Patents

Literature

76results about How to "Small amount of inoculum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

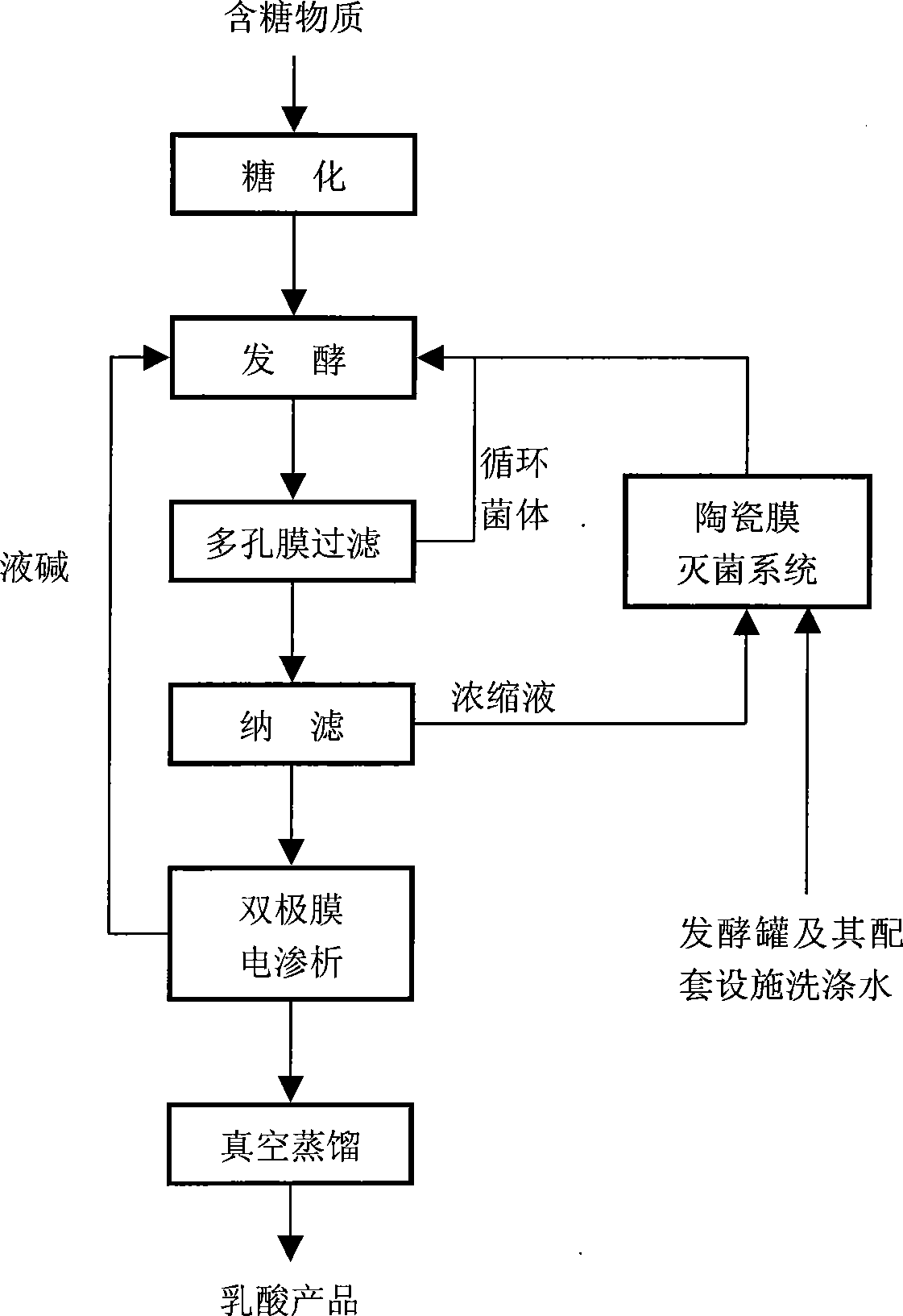

Clean production process of lactic acid

ActiveCN101392273AGreat advantageProduction to preventSemi-permeable membranesMicroorganism based processesPollutionElectrodialysis

Owner:NANJING TECH UNIV

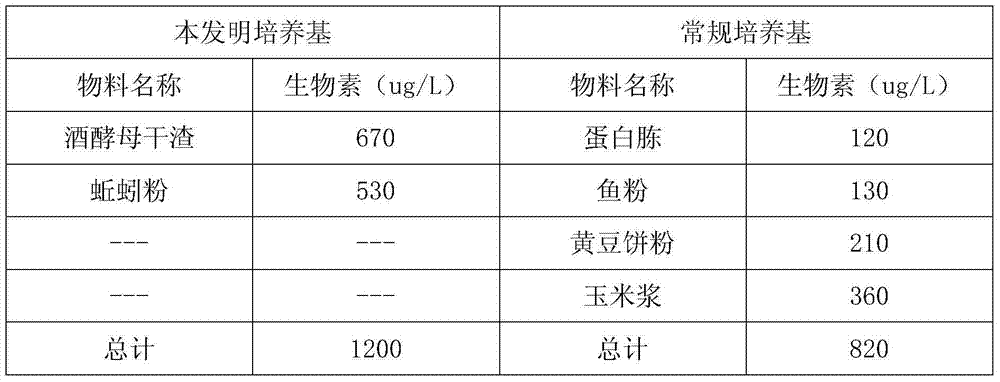

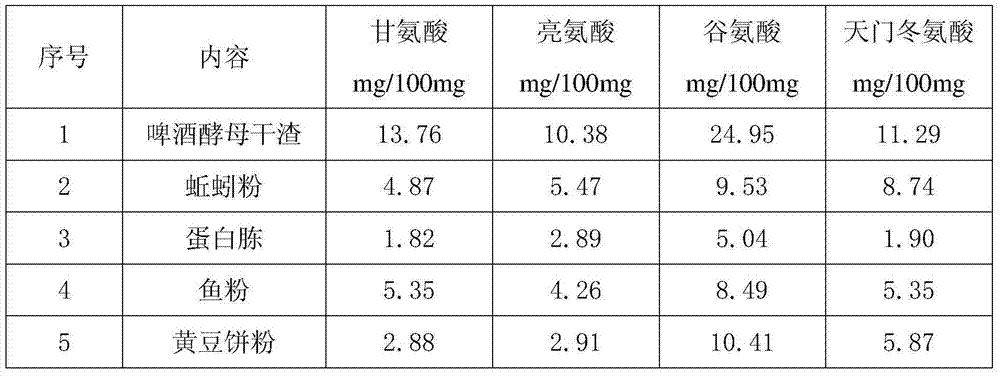

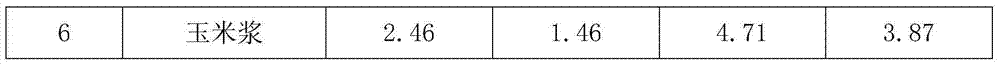

Culture medium for fermentation production of spectinomycin through streptomyces spectabilis and fermentation method

ActiveCN103484509AReduce dosageReduce typesMicroorganism based processesFermentationBiotechnologySpectinomycin

The invention relates to a culture medium for fermentation production of spectinomycin through streptomyces spectabilis and a fermentation method. A primary seed culture medium, a secondary seed culture medium and a fermentation culture medium all contain corn oil, maltose, beer yeast dry residues and earthworm meal. According to the invention, maltose replaces glucose, beer yeast dry residues and earthworm meal replace fish meal, peptone, soybean cake meal and corn steep liquor, and the culture medium formula is optimized, so that the problem of high costs of raw materials is solved, the environmental effect on the source of the raw materials is reduced to the utmost extent, sufficient supply of the raw materials is guaranteed, and stable and efficient production of spectinomycin is realized. Meanwhile, the culture medium can improve the fermentation unit and shorten the fermentation period.

