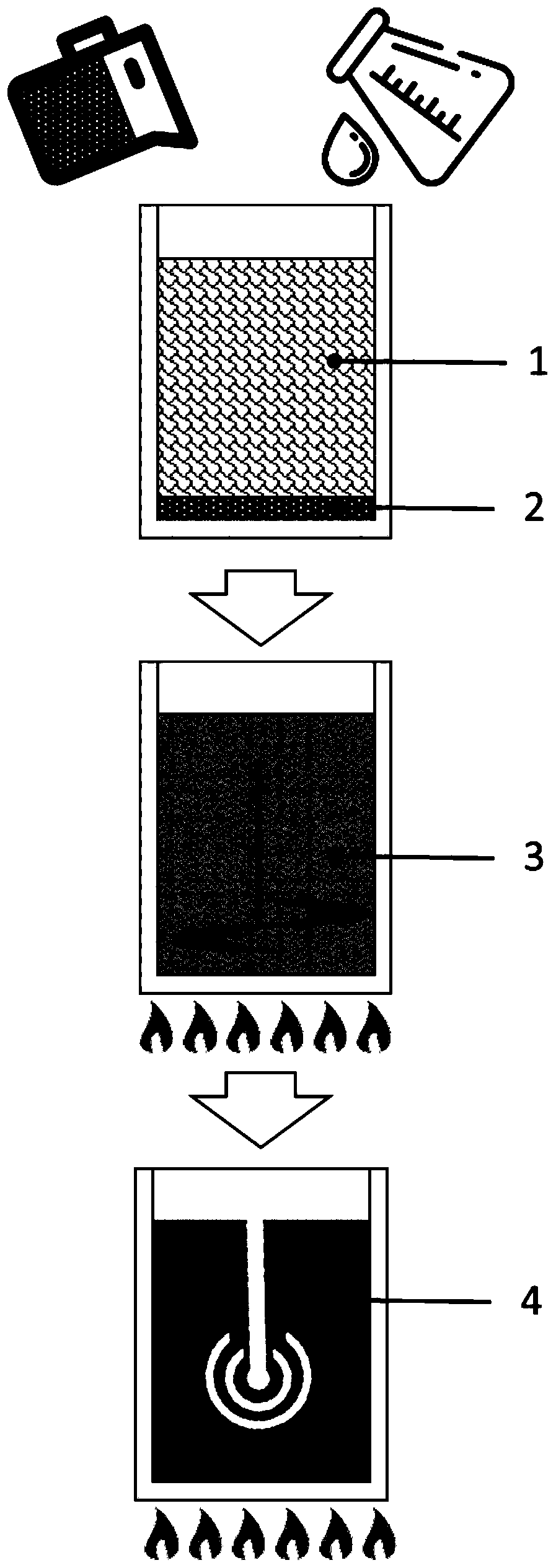

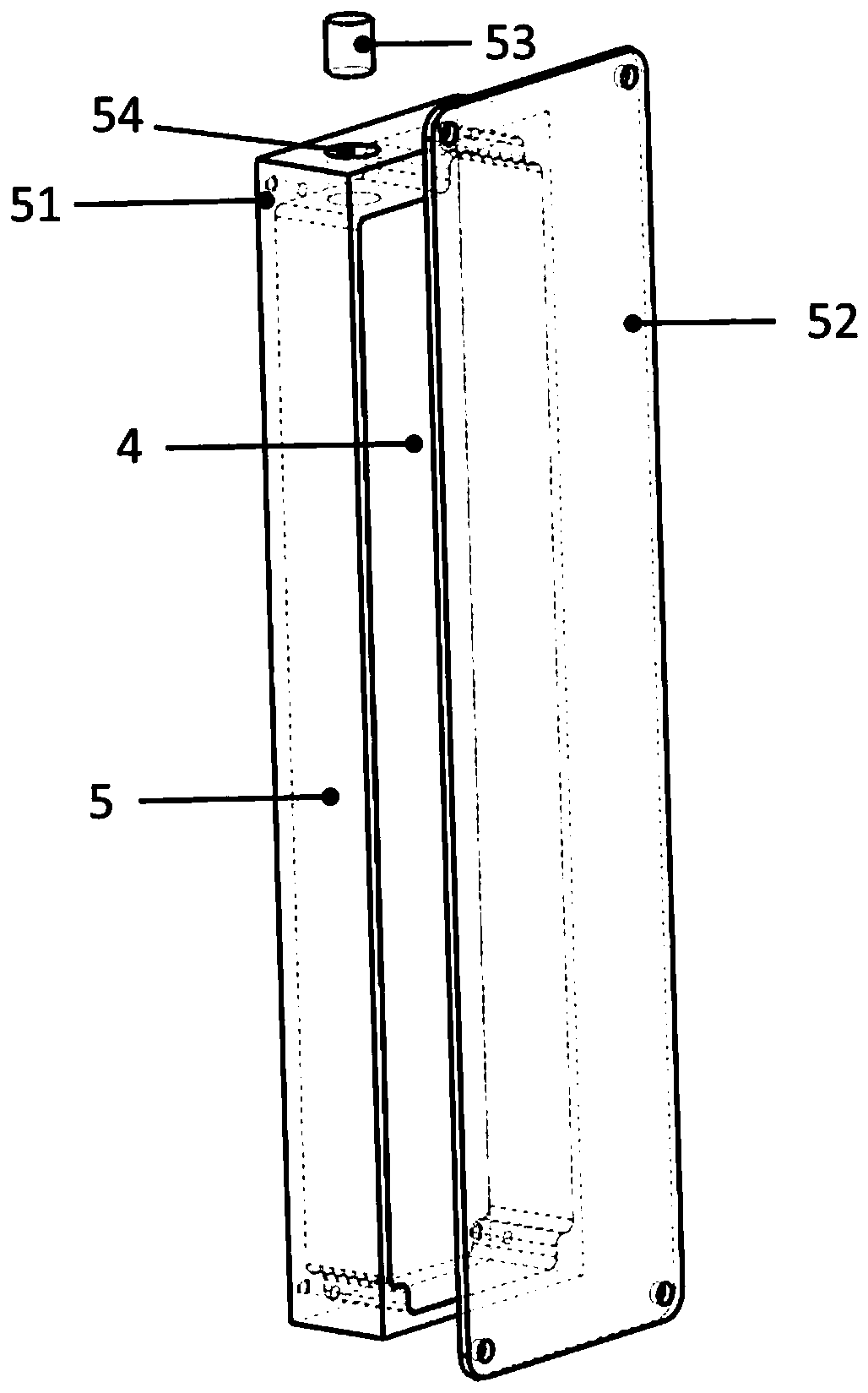

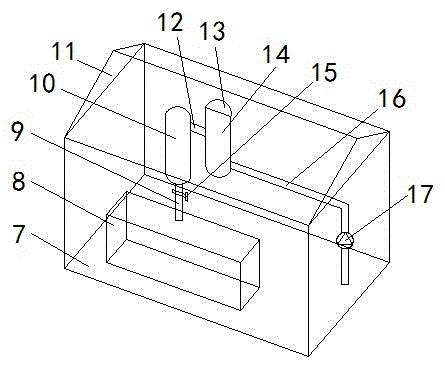

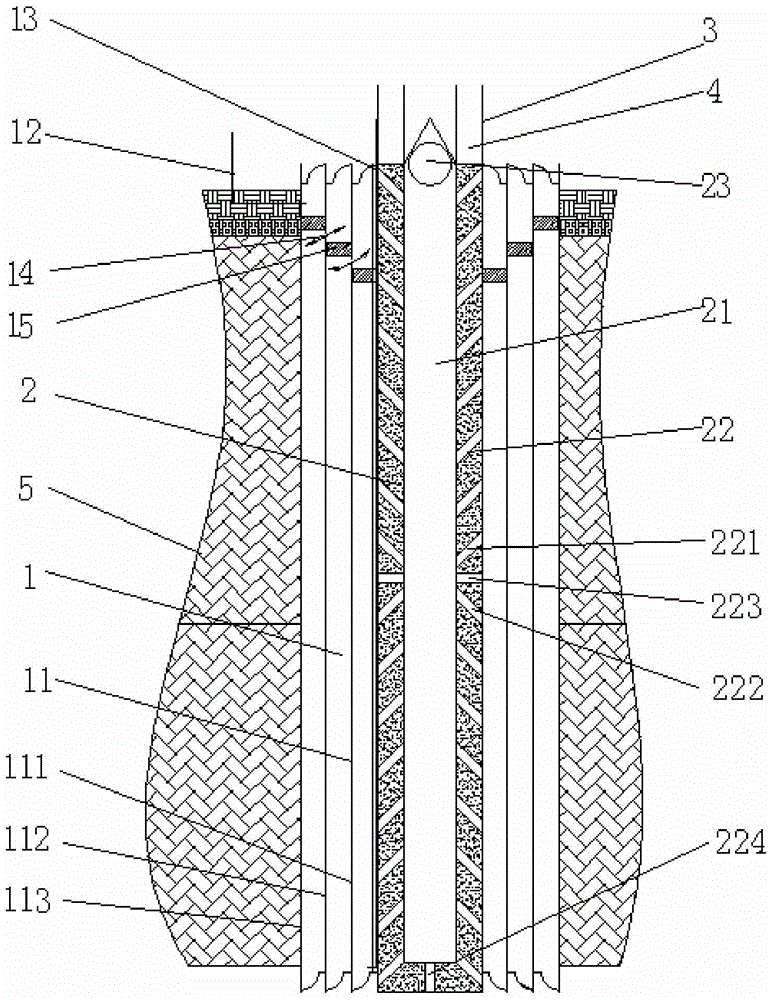

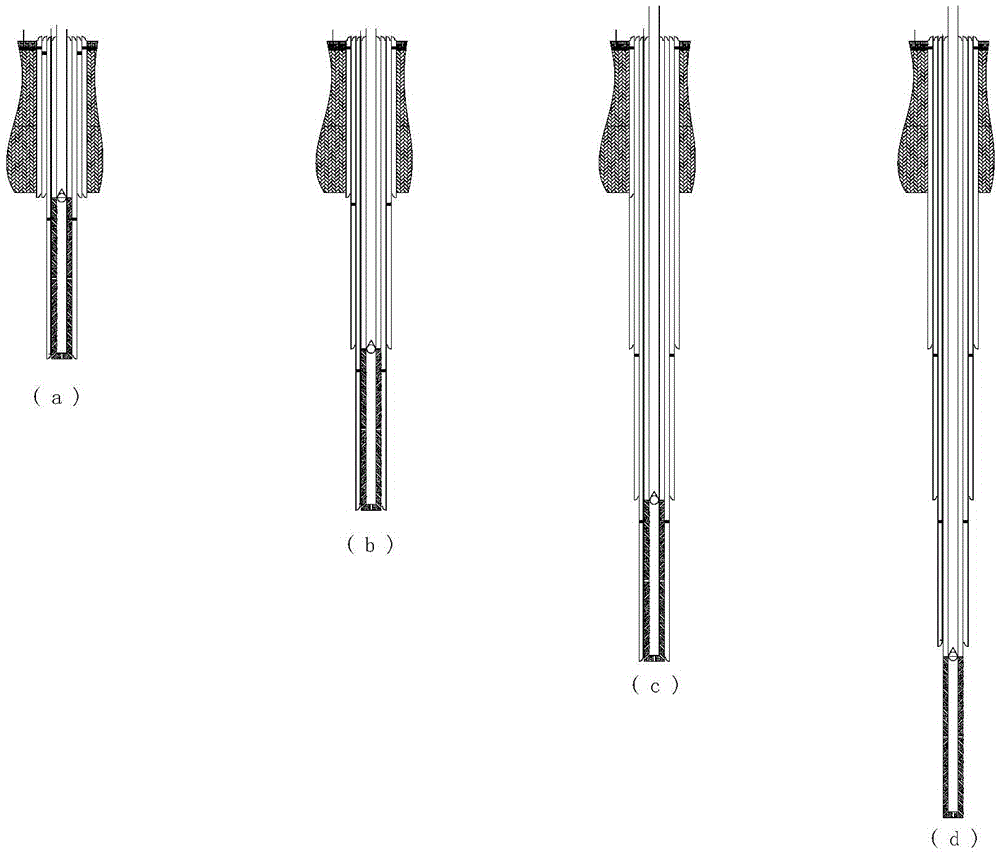

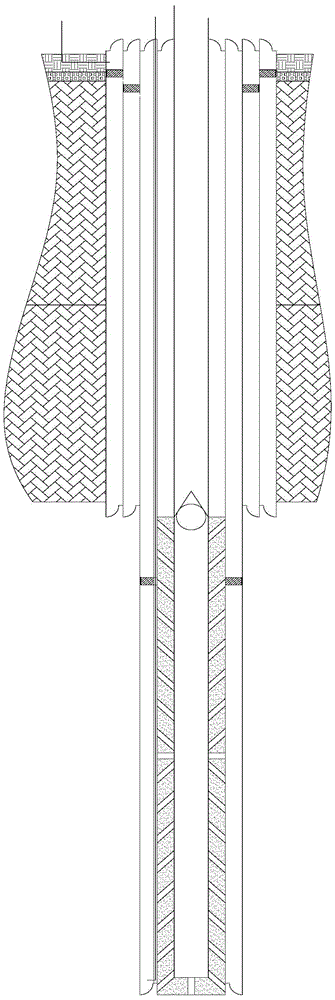

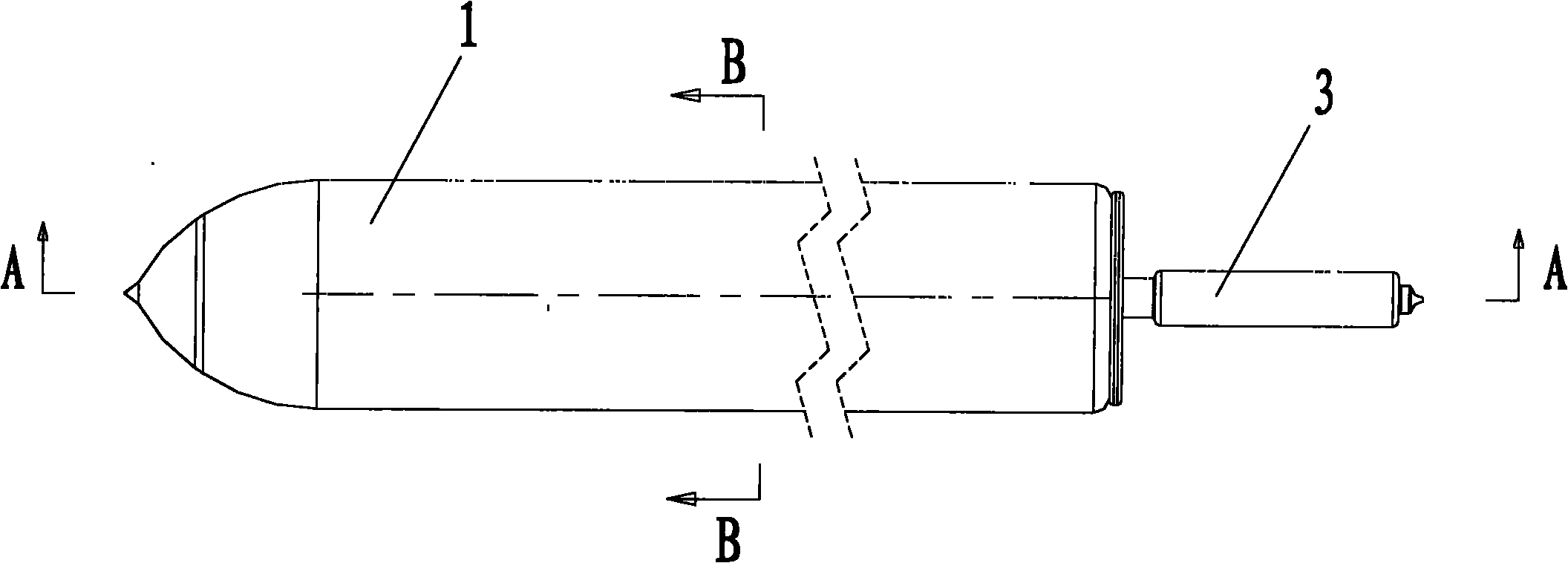

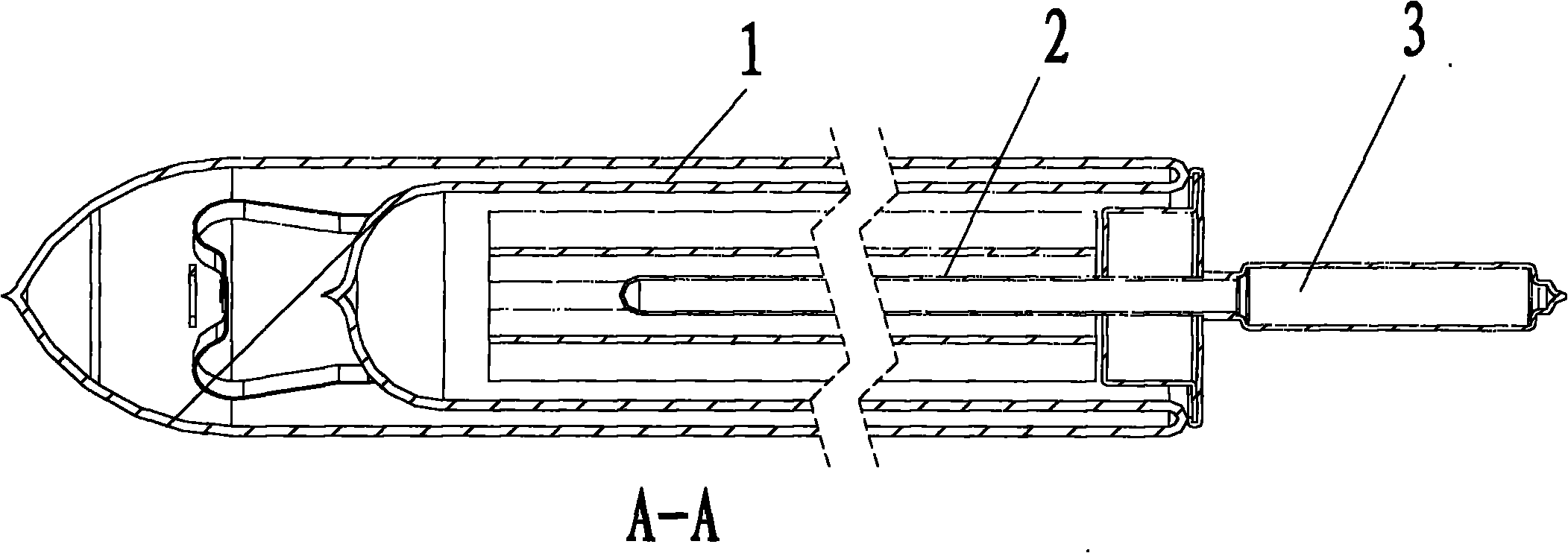

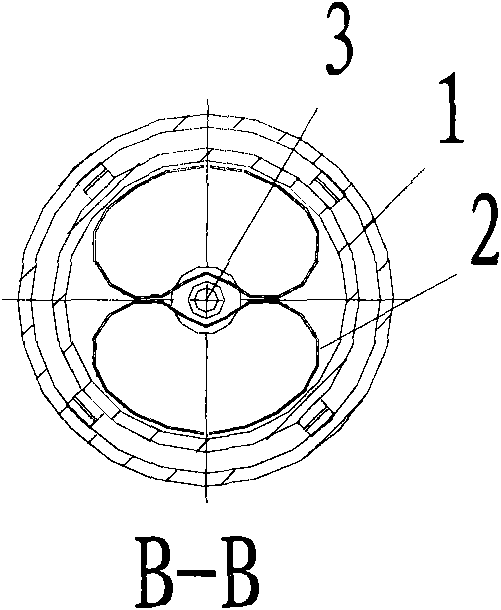

Packaging method and device for high-thermal-conductivity and high-temperature-resistance heat absorbentfor logging instrument

ActiveCN110145298AIncrease heat absorptionPromote gasificationConstructionsMagnetic tension forceParaffin wax

The invention belongs to the relative fields of logging technologies, and discloses a packaging method and device for a high-thermal-conductivity and high-temperature-resistance heat absorbent for a logging instrument. The method comprises the steps of mixing molten paraffin wax and expanded graphite, and carrying out magnetic stirring and ultrasonic treatment on the mixture to obtain a needed molten-state composite heat absorbent material; drilling a pouring hole in an end cover or a shell of a heat absorbent container, and then injecting the molten-state composite heat absorbent material into the heat absorbent container through the pouring hole, wherein the pouring hole penetrates through the end cover or the shell; and inserting a sealing pin into the pouring hole to execute tight fitsealing, and finally going on to execute welding sealing on an interval in fit. The invention further discloses a corresponding product. With the packaging method and device for the high-thermal-conductivity and high-temperature-resistance heat absorbent for the logging instrument, and the corresponding product, a heat absorbent module with the high conductivity, the high reliability and the highresistance to high temperatures can be obtained; and compared with the prior art, the technical problems that in the prior art, a heat absorbent module is poor in heat conductivity and cannot be usedin a high-temperature environment for a long time, and so on can be effectively solved.

