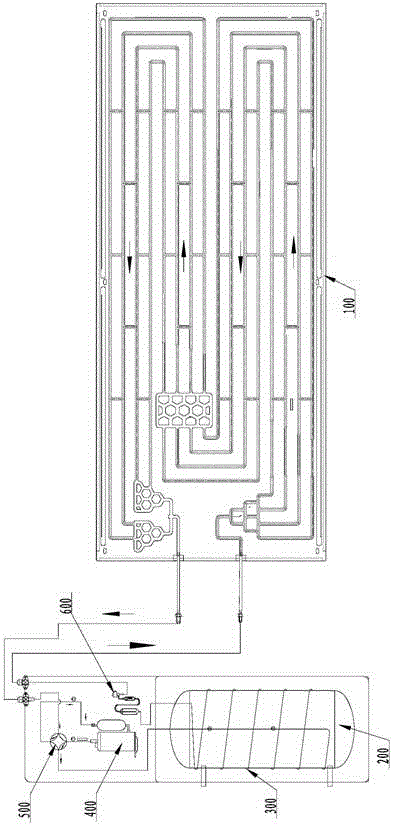

Solar heat pump huffing evaporator and water heater

A technology for solar heat pumps and evaporators, which is applied in the fields of inflation evaporators and solar heat pump water heaters, and can solve the problems of loud vibration and sound of refrigerant flowing in inflation evaporators, large plate area of solar heat pump evaporators, and utilization rate of heat-absorbing areas. Low-level problems, to achieve the effect of suitable promotion and use, significant effect, and avoid turbulent flow of condensed water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

