Low-melting-point polyester and preparation method thereof

A low-melting polyester and oligomer technology is applied in the field of low-melting polyester to achieve the effects of improving the heat absorption rate, stable product quality and low production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

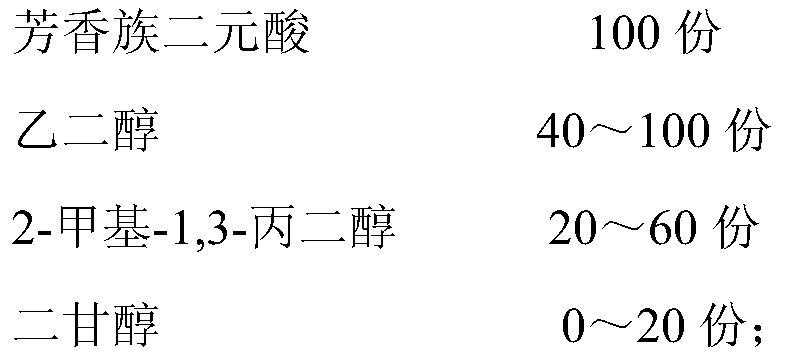

Method used

Image

Examples

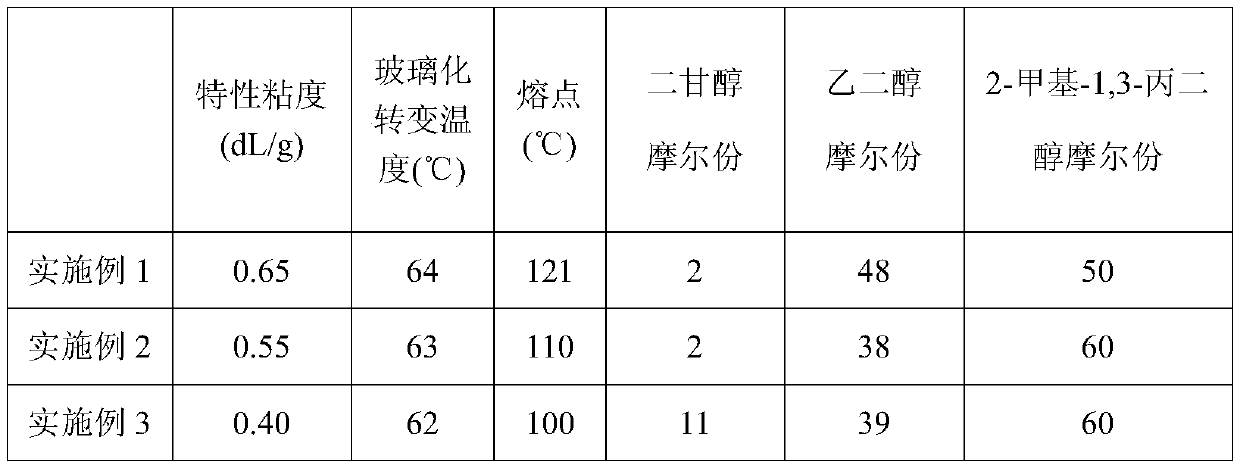

Embodiment 1

[0050] Prepare low melting point polyester according to the preparation method provided by the invention, the steps are as follows:

[0051] (1) Terephthalic acid, 2-methyl-1,3-propanediol, ethylene glycol and xylyldibutylbenzofuranone are prepared into a slurry, and the acid-alcohol molar ratio in the slurry is 1:1.12, Based on 100 mole parts of terephthalic acid, 2-methyl-1,3-propanediol is 50 mole parts and ethylene glycol is 62 mole parts, of which 12 mole parts of ethylene glycol are excess aliphatic diols It will be removed in the subsequent reaction process; relative to the total weight of the low-melting polyester, the amount of xylyl dibutylbenzofuranone added is 300ppm;

[0052] (2) The slurry prepared in step (1) is continuously added to the esterification system composed of the first vertical esterification kettle and the second vertical esterification kettle for esterification reaction. The reaction temperature of the first esterification kettle is 260°C, reactio...

Embodiment 2

[0057] Prepare low melting point polyester according to the preparation method provided by the invention, the steps are as follows:

[0058] (1) Prepare terephthalic acid, 2-methyl-1,3-propanediol, ethylene glycol and methylene bis(4-methyl-6-tert-butylphenol) monoacrylate into slurry, in the slurry The acid-alcohol molar ratio is 1:1.12, based on 100 mole parts of terephthalic acid, 2-methyl-1,3-propanediol is 60 mole parts, ethylene glycol is 52 mole parts, and 12 mole parts of ethylene Diol is excess aliphatic dihydric alcohol and will be removed in the subsequent reaction process, relative to the total weight of low melting point polyester, the addition of methylene bis (4-methyl-6-tert-butylphenol) monoacrylate 500ppm;

[0059] (2) The slurry prepared in step (1) is continuously added to the esterification system composed of the first vertical esterification kettle and the second vertical esterification kettle for esterification reaction. The reaction temperature of the ...

Embodiment 3

[0064] Prepare low melting point polyester according to the preparation method provided by the invention, the steps are as follows:

[0065] (1) Terephthalic acid, 2-methyl-1,3-propanediol, diethylene glycol, ethylene glycol and [4-tert-butyl-2-(5-tert-butyl-2-oxo-3H- 1-benzofuran-3-yl)phenyl]-3,5-di-tert-butyl-4-hydroxybenzoate is formulated into a slurry, the acid-alcohol molar ratio in the slurry is 1:1.1, and aromatic The dibasic acid is based on 100 mole parts, so 2-methyl-1,3-propanediol is 60 mole parts, diethylene glycol is 10 mole parts, and ethylene glycol is 40 mole parts. Among them, the aromatic dibasic acid contains p- 90 molar parts of phthalic acid, 10 molar parts of isophthalic acid, and the ethylene glycol of 10 molar parts is that excess aliphatic dihydric alcohol will be removed in subsequent reaction process, with respect to the total weight of low-melting point polyester, [4 -tert-butyl-2-(5-tert-butyl-2-oxo-3H-1-benzofuran-3-yl)phenyl]-3,5-di-tert-butyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com