Owner:武汉华兴志远科技有限公司

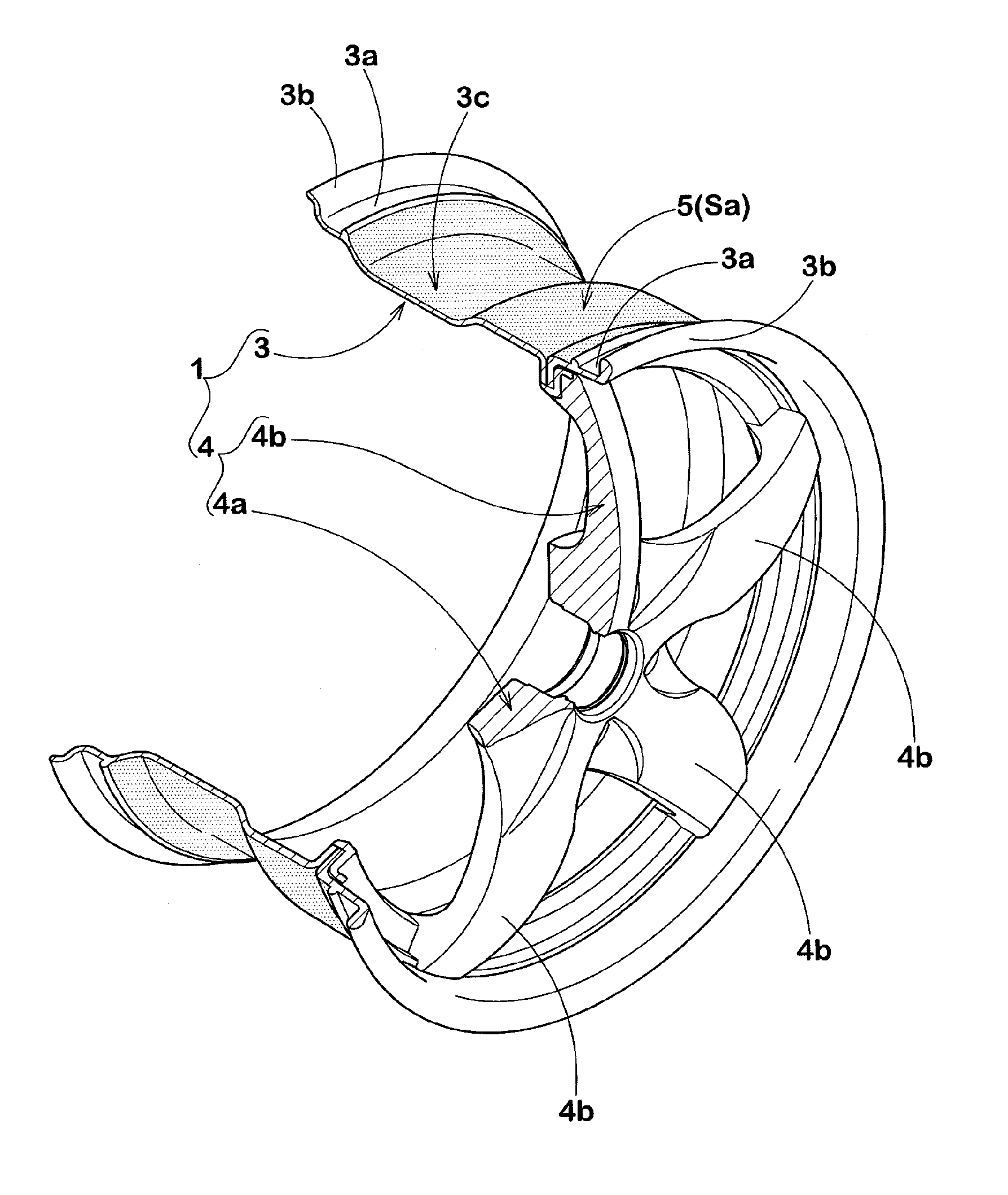

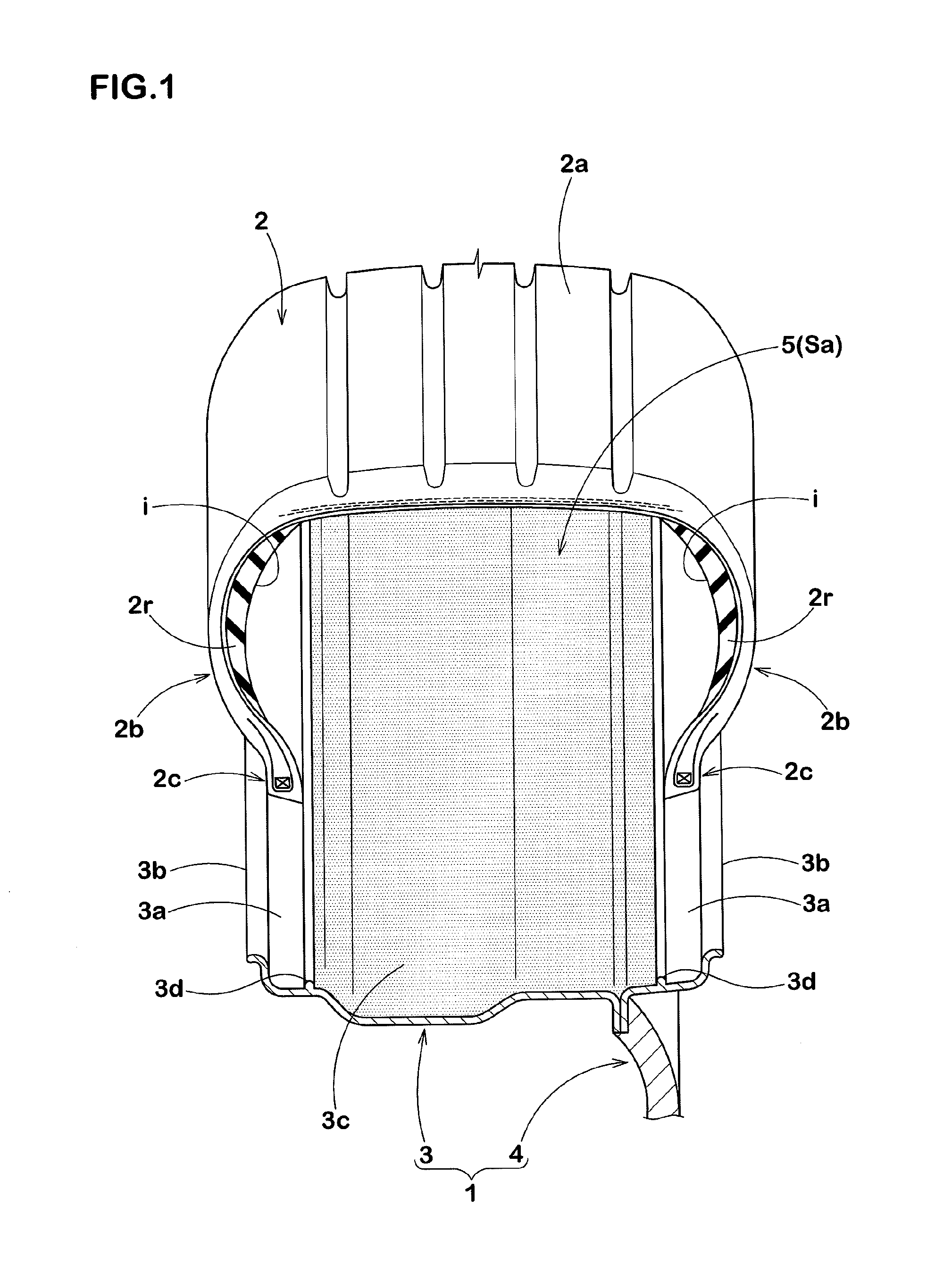

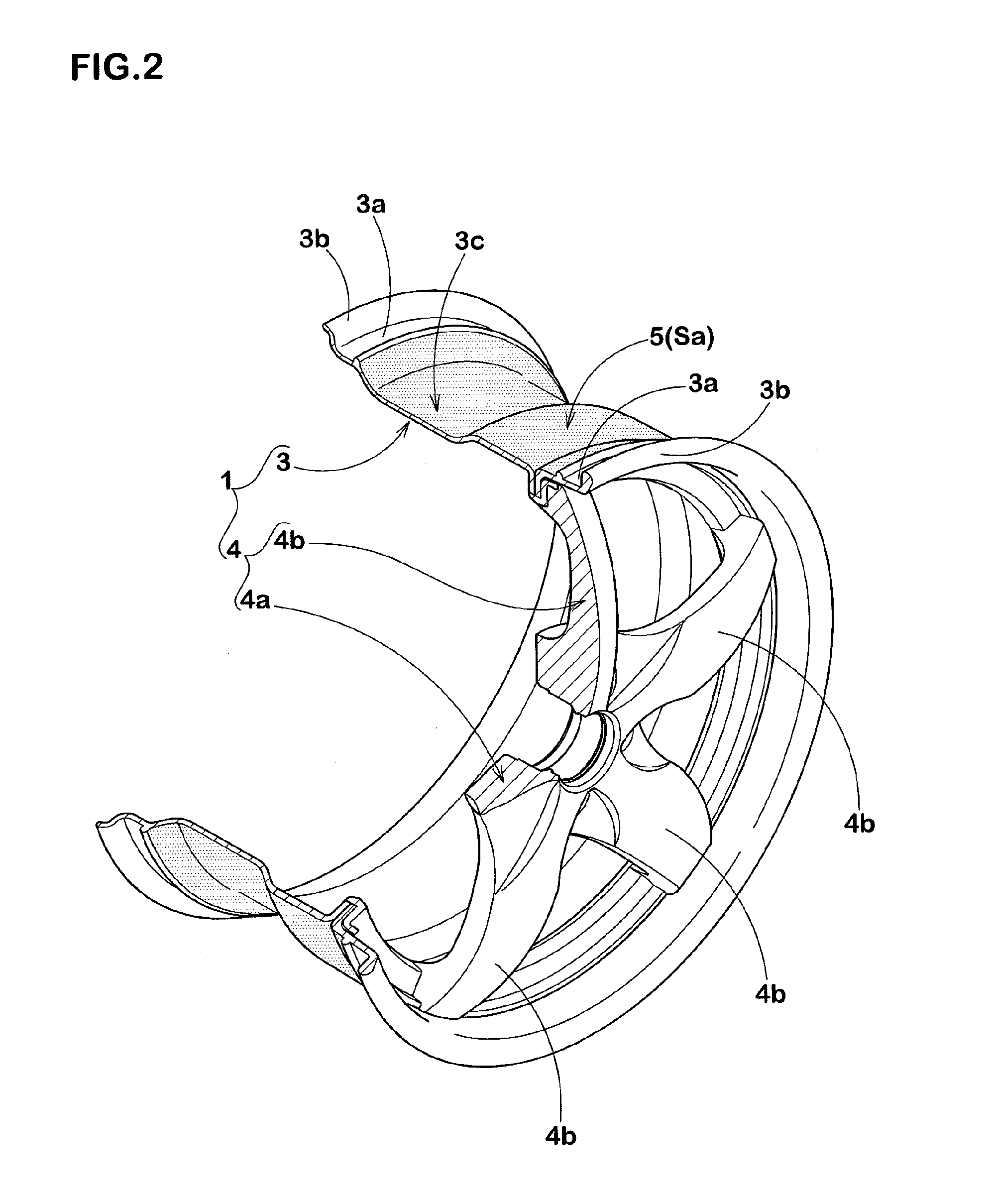

Wheel rim, and wheel and vehicle using same

A wheel rim configured to enhance the durability of the tire by reducing the temperature of the tire during running. A wheel rim 1 consisting of a metallic material and adapted so that a pneumatic tire 2 is mounted thereon, wherein a coating 5 having high heat emissivity is formed on at least a part of the surface of the wheel rim 1.

Owner:SUMITOMO RUBBER IND LTD

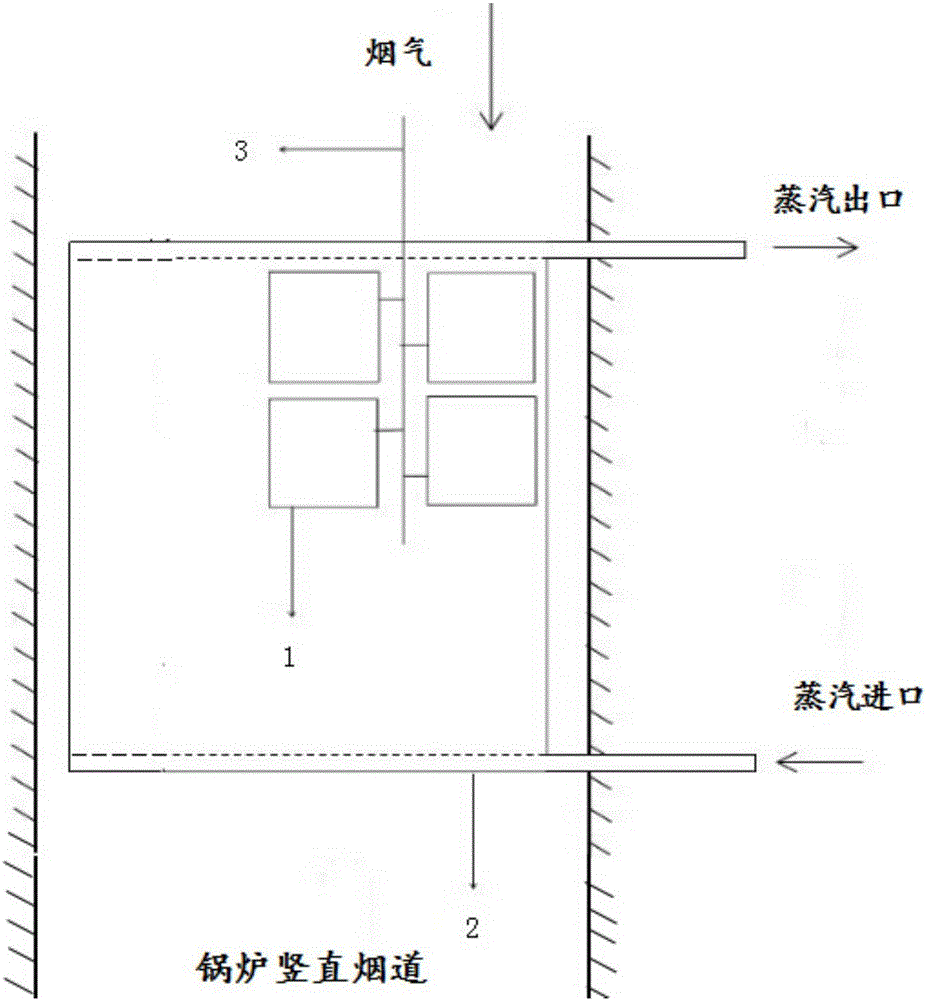

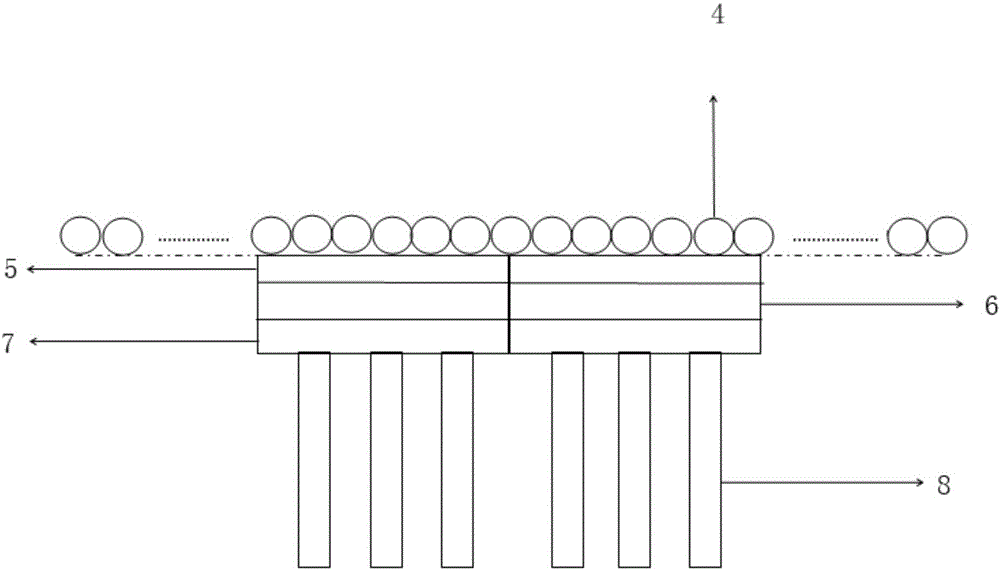

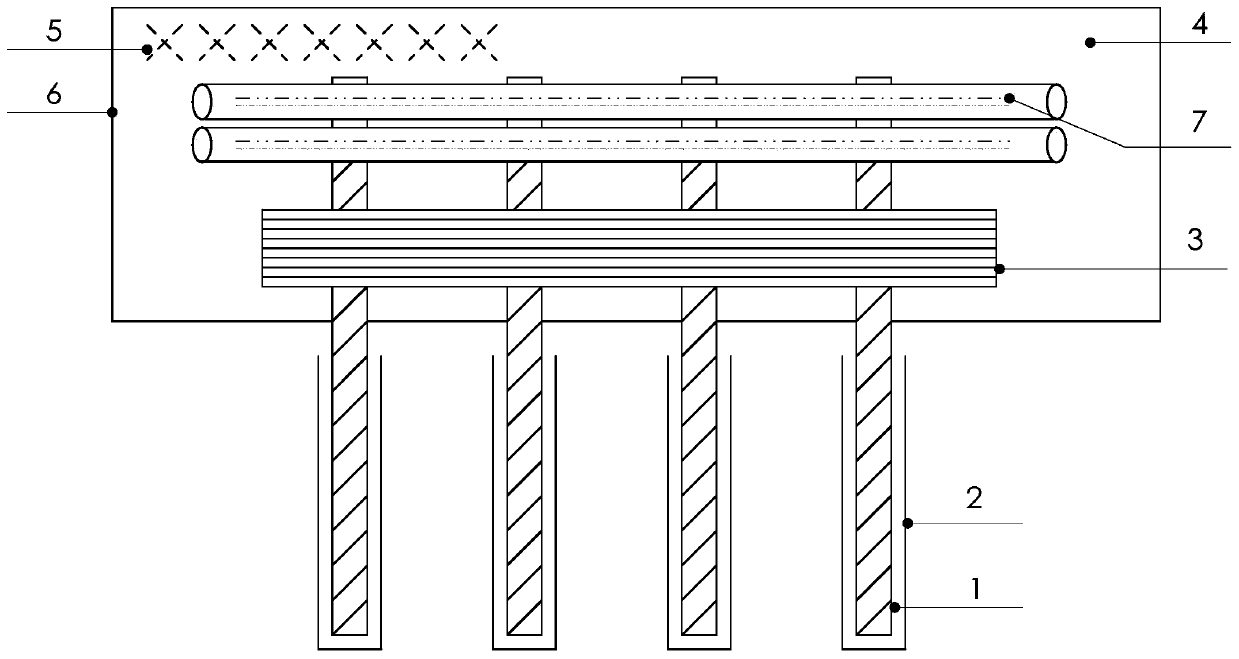

Thermoelectric power generation energy storage and power transmission system applied to boiler economizer

