Reutilizing device for ship low-grade heat source

A low-grade heat source and ship technology, applied in heat exchangers, heat exchanger types, indirect heat exchangers, etc., can solve the problems of low energy, low grade, low concentration, etc., achieve large contact area, reduce energy consumption, The effect of convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

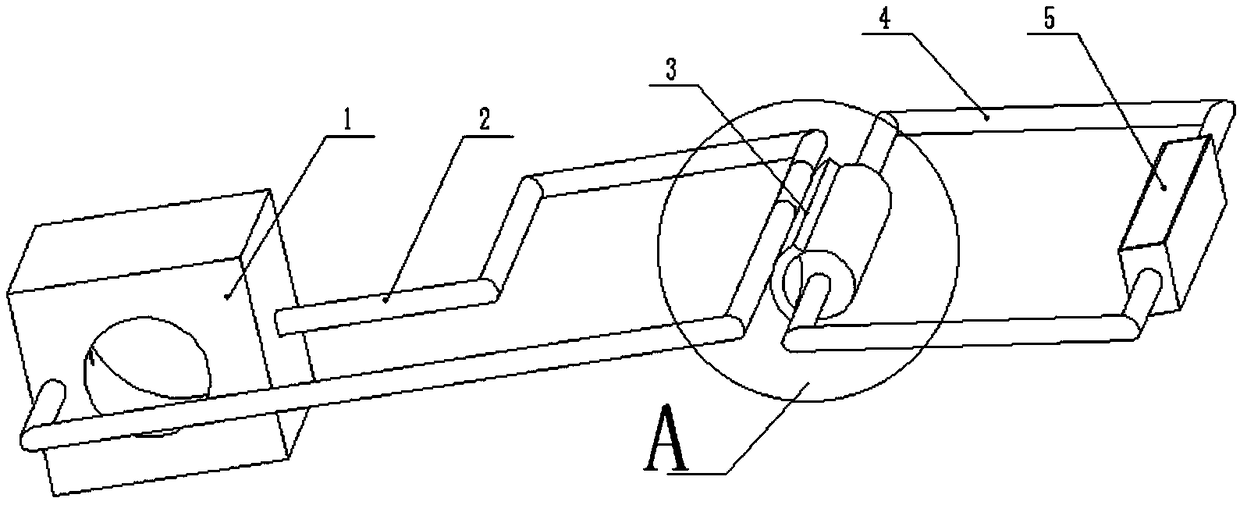

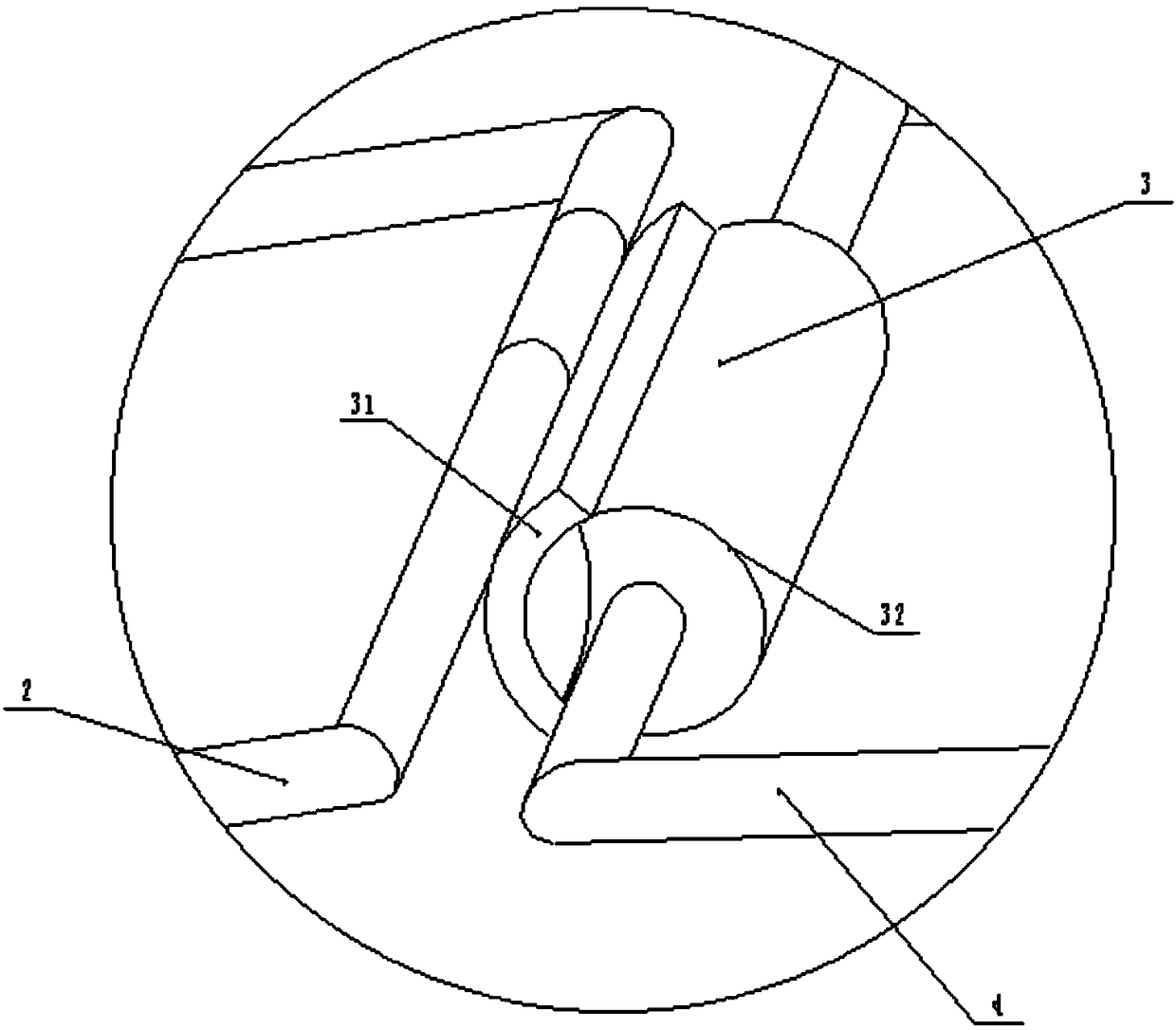

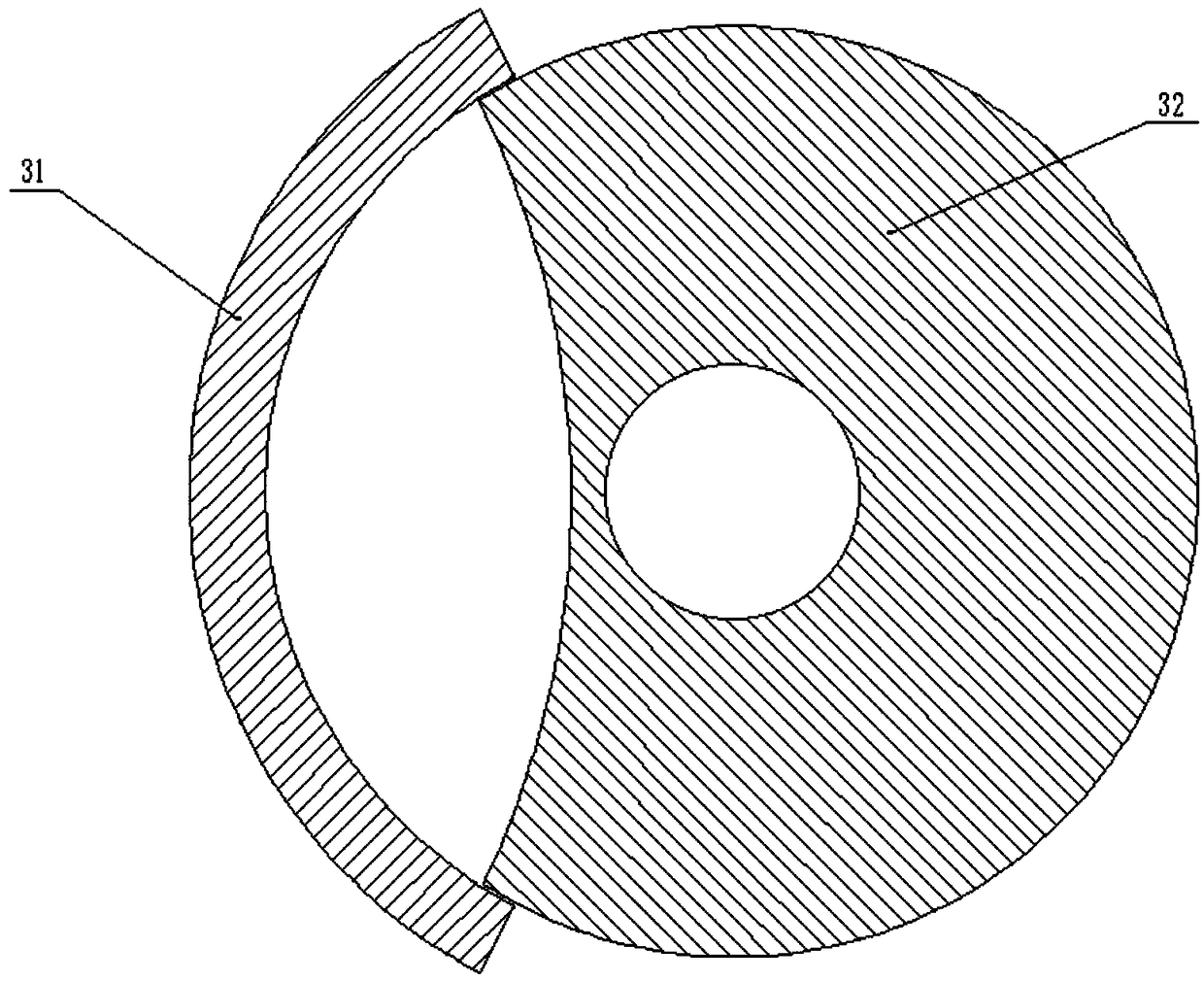

[0017] Such as figure 1 , figure 2 As shown, the recycling device of a low-grade heat source of a ship described in the embodiment of the present invention includes a heat exchanger 3 and a hot oil pipeline 2 connected to the heat exchanger 3, and a thermal insulation pipeline 4. The heat exchanger 3 includes A left half body 31 and a right half body 32 that can rotate relative to the left half body 31. The shape of the left half body 31 is a curved panel, and the right half body 32 is a cylinder. The cylinder is partially cut along the length to form a crescent. shaped depression, the center of the curved plate coincides with the center of the cylinder, the hot oil pipeline 2 is fixed on the side wall of the left half body 31, and the heat preservation pipeline 4 is fixed on the middle part of the right half body 32 and the right half body 32 rotates at the same time , the hot oil pipeline 2 communicates with the external low-grade heat source 1, the heat preservation pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com