Owner:宁夏泰瑞制药股份有限公司

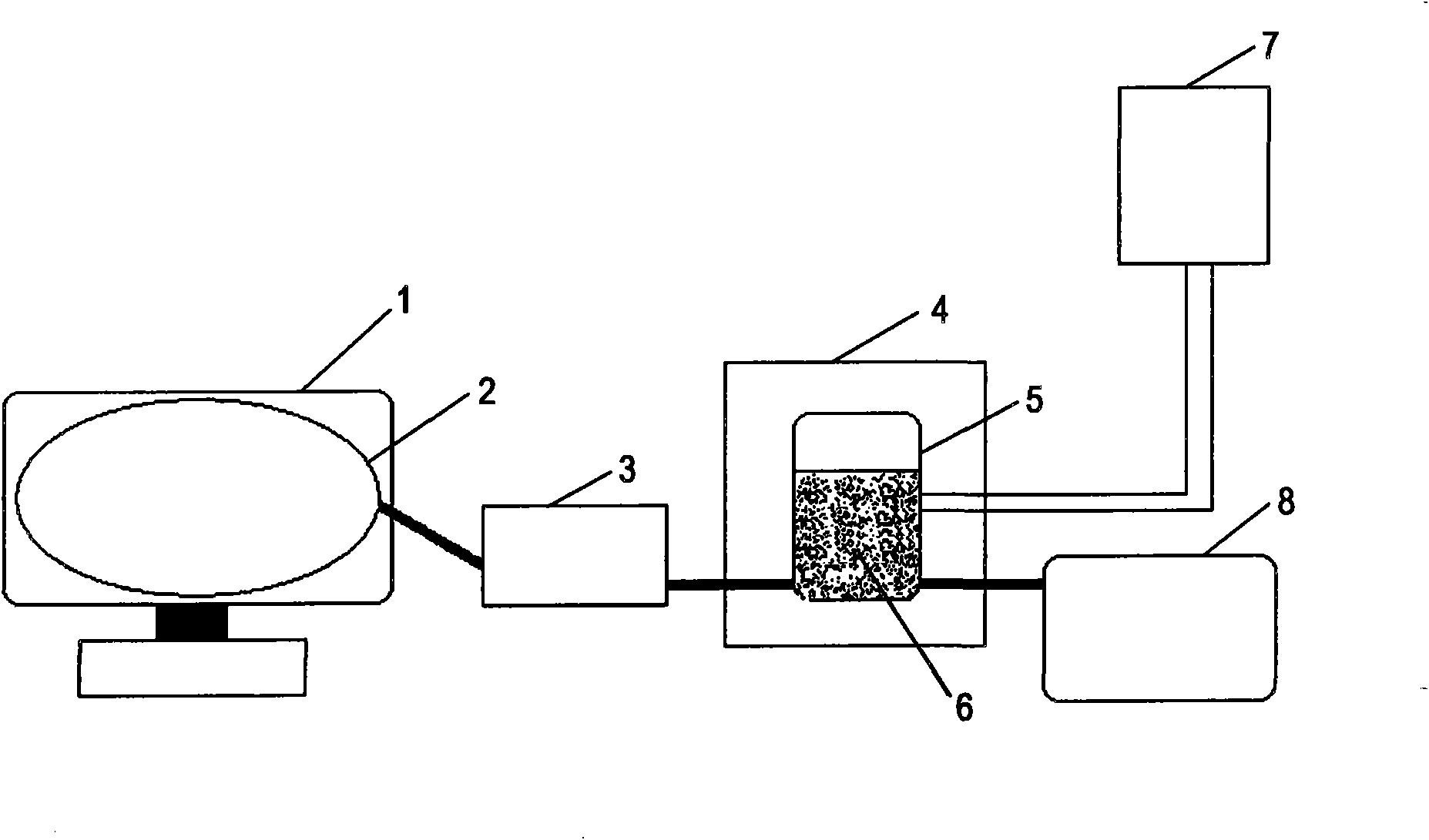

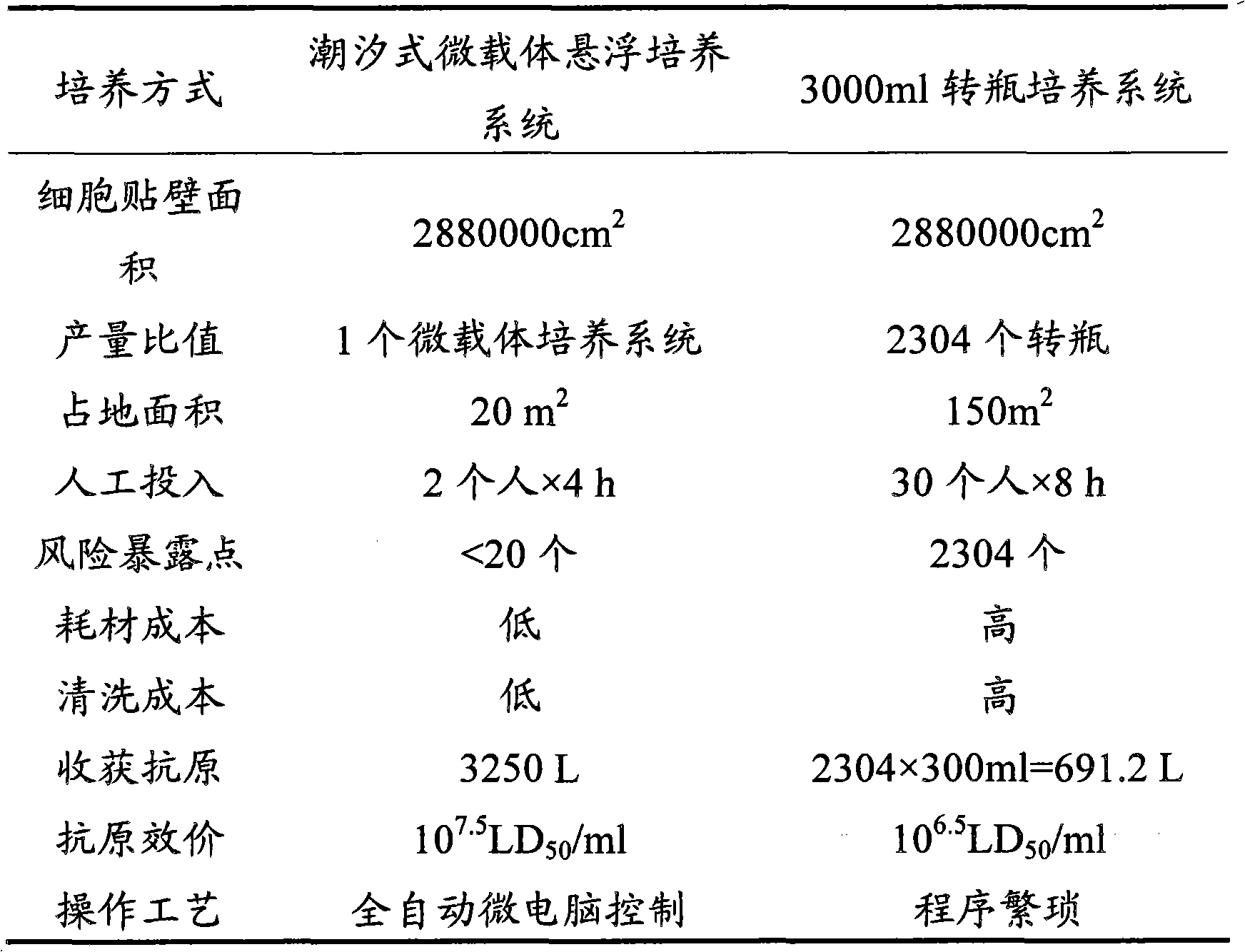

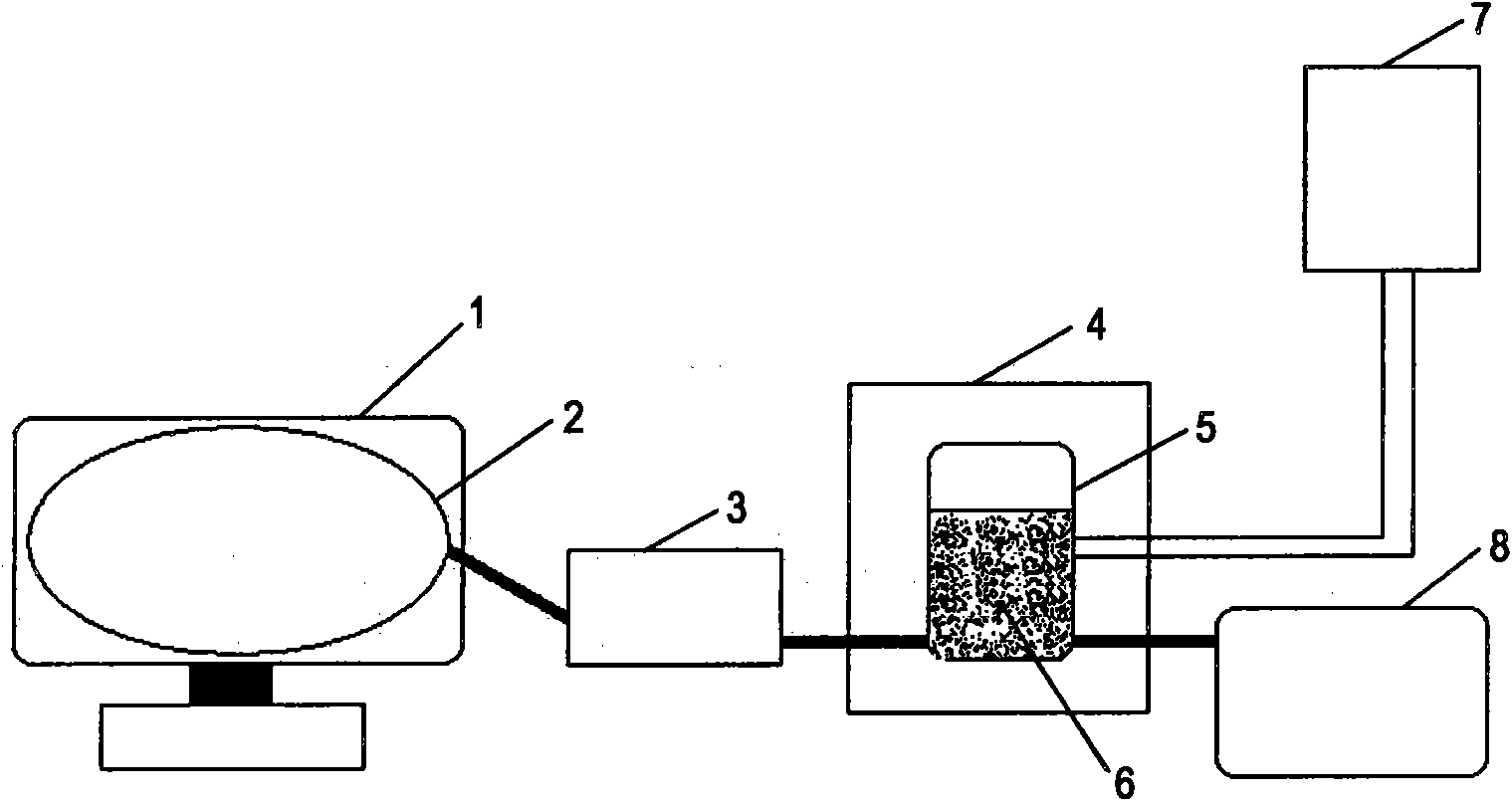

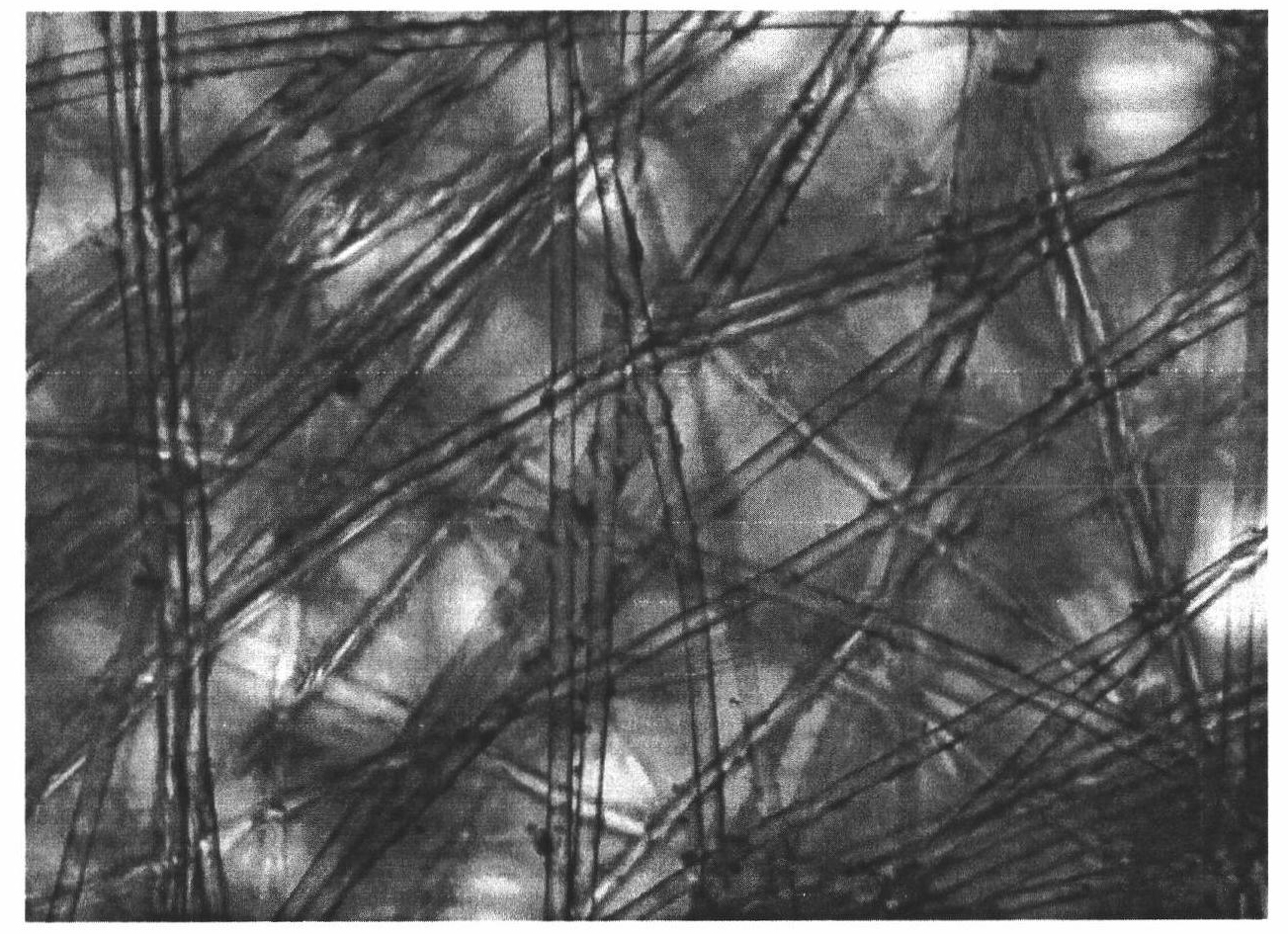

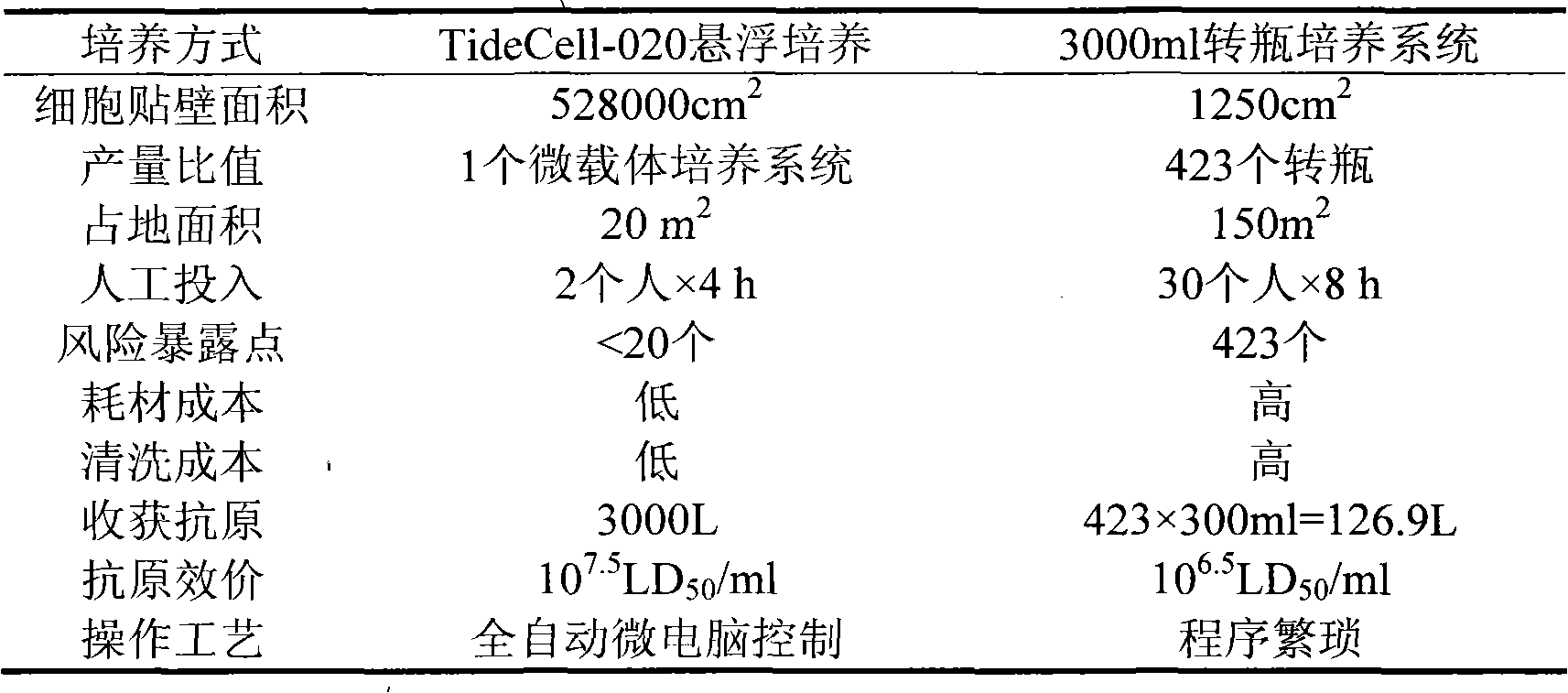

Vaccine produced by suspended microcarrier cell culture system and method for producing vaccine

ActiveCN101869702AReduce usageReduce exposureViral antigen ingredientsMicroorganism based processesAdjuvantFreeze-drying