InactiveCN105703463AImprove power generation efficiencyReduce lossesBatteries circuit arrangementsElectric powerHeat currentHeat flow

The invention relates to a thermoelectric power generation energy storage and power transmission system applied to a boiler economizer, including a thermoelectric power generation device, an energy storage device and a power transmission device. The thermoelectric power generation device includes a plurality of thermoelectric power generation units, and the plurality of The thermoelectric power generation unit is respectively connected to the energy storage device and the power transmission device through wires. The thermoelectric power generation device is installed on the boiler economizer, and the hot end of the thermoelectric power generation unit is in contact with the hot flow flue gas of the vertical flue of the boiler, and the cold end In contact with the boiler economizer, the energy storage device and power transmission device are arranged outside the boiler. Compared with the prior art, the present invention has the advantages of improving power generation efficiency, increasing heat absorption rate, improving heat transfer efficiency, providing high-voltage direct and alternating current, fully Take advantage of other advantages.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Novel solar heat collecting material and preparation method thereof

InactiveCN109054557AExcellent solar absorption performanceHigh thermal conductivityAnti-corrosive paintsRadiation-absorbing paintsPolyethylene glycolWetting

The invention provides a novel solar heat collecting material and a preparation method thereof. The novel solar heat collecting material is prepared from the following components of modified acrylateemulsion, organosilicone resin, terephthalate, filler, graphite, carbon fiber, an organic solvent, nanometer spinel material, polyethylene glycol, ferric nitrate, manganese nitrate, silicone oil, a curing agent, a leveling agent, a coupling agent, a light absorbent, a wetting agent, a film forming agent and deionized water. The prepared novel solar heat collecting material has the advantages thatthe solar absorbing property is excellent; the solar absorbing range is expanded, the heat conductivity of the heat collecting material is enhanced, and the service life is longer; the conditions of reaction technology are mild, the production cost is low, and the novel solar heat collecting material is suitable for industrialized large-scale production.

Owner:HEFEI HUAGAI PHOTOVOLTIAC TECH CO LTD

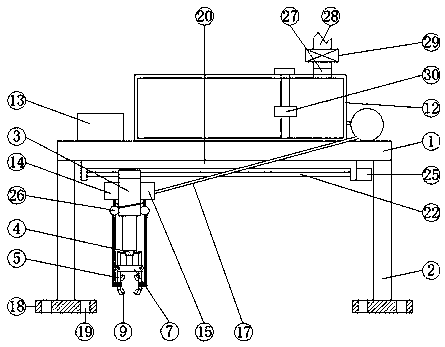

Novel intelligent linkage type part fetching machine for die casting machine

The invention discloses a novel intelligent linkage type part fetching machine for a die casting machine. The novel intelligent linkage type part fetching machine comprises a supporting plate, a translation device, a clamp device, an air pump, a water pump and a PLC. Supporting columns are fixedly arranged under the four corners of the supporting plate, the translation device is arranged below thesupporting plate, a hydraulic cylinder is fixedly arranged under a sliding block of the translation device, and the clamp device is fixedly arranged under a piston rod of the hydraulic cylinder. Theclamp device comprises a clamping jaw air cylinder, the clamping jaw air cylinder is fixed under the piston rod of the hydraulic cylinder, and connecting rods are movably arranged on telescopic rods at the two ends of the clamping jaw air cylinder through pins. The novel intelligent linkage type part fetching machine has the beneficial effects that die-casting parts can be automatically fetched, the die-casting parts can be subjected to water spraying to be cooled in the fetching process, the die-casting parts can be subjected to air spraying, evaporation of water on the surfaces of the die-casting parts is accelerated, thus, the heat absorption rate is increased, the die-casting parts can be rapidly cooled, and the working efficiency of die casting is improved.

Owner:周芮冬

Power equipment cooling circulation device

InactiveCN104994714AImprove stabilityAvoid enteringCooling/ventilation/heating modificationsWater storageThermodynamics

The invention discloses a power equipment cooling circulation device, which comprises a first box body, a groove, a moisture-absorbing plate, a partition plate, a heat-absorbing pipe, a water drain pipe, a second box body, a storage battery, a water inlet pipe, a water storage tank, a top cover, a communicating pipe, a cover, a condensing tank, a water shut-off valve, a water pumping pipe, a pump body and solar photovoltaic panels, wherein the first box body and the second box body are separated by the partition plate arranged in the middle, the water inlet pipe and the water pumping pipe in the second box body are connected with two ends of the heat-absorbing pipe in the first box body respectively, the condensing tank and the water storage tank are connected between the water inlet pipe and the water pumping pipe, the condensing tank and the water storage tank are connected through the communicating pipe, the storage battery is arranged in the second box body, the moisture-absorbing plate is arranged in the first box body, the groove is formed in the bottom part of the first box body, and the bottom part of the first box body is provided with the water drain pipe. The power equipment cooling circulation device adopts the method of absorbing heat through a liquid, can absorb heat produced by power equipment quickly, prevents water vapor produced during heat absorption from entering into the power equipment, and is very practical.

Owner:王学香

High-efficiency solar heat absorbing material and preparation method thereof

InactiveCN109021639AExcellent solar absorption performancePromote absorptionRadiation-absorbing paintsFiberCarbon fibers

The invention provides a high-efficiency solar heat absorbing material and a preparation method thereof. The high-efficiency solar heat absorbing material is prepared from organosilicone resin, graphene, carbon fibers, butyl acrylate, hydroxylated linseed oil, sodium lauryl sulfate, nano-powder, metal nitrate, a curing agent, a light absorbing agent, a film former, polyethylene glycol, an organicsolvent and a polyether modified silicone oil defoamer. The heat absorbing material has excellent solar energy absorption performances, utilizes a heat conductive material having photocatalytic migration properties, increases a solar energy absorption range and the heat conduction performance and has a long service life. The preparation method has mild reaction process conditions, realizes a low production cost and is suitable for industrial large-scale production.

Owner:来安县森浩茂环保工程有限公司

High-efficiency solar heat absorbing material

PendingCN109535635AOvercoming the problem of low thermal efficiencyIncrease heat absorption rateSynthetic resin layered productsLaminationPolyvinyl chlorideWhite oil

The invention discloses a high-efficiency solar heat absorbing material, which is a large-area heat absorbing material formed by mixing graphene, graphite, an auxiliary material and a catalyst, and then performing extrusion, blow molding and hot melting. The auxiliary material is a mixture of acrylonitrile-butadiene-styrene, ethylene-vinyl acetate copolymer, polyvinyl chloride, polypropylene, polyphenylene sulfide, silicon carbide, boron nitride, iron black, iron blue, iron red, chromium oxide, titanium nitride, CuFeMnO4, alumina, magnesia, zinc oxide, beryllia and silver powder. The catalystincludes a titanate coupling agent, a compatibilizer, and silicone powder. The compatibilizer refers to a maleic anhydride grafted compatibilizer such as maleic anhydride grafted PE and maleic anhydride grafted PP. The titanate coupling agent is preferably NDZ-201, and is diluted with white oil in equal proportions. The solar heat absorbing material can be in direct contact with water, has super absorption, less heat loss, fast heating, and high thermal efficiency, and can achieve mass production.

Owner:山西臣功新能源科技有限公司

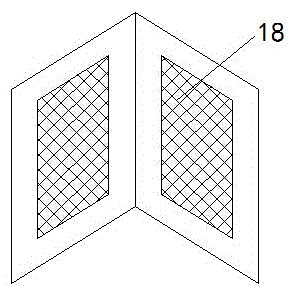

Solar heat collector and air heat collecting device and hot water device both made by using same

InactiveCN103017359AImprove efficiencyEasy to installSolar heating energySolar heat devicesElectricityCollector device

The invention discloses a solar heat utilization device or equipment, and particularly discloses a solar heat collector with a triangular tubular heat radiation structure. The solar heat collector comprises a plurality of heat absorbing and radiating bodies arranged in parallel, wherein a single heat absorbing and radiating body is in a triangular tubular structure; the external surfaces of one sides of the heat absorbing and radiating bodies are heat absorbing surfaces for absorbing solar energy; heat absorbing materials are arranged on the heat absorbing surfaces; the inner tube walls and the outer tube walls of the heat absorbing and radiating bodies all can exchange heat, so that the contact area between the solar heat collector and circulating air is increased because the inner tube walls and the outer tube walls of the heat absorbing and radiating bodies all can exchange heat; the triangular tubular heat collector for absorbing heat and radiating heat is used for directly heating air in buildings by mainly using solar energy to supply heat to rooms in winters and providing assistance to heat supply by using power in cloudy days, rainy days and snowy days; and as water circulating inlet and outlet are reserved in a solar heating plate, the hot water can be heated when the heating is not needed by the buildings in summer, so that the domestic use of hot water is solved for families and no investment waste is taken.

Owner:崔艳斌

Glass fiber composition, glass fiber and composite material thereof

ActiveUS11078109B2Improve the heat absorption effectIncrease heat absorption rateGlass making apparatusGlass fiberIron(II) oxide

A composition for producing a glass fiber, including the following components with corresponding percentage amounts by weight: 54.2-64% SiO2, 11-18% Al2O3, 20-25.5% CaO, 0.3-3.9% MgO, 0.1-2% of Na2O+K2O, 0.1-1.5% TiO2, and 0.1-1% total iron oxides including ferrous oxide (calculated as FeO). The weight percentage ratio C1=FeO / (iron oxides−FeO) is greater than or equal to 0.53. The total content of the above components in the composition is greater than 97%. The invention also provides a glass fiber produced using the composition and a composite material including the glass fiber.

