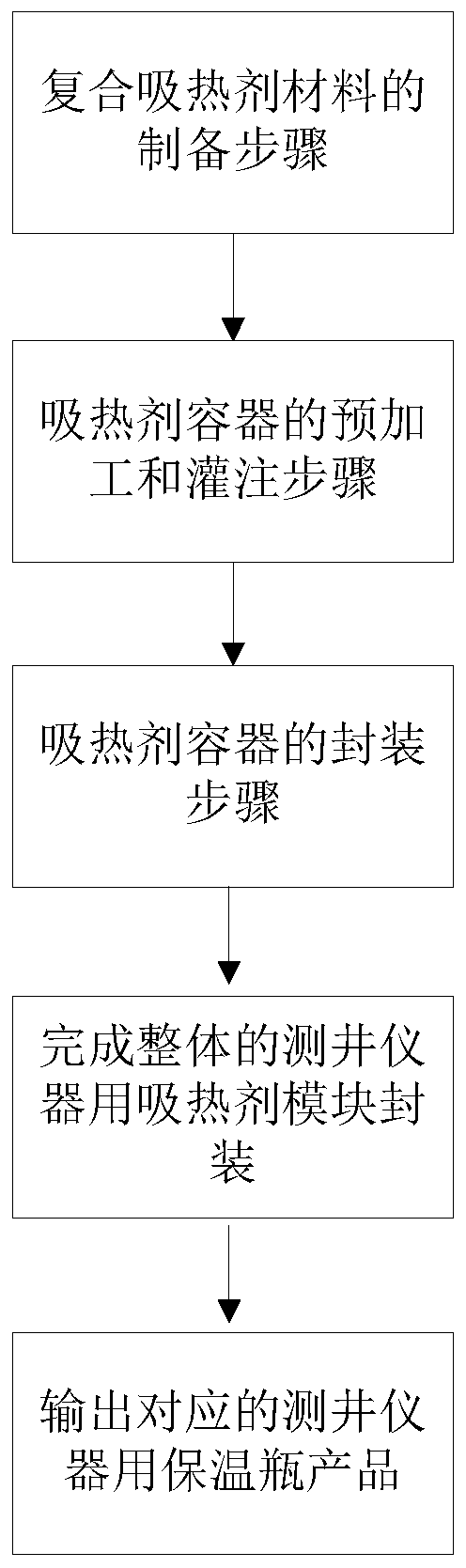

Packaging method and device for high-thermal-conductivity and high-temperature-resistance heat absorbentfor logging instrument

A technology of logging instrument and encapsulation method, which is applied in construction and other fields, can solve problems such as slow heat absorption and release speed, sudden pressure rise, and inability to withstand high temperatures, so as to improve heat absorption rate, increase overall thermal conductivity, and good absorption The effect of thermal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