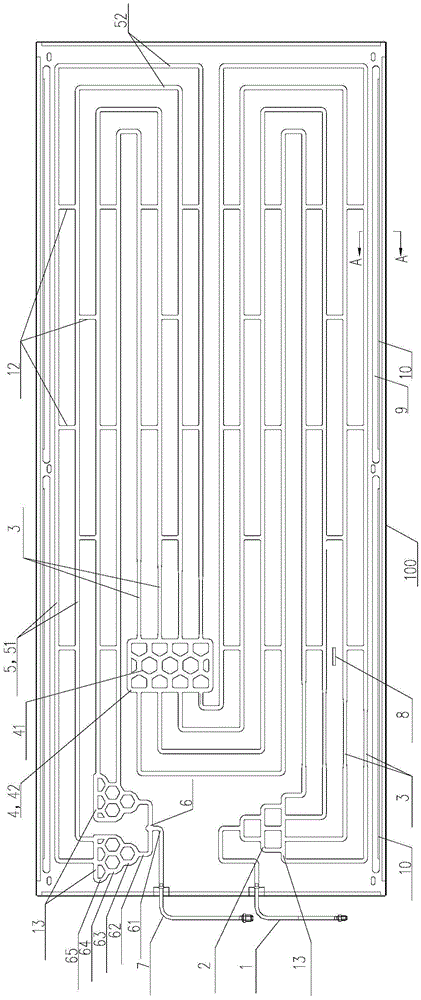

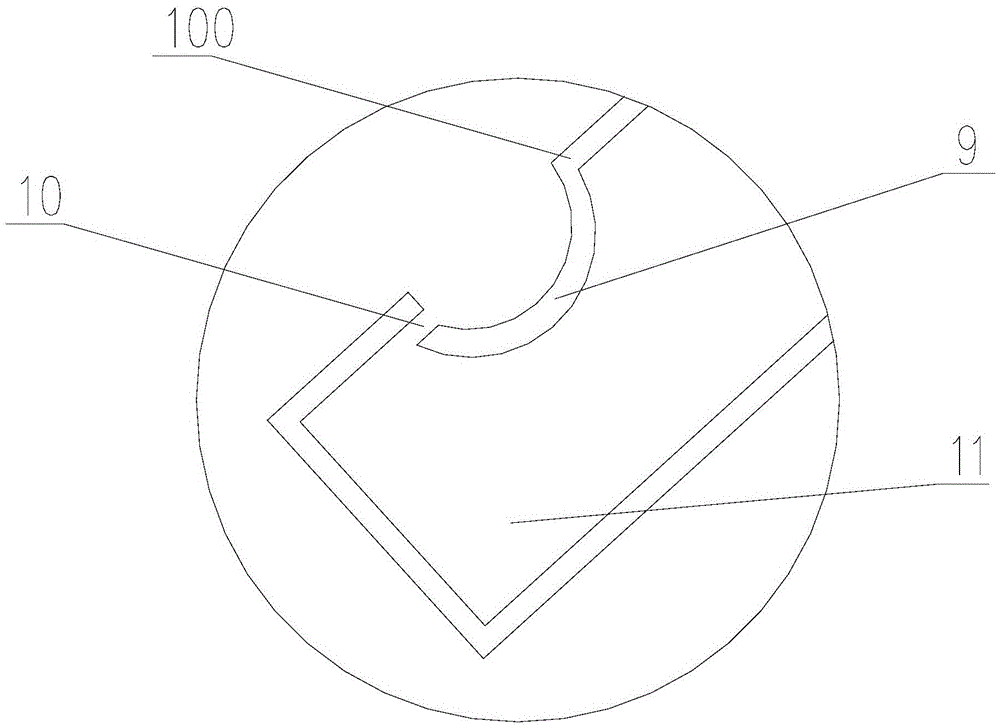

[0045] Such as figure 2 As shown, in this embodiment, the flow channels on the evaporator 100 include multiple heat exchange flow channels 5 arranged in parallel. The heat exchange channel 5 bends and extends in an "s" shape, coiling from the upper side to the lower side of the evaporator 100 . The heat exchange channel 5 includes a plurality of straight pipe sections 51 parallel to the axis of the evaporator 100, each straight pipe section 51 is arranged at intervals, and the ends of each straight pipe section 51 pass through a vertical pipe section 52 perpendicular to the axis of the evaporator 100 and Corresponding adjacent straight pipe sections 51 are connected, so that each straight pipe section 51 is connected in sequence to form an "s"-shaped flow channel. Therefore, the heat exchange channel 5 is curved and coiled on the entire plate surface of the evaporator 100 to increase the length of the heat exchange channel 5 as much as possible; The plate surface area is in...

Embodiment 2

[0049] Such as figure 2 As shown, in this embodiment, the tree-like branch flow channel 2 includes a main pipe section 61 connected with the evaporator inlet 1, and the main pipe section 61 is respectively connected with two first-stage pipe sections 62 through a three-way joint, and the first-stage pipe section 62 are respectively connected to two second-stage pipe sections 63 through a three-way joint, and the second-stage pipe sections 63 are respectively connected to the inlet ends of the corresponding heat exchange channels 5 .

[0050] In this embodiment, the tree-like converging channel 6 includes a main pipe section 61 connected to the outlet 2 of the evaporator. The main pipe section 61 communicates with two first-stage pipe sections 62 through a three-way joint, and the first-stage pipe sections 62 respectively pass through The three-way joint communicates with two second-stage pipe sections 63 , and the second-stage pipe sections 63 communicate with the outlet ends...

Embodiment 3

[0056] Such as figure 2 As shown, in this embodiment, the honeycomb-shaped converging flow channel 4 includes a plurality of equilateral polygonal annular pipe sections 41; each annular pipe section 41 is arranged in multiple rows and columns, and adjacent sides of adjacent annular pipe sections 41 The sides share the same pipe so that the annular pipe sections 41 communicate with each other. Preferably, the annular pipe section 41 is in the shape of an equilateral hexagon, so as to increase the density of flow channels arranged on the evaporator plate per unit area as much as possible and increase the heat exchange efficiency of the evaporator.

[0057] In the present embodiment, the outer circumference of the converging flow passage 4 is provided with a square outer ring pipe section 42, and the ring pipe sections 41 near the outer side are respectively connected with the outer ring pipe section 42; One side goes into the connection and the opposite side goes out the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com