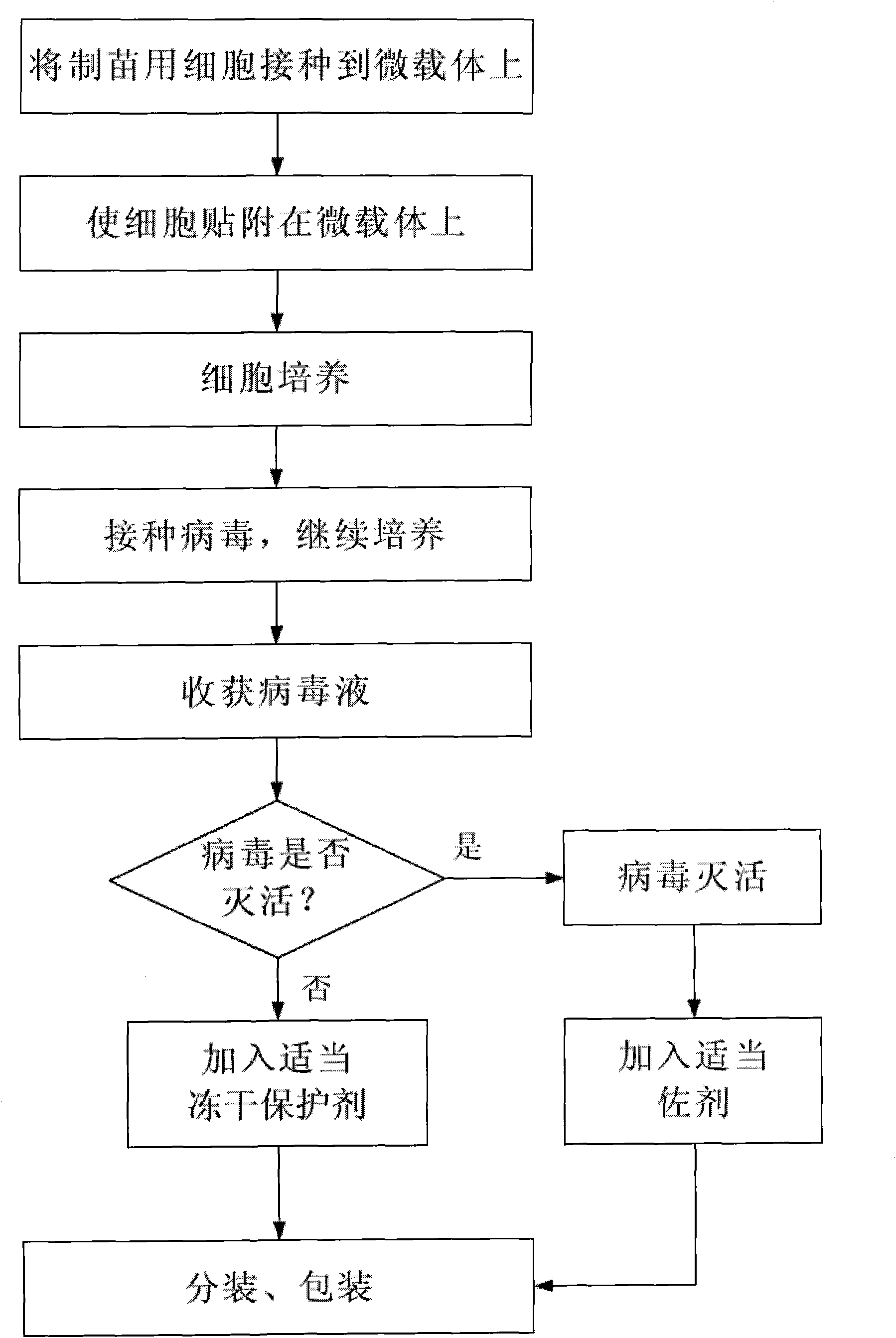

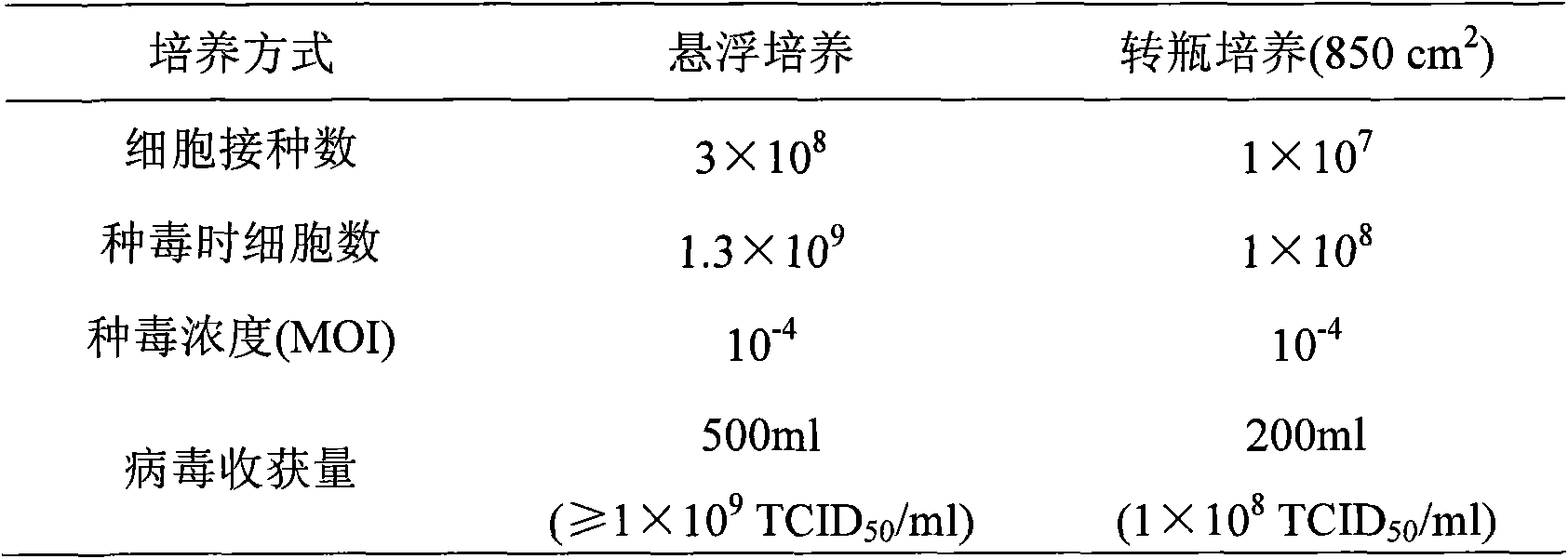

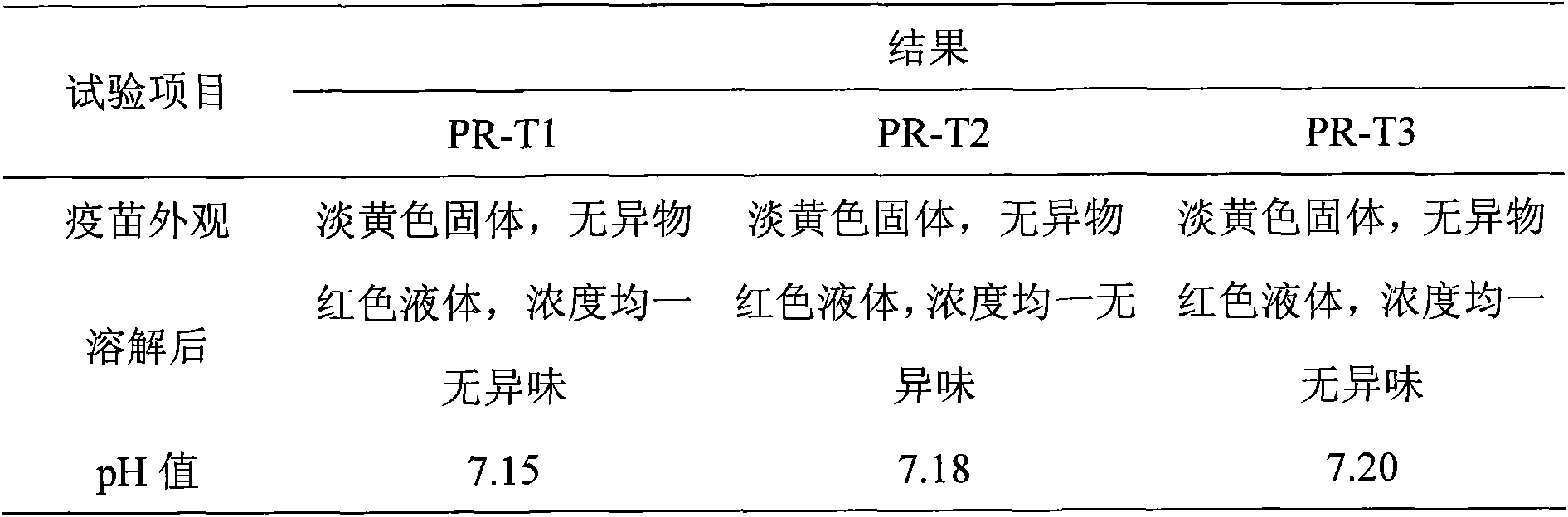

The invention discloses a vaccine produced by a suspended microcarrier cell culture system and a method for producing the vaccine. The method comprises the following technical steps of: (1) inoculating cells for preparing the vaccine to a culture tank which contains a culture medium and a microcarrier; (2) uniformly mixing the cells and the microcarrier to make the cells attached to the microcarrier; (3) providing sufficient nutrient and gas for the cells at an appropriate temperature to make the cells continue growing on the microcarrier; (4) preparing virus suspension from viruses for preparing the vaccine, inoculating the virus suspension to the cells and continuing culturing, and harvesting virus liquid or the cells containing the viruses and replacing culture solution at intervals of1 to 3 days; and (5) after purifying the harvested virus liquid, inactivating the virus liquid as required, adding a proper adjuvant into the inactivated virus liquid, adding a proper freeze-drying protective agent into activated virus liquid, and quantitatively packaging after fully and uniformly mixing to obtain the vaccine. The method has the advantages of simple production process and capability of obviously improving the yield and quality of the vaccine.

Owner:香港维克贸易有限公司

Aerobic salt-resistant granular sludge cultivation method

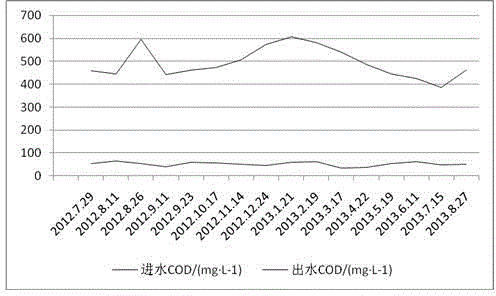

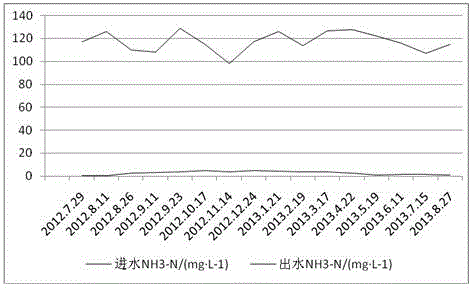

ActiveCN104085981AAccelerated settlementSmall amount of inoculumSustainable biological treatmentBiological water/sewage treatmentNitrogen removalSludge

The invention discloses an aerobic salt-resistant granular sludge cultivation method. The method comprises the steps of mixed wastewater preparation, sludge inoculation, powdery active carbon addition, closed aeration, aeration and salinity increase. Aerobic salt-resistant granular sludge with strong salinity impact resistance, high bioactivity, stable COD degradation and nitrogen removal effects and good sludge settlement can be obtained by domesticating through the aerobic salt-resistant granular sludge cultivation method, so discharged water reaches standards; and the inoculation amount of sludge required by the cultivation method is small, so manpower and material resources can be saved, and resource waste can be avoided.

Owner:NANJING GREEN ISLAND ENVIRONMENTAL ENG

Method for producing liquid strain of cordyceps militaris

InactiveCN101861794AEase of evaluationEasy to controlHorticultureDipotassium phosphateMonopotassium phosphate

The invention provides a method for producing the liquid strain of cordyceps militaris. The method comprises the following steps: (1) inoculating the mother culture of cordyceps militaris to a dedicated strain culture medium to carry out the shaking culture; (2) moving the strain solution cultured in step (1) into a dedicated strain culture medium to carry out the amplification culture, wherein the inoculation amount accounts for 2% to 20% of the volume of the culture medium; (3) filtering the strain solution cultured in step (2) by using a sieve with the bore diameter thereof being 50 to 500 meshes to obtain the filtrate containing more than 107 conidia per ml; and (4) diluting the filtrate obtained in step (3) by using sterile water until the density thereof is 105 to 107 conidia per ml to obtain the liquid strain of cordyceps militaris. The method of the invention is applicable to inoculating and cultivating the fruit body of cordyceps militaris, wherein the dedicated strain culture medium contains carbon source, yeast nitrogen base, magnesium sulfate, monopotassium phosphate, dipotassium phosphate and agar.

Owner:和润通(重庆)供应链管理有限责任公司

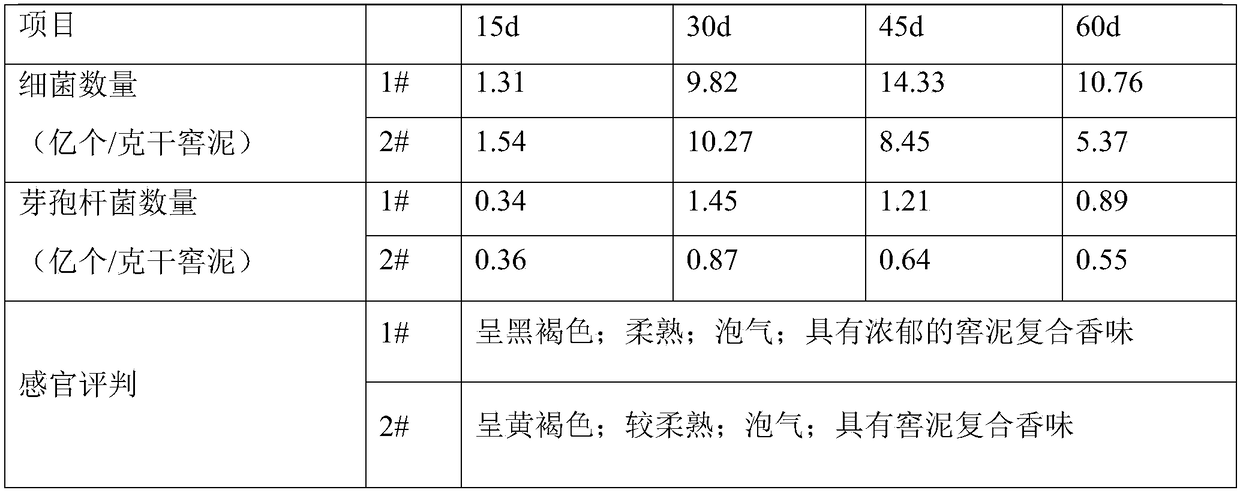

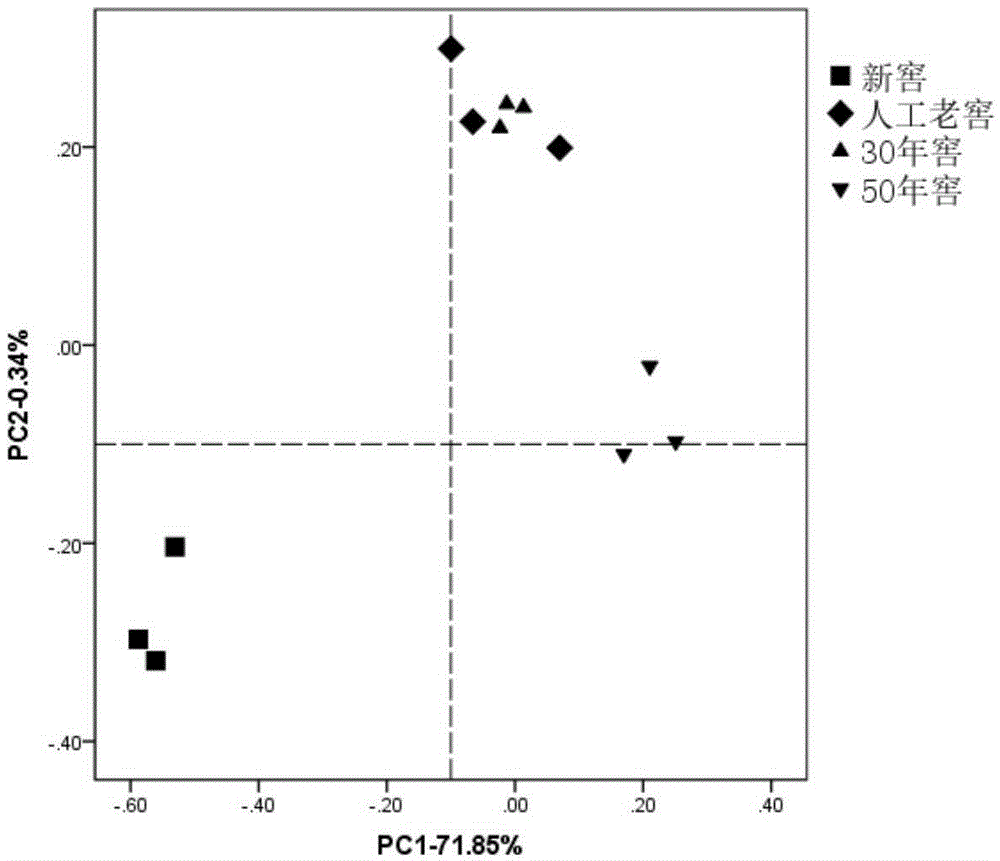

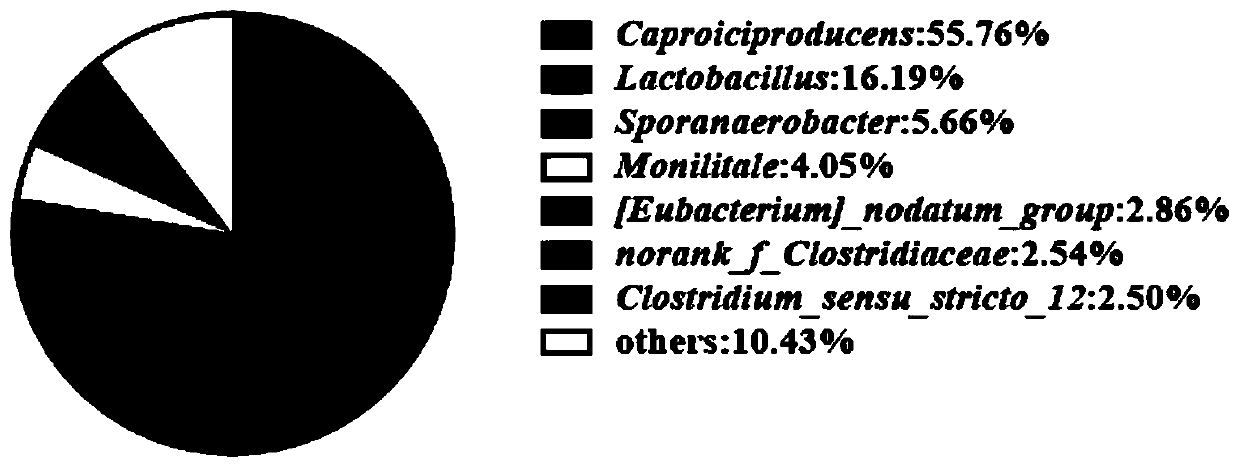

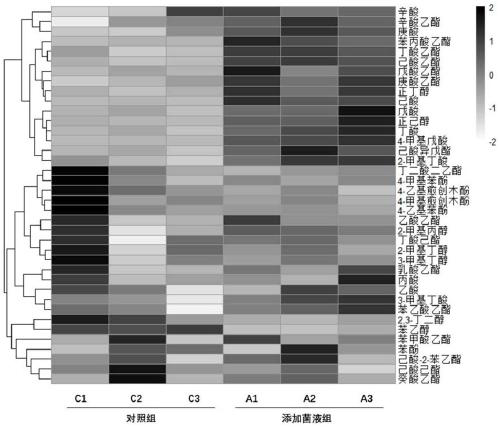

Amplification culture method of composite caproic acid bacteria liquid

InactiveCN108102965ASmall amount of inoculumReduce the number of expansionBacteriaMicroorganism based processesMicrobiologyAcetic acid bacteria

The invention belongs to the technical field of wine brewing, and particularly relates to an amplification culture method of composite caproic acid bacteria liquid. In allusion to the problems that during existing caproic acid bacteria culture, the culture cycle is long, the bacterial colony structure is single, the caproic acid yield is low, the large-scale degree and the mechanization degree arelow, miscellaneous bacteria are easily caused, the quality is unstable and the like, the invention provides the amplification culture method of the composite caproic acid bacteria liquid. The amplification culture method comprises the following steps: a, activating a caproic acid bacteria, and performing proliferation culture; b, performing amplification culture on caproic acid bacteria; c, performing amplification culture on kiln mud enrichment liquid; d, performing mixed fermentation culture; e, performing mixed amplification culture. Through adoption of mixed culture of the pure caproic acid bacteria and the high-quality kiln mud enrichment liquid, the composite caproic acid bacteria liquid with rich bacterial colonies is obtained; the composite caproic acid bacteria liquid is stable in quality, uses the caproic acid bacteria as dominant bacteria, and has a very strong caproic acid producing capability; in addition, the culture amount is increased, the culture steps are reduced, the operating process is simplified, and the culture cycle is shortened, so that the production efficiency is improved and the production cost is saved.

