Virtual power plant load optimization scheduling device based on virtual unit subgroup

A technology for virtual power plants and virtual units, which is applied in program control devices, electrical digital data processing, software simulation/interpretation/simulation, etc. Heat adjustment and other issues to achieve the effect of improving ventilation and heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

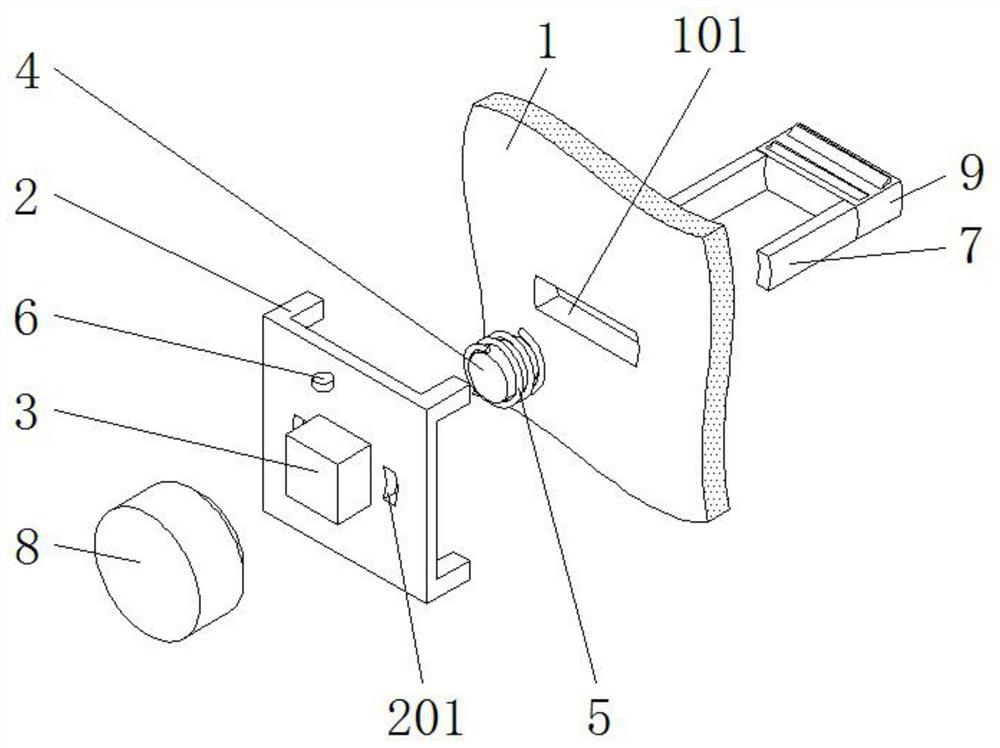

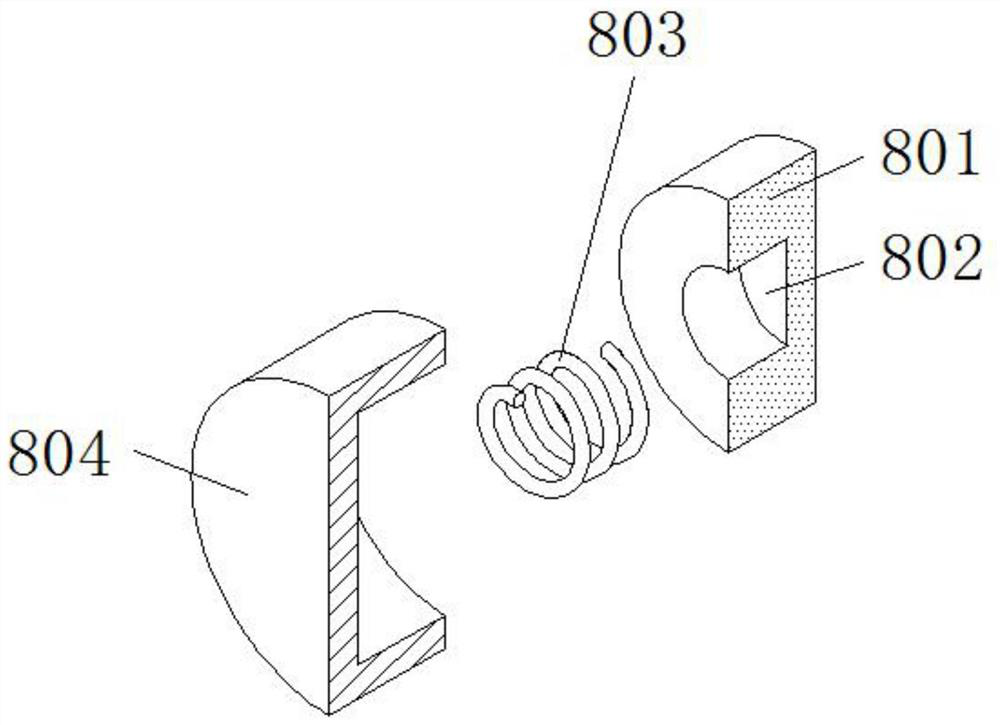

[0036] see Figure 1-4, a load optimization dispatching device for a virtual power plant based on a virtual unit subgroup, comprising a box body 1, a circuit board 2 and an electrical module 3, the electrical module 3 is fixedly installed on the front of the circuit board 2, and the top surface of the electrical module 3 is fixedly installed with The temperature sensor 6 is used to monitor the temperature of the electrical module 3. The front of the circuit board 2 and one side of the electrical module 3 are provided with a through hole 3 201 for installing the sliding assembly. The number of the through hole 3 201 is two , two through holes 201 are symmetrically distributed in the left and right directions on the front of the circuit board 2, the through holes 201 run through the