Owner:JUSHI GRP CO

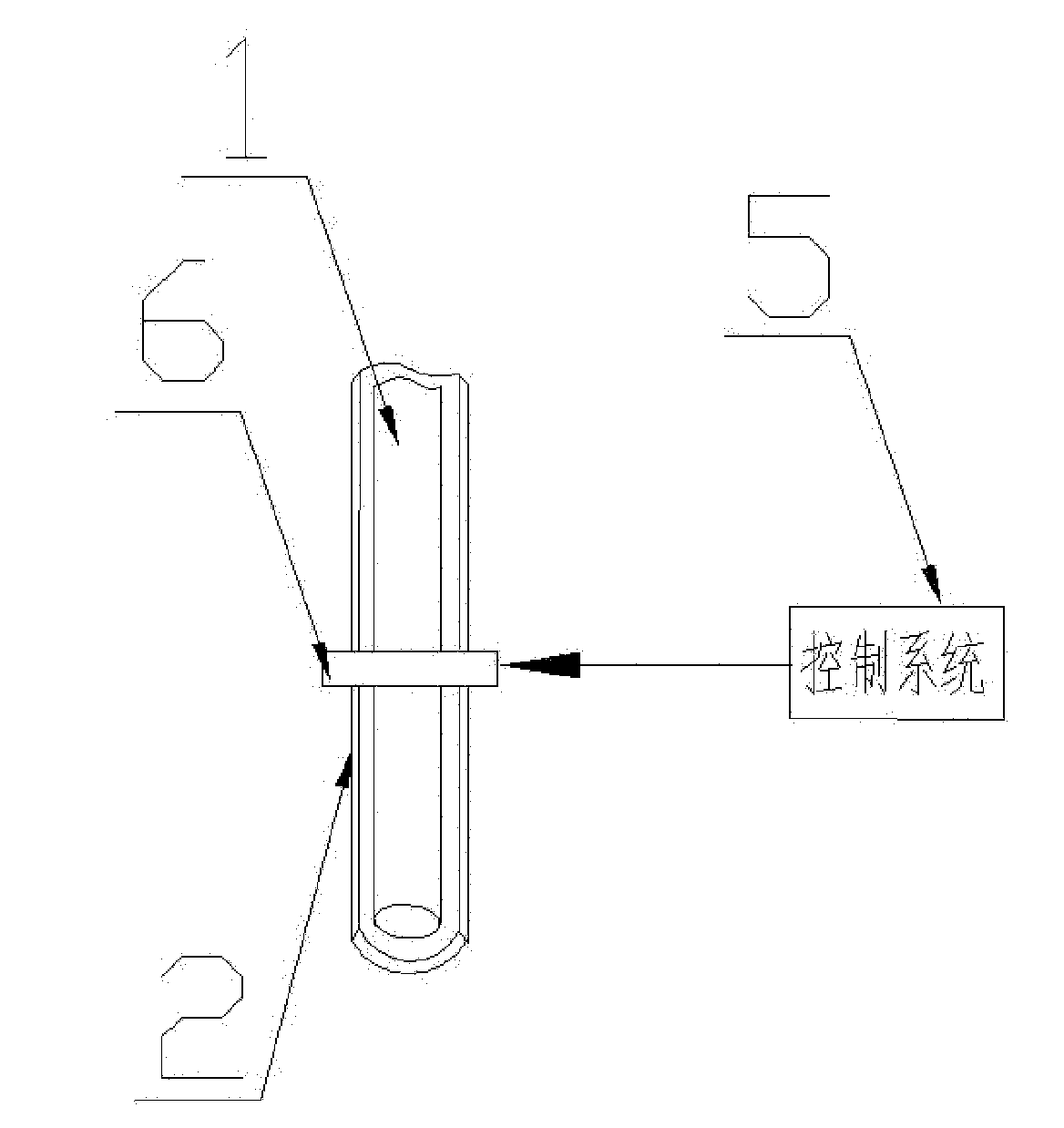

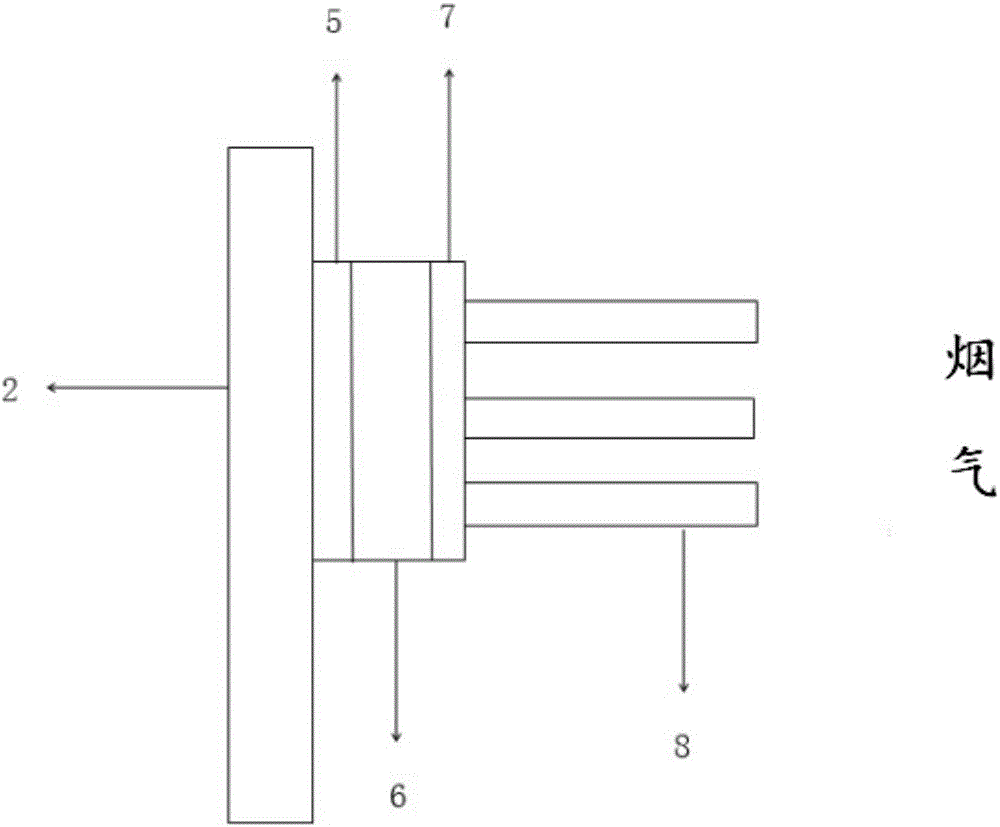

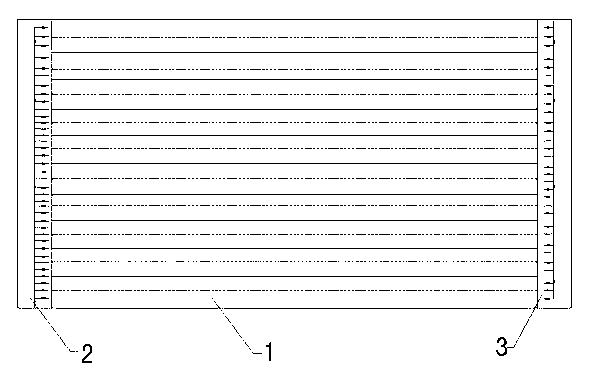

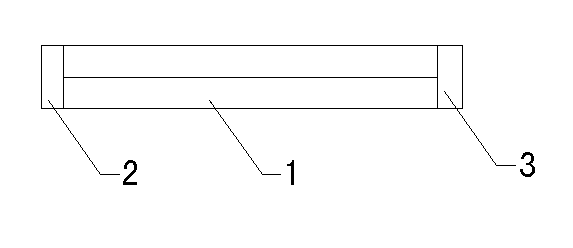

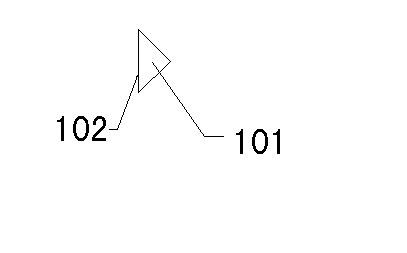

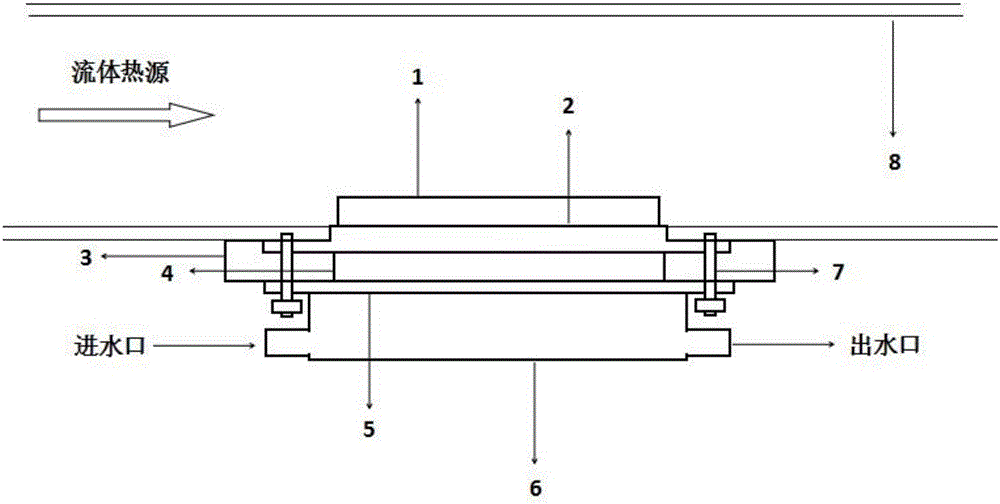

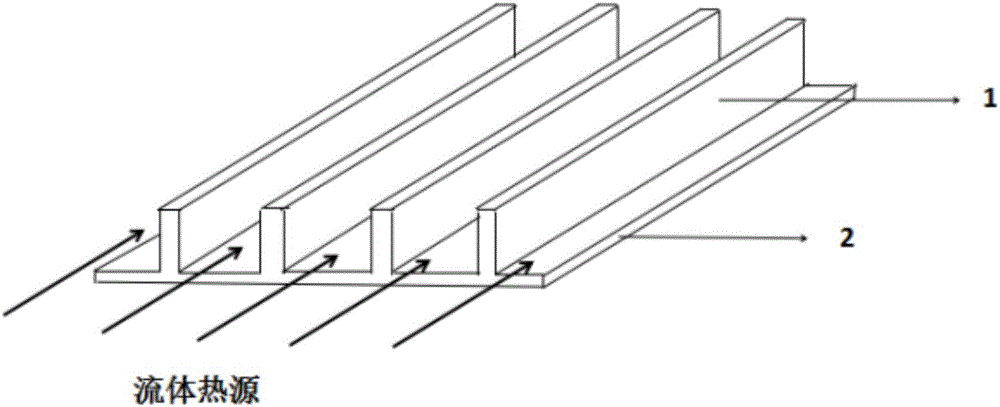

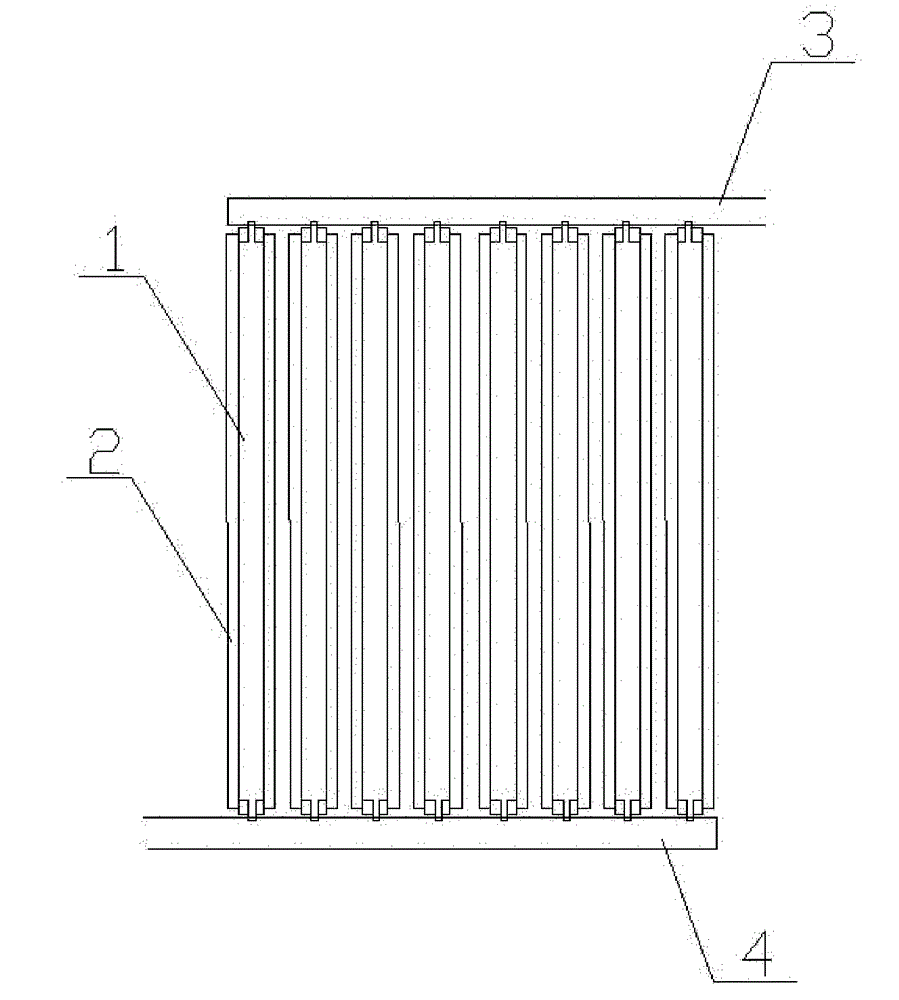

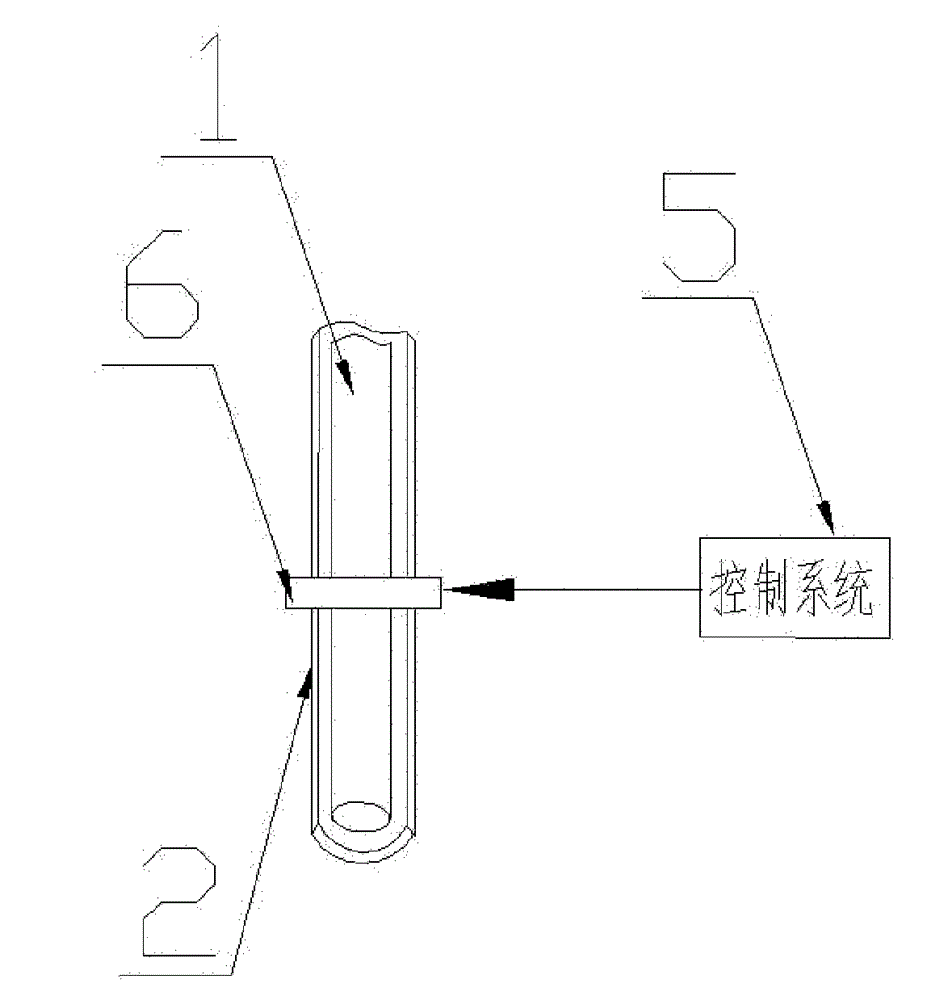

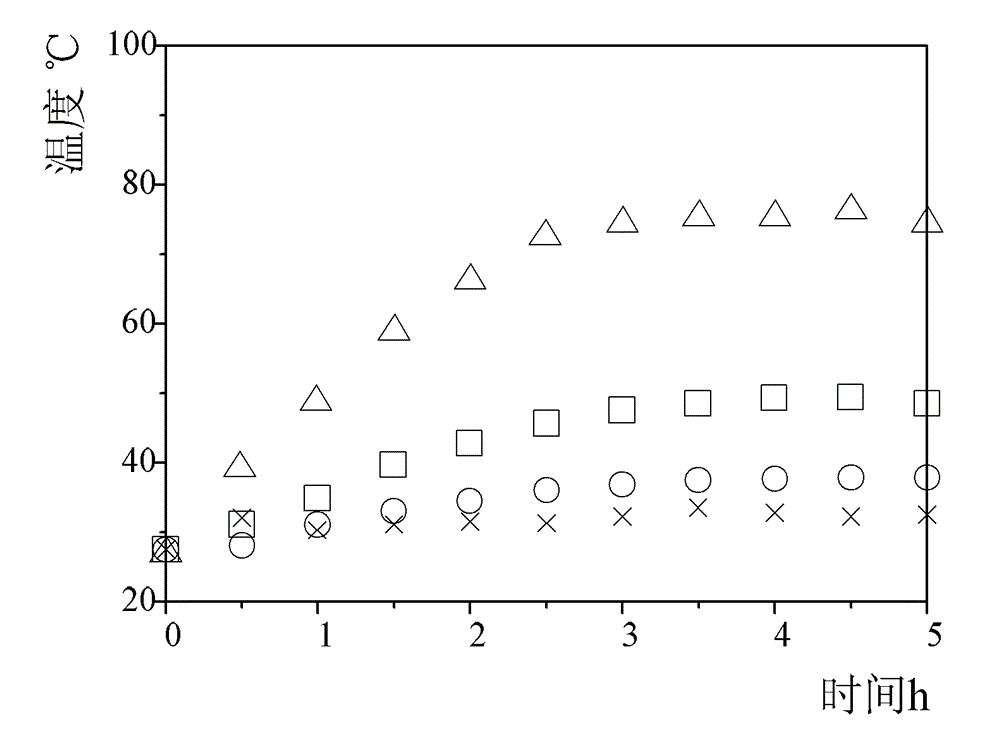

Thermoelectric power generation device utilizing medium/high temperature fluids

InactiveCN106301084AImprove energy efficiencyIncrease heat absorption rateGenerators/motorsEngineeringWater tanks

The invention relates to a thermoelectric power generation device utilizing medium / high temperature fluids. The device comprises a fluid heat source, a thermoelectric power generation component and a monitoring component, wherein the fluid heat source is used for supplying medium / high temperature fluid heat source to the thermoelectric power generation device; the thermoelectric power generation component comprises a fluid channel, a radiating water tank and a thermoelectric power generation unit; the fluid channel is respectively connected with the fluid heat source and the heat end of the thermoelectric power generation unit; the radiating water tank is respectively connected with an external thermostatic water source and the cold end of the thermoelectric power generation unit; the monitoring component is used for measuring the temperature of the heat end and cold end of the thermoelectric power generation unit and regulating the flow speed and temperature of the air fluid heat source. Compared with the prior art, the thermoelectric power generation device has the advantages of improving energy use efficiency, improving heat absorbing efficiency, improving heat dissipation rate, and being long in service life and convenient in detaching.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Nano-fluid direct absorption type solar heat collector

ActiveCN101915459BImprove heat collection efficiencyImprove thermal conductivitySolar heating energySolar heat devicesNanoparticleCollector device

The invention relates to a nano-fluid direct absorption type solar heat collector, in particular to a solar heat collector, which solves the problems of great heat loss and low heat collection efficiency of the conventional heat collectors. The nano-fluid direct absorption type solar heat collector of the invention comprises N vacuum pipes, N reflecting mirrors, a first heat insulation communicating pipe and a second heat insulation communicating pipe, wherein the N vacuum pipes are arranged in a row; one open end of each vacuum pipe is communicated with the first heat insulation communicating pipe through a rotary joint respectively, while the other end is communicated with the second heat insulation communicating pipe through the rotary joint respectively; the first communicating pipe is communicated with a water outlet; the second heat insulation communicating pipe is communicated with a water inlet; one reflecting mirror is arranged below each vacuum pipe respectively; working medium in each vacuum pipe comprises a fluid substrate; nanoparticles are also added into the working medium in each vacuum pipe; and N is an integer more than 2. The solar heat collector is used for converting solar energy into heat energy.

Owner:HARBIN INST OF TECH

A kind of preparation method of antibacterial stainless steel

InactiveCN105200375BTightly boundFast heat transferVacuum evaporation coatingSputtering coatingCorrosion resistantLaser