Owner:LUZHOU PINCHUANG TECH CO LTD

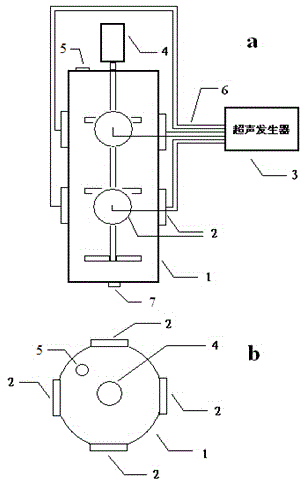

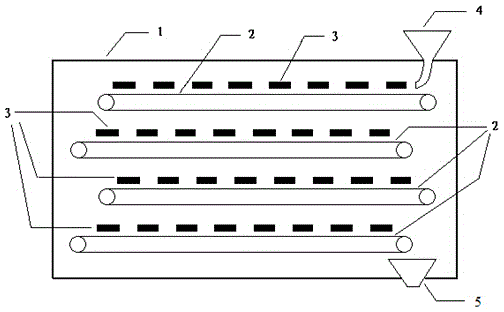

Method for preparation of oligopeptides by solid state fermentation cake

ActiveCN104372060ASimple production processEven and convenient turningMicroorganism based processesFermentationBiotechnologyMicroorganism

The invention relates to a method for preparation of oligopeptides by solid state fermentation cake, and relates to the field of biological engineering. One or more cakes as a raw material is crushed for pretreatment, a sweep frequency ultrasonic assisted cultured microbial fermentation liquid seed is inoculated, the cake moisture content is adjusted to 50%-60% (w / w), field assisted fermentation is performed for 60-80 hours at 30 to 35 DEG C in a multi-layer conveyer belt type fermentation bed, after the fermentation is completed, water is added for extracting the oligopeptides, and a cake oligopeptide product is obtained by centrifugal slag removal, decolorization, drying and other steps of extracting solution. The method can significantly reduce the cost of preparation of the oligopeptides by the solid state fermentation cake, and improve the production efficiency. The oligopeptides prepared by the method can be used for human health and nutrition products, animal daily diets and the like.

Owner:JIANGSU UNIV

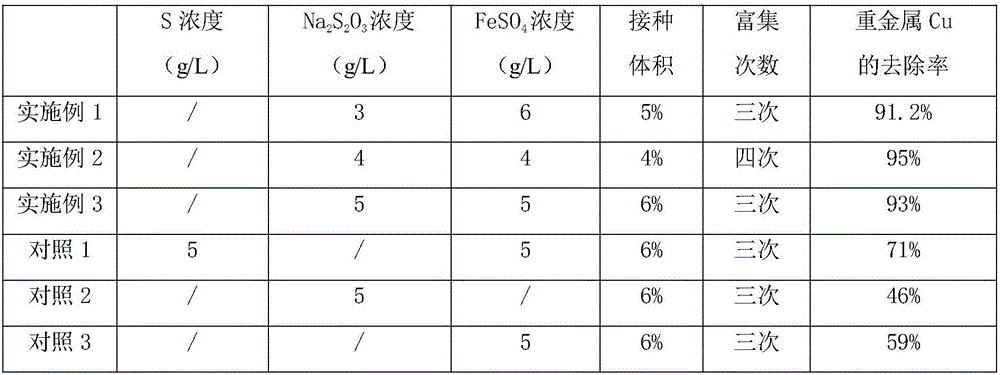

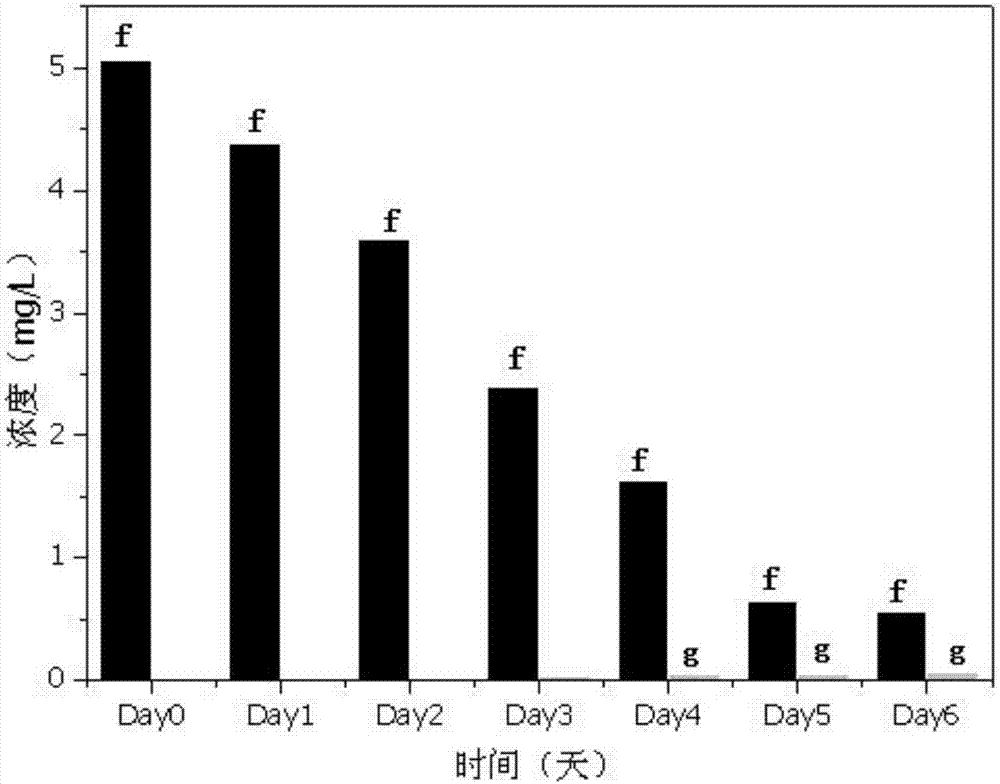

Method for removing heavy metal Cu in sludge of urban sewage treatment plant in bioleaching mode

ActiveCN105776788ASmall amount of inoculumImprove the growing environmentSpecific water treatment objectivesWater contaminantsThiobacillusMunicipal sewage

The invention discloses a method for removing heavy metal Cu in sludge of an urban sewage treatment plant in a bioleaching mode, by means of the method, the problem that sludge of the urban sewage treatment plant contains much heavy metal Cu is solved, and the treated sludge can serve as fertilizer for agricultural utilization. The method includes the following specific steps that original thiobacillus in the sludge is enriched and cultured, acclimated sludge is obtained, the acclimated sludge serves as the inoculum and is added to raw sludge, Na2S2O3 and FeSO4 substrates are fed, the feeding amount of Na2S2O3 is controlled to be 3-5 g / L, the feeding amount of FeSO4 is controlled to be 4-6 g / L, air is blown into the sludge at the speed of 1.0-1.5 L / (min-L), stirring is conducted at a certain rotation speed, the temperature is controlled to be 20-30 DEG C, and the sludge is subjected to bioleaching; after bioleaching is conducted for 3-4 days, the removal rate of the heavy metal Cu reaches 90% or above. The method is reasonable in design and high in practicability.

Owner:FUZHOU UNIV

Animal rabies virus and vaccine and production method thereof

ActiveCN101979515AHigh infection efficiencyHigh titerInactivation/attenuationAntiviralsFreeze thawingAdjuvant

Owner:PULIKE BIOLOGICAL ENG INC

Seed culture medium and culture method for streptomyces aureus

ActiveCN103484406AReduce dosageReduce typesBacteriaMicroorganism based processesBiotechnologyAmylase

The invention relates to a seed culture medium and a culture method for streptomyces aureus. The seed culture medium comprises beer yeast dry residue, and particularly comprises the following raw materials: 8 to 10 ml / L oil, 20 to 22 g / L starch, 27 to 29 g / L beer yeast dry residue, 8 to 9 g / L yeast extract, 11 to 13 g / L low temperature soybean cake powder, 0.3 to 0.4 g / L dipotassium phosphate, 0.8 to 1 g / L light calcium carbonate, 0.04 to 0.06 g / L magnesium sulphate, 0.8 to 0.9 g / L sodium chloride, 0.2 to 0.3 g / L amylase, 0.05 to 0.07 g / L ammonium sulfate and 0.03 to 0.04 g / L polyether antifoaming agents. The seed culture medium and the culture method can effectively improve the bacterial cell consistence and bacterial cell culture quality of streptomyces aureus, reduce the inoculum dose in the initial stage of the seed culturing, shorten the seed culturing period, meanwhile reduce the raw auxiliary material dose in the seed culturing to the maximum extent, reduce the production cost, ensure the abundant supply, and realize the stability and high quality culturing of the streptomyces aureus.

Owner:宁夏泰瑞制药股份有限公司

Method for rapidly preparing man-made pit mud through functional microbial group of high-yield butyric acid and caproic acid

ActiveCN105400652AIncrease initial contentShorten the timeMicroorganism based processesAlcoholic beverage preparationMicroorganismFood flavor

The invention relates to a method for rapidly preparing man-made pit mud through a functional microbial group of butyric acid and caproic acid produced through clostridium, belongs to the technical field of liquor brewing and aims to achieve the technical purpose that the method for rapidly preparing man-made pit mud through the functional microbial group is provided. A pit applying the man-made pit mud can produce high-quality strong-flavor baijiu. The method includes the following specific steps that 1, functional microbial group fermentation liquid is cultured; 2, preliminarily-cultured pit mud is piled and fermented for 20-25 days, and the temperature is conducted to 25-35 DEG C; 3, man-made pit mud is piled and fermented for 30-35 days, and a finished product can be obtained. According to the method, the functional microbial group fermentation liquid serves as one of the most important inoculums, the high-quality pit mud resource is protected, high-quality man-made pit can be rapidly obtained, and the quality of baijiu of a new pit is improved. A new scheme is provided for preparation of the pit mud of a new pit pool, and wide application prospect is achieved.

Owner:LUZHOU PINCHUANG TECH CO LTD +1

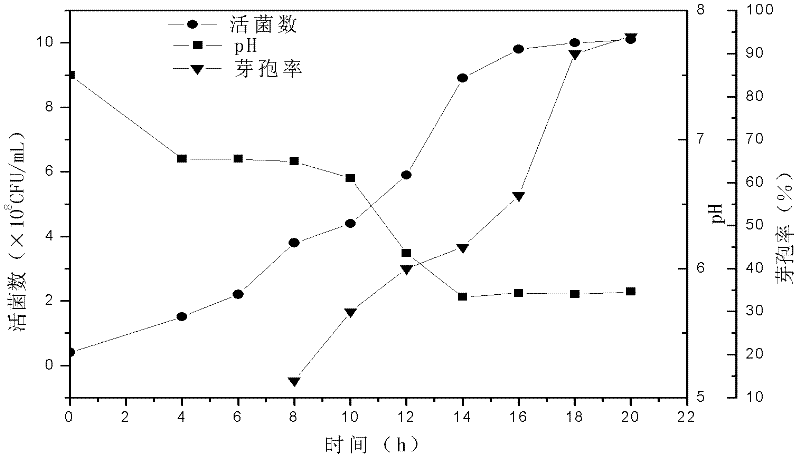

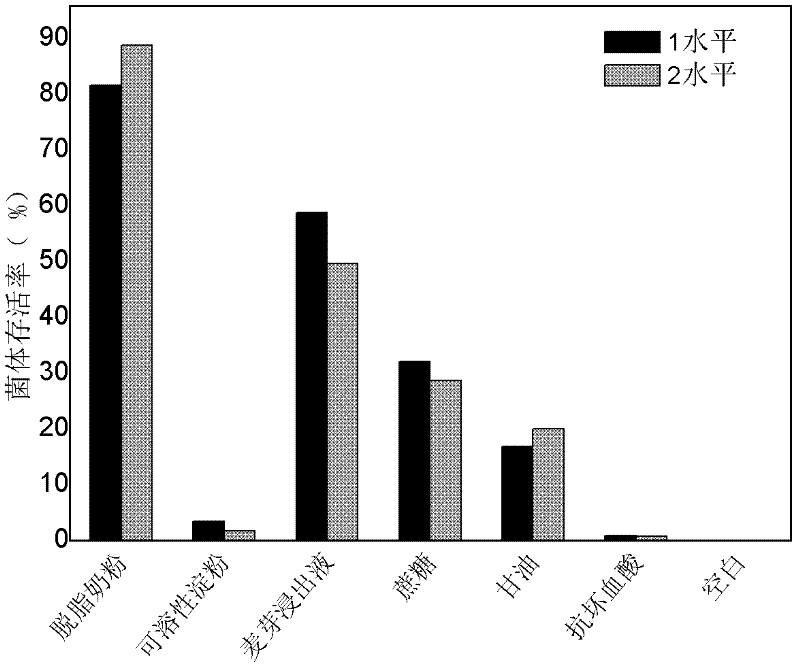

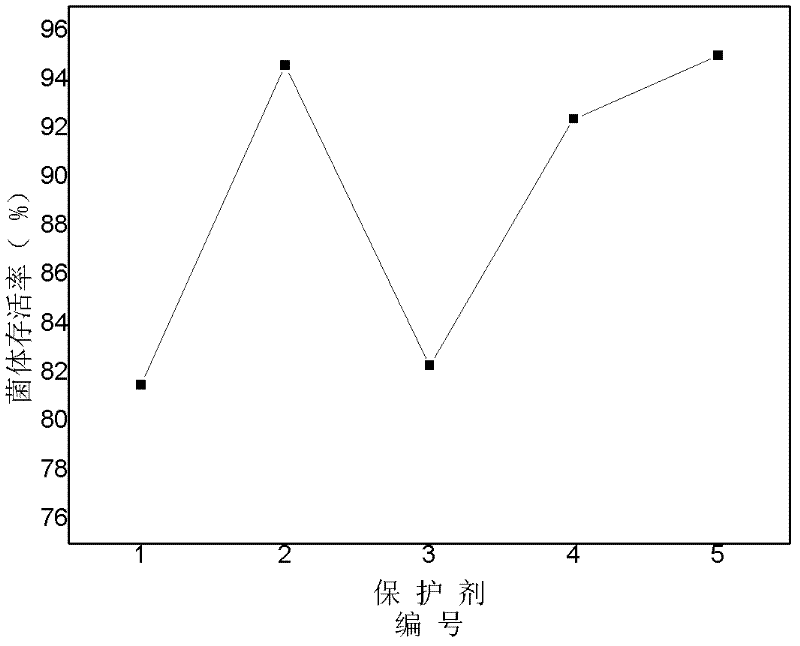

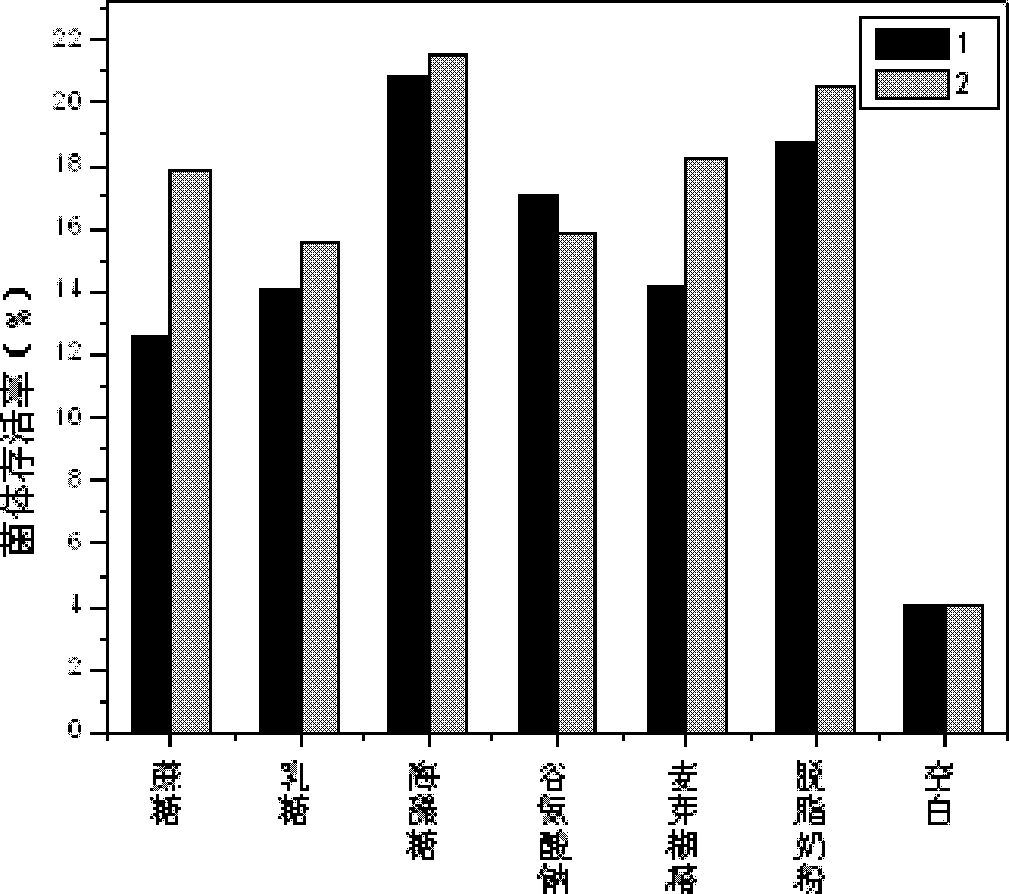

Direct vat set clostridium butyricum starter and preparation method thereof

ActiveCN102334605AIdeal liquidIdeal solid-state fermentation effectBacteriaAnimal feeding stuffFreeze-dryingHigh activity

The invention relates to a direct vat set clostridium butyricum starter and a preparation method thereof. The method comprises the following steps of: performing clostridium butyricum seed culture; performing high-density scale-up culture; preparing thallus starter by using a freeze-drying method; and finally obtaining the direct vat set clostridium butyricum starter, wherein one liter of culturemedium for clostridium butyricum seed culture and high-density scale-up culture is prepared from 1.75-2g of peptone, 0.5g of glucose, 0.02g of MgSO4, 0.5g of K2HPO4 and 0.02g of MnSO4; and concentration conditions for preparing the thallus starter by using the freeze-drying method are that: the centrifugal rotation speed is 5,000r / min, centrifugation time is 10 minutes, centrifugation temperatureis 4 DEG C, and a freeze-dry protecting agent comprises 10 percent dry skim milk and 10 percent malt extract. The survival rate of the direct vat set clostridium butyricum starter produced by the method is 94.6 percent, the viable count is 3.92*10<10>cfu / g, and an ideal liquid-state and solid-state fermentation effect can be achieved according to inoculum size of 0.1 percent. A novel preparation method for the high-activity direct vat set clostridium butyricum starter is developed on the basis of the strain to be applied to fermentative culture of clostridium butyricum.

