Cantilever wheel belt polishing device with controlled pressure and polishing method

A polishing device and cantilever technology, which is applied in the direction of grinding/polishing equipment, abrasive belt grinders, optical surface grinders, etc., can solve the problems of inability to effectively polish complex surface optical elements, inability to efficiently polish workpieces, singleness, etc., and achieve improved polishing surface Shape accuracy, improve polishing accuracy, and avoid slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

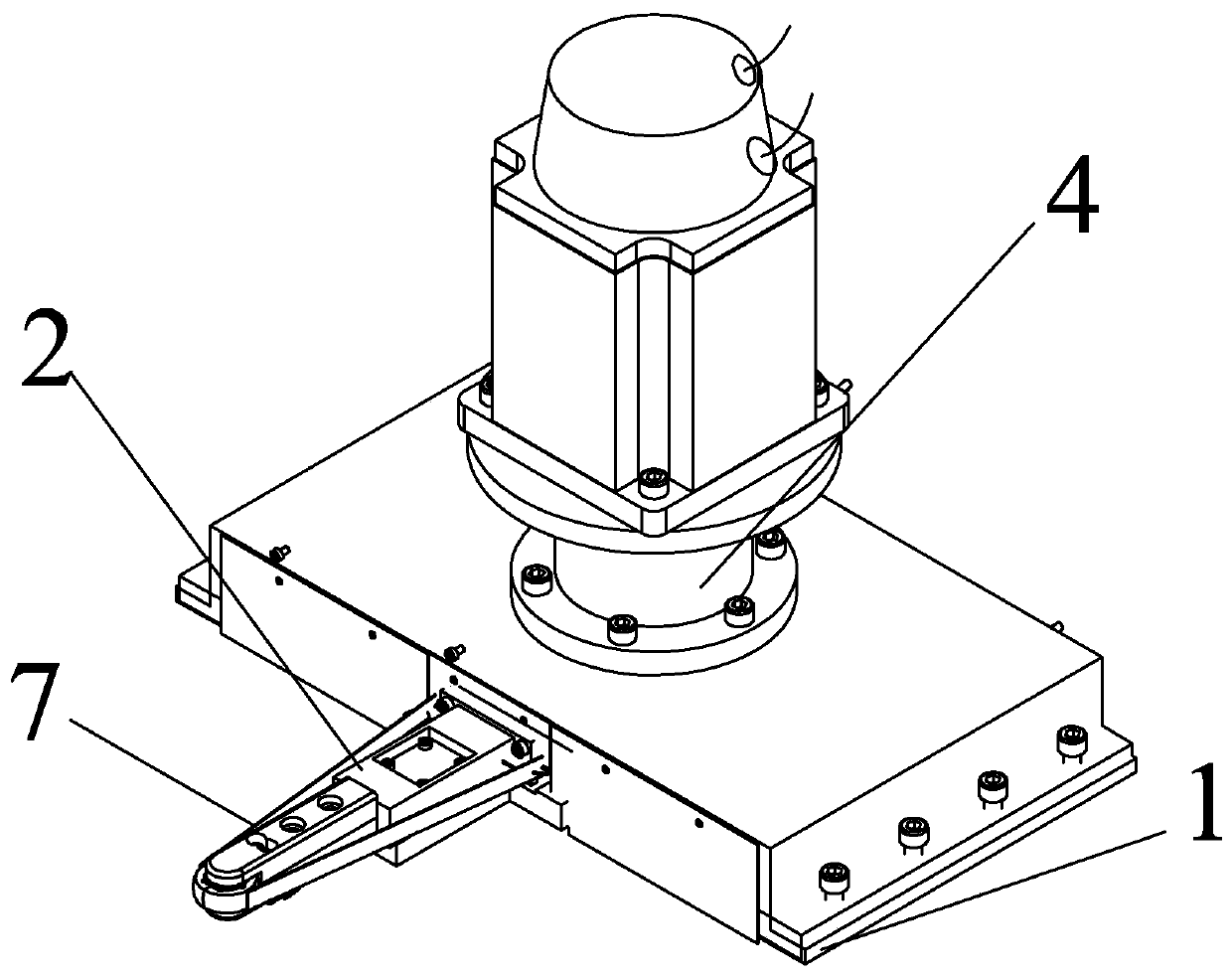

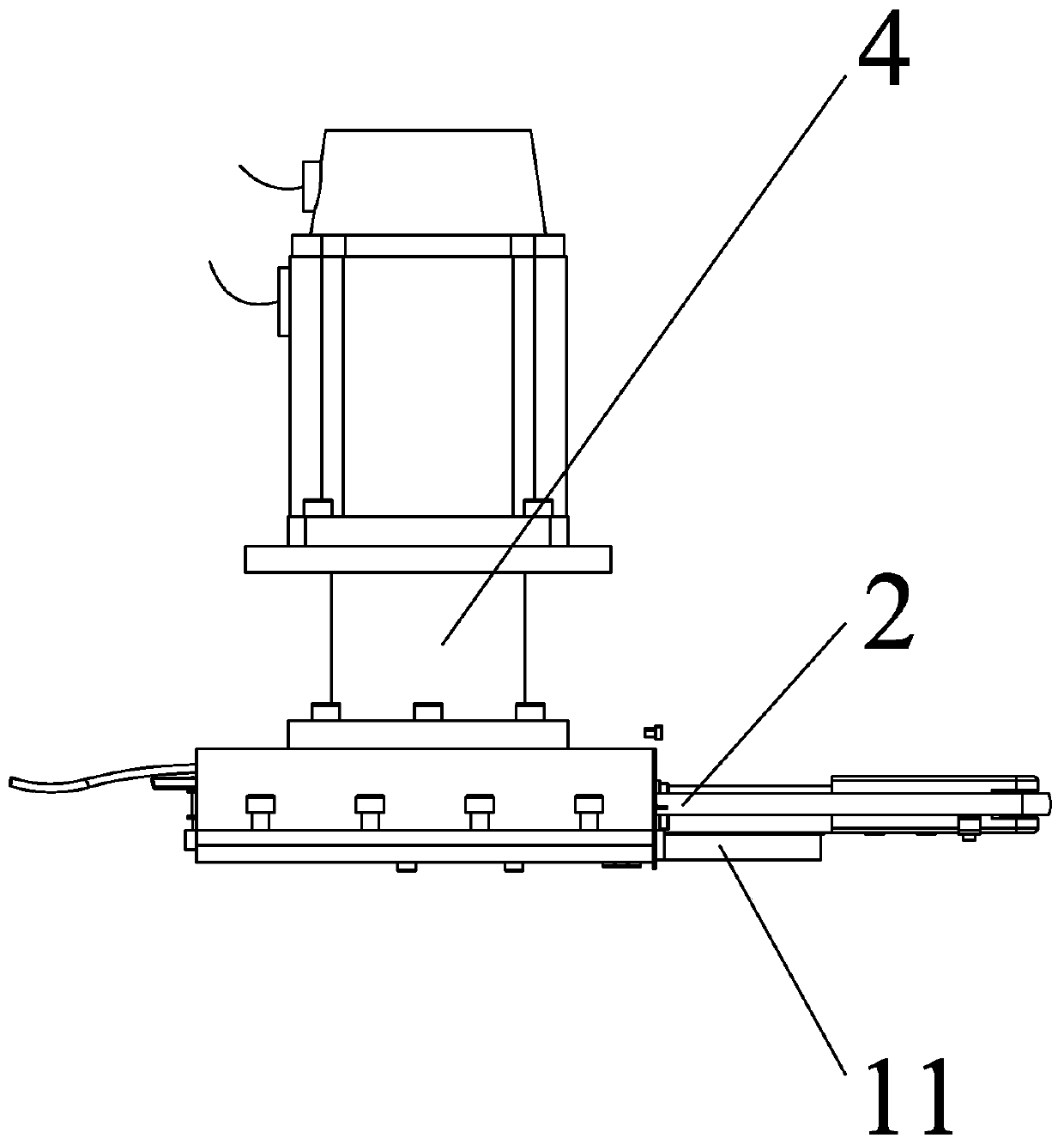

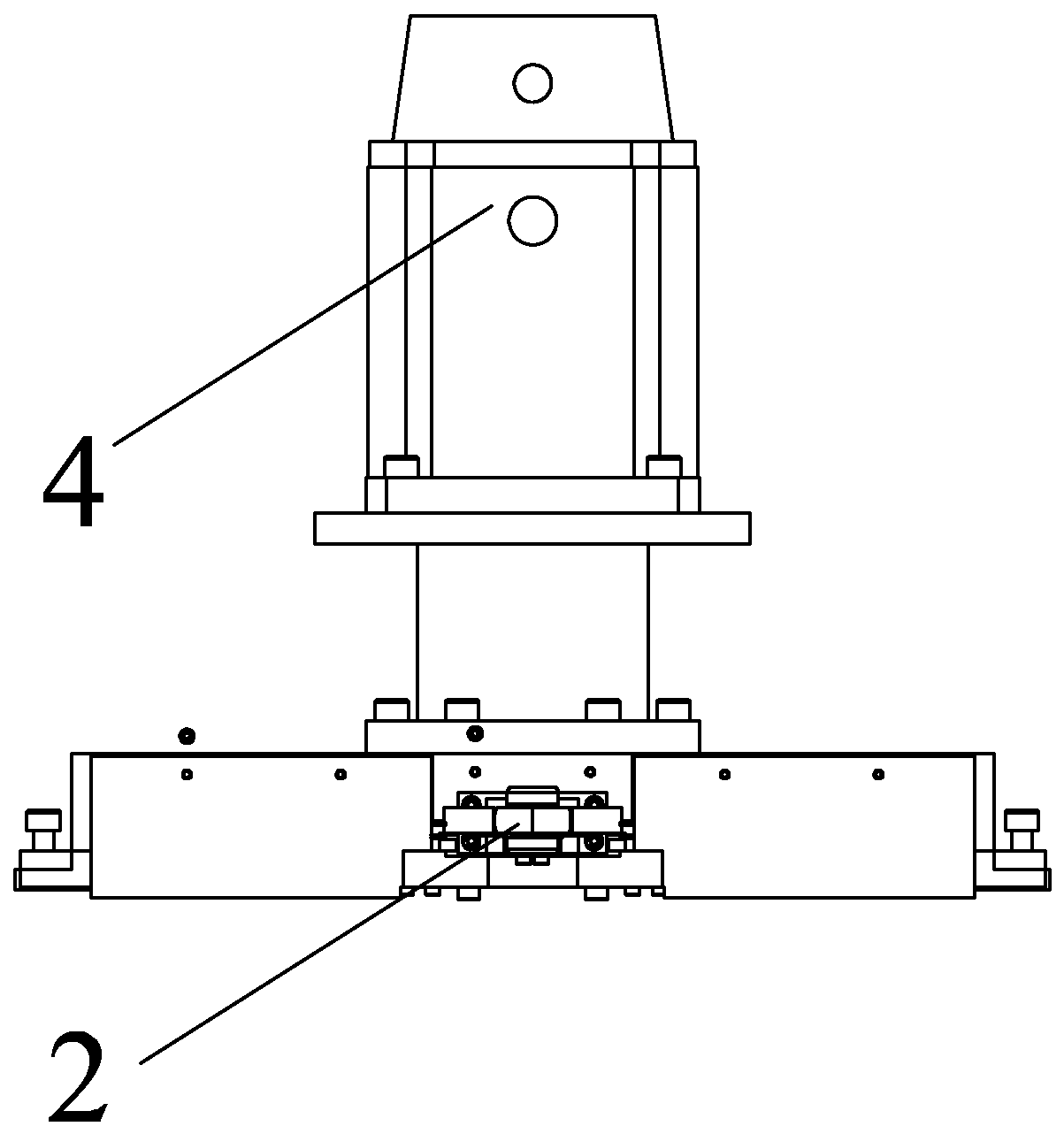

[0044] Specific implementation mode one: combine Figure 1 to Figure 3 and Figure 19 to Figure 23 Describe this embodiment, a cantilever belt polishing device with controllable pressure in this embodiment, which includes a bottom plate 1, a contact wheel cantilever wheel rod assembly 2, a motor drive assembly 4, a polishing belt trimming assembly 5, a polishing belt 7, two a cylinder tensioning assembly 3 and N waterproof guide idlers 6, where N is a positive integer;