The invention discloses a method for introducing silver serving as an antibacterial material to the surface of 304 stainless steel. The method comprises the steps of material preparing; evaporating; ultrasonic washing; sooting; laser cladding and the like and is a brand new method for introducing silver powder to the surface of 304 stainless steel. By using the method, the aim of achieving a relatively good antibacterial effect of the 304 stainless steel by using a relatively small quantity of silver is achieved, the antibacterial rate can be up to more than 95%, meanwhile, the corrosion resistance of the stainless steel is improved, and the thickness of a surface modified layer can be up to 520mu m.

Owner:惠州丰正不锈钢制品有限公司

Sleeve type spraying system used for liquid tank precooling of liquefied natural gas (LNG) vessel and spraying method of sleeve type spraying system

InactiveCN105460197AImprove sealingUniform trajectoryAuxillariesVessel ventillation/heating/coolingControl engineeringLiquid tank

The invention discloses a sleeve type spraying system used for liquid tank precooling of a liquefied natural gas (LNG) vessel and a spraying method of the sleeve type spraying system. The sleeve type spraying system comprises a hydraulic sleeve system and a spraying executing mechanism. The hydraulic sleeve system is embedded in the central of a ceiling of a liquid tank, penetrates through a multi-layer structure of a liquid tank cargo maintaining system and then reaches the interior of the liquid tank. The spraying executing mechanism is internally embedded in the hydraulic sleeve system. The hydraulic sleeve system is used for controlling the spraying executing mechanism to unfold and fold. According to the sleeve type spraying system used for liquid tank precooling of the LNG vessel and the spraying method of the sleeve type spraying system, the defects of an existing spraying device used for liquid tank precooling of an LNG vessel are overcome, the atomization effect of a precooling agent is improved, a flow field formed by the precooling agent in the liquid tank is more uniform during precooling, and then the precooling efficiency is improved, the precooling time is shortened, and the operation economy of the LNG transport vessel is improved.

Owner:ZHEJIANG OCEAN UNIV

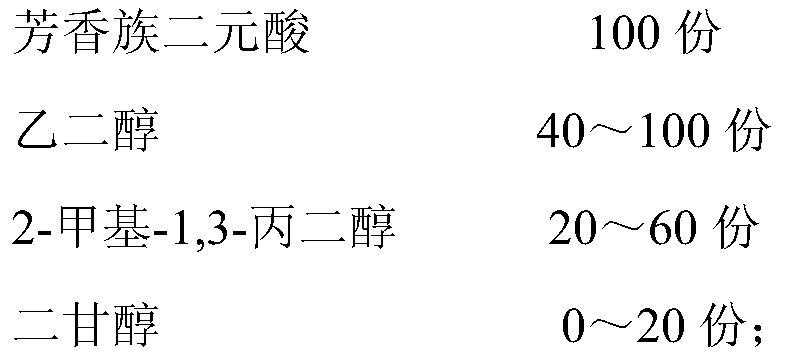

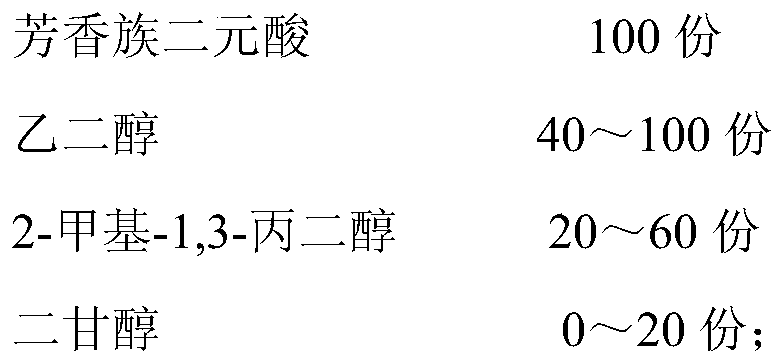

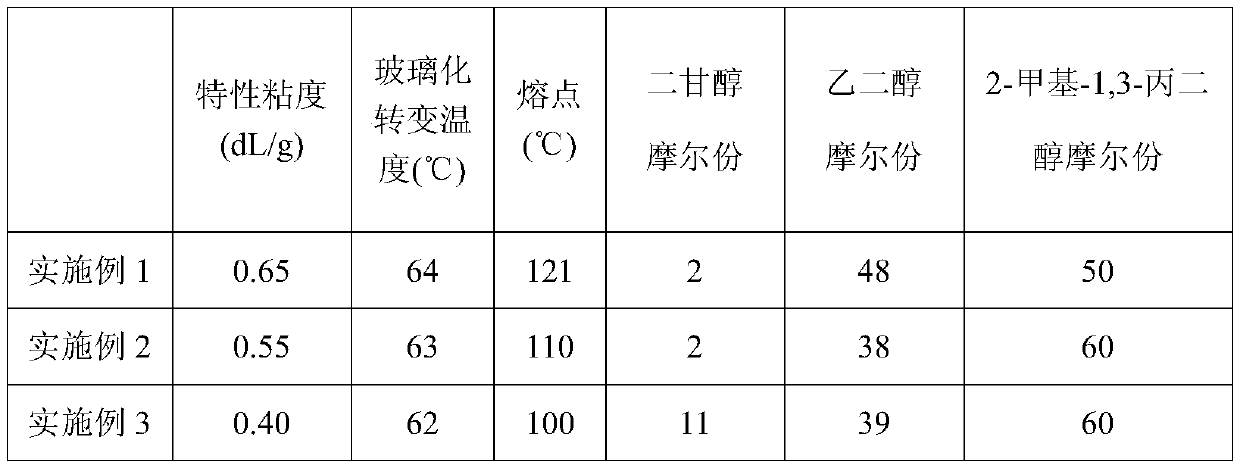

Low-melting-point polyester and preparation method thereof

InactiveCN110938196AIncrease heat absorption rateReduce energy consumptionThermal bondingIsopropylene glycol

The invention discloses a low-melting-point polyester and a preparation method thereof. The low-melting-point polyester is prepared by copolymerizing the following aromatic dibasic acid and aliphaticdihydric alcohol in parts by molar weight: 100 parts of an aromatic dibasic acid, 40-100 parts of ethylene glycol, 20-60 parts of 2-methyl-1, 3-propylene glycol and 0-20 parts of diethylene glycol. The low-melting-point polyester also contains an infrared absorbent and a free radical scavenger. The preparation method of the low-melting-point polyester comprises the following steps: mixing the aromatic dibasic acid, the aliphatic dibasic alcohol and a free radical scavenger to prepare a slurry, esterifying, adding the infrared absorbent in an online adding manner, and carrying out pre-polycondensation and final polycondensation to prepare the low-melting-point polyester. The heat absorption rate of the low-melting-point polyester is increased by utilizing the infrared absorbent, so that theenergy consumption in the thermal bonding processing process of the polyester product can be remarkably reduced; free radicals formed by the polyester in a high-temperature heated environment can beefficiently captured by utilizing the free radical scavenger, so that the thermal stability of the low-melting-point polyester is remarkably improved.