Owner:SHENZHEN JINXINNONG FEED

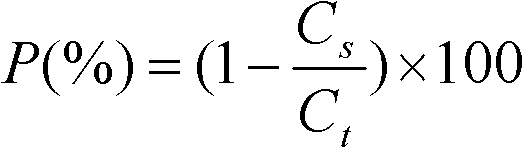

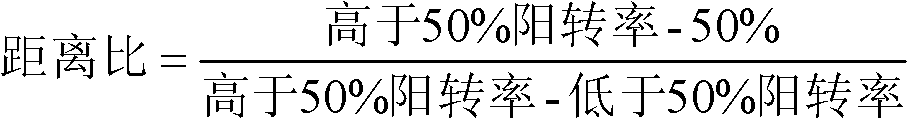

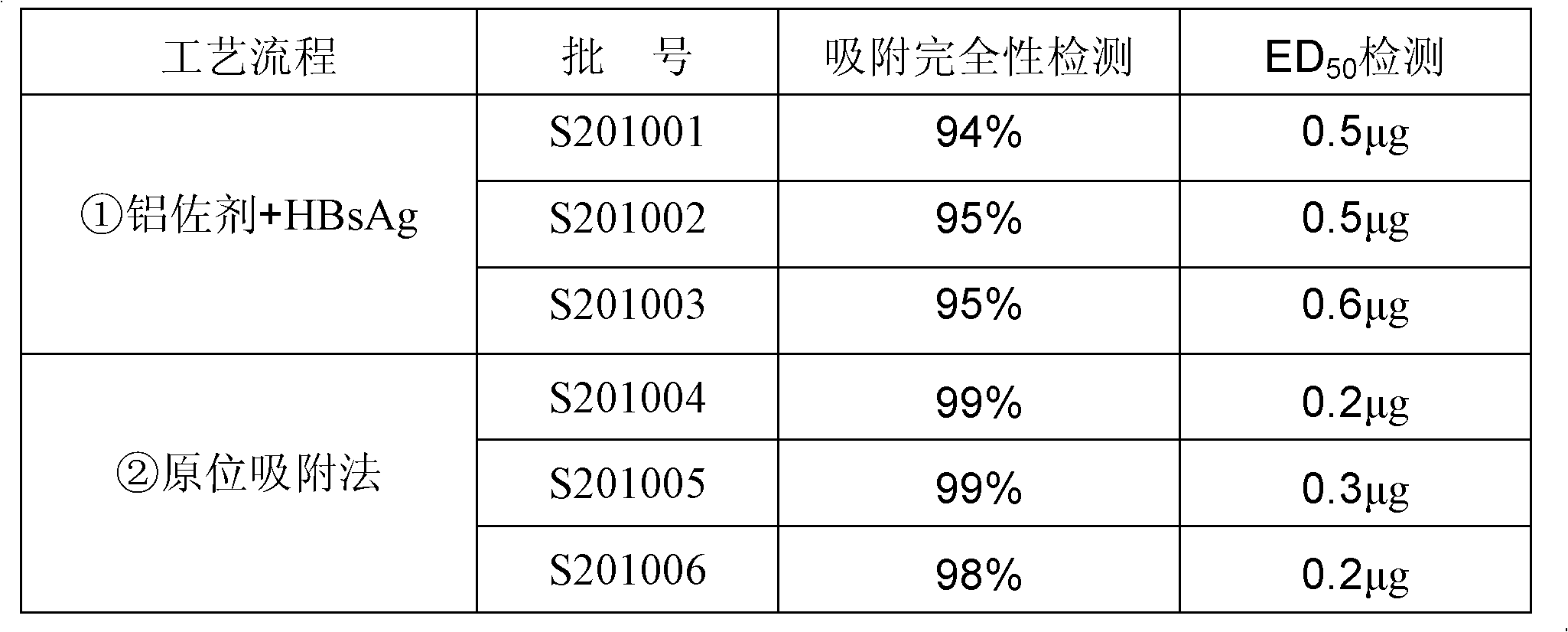

Preparation method of aluminum-containing adjuvant hepatitis B vaccine

ActiveCN102198270AIncrease inoculum volumeHigh positive conversion rateViral antigen ingredientsDigestive systemAdjuvantIn situ adsorption

The invention discloses a preparation method of an aluminum-containing adjuvant hepatitis B vaccine, belonging to the biotechnology field. The preparation method is characterized in that an aluminum adjuvant Al(OH)3 is produced by an on-line reaction, i.e. after a phosphate buffer solution (PBS), a KAl(SO4)2 solution and a hepatitis B surface antigen stock solution are mixed, an NaOH solution is added to the mixed solution, an Al(OH)3 adjuvant is continuously produced, and simultaneously, hepatitis B surface antigens are continuously coated and adsorbed; and the process is called 'in-situ adsorption'. In the invention, the Al(OH)3 adjuvant is produced by an in-situ reaction to greatly improve the adsorption rate of the hepatitis B surface antigens, thereby improving the immunogenicity of the antigens, being capable of more effectively causing organisms to generate an immune response, and producing more protective antibodies. The practice proves that the aluminum adjuvant hepatitis B vaccine produced by the method disclosed by the invention has the advantages of small inoculation amount, few adverse responses, high antibody positive conversion rate and the like, and can induce high-level antibody response after being immunized. Simultaneously, the processing steps are also simplified, and the production cost is greatly lowered.

Owner:DALIAN HISSEN BIO-PHARM CO LTD

Classical swine fever virus vaccine and production method thereof

InactiveCN101926991AHigh poison priceExpand production scaleInactivation/attenuationMicroorganism based processesCulture fluidFreeze-drying

The invention discloses a method for preparing a classical swine fever (CSF) vaccine by using a cell microcarrier suspension culture system, which comprises the following steps of: (1) inoculating cells for preparing the vaccine to a carrier tank containing culture solution and a microcarrier, and uniformly mixing the cells and the microcarrier to make the cells attached to the microcarrier; (2) when the concentration after cell proliferation is 5 to 40 times of the initial inoculation concentration, inoculating CSF virus (lapinized virus) to the cells according to multiplicity of infection (M.O.I.) of the virus of 0.01-1 and reproducing the virus; and (3) mixing prepared virus liquid, adding an appropriate freeze-drying protective agent, fully and uniformly mixing, quantitatively packaging, and freeze-drying to obtain the CSF vaccine. The CSF vaccine produced by the method has the advantages of high density of cultured cells, continuous culture, high yield of the virus, high immune effect, high safety, complete immune protection on attack of violent CSF, and the like.

Owner:PU LIKE BIO ENG

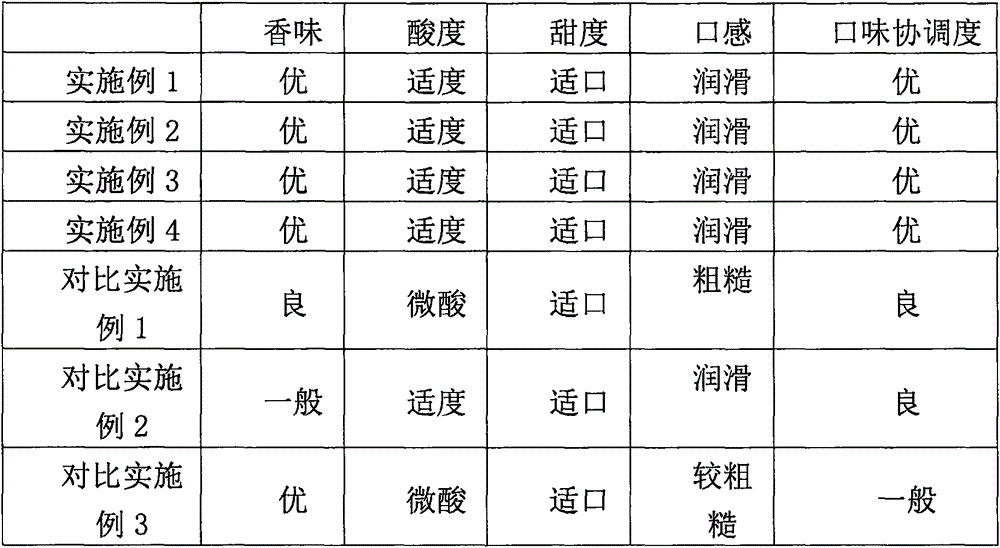

Potato yoghourt and making method thereof

InactiveCN106465750APrevent browningNo precipitationMilk preparationOther dairy technologySweetnessSolanum tuberosum

Potato yoghourt and a making method thereof are disclosed. 40-60% of potato juice is creatively added into yoghourt, and lactobacillus bulgaricus and streptococcus thermophilus are used in cooperation for fermentation. On the basis of controlling the ratio of the materials and the making method, the potato yoghourt with rich nutrients, moderate sweetness and palatable sour taste is prepared.

Owner:SHENYANG AGRI UNIV

Virus and vaccine of porcine reproductive and respiratory syndrome and preparation method of same

ActiveCN101979514AHigh viral titerHigh poison priceViral antigen ingredientsAntiviralsFreeze-dryingCells/microL

The invention discloses a method for preparing virus of porcine reproductive and respiratory syndrome on a large scale. In the method, the virus of the porcine reproductive and respiratory syndrome is prepared in a cell microcarrier suspension culture system by a bioreactor. The method comprises the following steps of: inoculating host cells for preparing the virus to a carrier tank containing culture solution and a microcarrier, and mixing the cells and the microcarrier uniformly to ensure that the cells are attached to the microcarrier; providing sufficient nutrients and appropriate gas environment for the cells under the appropriate culture environment to ensure that the cells are grown until the cells are in an amount which are 10 to 20 times of the inoculation concentration on the microcarrier; preparing virus suspension from the virus of the porcine reproductive and respiratory syndrome by using cell maintenance culture solution to ensure that the suspension is adsorbed to the cells; culturing the virus under the appropriate culture environment; culturing continuously for 2 to 3 days to obtain virus solution; and after the virus solution passes inspection, performing freeze thawing on the virus solution twice at the temperature of -20 DEG C, and inactivating and purifying to prepare an inactivated vaccine of the porcine reproductive and respiratory syndrome or adding a freeze-drying protective agent for freeze drying to prepare a live vaccine of the porcine reproductive and respiratory syndrome. The method has large production scale, high yield of single batch and low production cost.

Owner:PU LIKE BIO ENG

Method for producing rabies virus antigens for animals at a large scale

The invention discloses a method for producing rabies virus antigens for animals at a large scale, which produces the rabies virus antigens at a large scale by utilizing a bioreactor by a cell microcarrier suspension culture system. The method comprises the following steps: inoculating cells for preparing the antigens into a carrier tank containing a culture solution and microcarriers to enable the cells to be attached to the microcarriers; in a proper culture environment, enabling the cells to grow on the microcarriers until the quantity of the cells is 5-40 times more than inoculum density; making rabies viruses into a virus suspension, and enabling the virus suspension to be adsorbed on the cells; culturing the viruses in the proper culture environment by using a cell maintenance culture solution; continuously culturing for 3-5 days and then harvesting a virus solution for the first time, wherein a semicontinuous process is adopted and the ratio of a changed solution is 50 percent; continue culturing for 9-11 days, and harvesting the changed solution once every 24 hours; mixing the harvested virus solution with the virus solution of the bioreactor; and carrying out freeze thawing at the temperature of -20 DEG C and inactivation purification to obtain the rabies virus antigens. The method has large production scale, high single-scale yield and relatively low production cost.

Owner:PU LIKE BIO ENG

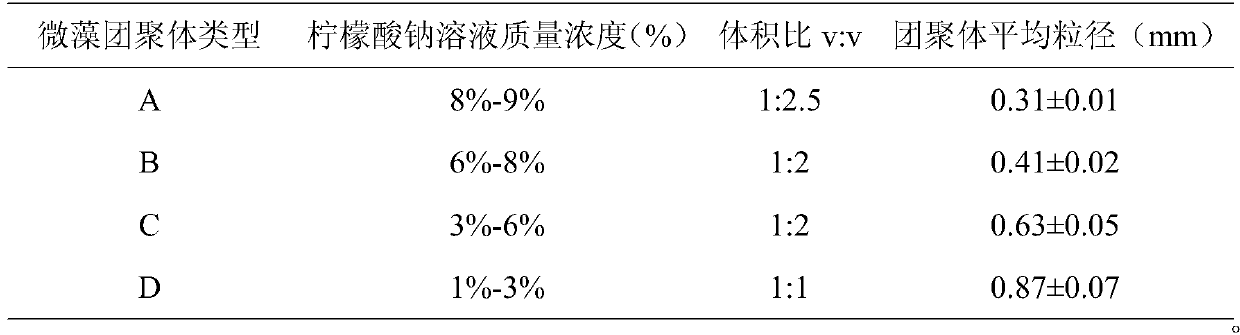

Novel biological floc, application thereof and method for nursing litopenaeus vannamei using novel biological floc