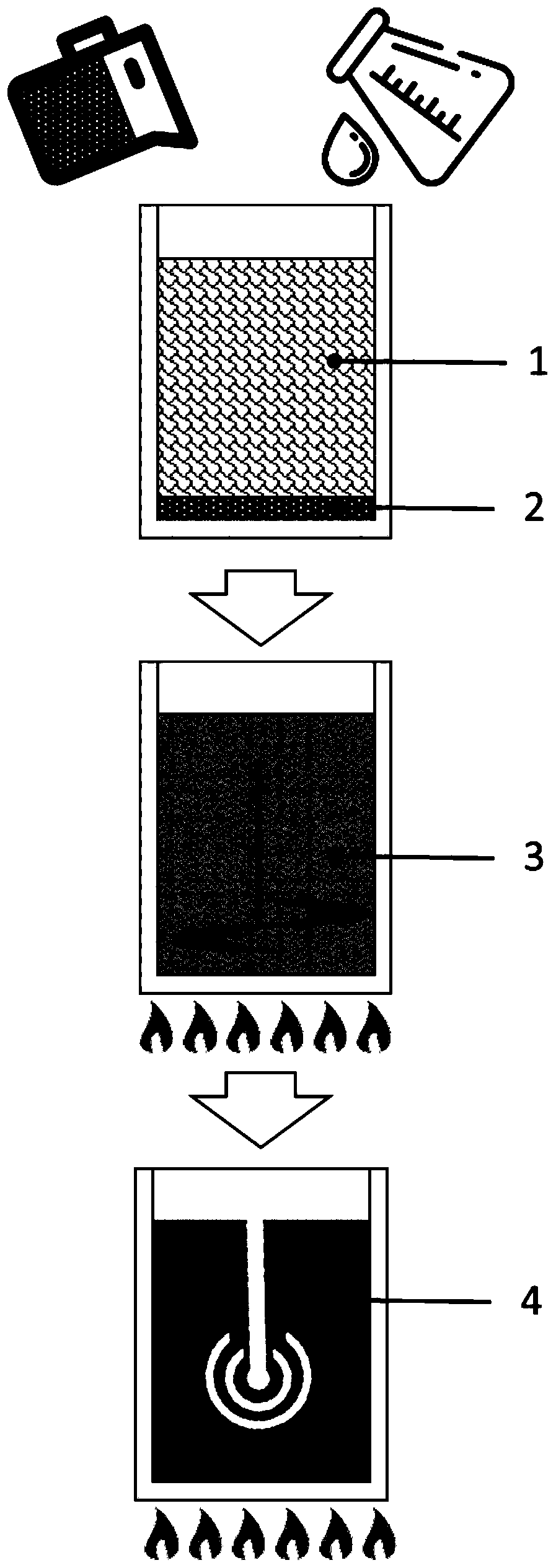

[0042] see image 3, the molten paraffin and expanded graphite are mixed according to the ratio of the former to the latter 2% by mass; the mixture of molten paraffin and expanded graphite is magnetically stirred and ultrasonically treated to obtain a composite endothermic agent doped with expanded graphite Material. Wherein, the magnetic stirring process needs continuous heating, and the stirring time is 10 minutes to 30 minutes, and the ultrasonic process needs continuous heating, and the ultrasonic time is preferably between 2 to 5 minutes.