Owner:CHINESE TEXTILE ACAD +1

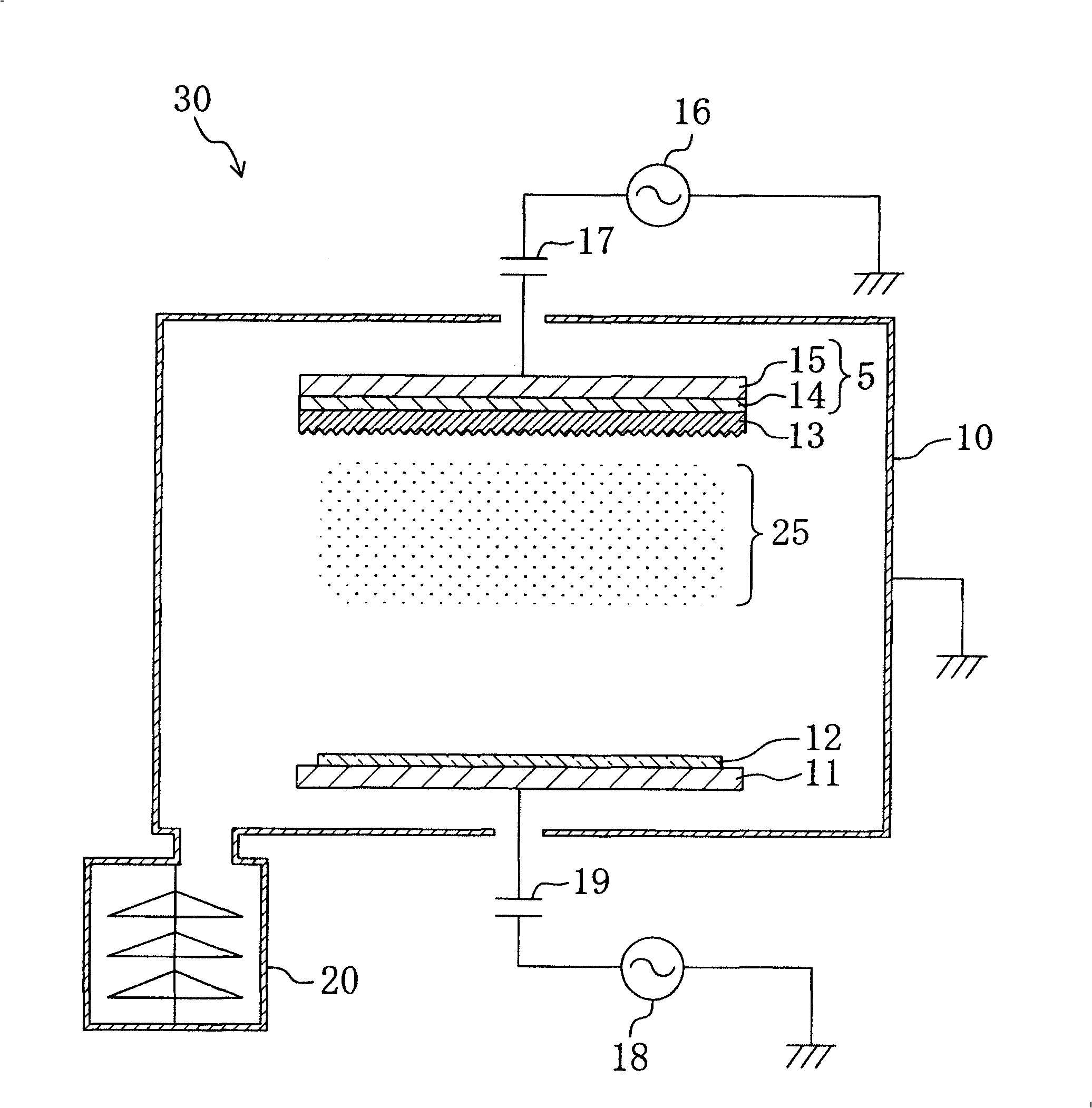

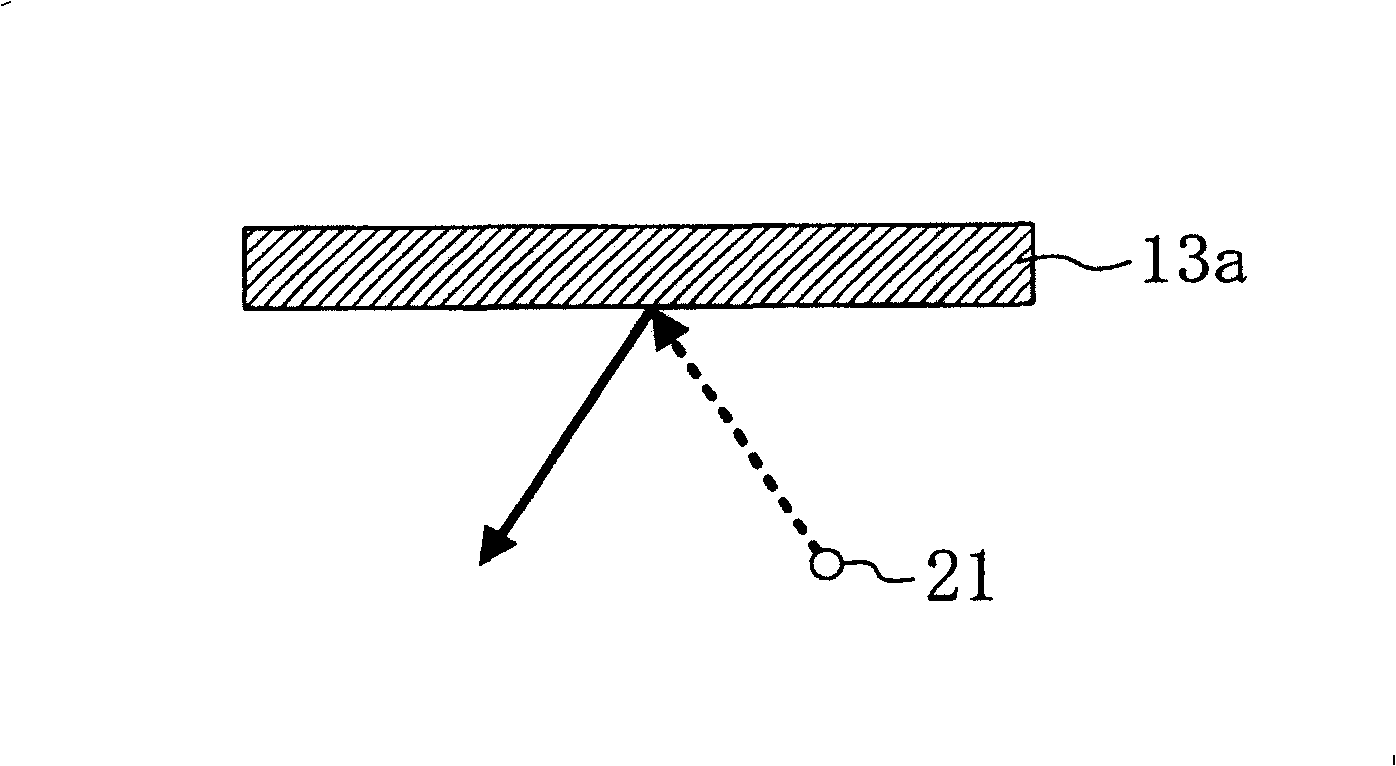

Plasma processing system

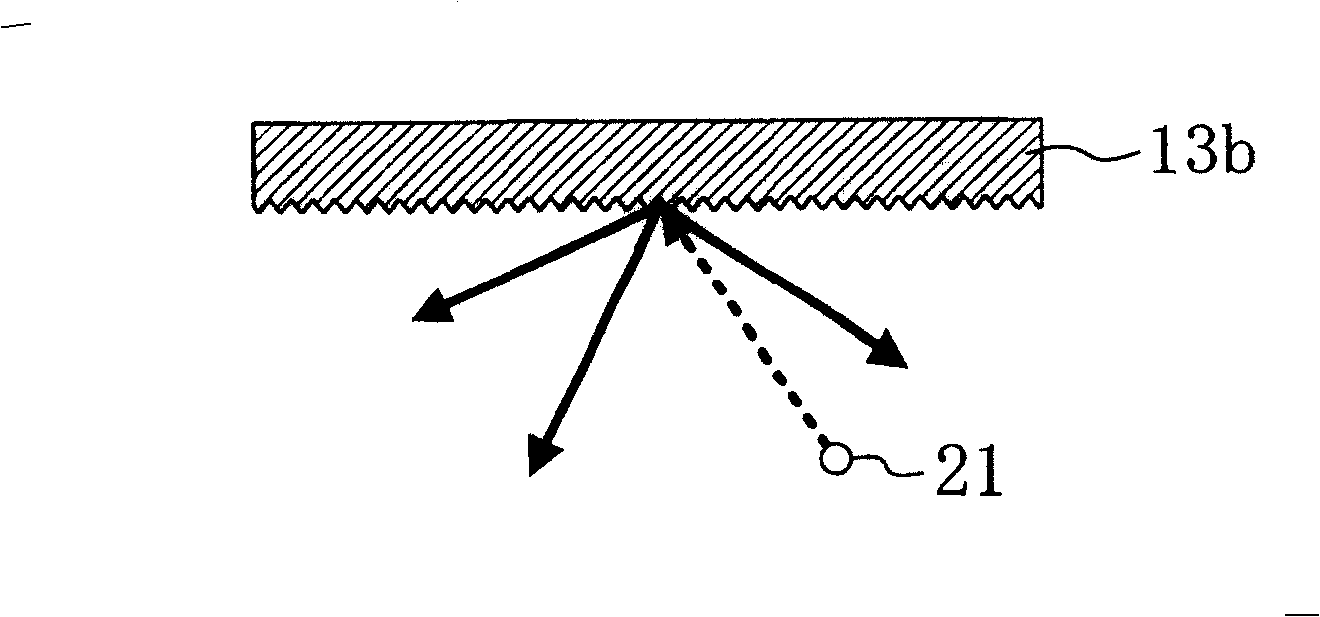

InactiveCN100440452CUniform treatmentIncrease heat absorption rateElectric discharge tubesSemiconductor/solid-state device manufacturingBiochemical engineeringQuartz

A plasma processing system comprising a processing chamber (10), first and second electrode units (5, 11) provided in the processing chamber (10) and arranged opposite to each other, and a quartz plate (13) provided on the second electrode unit (11) side of the first electrode unit (5) for protecting the first electrode part (5). The plasma processing system plasma-processes an article to be processed which is provided on the first electrode unit (5) side of the second electrode unit (11) by generating plasma between the first electrode unit (5) and the second electrode unit (11) and exciting a reaction gas in the processing chamber (10). The quartz plate (13) has a roughened surface on the second electrode unit (11) side.

Owner:SHARP KK

Formula of insulation material of water tank of solar water heater

A formula of an insulation material of a water tank of a solar water heater is disclosed. The formula includes, by weight, 60-70 parts of glyceryl glucoside polyether glycol, 5-10 parts of chitosan, 8-15 parts of dimethyl methylphosphonate, 8-15 parts of titanium dioxide, 5-10 parts of aluminum silicate and 2-10 parts of calcium chloride. The insulation material is used on the surface of the watertank of a solar water heater, and has a high heat absorption rate, and improved heating efficiency. The material overcomes the shortcomings of large shrinkage after foaming molding, avoids deformation of the water tank, and ensures the thermal insulation performance of the water tank of the water heater.

Owner:SICHUAN JINMING NEW ENERGY TECH

Solar water heater heat collection pipe coating material

InactiveCN110819234AAvoid safety hazardsImprove heating efficiencyRadiation-absorbing paintsPolymer resinHeat conducting

The invention discloses a solar water heater heat collection pipe coating material. The material is prepared from, by weight, 8-10 parts of carbon powder, 2-6 parts of zinc powder, 8-10 parts of titanium dioxide, 2-8 parts of aluminum silicate, 2-7 parts of calcium chloride, 20-50 parts of waterborne polymer resin, 5-10 parts of silane coupling agent and 40-50 parts of heat conducting agent. The material is sprayed on the surface of a heat collection pipe to prevent a potential safety hazard brought by bursting of the heat collection pipe; and meanwhile, the polymer coating is used as a carrier of the heat conducting agent, so that the heat efficiency of inner pipe glass is improved, the heat absorption rate is high, and the heating efficiency is improved.