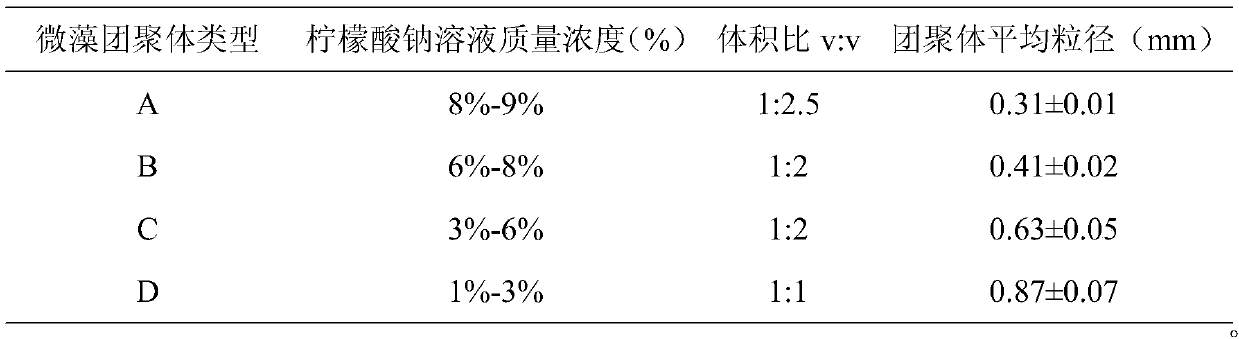

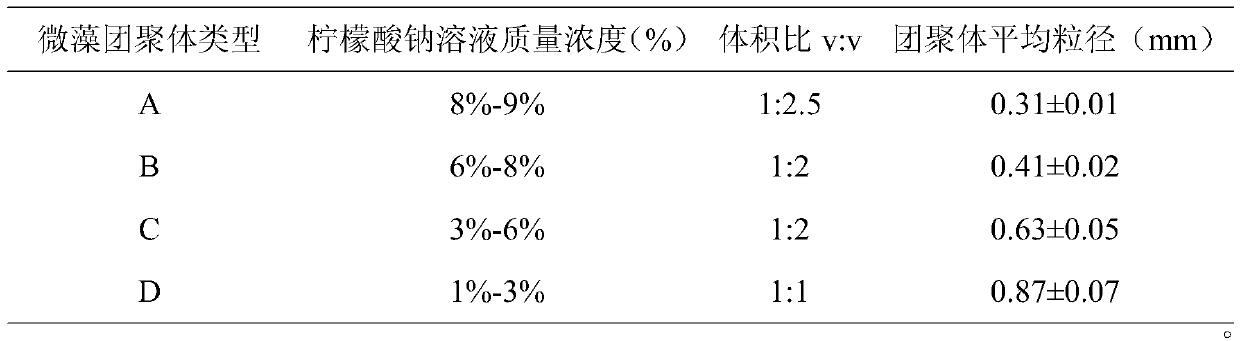

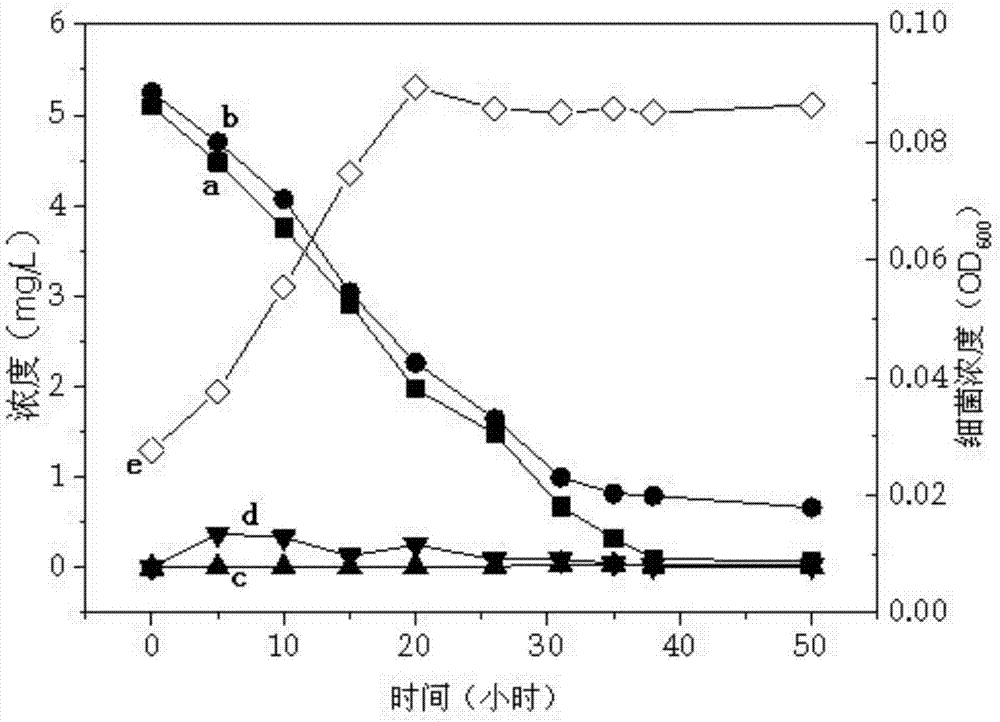

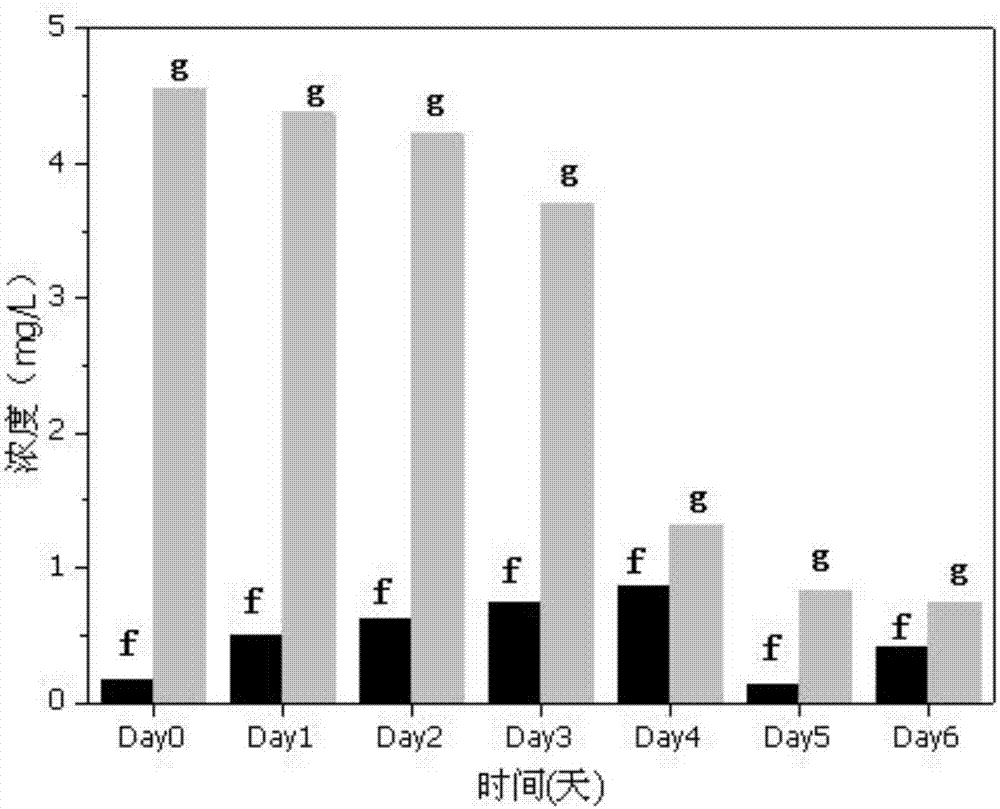

ActiveCN110628644AImprove water qualityImprove survival rateBacteriaUnicellular algaeBiotechnologyWater quality

The invention relates to a novel biological floc. The biological floc includes microalgae aggregates and commensalism heterotrophic bacteria, and the commensalism heterotrophic bacteria are Pesudomonas sp. and Bacillus sp. The biological floc significantly improves the water quality of the nursing pond of the litopenaeus vannamei, improves the survival rate, growth index and immunity of the litopenaeus vannamei, reduces the application amount of compound feed and external carbon sources, and reduces the aeration intensity and quantity of exchanged water.

Owner:TIANJIN AGRICULTURE COLLEGE +1

Oligotrophic low-temperature denitrifying bacterium and its application

ActiveCN107189974ASmall amount of inoculumSuitable for handlingBacteriaWater contaminantsMicroorganismNitrogen

The invention relates to an oligotrophic low-temperature denitrifying bacterium and its application so as to solve the problem that an existing denitrifying bacterium is not adapted to oligotrophic low-temperature water. The oligotrophic low-temperature denitrifying bacterium refers to janthinobacterium ((Janthinobacterium sp.) M-11, and is preserved in the China General Microbiological Culture Collection Center, the preservation address is No.3 institution, No.1 Beichen west road, Chaoyang district, Beijing city, the preservation data is in July 3, 2017, and the preservation number is CGMCC No.14380. The application refers to the application of the denitrifying bacterium in denitrifying oligotrophic low-temperature water. Compared with other strains, the inoculation quantity of the oligotrophic low-temperature denitrifying bacterium is smaller, and the oligotrophic low-temperature denitrifying bacterium is more suitable for the treatment of oligotrophic water. The oligotrophic low-temperature denitrifying bacterium is applied to the technical field of environmental microorganisms.

Owner:HARBIN INST OF TECH

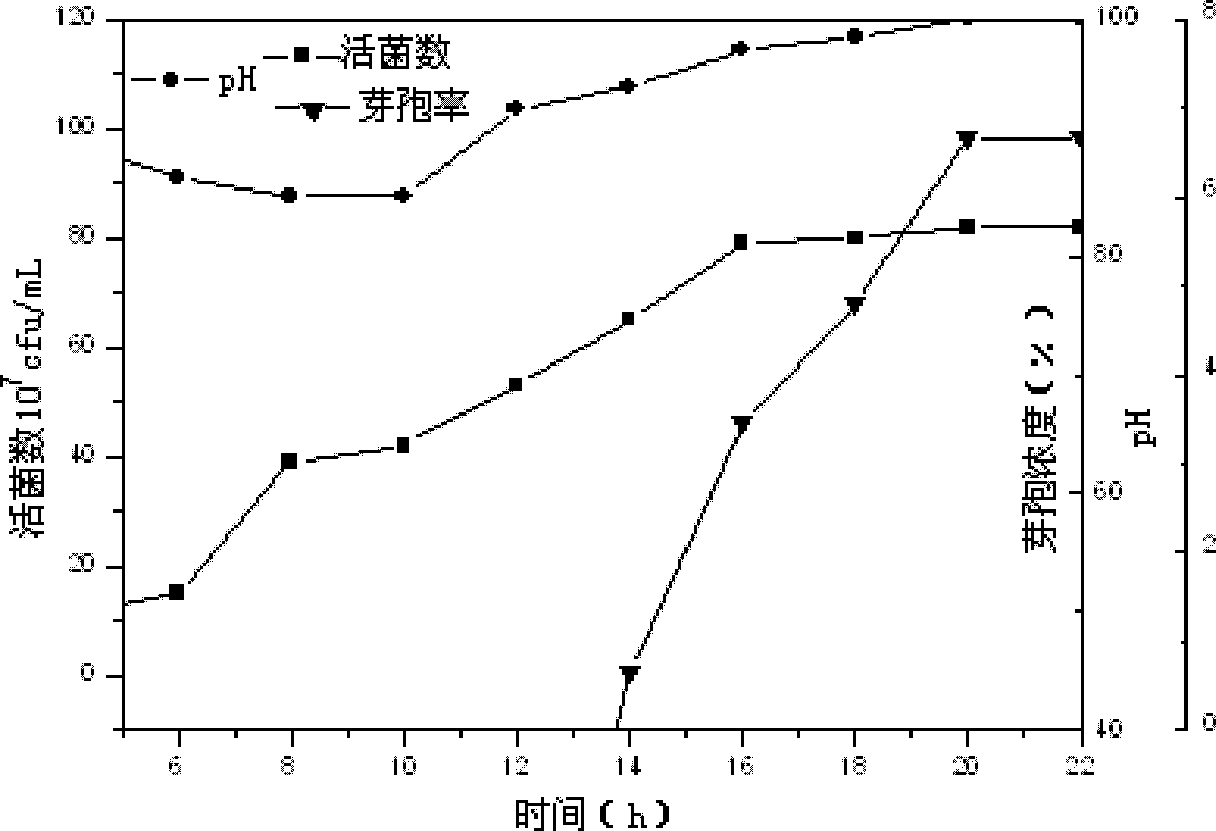

Bacillus sp. NB-1 and culture method and application thereof

ActiveCN112111435AImproved emission reductionsSmall amount of inoculumBacteriaWater contaminantsBiotechnologyAmmoniacal nitrogen

The invention provides Bacillus sp. NB-1 and a culture method and application thereof. The Bacillus sp. NB-1 is Bacillus sp. NB-1, is preserved in the China Center for Type Culture Collection on July13 , 2020, the address is Wuhan University, Wuhan Province, China, and the preservation number is CCTCC NO: M2020304; the Bacillus sp. NB-1 is cultured for 24h at 30 DEG C by using an LB liquid culture medium; and the Bacillus sp. NB-1 is used for degrading the concentration of ammonia nitrogen and nitrite in aquaculture water and aquaculture tail water. The Bacillus sp. NB-1 can obviously reduce the concentration of ammonia nitrogen and nitrite in the aquaculture water and the aquaculture tail water, is harmless to people and cultured animals, does not generate secondary pollution, and can be applied to improvement of aquaculture environment and aquaculture tail water emission reduction in large-scale production.

Owner:JIMEI UNIV

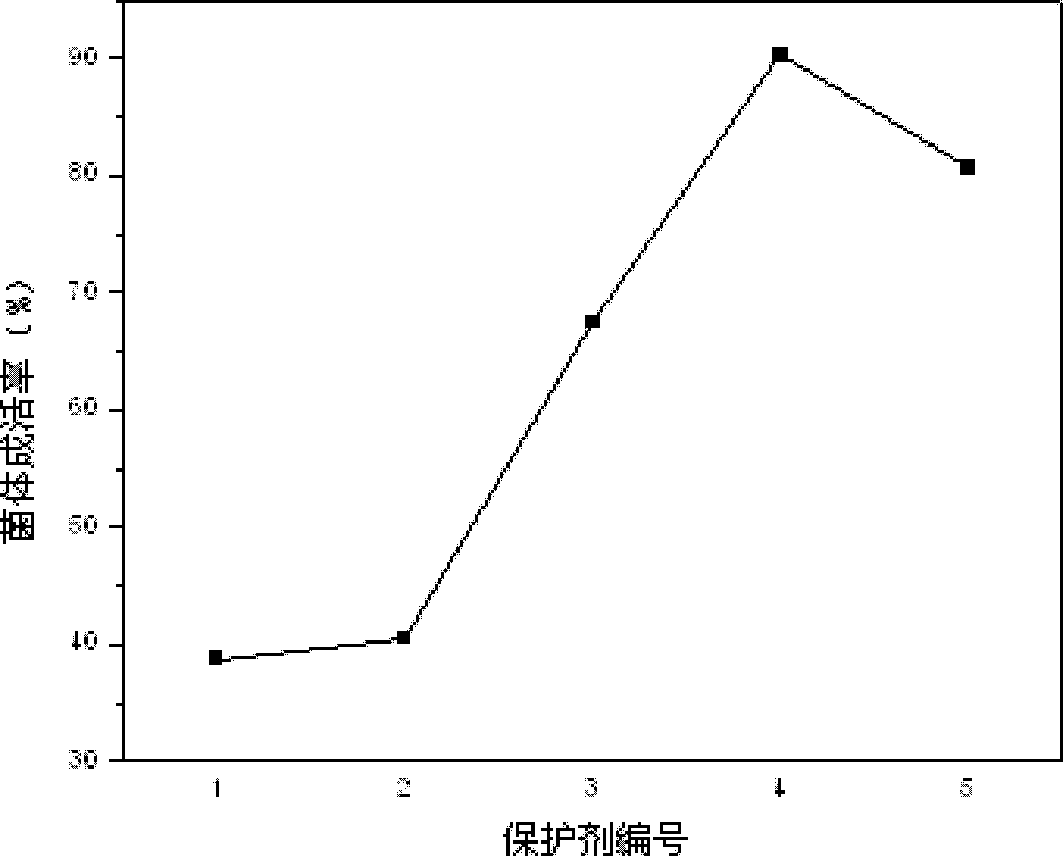

Method for preparing directed vat set bacillus coagulans starter

ActiveCN102433279ASmall amount of inoculumLabor savingBacteriaMicroorganism based processesChemistrySucrose

The invention relates to a method for preparing a directed vat set bacillus coagulans starter. The method comprises the following steps of: concentrating fermentation liquor of bacillus coagulans, wherein the concentration conditions of the fermentation liquor are that: the centrifugal rotating speed is 6,000r / min, the centrifugal time is 20min, and the centrifugal temperature is 4 DEG C; adding a protective agent, wherein the adopted protective agent is an aqueous solution which contains 5 percent m / m sucrose and 10 percent m / m maltodextrin; adding bacterial sludge into the aqueous solution of the protective agent; and drying by a vacuum drying method at the drying temperature of 60 DEG C under the drying pressure of 12,000Pa. The viable count of the obtained starter is 3.24*10<10>cfu / g; the sporation rate reaches 90.3 percent; and ideal liquid and solid fermentation effects can be achieved according to one thousandth of inoculation amount.

