An electronically controlled magnetic field flexible capsule liquid-filled polishing device

A polishing device and flexible capsule technology, applied in grinding/polishing equipment, optical surface grinders, grinders, etc., can solve the problems of complex polishing tool structure, inability to precisely control the flexibility of the contact area, frequent replacement of tool heads, etc., and achieve controllable Good performance, delaying the weakening of the magnetic field, and ensuring a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

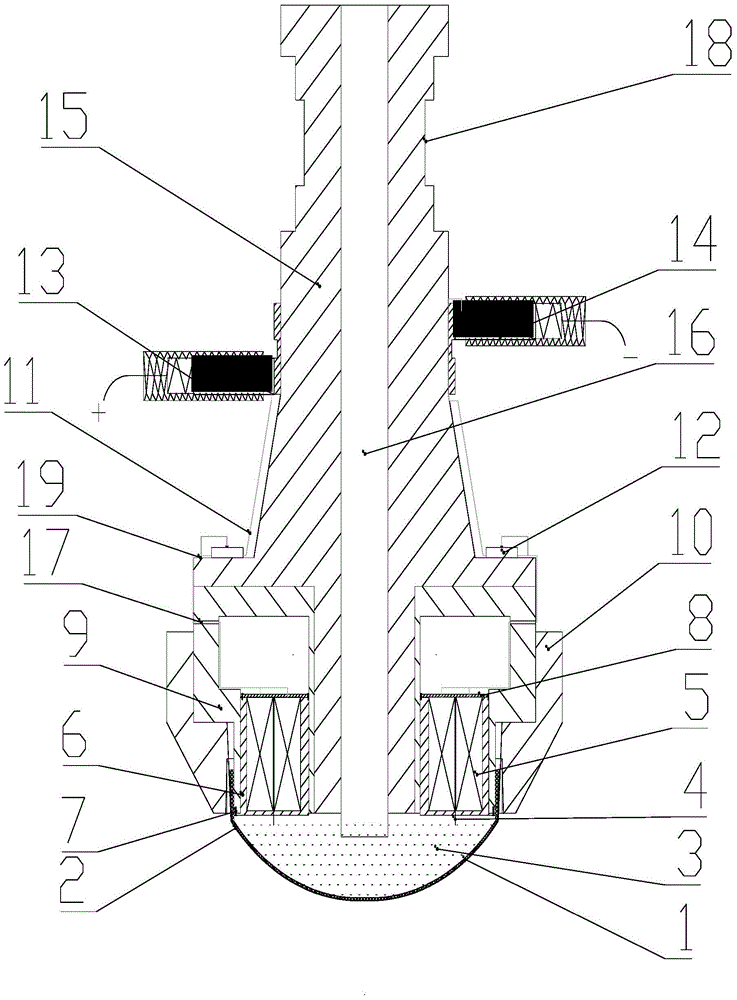

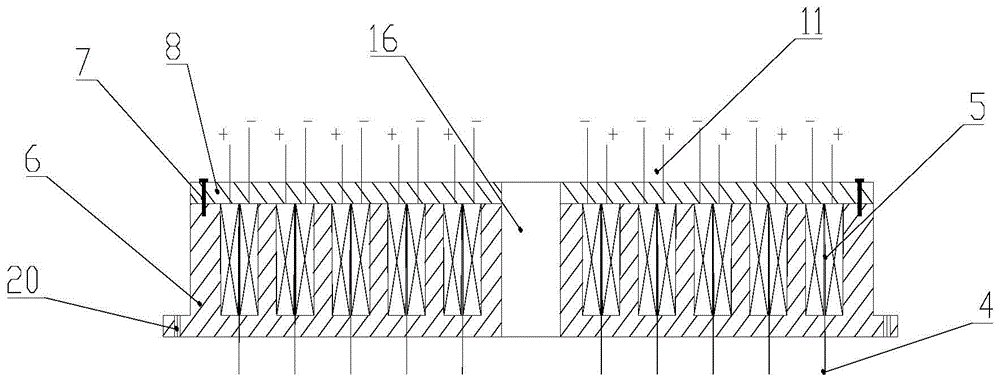

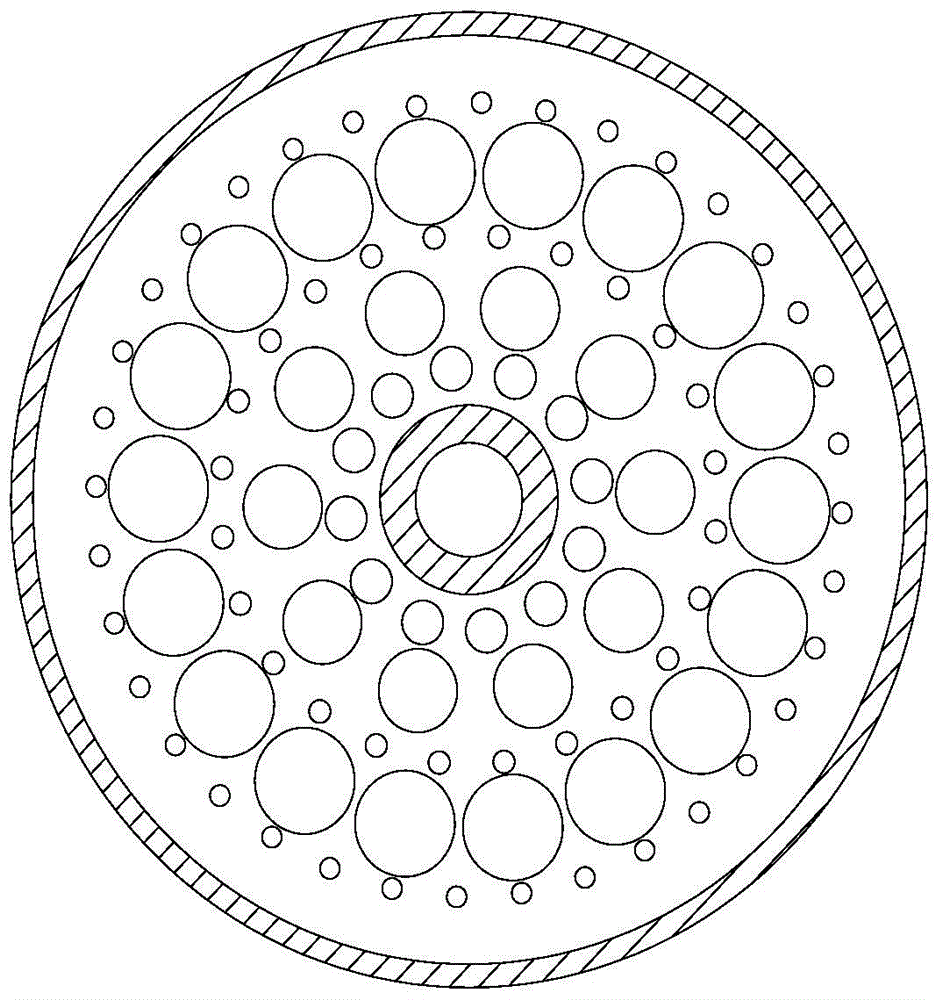

[0025] Such as figure 1 , is a structural schematic diagram of the electronically controlled magnetic field flexible capsule liquid-filled polishing device of the present invention, including 1-flexible capsule, 2-polishing cloth, 3-rheological fluid, 4-probe, 5-electromagnet, 6-probe Needle base, 7-screw, 8-fixed cover, 9-base, 10-fastening sleeve, 11-wire, 12-varistor, 13-anode brush, 14-cathode brush, 15-rotation shaft , 16-guiding channel, 17-wire hole, 18-card slot; the probe 4 and the electromagnet 5 are placed in the fixed slot of the probe base 6 according to the pre-designed scheme, and the probe 4 passes through the probe The hole reserved by the base 6 extends into the capsule, and the wire 11 is drawn out through the wire hole 17; the electromagnet 5 is further fixed on the probe base 6 with the fixed cover 8, and the fixed cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com