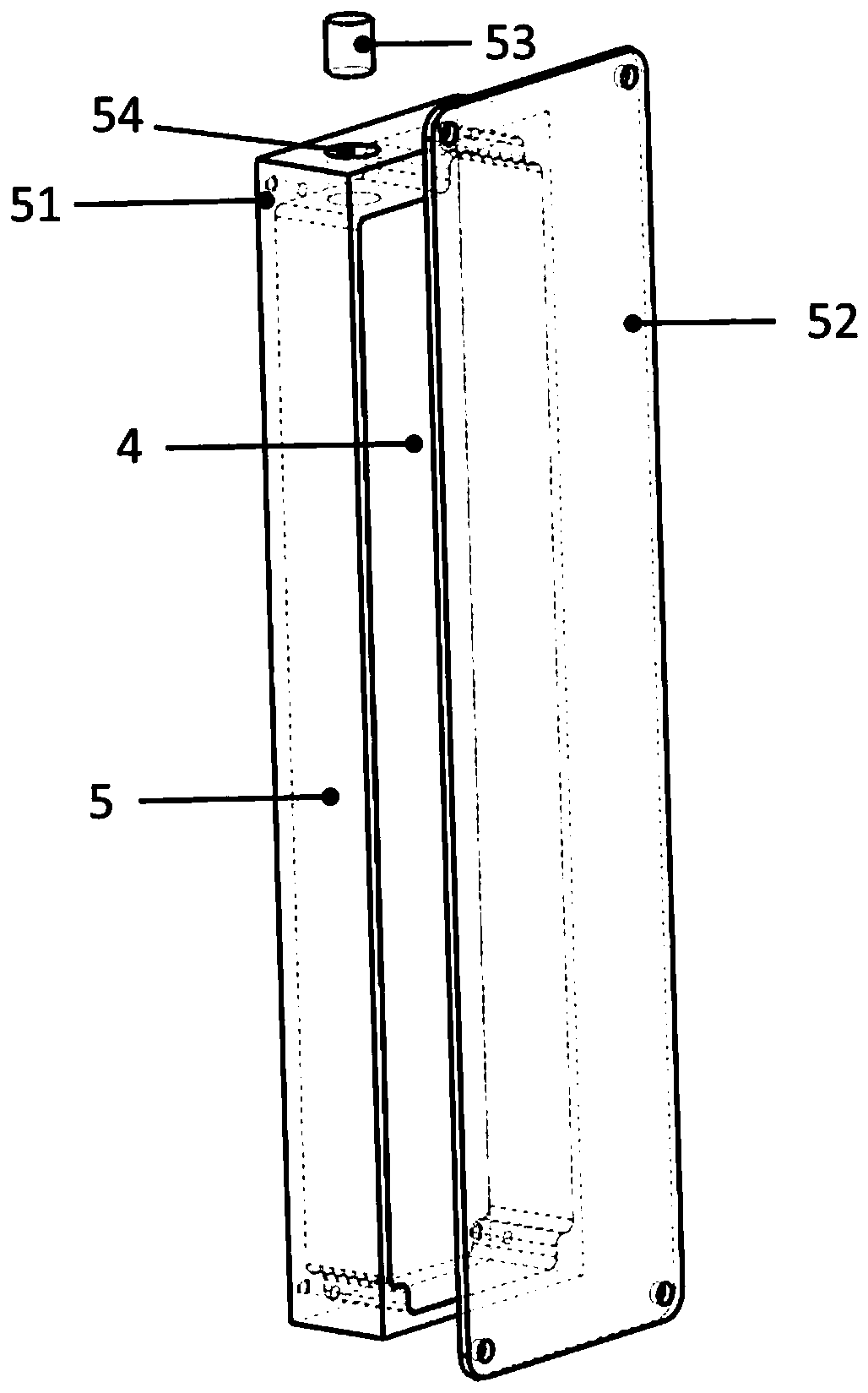

[0043] To form the shell of the endothermic container, the end cap is processed respectively, then drill through holes on the end cap or the endothermic shell, and the shell and the end cap are welded to form the endothermic container; in the present embodiment 1, The specific process is as follows: the square endothermic shell 51 and the square end cap 52 forming the square endothermic container 5 are processed respectively; through ...

Embodiment 2

[0047] see Figure 4 , the molten paraffin and expanded graphite are mixed according to the ratio of the former to the latter 4% by mass; the mixture of molten paraffin and expanded graphite is magnetically stirred and ultrasonically treated to obtain a composite endothermic agent doped with expanded graphite Material. Wherein, the magnetic stirring process needs continuous heating, and the stirring time is 10 minutes to 30 minutes, and the ultrasonic process needs continuous heating, and the ultrasonic time is preferably between 2 to 5 minutes.

[0048] To form the shell of the endothermic container, the end cap is processed respectively, then drill through holes on the end cap or the endothermic shell, and the shell and the end cap are welded to form the endothermic container; in this embodiment 2, The specific process is as follows: the wing-shaped heat-absorbing agent shell 61 and the wing-shaped end cap 62 that form the wing-shaped heat-absorbing agent container 6 are pr...

Embodiment 3

[0052] see Figure 5 , the molten paraffin and expanded graphite are mixed according to the ratio of the former to the latter, 1% by mass; the mixture of molten paraffin and expanded graphite is magnetically stirred and ultrasonically treated to obtain a composite endothermic material doped with expanded graphite agent material. Wherein, continuous heating is required in the magnetic stirring process, and the stirring time is 10 minutes to 30 minutes, and continuous heating is required in the ultrasonic process, and the ultrasonic time is preferably between 2 to 5 minutes.

[0053] To form the shell of the endothermic container, the end cap is processed respectively, then drill through holes on the end cap or the endothermic shell, and the shell and the end cap are welded to form the endothermic container; in this embodiment 3, Its specific process is as follows: process respectively the cylindrical endothermic shell 71, the bottom end cover 72 and the top end cover 73 that f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com