Owner:武汉华联科生物技术有限公司

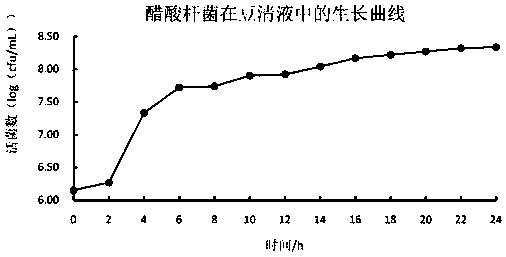

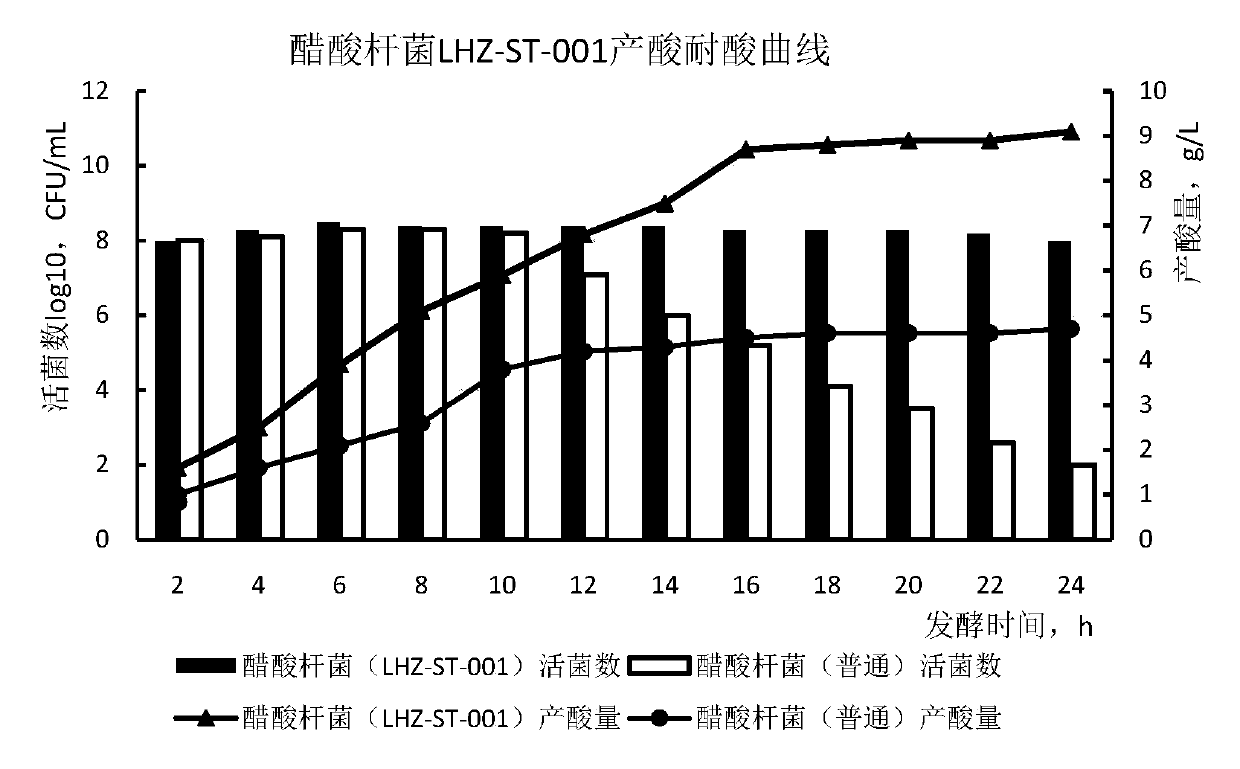

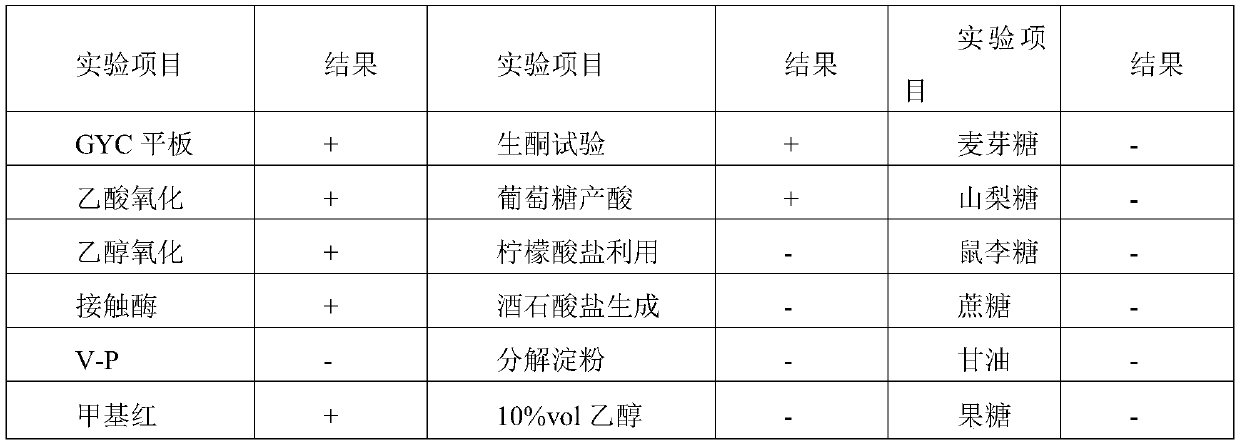

Acetobacter aceti and application thereof

ActiveCN110628662APromote growthStrong acid resistanceBacteriaMicroorganism based processesEthanol dehydrogenaseBio engineering

The invention relates to the technical field of microbial engineering, and particularly relates to acetobacter aceti and application thereof. Wherein the bacillus aceticus is lactobacillus aceticus LHZ-ST001, wherein a preservation unit is China General Microbiological Culture Collection Center (CGMCC for short), a preservation address is No.3, Yard 1, West Beichen Road, Chaoyang District, Beijing, a preservation date is September 10th, 2018, and a preservation number is CGMCC No.16448; the acetobacter aceti has high viable count in a fermentation culture medium, has strong acid and ethanol dehydrogenase producing capacity, has the capacity of being compounded with other lactic acid bacteria or saccharomycetes, has good tolerance to acid, and has the characteristic of high acid resistance.

Owner:贵州亮欢寨生物科技有限公司

Method for rapidly enriching functional flora without production of foreign odor substances in pit mud and application of functional flora

ActiveCN111088189AImprove anti-interference abilityReduce operating costsBacteriaAlcoholic beverage preparationBiotechnologyMicroorganism

The invention discloses a method for rapidly enriching a functional flora without production of foreign odor substances in pit mud and an application of the functional flora, belonging to the technical field of brewing microorganisms. According to the method, tested and screened aged pit mud with high quality is used as seed mud, and selected high-quality pit mud is subjected to step-by-step amplification culture by adopting a specific culture medium. The obtained flora is a caproic acid-producing flora taking a clostridium rumen flora as a main body, and the flora does not generate a mud odorsubstance, namely 4-methylphenol. The mixed flora obtained by using the method disclosed by the invention can be used for a solid fermented grain fermentation process of a pit-mud-free system; the content of beneficial flavor substances of fermented grains can be remarkably increased; the generation of bad flavor substances in the pit mud is avoided; thus, the quality of raw wine is improved. Themixed flora can also be used in a culture process of artificial pit mud and a daily pit mud maintenance process, so the caproic acid-producing main flora in a pit can be increased; pit mud aging is promoted; pit mud aging and hardening are prevented; meanwhile, generation of the mud odor substance, namely the 4-methylphenol is effectively reduced.

Owner:JIANGNAN UNIV +1

Method for rapidly and selectively breeding terramycin strains

InactiveCN104611280AReduce verification timeImprove work efficiencyBacteriaMicroorganism based processesSporeTiter

The invention relates to a method for rapidly and selectively breeding terramycin strains. The method comprises the following steps: a, test tube slant culture; b, preparation of spore suspension; c, isolated culture; d, fermentation culture; e, strain re-testing. Single colonies obtained through isolated culture are directly inoculated into a fermentation medium for fermentation culture, so that the titer of the terramycin obtained through screening is high, the titer validation time of the single colonies is shortened to 48-50h, and the working efficiency is greatly improved.

Owner:HEBEI SHENGXUE DACHENG PHARMA

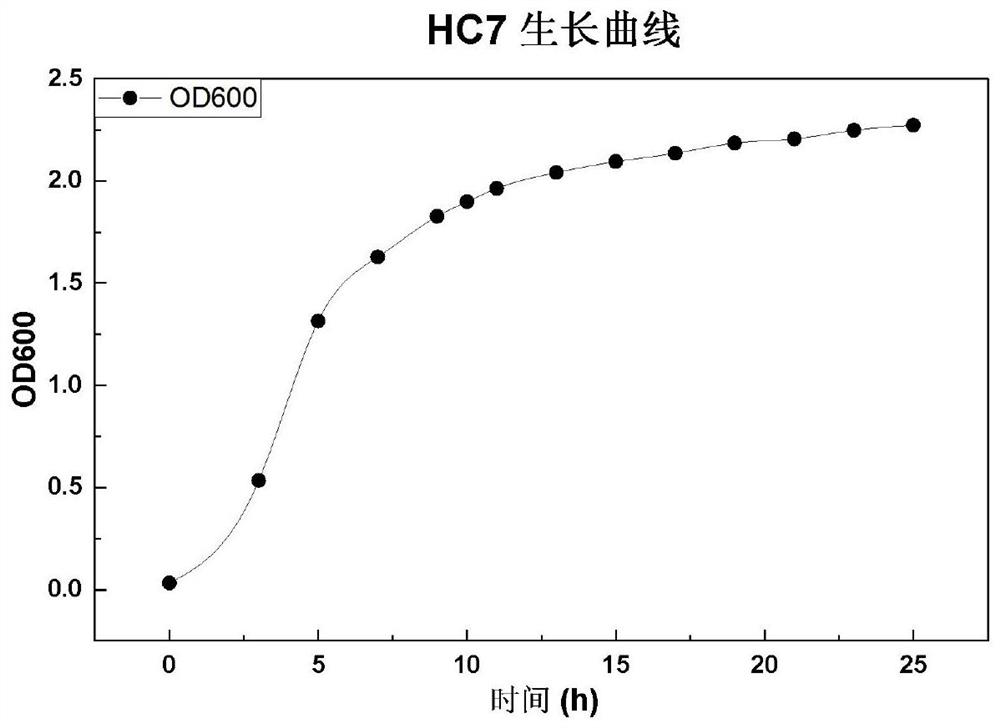

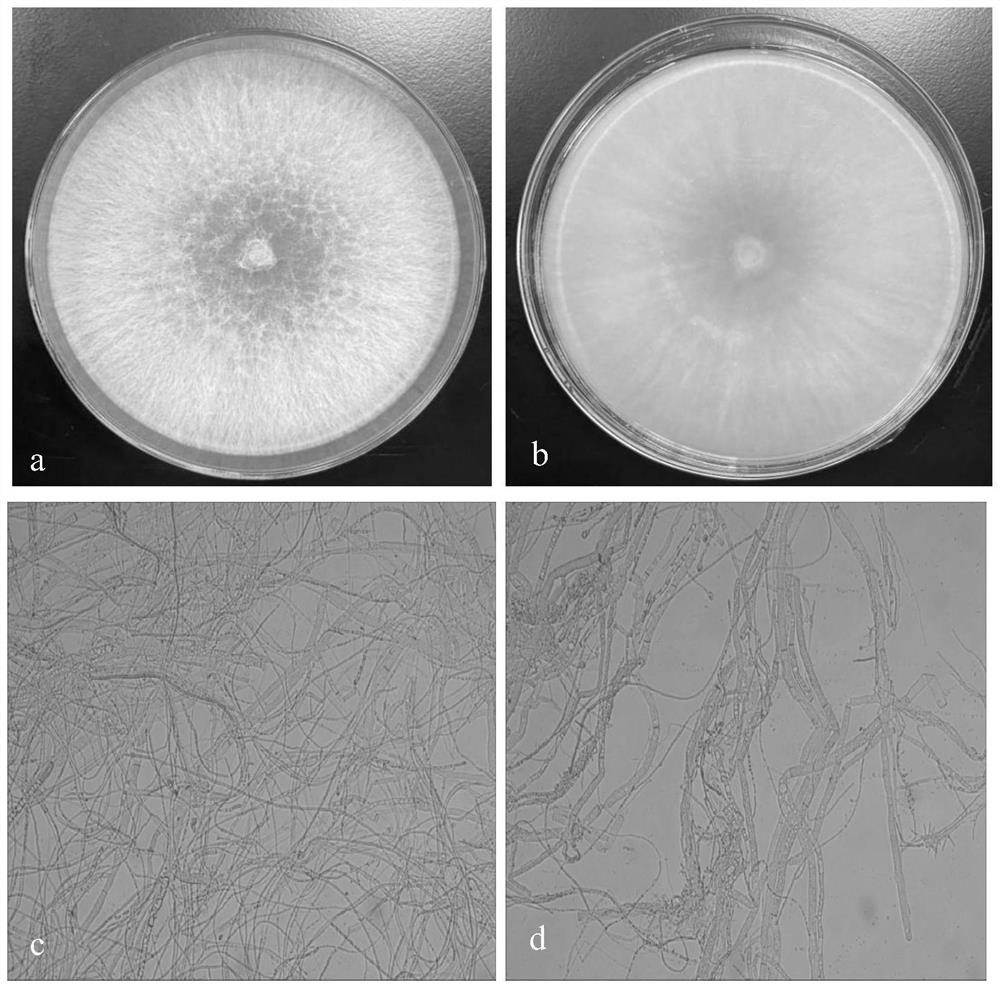

Bacillus cereus and application

ActiveCN113215023ALow application costWide range of temperature adaptationBacteriaMicroorganism based processesBiotechnologyBacillus cereus

The invention discloses bacillus cereus and application. The bacillus cereus HC7 is preserved in China General Microbiological Culture Collection Center of China Committee for Culture Collection of Microorganisms and has a preservation number of CGMCC No. 21660. The bacillus cereus HC7 can be used for effectively repairing water mass and can be used for repairing black and smelly water mass, lowering concentrations of pollutants such as COD and ammonia nitrogen in water, improving the DO, ORP and transparency of the water mass and obviously improving the water quality of the water mass; and the strain is wide in temperature adaptation range, relatively high in environmental adaptation, good in environmental stability, low in water mass repairing inoculum size and low in application cost, can withstand low-temperature deamination and has a huge popularization value.

