Sleeve type spraying system used for liquid tank precooling of liquefied natural gas (LNG) vessel and spraying method of sleeve type spraying system

An LNG ship and casing type technology, applied in the field of spray systems, can solve the problems of reduced cooling rate of pre-coolant, small heat exchange area, and reduced cooling effect of pre-coolant, saving time and fog of pre-cooling operation. The effect of improving the cooling effect and improving the cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with specific embodiment:

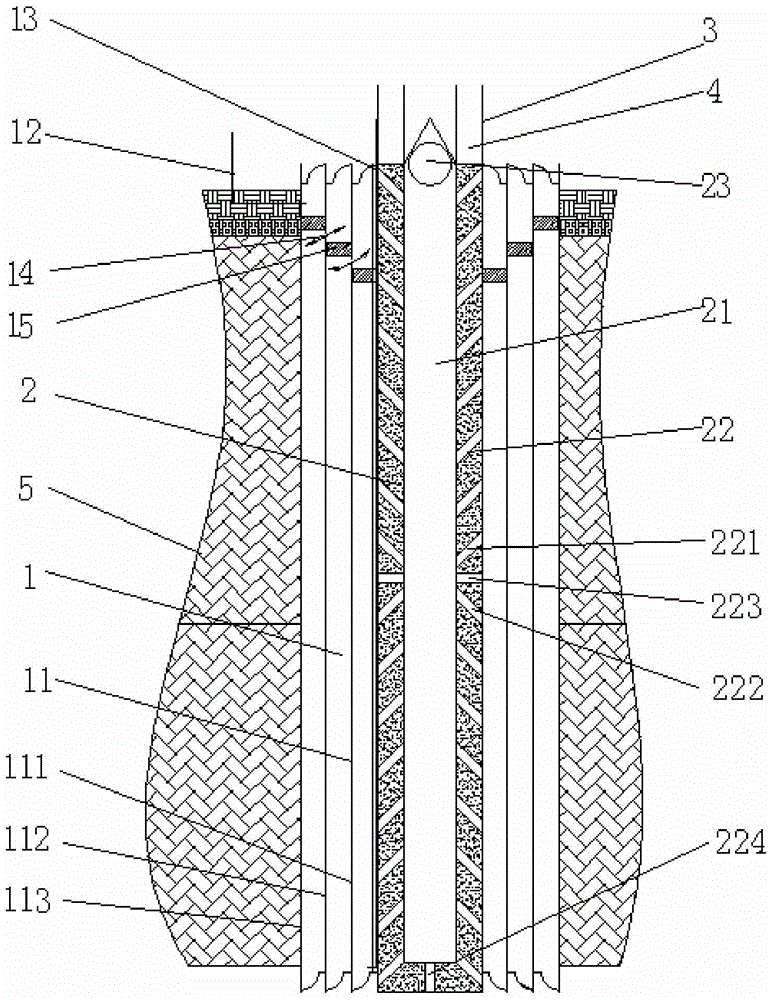

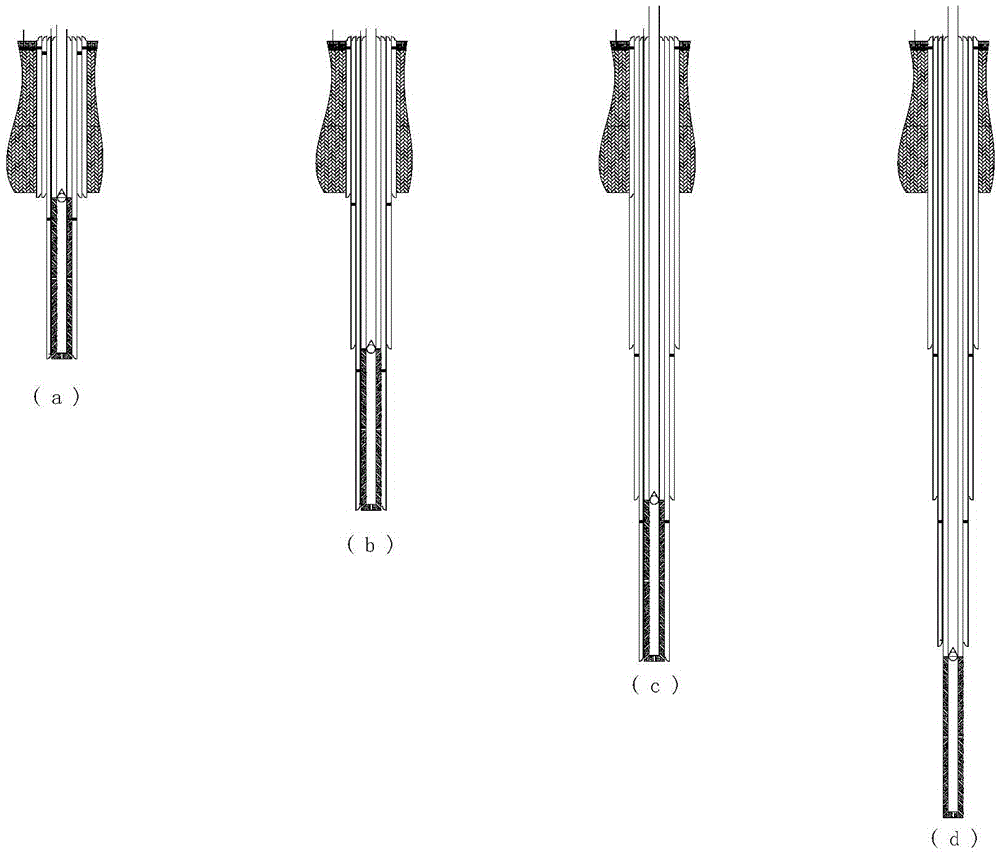

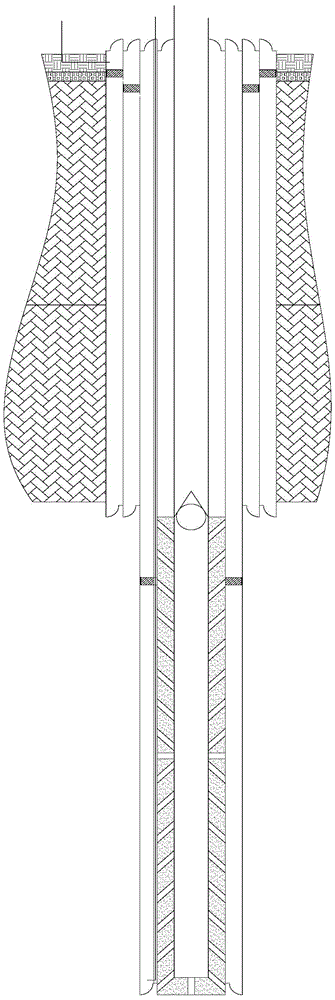

[0029] Such as figure 1 As shown, a casing type spraying device for tank precooling of an LNG ship includes a hydraulic casing system 1 and a spray actuator 2, the hydraulic casing system 1 is embedded in the center of the tank ceiling, and After passing through the multi-layer structure of the tank cargo maintenance system 5 and reaching the interior of the tank, the spray actuator 2 is embedded in the hydraulic bushing system 1, and the hydraulic bushing system 1 is used to control the spray actuator 2, a power tube 3 is installed on the upper end of the spray actuator, and a precoolant input pipe is arranged in the space inside the tube to complete the independent control of the operation action of the spray actuator 2.

[0030] The hydraulic casing system 1 includes a three-stage casing 11, a hydraulic oil inlet pipe 12 and a hydraulic oil return pipe 13. A hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com