Owner:SICHUAN JINMING NEW ENERGY TECH

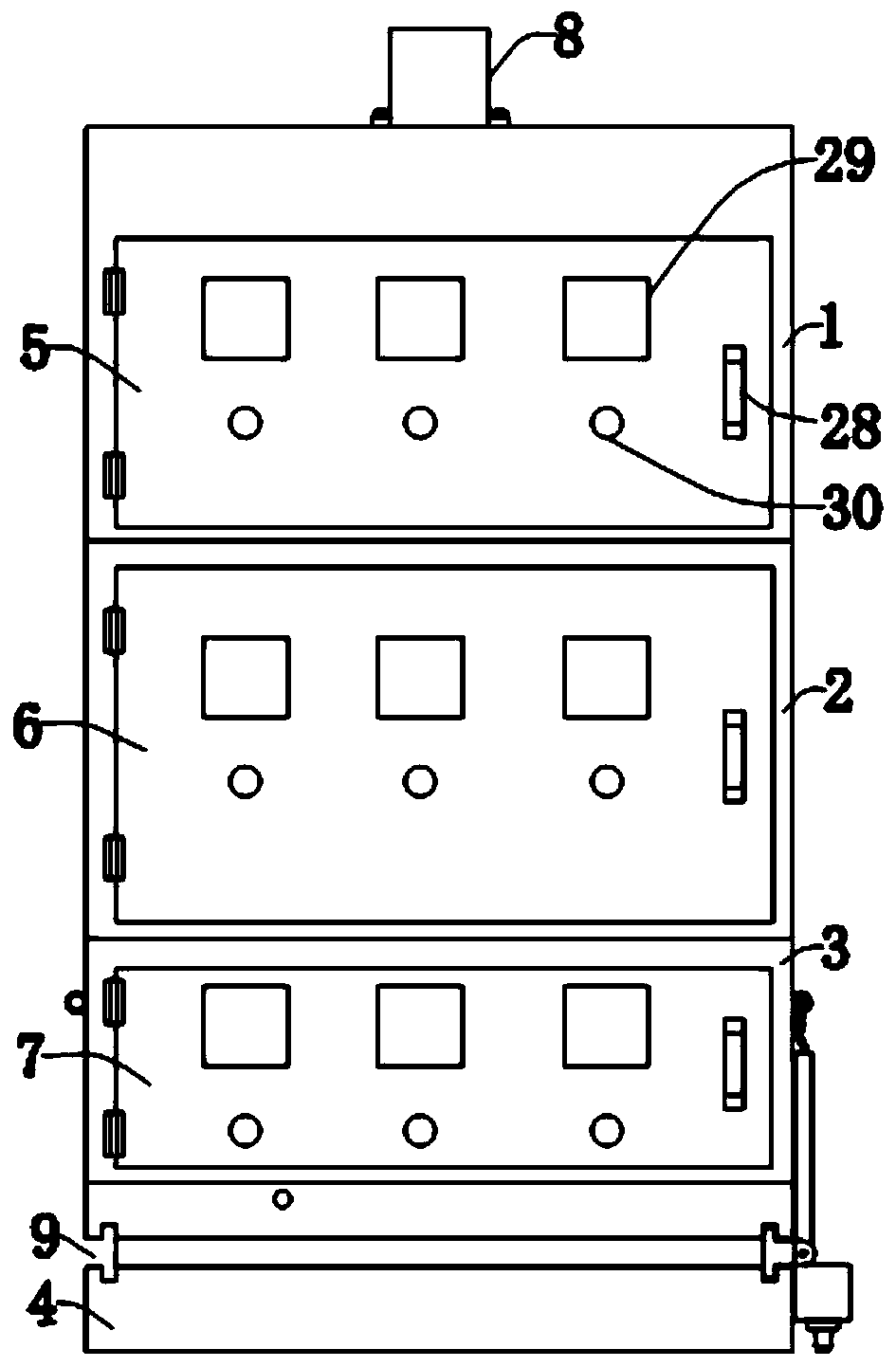

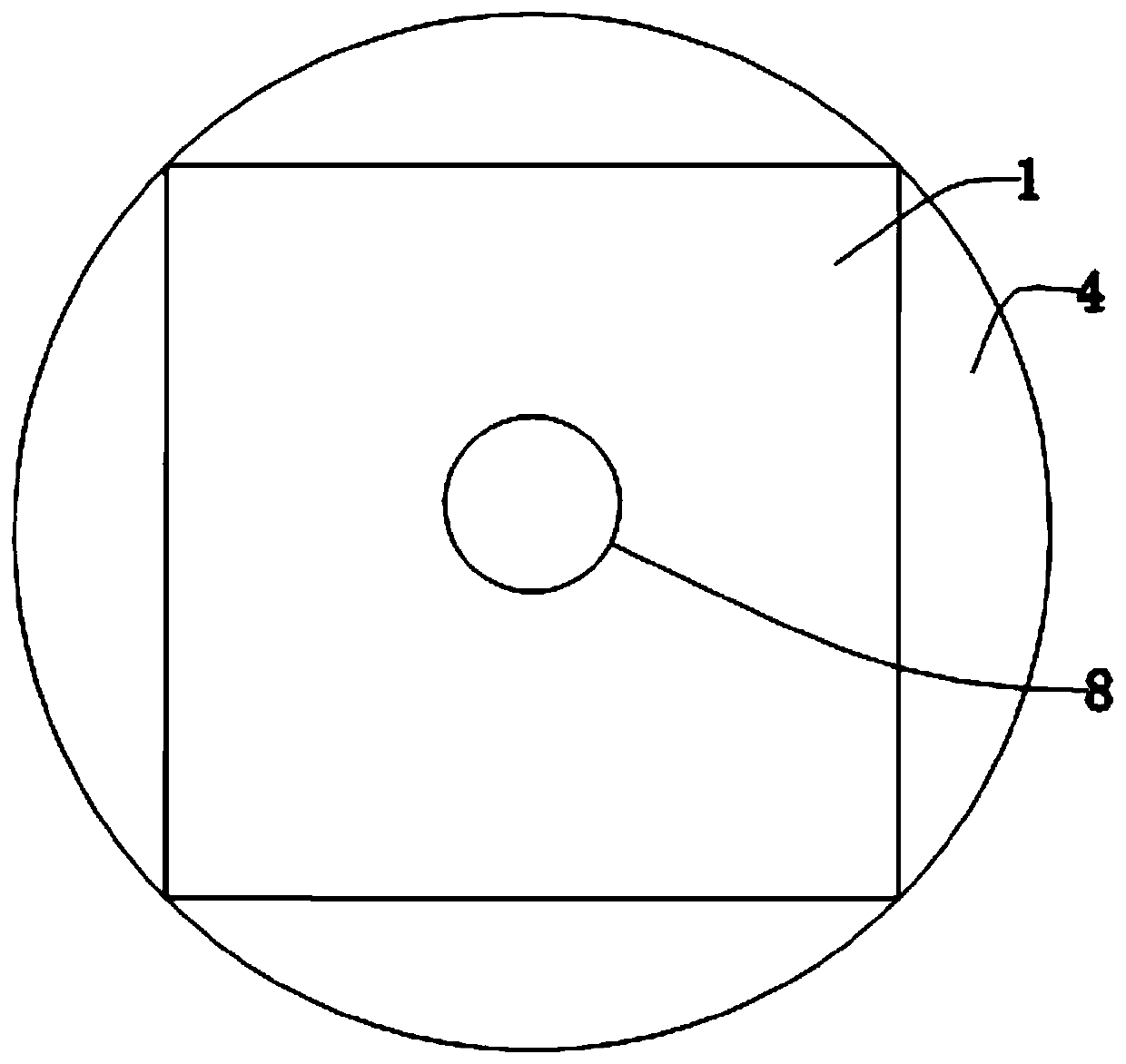

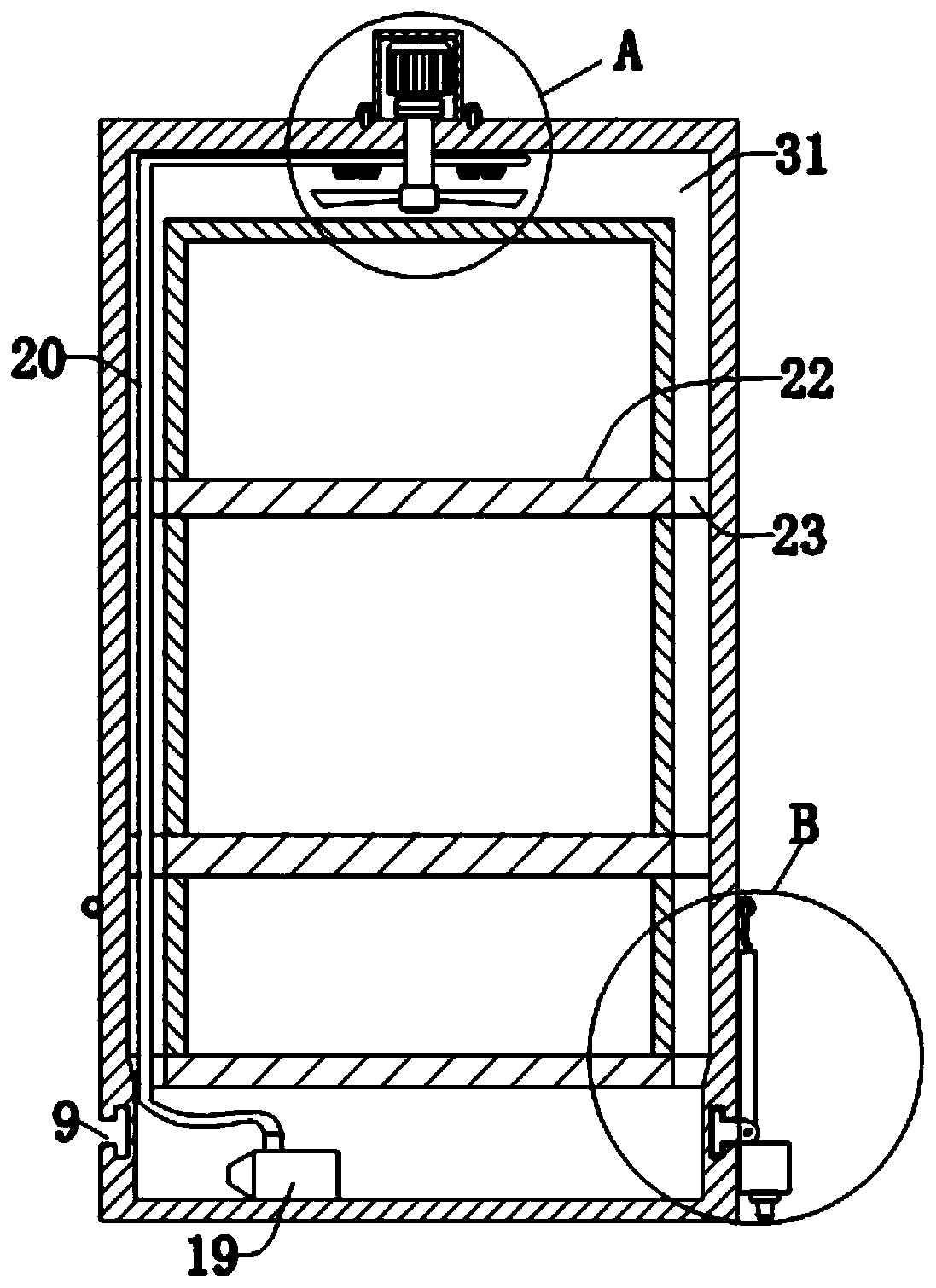

Indoor AC metal armored open switchgear

InactiveCN108598980BNovel structureStructural regulationSwitchgear detailsSubstation/switching arrangement cooling/ventilationEngineeringSwitchgear

The invention discloses an indoor alternating current metal-armored open type switchgear, which comprises an upper cabinet, a middle cabinet and a lower cabinet, wherein a water tank is fixedly connected to the lower part of the lower cabinet, an upper cabinet door is hinged to one side of the upper cabinet through hinges, a middle cabinet door is hinged to the middle cabinet through hinges, a lower cabinet door is hinged to the lower cabinet through hinges, a sliding chute is formed in the outer side of the water tank, a sliding block is connected in the sliding chute in a sliding manner anda connecting seat is fixedly connected to one side of the sliding block. A pedal can be put down and a worker can step on the pedal to conveniently overhaul equipment in the upper cabinet. After the pedal is used, the pedal is folded and a hook is hung in a hanging ring. A limiting plate is arranged to realize supporting and limiting functions when the pedal is put down. A protective cover is arranged to enable a motor to run in a safe and clean working environment. A moving wheel is arranged to enable the sliding block and the pedal to rotate around the sliding chute for angle regulation.

Owner:靖江市华宏机械有限公司

Heat collection tube for solar water heater

InactiveCN101975476AImprove heat transfer performanceIncrease heat absorption rateSolar heat devicesSolar thermal energy generationHeat conductingSolar water

The invention relates to a heat collection tube for a solar water heater, which comprises the heat collection tube, a fin and a superconductive rod, wherein the fin and the superconductive rod are positioned in the heat collection tube; the heat collection tube is transparent; the superconductive rod and the fin are integrally molded; the superconductive rod is hollow; and heat-conducting liquid is arranged in the superconductive rod. The heat collection tube has the advantages that: the superconductive rod of the heat collection tube has high heat transfer performance; the fin ensures high heat absorption rate and has stable performance; and relatively less heat migration on the surface of the fin and the high utilization rate of solar energy are ensured.

Owner:CHANGZHOU SUNLIGHT SOLAR ENERGY

Photo-thermal different-energy-gathering heat pump integrated system

PendingCN114811707ALow vaporization temperatureSolve the problem of poor heating effectMechanical apparatusHeat pumpsPlate heat exchangerLiquid storage tank

The invention discloses a photo-thermal different-energy-gathering heat pump integrated system, and relates to the technical field of energy utilization. The plate heat exchanger is communicated with the liquid storage tank; the evaporator is communicated with the plate heat exchanger, and an enthalpy supplementing expansion valve and an electronic expansion valve are arranged between the evaporator and the plate heat exchanger; the compressor is communicated with the plate heat exchanger; the liquid storage separator is communicated with the compressor; a channel is formed in the heat collection panel, and the two ends of the channel communicate with the liquid inlet and the liquid outlet correspondingly. The four-way valve is communicated with the tee joint, a liquid inlet of the heat collection panel is communicated with the tee joint, a liquid outlet of the heat collection panel is communicated with the four-way valve, a one-way valve is arranged between the heat collection panel and the four-way valve, an electromagnetic valve is arranged between the heat collection panel and the tee joint, and the compressor and the liquid storage separator are both communicated with the four-way valve. The two ends of the refrigerant area communicate with the liquid storage tank and the four-way valve correspondingly, and the water area is provided with a water inlet and a water outlet. Therefore, the problem that in the prior art, a heat supply system is low in energy utilization rate, and consequently the heat supply effect is poor is solved.

Owner:耿丙义

Vacuum instant-heating type micro-heat tube solar water heater

PendingCN110186201AIncrease heat absorption rateReduce thermal resistanceSolar heating energySolar heat storageHeat resistanceEngineering

The invention discloses a vacuum instant-heating type micro-heat tube solar water heater, and relates to the field of solar energy utilization. The vacuum instant type micro-heat tube solar water heater integrates the advantages of a micro-heat tube type heat collector and a vacuum tube type heat collector, the heat collection efficiency is high, the heat preservation performance is good, and thephoto-thermal conversion efficiency can be greatly improved; the vacuum instant-heating type micro-heat tube solar water heater comprises surface coating micro-heat tubes, coating vacuum tubes, a heatexchanger and an energy storage heat exchange water tank, wherein the surface coating micro-heat tubes are inserted into the coating vacuum tubes, the surface coating micro-heat tubes penetrate through the upper end and the lower end of the micro-heat tubes, solar spectrum selective coatings are arranged at the parts, outside the energy storage heat exchange water tank, of the lower ends of the micro-heat tubes, the middles of the micro-heat tubes are connected with the heat exchanger, the connection parts are coated with heat conduction glue and fixed in a buckled mode, the upper ends of themicro-heat tubes are connected with heat transfer metal pipes, and the connection parts are coated with the heat conduction glue and fixed in a buckled mode; the energy storage heat exchange water tank is composed of a heat preservation layer and a shell, the energy storage heat exchange water tank is provided with an opening, the surface coating micro-heat tubes are inserted into the water tank,the heat exchanger and the heat transfer metal pipes are fixed inside the water tank through a buckle, and the heat resistance of the heat transfer metal pipes is smaller than that of heat exchangerfins.

Owner:北京结力能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com