Owner:SICHUAN JUNHE ENVIRONMENTAL PROTECTION

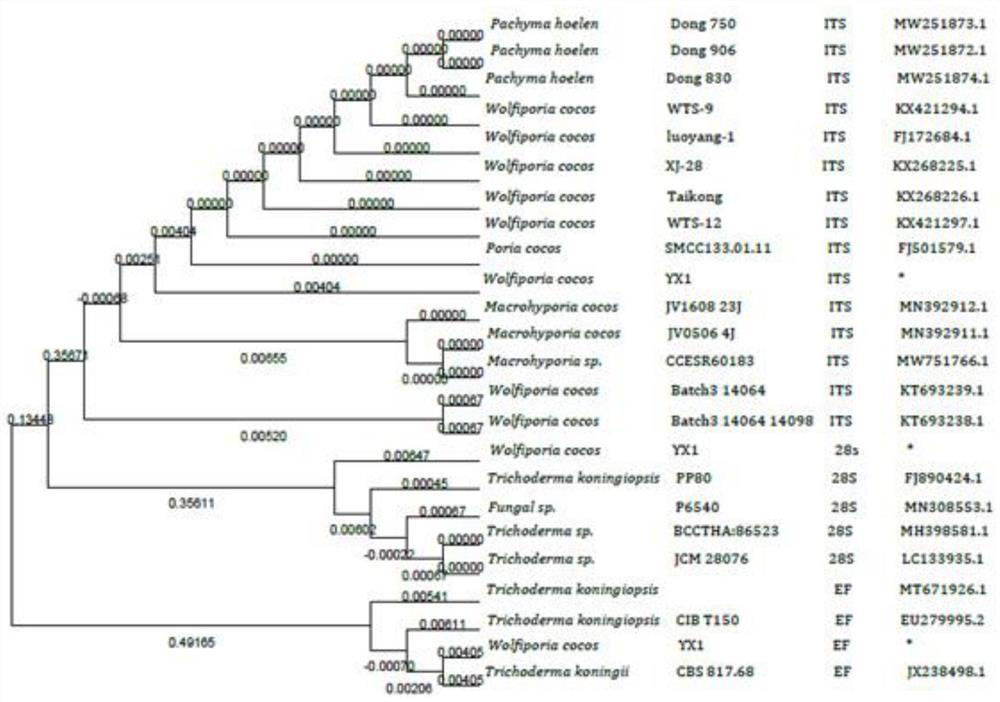

Wolfiporia cocos YX1 and culture media and cultivation method thereof

ActiveCN113796260ARich germplasm resourcesImprove qualityBio-organic fraction processingCultivating equipmentsBiotechnologyWolfiporia cocos

The invention discloses a wolfiporia cocos YX1 which is preserved in the China Center for Type Culture Collection (CCTCC) with the preservation number of CCTCC NO: M2021434. The invention further discloses a stock culture medium and a mother culture medium of the wolfiporia cocos YX1. The invention further discloses a cultivation method of the wolfiporia cocos YX1. The wolfiporia cocos YX1 is screened out, and is stable in economic character, high in yield, excellent in quality and stable in genetic gene; a high-yield and stable-yield culture medium of the wolfiporia cocos YX1 is screened out; and the scientific and practical cultivation method is provided.

Owner:ANQING NORMAL UNIV +1

Fruit peel appetite-improving duck meat sausage and preparation method thereof

InactiveCN105942262AHigh activityGood tenderizing effectClimate change adaptationNatural extract food ingredientsMonosodium glutamateBiotechnology

The invention discloses a fruit peel appetite-improving duck meat sausage which is prepared from the raw materials including, by weight, 220-250 parts of duck breast meat, 8-10 parts of fresh grapefruit peel, 7-8 parts of purple sweet potato peel, 4-5 parts of flos puerariae, 1-2 parts of ligustrum lucidum, 3-4 parts of momordica grosvenori leaves, 2-3 parts of monosodium glutamate, 4-6 parts of five-spice powder, 2-3 parts of soybean sauce, 4-5 parts of white sugar, 6-8 parts of salt, a proper amount of lactobacillus plantarum, a proper amount of a calcium chloride solution and a proper amount of water. The added purple sweet potato peel has the effects of preventing cancer, protecting liver, moistening intestines and relaxing bowel. The sausage also contains various traditional Chinese medicine components, such as the flos puerariae, so that the sausage has the effects of clearing heat and detoxifying body, protecting liver and tonifying kidney.

Owner:刘卫春

Large-scale production method of porcine transmissible gastroenteritis virus

The invention provides a large-scale production method of a porcine transmissible gastroenteritis virus. The method comprises the steps that: in a tidal-type bioreactor, cells are inoculated to micro-carriers, such that cell absorption culturing and amplification culturing are carried out; porcine transmissible gastroenteritis virus is inoculated, and virus absorption culturing is carried out; virus proliferation culturing is carried out; and when cell CPE reaches 70% or higher, virus solution is collected. The porcine transmissible gastroenteritis virus large-scale production method provided by the invention shows a trend of animal cell and virus continuous culturing and large-scale production. Compared with a traditional shake flask culturing process, an antigen titer is improved by more than 30 times. Product quality is homogenous, production process is simplified, operation is simple, production efficiency is improved, and production cost is reduced.

Owner:PU LIKE BIO ENG

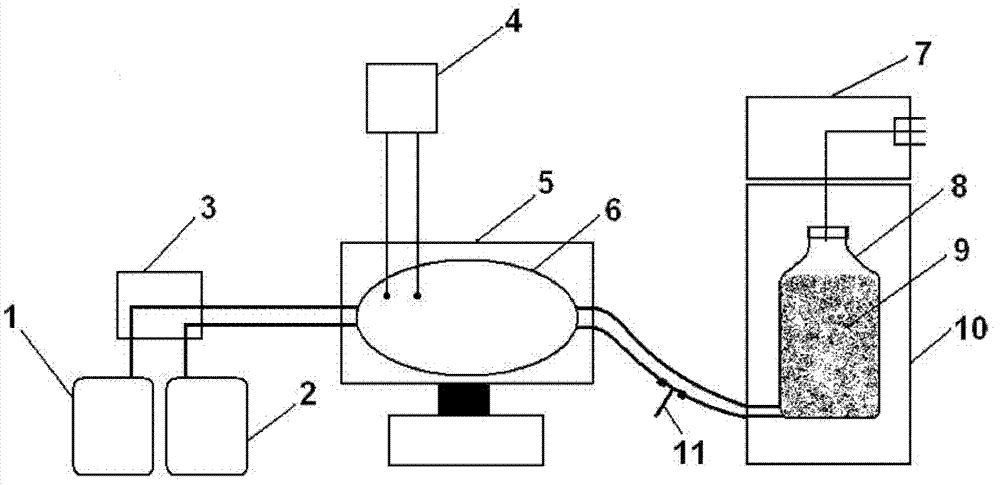

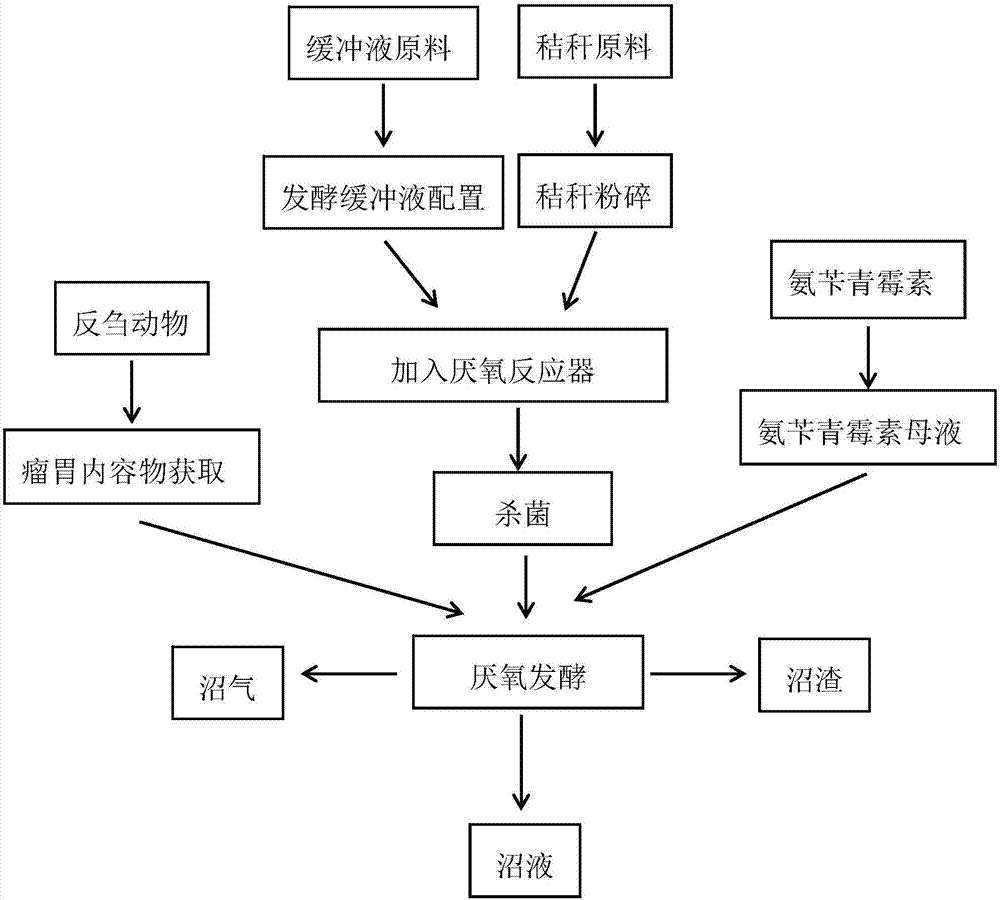

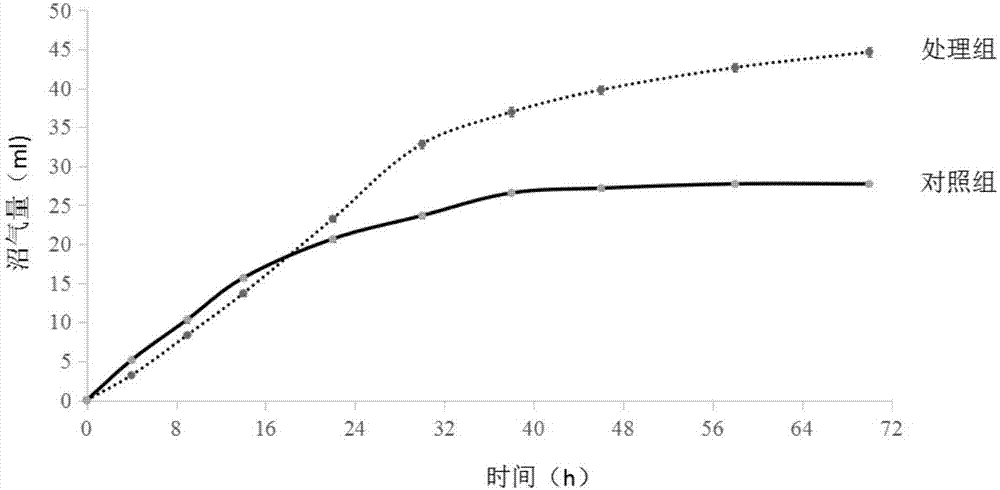

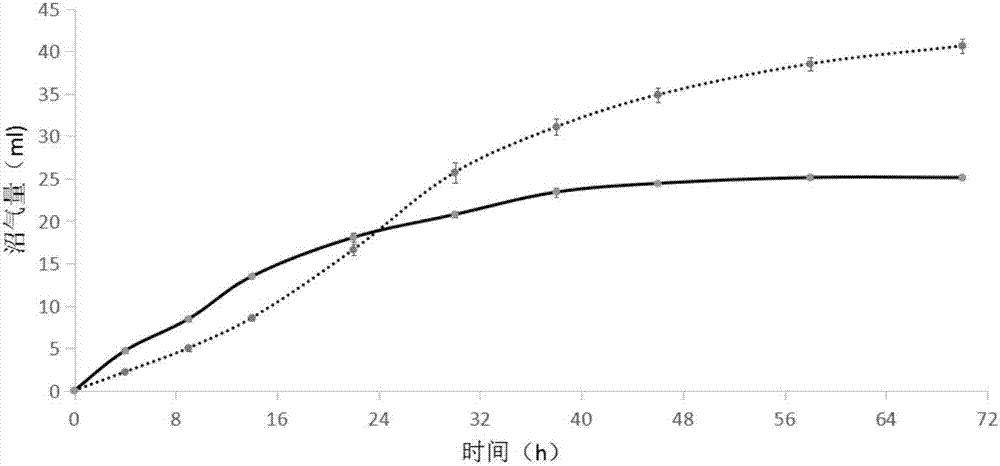

Method for producing biogas through anaerobic fermentation of degradation straw raw material

InactiveCN107164414AIncrease gas yieldRaise the ratioWaste based fuelFermentationAmpicillinReaction temperature

The invention discloses a method for producing biogas through anaerobic fermentation of a degradation straw raw material. The method concretely comprises the following steps: chopping the straw raw material to form 0.3-0.8 cm fragments; adding the chopped fragments into an anaerobic reactor as a fermentation material; adding a fermentation buffer solution to the fermentation material in the anaerobic reactor according to a weight / volume ratio of the fermentation material to the fermentation buffer solution of 1:(45-90); inoculating the anaerobic reactor with an inoculation material according to a weight / volume ratio of the fermentation material to the inoculation material of 1:(5-10) to make the final concentration of the fermentation material be 1-2%; and adding ampicillin into the anaerobic reactor to make the final concentration of the ampicillin be 1800-2200 U / ml, and carrying out fermentation at a controlled reaction temperature of 38-40 DEG C for 48-72 h to obtain the biogas. Compared with the prior art, the method disclosed in the invention has the advantages of effective increase of the yield of the biogas produced from the straw raw material by 55-60%, increase of the proportion of the biogas in cumulative gas production, and increase the biogas yield per unit straw raw material.

Owner:NANJING AGRICULTURAL UNIVERSITY

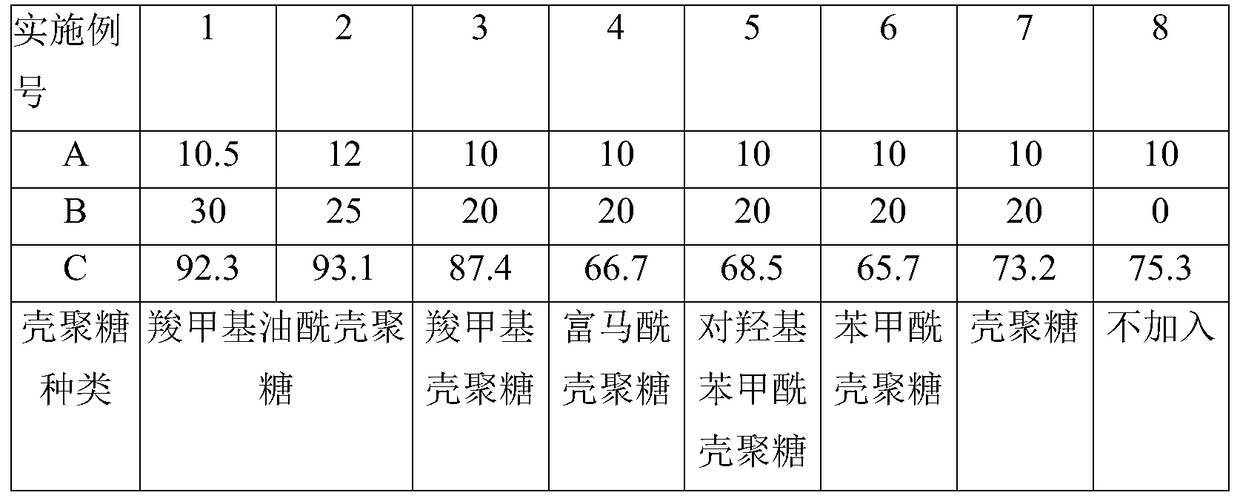

A method for preparing 7α, 15α-dihydroxydhydroepiandrosterone by using Trichospora flaxensis

ActiveCN104561216BImprove conversion rateSmall amount of inoculumMicroorganism based processesFermentationSporeAcetic acid

The invention discloses a method for preparing 7alpha,15alpha-dyhydroxyldehydroepiandrosterone by utilizing flax colletotrichum mould. The method comprises the following steps: (1) performing spore culture, namely taking flax colletotrichum mould ST-1 as a production strain, performing slant culture, thereby obtaining mature spores; (2) performing mycelium culture, namely performing mycelium culture in a mycelium culture medium in which the spores obtained in the step (1) are inoculated, thereby obtaining the mycelium culture liquid; (3) performing biotransformation, namely adding carboxymethyl oleoyl-chitosan and DHEA into the mycelium culture liquid in the step (1), wherein the final concentration of the DHEA is 10.5-12g / L, the weight ratio of the carboxymethyl oleoyl-chitosan to DHEA is (2-3):1, transforming under the stirring and rotating speed of 200-220 revolutions per minute for 36-60 hours, thereby obtaining the transformation liquid; and (4) extracting the product, extracting and concentrating the transformation liquid by using ethyl acetate, thereby obtaining the 7alpha,15alpha-dyhydroxyldehydroepiandrosterone.

Owner:ZHEJIANG XIANJU JUNYE PHARM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com