Preparation method of aluminum-containing adjuvant hepatitis B vaccine

A hepatitis B vaccine, aluminum adjuvant technology, applied in biochemical equipment and methods, medical preparations containing active ingredients, antiviral agents, etc., can solve the problem of high vaccination volume, low adjuvant adsorption rate, and antibody positive conversion rate Not ideal, etc., to achieve the effect of high antibody positive conversion rate, less adverse reactions, and improved immunogenicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation of embodiment 1 recombinant (hansenula) hepatitis B surface antigen stock solution

[0043] Fermentation: Take 1 strain of recombinant Hansenula working seed batch (obtained from the original strain of recombinant Hansenula hepatitis B vaccine with strain number HBsAgU35-16-9), inoculate in 300ml culture medium After culturing at 35°C for 24 hours, transfer to 3L medium, culture at 35°C for 24 hours, then transfer to 30L medium, culture at 35°C for 15 hours, and finally transfer to 200L medium, culture at 35°C, control The dissolved oxygen is greater than 20%, the pH is 6.8, and the air flow rate is 30-200ml / h. After culturing for 65 hours, collect about 240L of Hansenula cell fermentation liquid expressing the surface antigen of hepatitis B virus.

[0044] Preliminary purification: Grinding and crushing Hansenula cell fermentation liquid by physical crushing method to achieve a crushing rate of 92%, centrifuging at a speed of 4000rpm to remove cell debr...

Embodiment 2

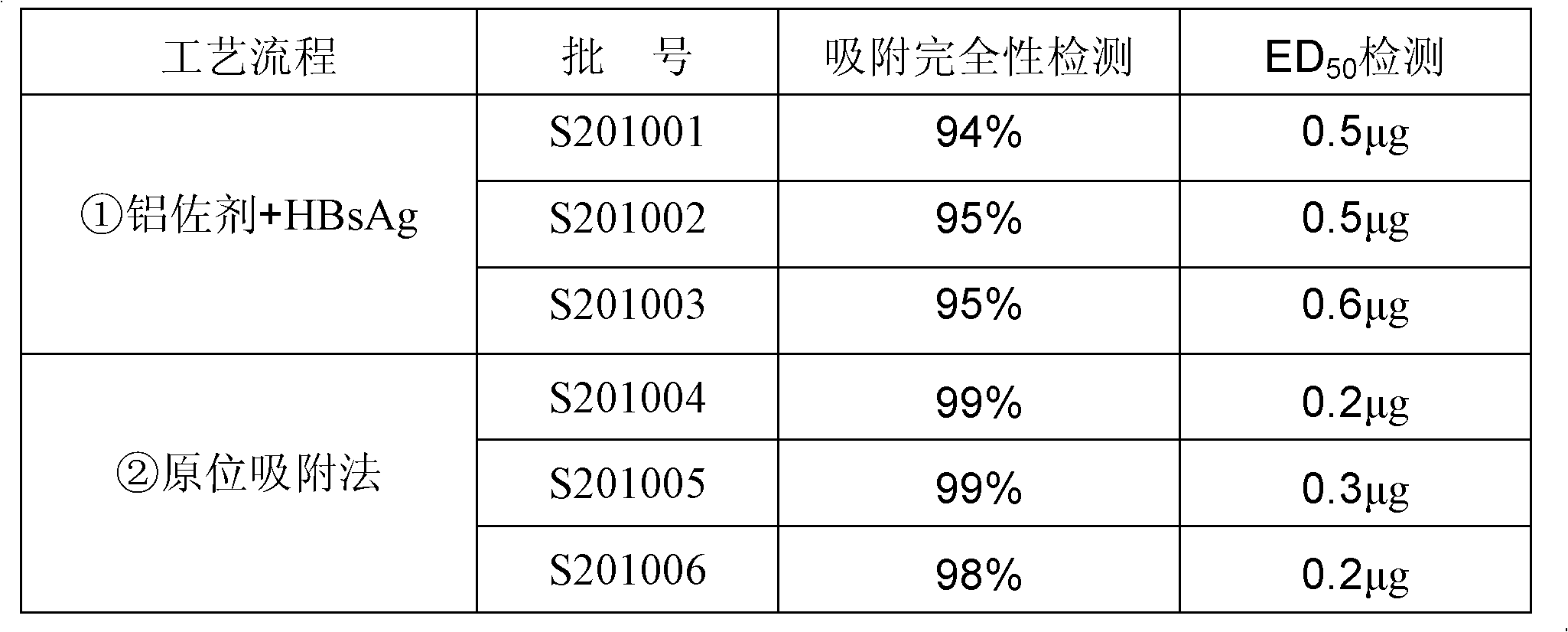

[0046] Embodiment 2 preparation of hepatitis B vaccine semi-finished product (aluminum adjuvant+HBsAg technology-prior art), semi-finished product batch number is S201001

[0047] Aluminum adjuvant preparation: start stirring, add 10% AlCl to the reaction bottle 3 Solution 54ml, add 0.5mol / L NaOH solution at a speed of 50ml / min, take samples at any time to measure the pH value, when the pH value reaches 7.00, stop adding the solution, add 110ml of 0.5mol / L NaOH solution, and then add 0.9% NaCl solution 436ml with a final volume of 600ml, and then sterilized by moist heat at 121°C for 30 minutes to be ready-to-use aluminum adjuvant.

[0048] Dilution of the stock solution: 54.5ml of the stock solution (prepared by Example 1) with a protein content of 220 μg / ml was placed in a 500ml Erlenmeyer flask, and 300ml of 0.9% NaCl solution was added to make the protein content 40 μg / ml.

[0049] Adsorption of semi-finished product: Start stirring, add 300ml of aluminum adjuvant to anot...

Embodiment 3

[0050] Embodiment 3 preparation of hepatitis B vaccine semi-finished product (aluminum adjuvant+HBsAg technology-prior art), semi-finished product batch number is S201002

[0051] Aluminum adjuvant preparation: start stirring, add 10% AlCl to the reaction bottle 3 Solution 54ml, add 0.5mol / L NaOH solution at a speed of 50ml / min, take samples at any time to measure the pH value, when the pH value reaches 6.95, stop adding the solution, add 0.5mol / L NaOH solution 108ml, and then add 0.9% NaCl solution 438ml with a final volume of 600ml, and then sterilized by moist heat at 121°C for 30 minutes to prepare aluminum adjuvant for use.

[0052] Dilution of the stock solution: 54.5ml of the stock solution (prepared by Example 1) with a protein content of 220 μg / ml was placed in a 500ml Erlenmeyer flask, and 300ml of 0.9% NaCl solution was added to make the protein content 40 μg / ml.

[0053] Adsorption of semi-finished product: Turn on stirring, add 300ml of aluminum adjuvant to anoth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crush indicators | aaaaa | aaaaa |

| crush indicators | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com