front and rear sides of the circuit board 2, and the front of the box body 1 is provided with a through groove 101, and the through hole 201 and the through hole The inside of the groove 101 is movab...

Embodiment 2

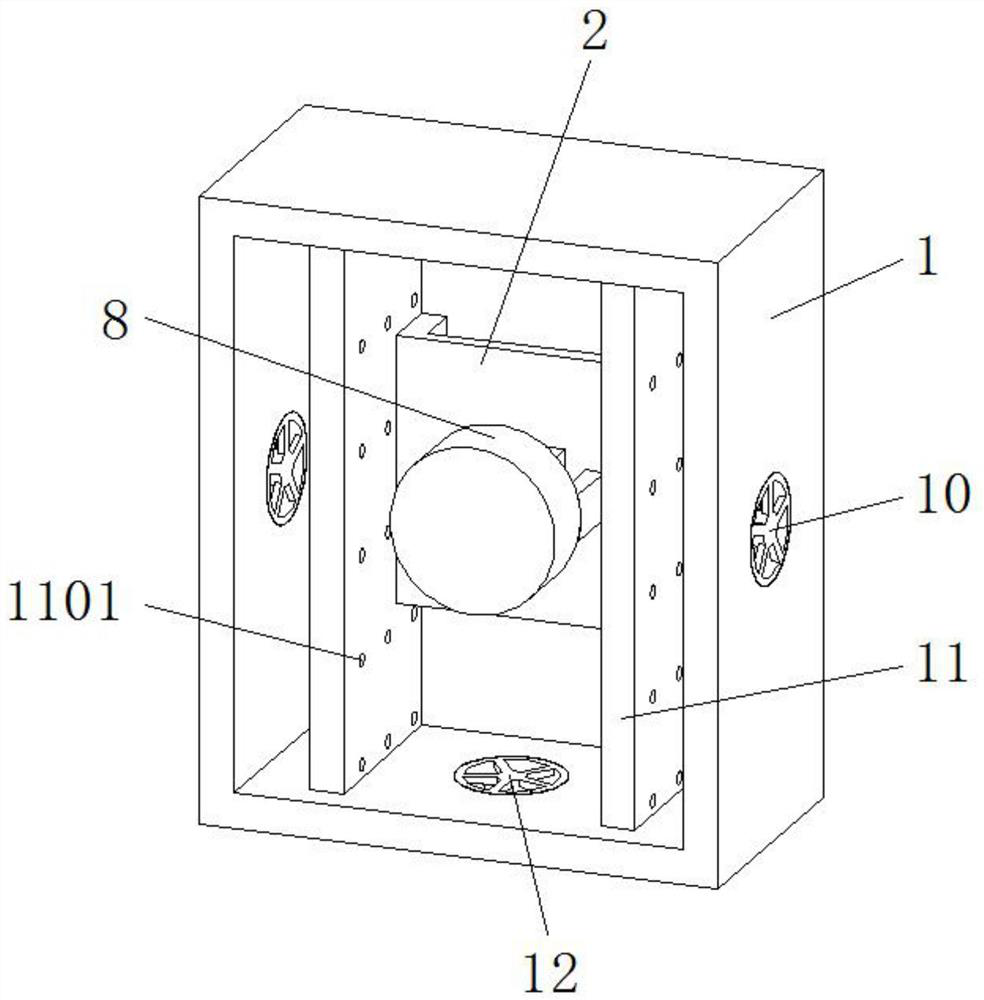

[0038] Based on Example 1, such as Figure 5 , the side of the box body 1 is provided with a through hole 102, the through hole 102 runs through the outer surface and the inner wall of the box body 1, the number of the through hole 102 is two, and the two through holes 102 are respectively located on the left and right sides of the box body 1 On the side, the inside of the through hole 102 is fixedly sleeved with a blower fan 10, the blowing direction of the blower fan 10 is towards the inside of the box body 1, the blower fan 10 is electrically connected to an external power supply, and the inside of the box body 1 is fixedly equipped with a partition plate 11, The number of partitions 11 is two, and the two partitions 11 are symmetrically distributed in the inside of the box body 1 and on both sides of the circuit board 2. The side of the partition 11 is provided with a through hole 1101, and the through hole 1101 runs through the partition. On the left and right sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com