[0045] The contact wheel cantilever wheel rod assembly 2 is installed on the upper surface of the bottom plate 1 through the cylinder body of the three-rod cylinder 25 and the guide rail base of the high-precision linear guide rail assembly 24, and the two cylinder tensioning assemblies 3 are relatively arranged on the contact wheel cantilever wheel rod The two sides of the component 2, and the tail ends of the two cylinder tensioning components 3 are set opposite to the tail ends of the trolley cantilever whee...

specific Embodiment approach 2

[0047] Specific implementation mode two: combination Figure 21 This embodiment is described. This embodiment is to further limit the base plate 1 described in the first embodiment. In this embodiment, the base plate 1 is a cuboid, and a connecting plate 11 is provided on one side of the base plate 1 . Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0048] Specific implementation mode three: combination Figure 4 to Figure 7 Describe this embodiment. This embodiment is to further limit the contact wheel cantilever wheel rod assembly 2 described in the first specific embodiment. In this embodiment, 3. The contact wheel cantilever wheel rod assembly 2 includes an integrated contact wheel 21 , high-precision linear guide rail assembly 24, three-rod cylinder 25, main support rod 26, acoustic emission sensor 27, two sealed race bearings 22 and two cantilever contact rods 23;

[0049] The high-precision linear guide rail assembly 24 includes a slider A and a high-precision linear guide rail, and the slider A is slidingly connected to the high-precision linear guide rail;

[0050] One end of the main support rod 26 is fixedly connected with the piston rod of the three-rod cylinder 25, the other end of the main support rod 26 is provided with a connecting arm, the upper surface of the main support rod 26 is provided with a groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com