A spray-assisted high-throughput microbial inoculation device

An inoculation device and microbial technology, applied in the field of high-throughput microbial inoculation devices, can solve problems such as inability to meet the needs of microbial culture and detection, and achieve ultra-high-throughput microbial single-cell inoculation, pure colony culture, and increase Effect of Inoculation Flux and Uniformity of Distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

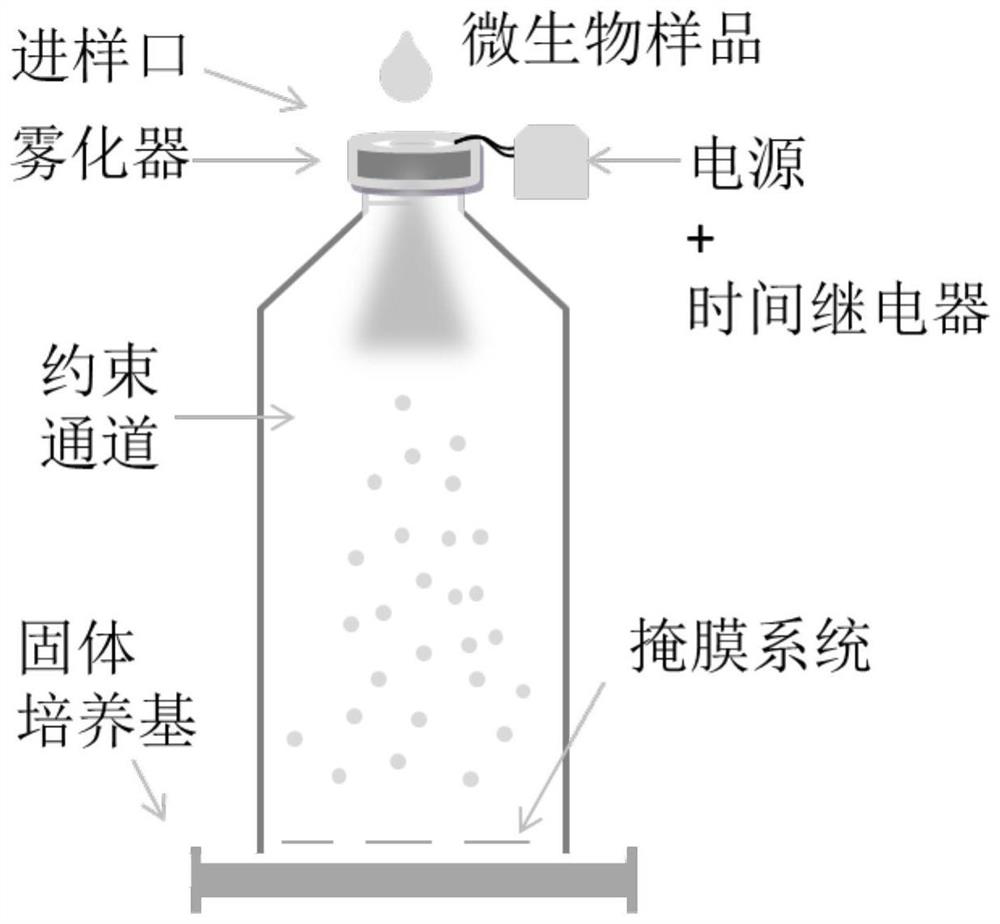

[0050] The spray-assisted high-throughput microbial inoculation device in the present invention can be used with a solid medium when in use, that is, it consists of four parts: a spray generator, a sedimentation channel, a mask assembly and a solid medium (of course, the mask assembly is also optional or optional).

[0051] like figure 1 As shown, the spray device is attached to the threaded settling channel. In this embodiment, the ultrasonic atomizing sheet is preferably selected, and its outer diameter is 18 mm. By fixing and sealing the screw mouth of the fixed seat and the sedimentation channel, the leakage of spray droplets is prevented.

[0052] In this embodiment, the settling channel is preferably refitted with a 500ml plastic bottle, which is low in cost and easy to process. Cut off the bottom of the plastic bottle, sand it to a level, and directly and seamlessly connect with the solid medium to prevent the leakage of spray aerosol droplets. The spray distance pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com