A method for continuously extracting high-purity lactic acid from lactic acid fermentation broth

A lactic acid fermentation, high-purity technology, applied in fermentation, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of non-continuous production, large loss of lactic acid, cumbersome process, etc., to facilitate industrial scale-up and reduce Fermentation costs and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

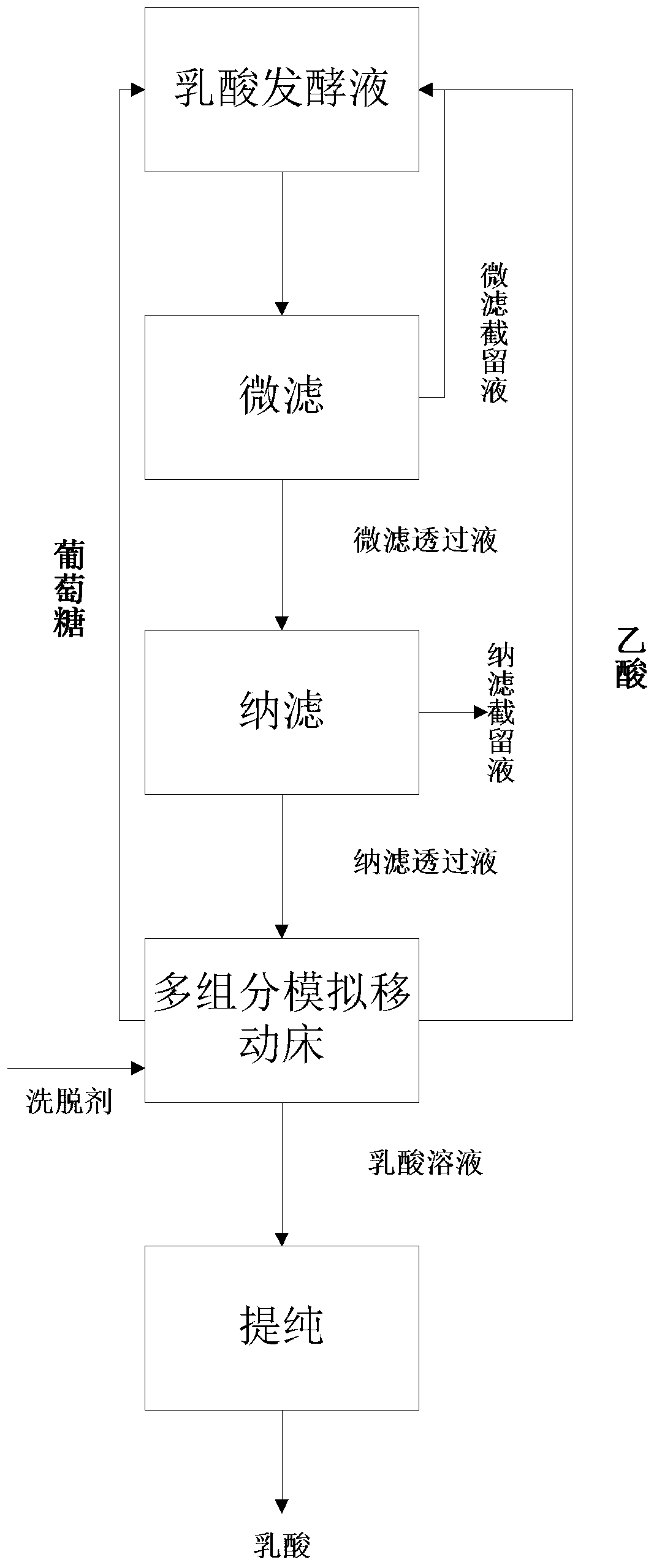

[0046] like figure 1 As shown, a method for continuously extracting high-purity lactic acid from lactic acid fermentation broth comprises the following steps:

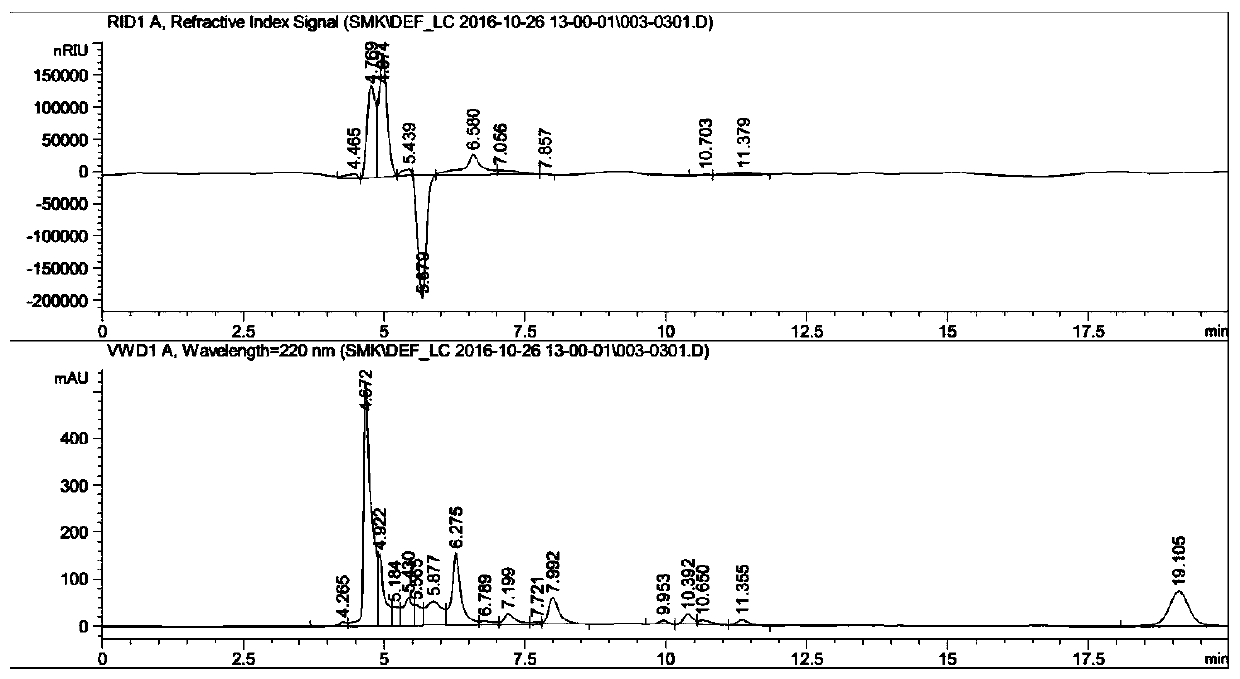

[0047] (1) Preparation of fermentation medium, specifically glucose 130g / L, yeast powder 15g / L, peptone 0.5g / L, magnesium sulfate 0.5g / L, sodium acetate 5g / L, prepared with deionized water; then Bacillus coagulans is the production strain, the inoculation amount is 10%; it is placed in a fermenter for anaerobic fermentation, the fermentation conditions are: temperature 50°C, ammonia water is used to adjust the pH of the fermentation broth to maintain at 6.5, the stirring speed is 150rpm, and lactic acid is obtained after 48 hours of fermentation fermentation broth. The liquid phase analysis diagram of each component of the obtained lactic acid fermentation broth is shown in the appendix figure 2 , containing many impurities in the lactic acid fermentation broth, the main components are glucose (retention time 4.7min...

Embodiment 2

[0054] A method for continuously extracting high-purity lactic acid from lactic acid fermentation broth, comprising the following steps:

[0055] (1) Preparation of fermentation medium, specifically glucose 110g / L, yeast powder 15g / L, peptone 0.5g / L, magnesium sulfate 0.5g / L, sodium acetate 5g / L, prepared with deionized water; then Bacillus coagulans is the production strain, the inoculation amount is 10%; it is placed in a fermenter for anaerobic fermentation, and the fermentation conditions are: temperature 60°C, ammonia water is used to adjust the pH of the fermentation broth to maintain at 6.5, the stirring speed is 200rpm, and lactic acid is obtained after 48 hours of fermentation fermentation broth;

[0056] (2) The 19-hole ceramic microfiltration membrane with a pore size of 0.2um is used for the preliminary separation step (1) Gained lactic acid fermentation liquid, the operating pressure is 0.3MPa, the volume of the permeated liquid of the microfiltration is 80% of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mobile phase | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com