Thermoelectric power generation device utilizing medium/high temperature fluids

A technology of thermoelectric power generation and thermoelectric power generation sheets, which is applied in the direction of generators/motors, electrical components, etc., can solve the problems of affecting the efficiency of thermoelectric power generation, low heat absorption rate and heat dissipation rate, and low energy utilization rate, and achieve the replacement of the device inside The components are convenient, the service life is improved, and the installation, disassembly and replacement are convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

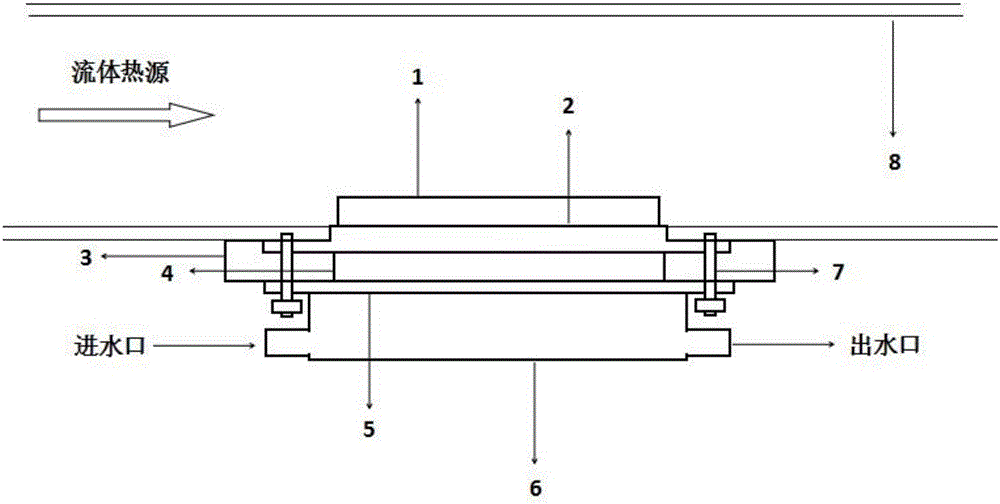

[0029] Such as figure 1 As shown, a thermoelectric power generation device using medium and high temperature fluid, the device includes:

[0030] Fluid heat source: used to provide medium and high temperature fluid heat source for thermoelectric power generation device;

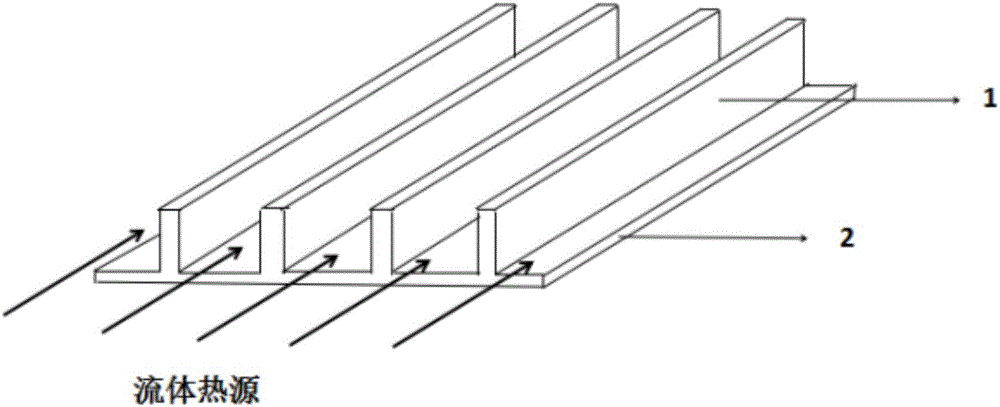

[0031] Thermoelectric power generation components: including a fluid channel 8, a heat dissipation water tank 6 and a thermoelectric power generation unit, the fluid channel 8 is respectively connected to the fluid heat source and the hot end of the thermoelectric power generation unit, and the heat dissipation water tank 6 is respectively connected to an external constant temperature water source and a cold end of the thermoelectric power generation unit, The thermoelectric generating unit includes a plurality of thermoelectric generating sheets 4, a heat absorbing plate 2 connected to the hot end of the thermoelectric generating sheet 4, and a heat dissipation plate 5 connected to the cold end of the thermo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com