Patents

Literature

32results about How to "Increase the wall area" patented technology

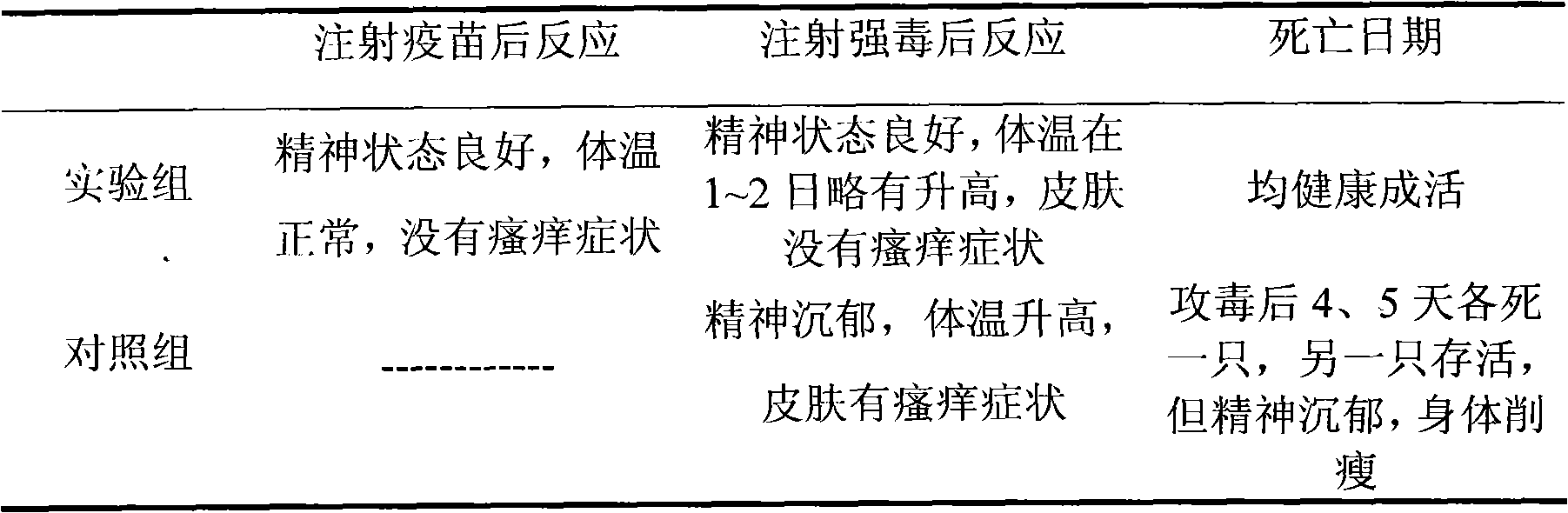

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

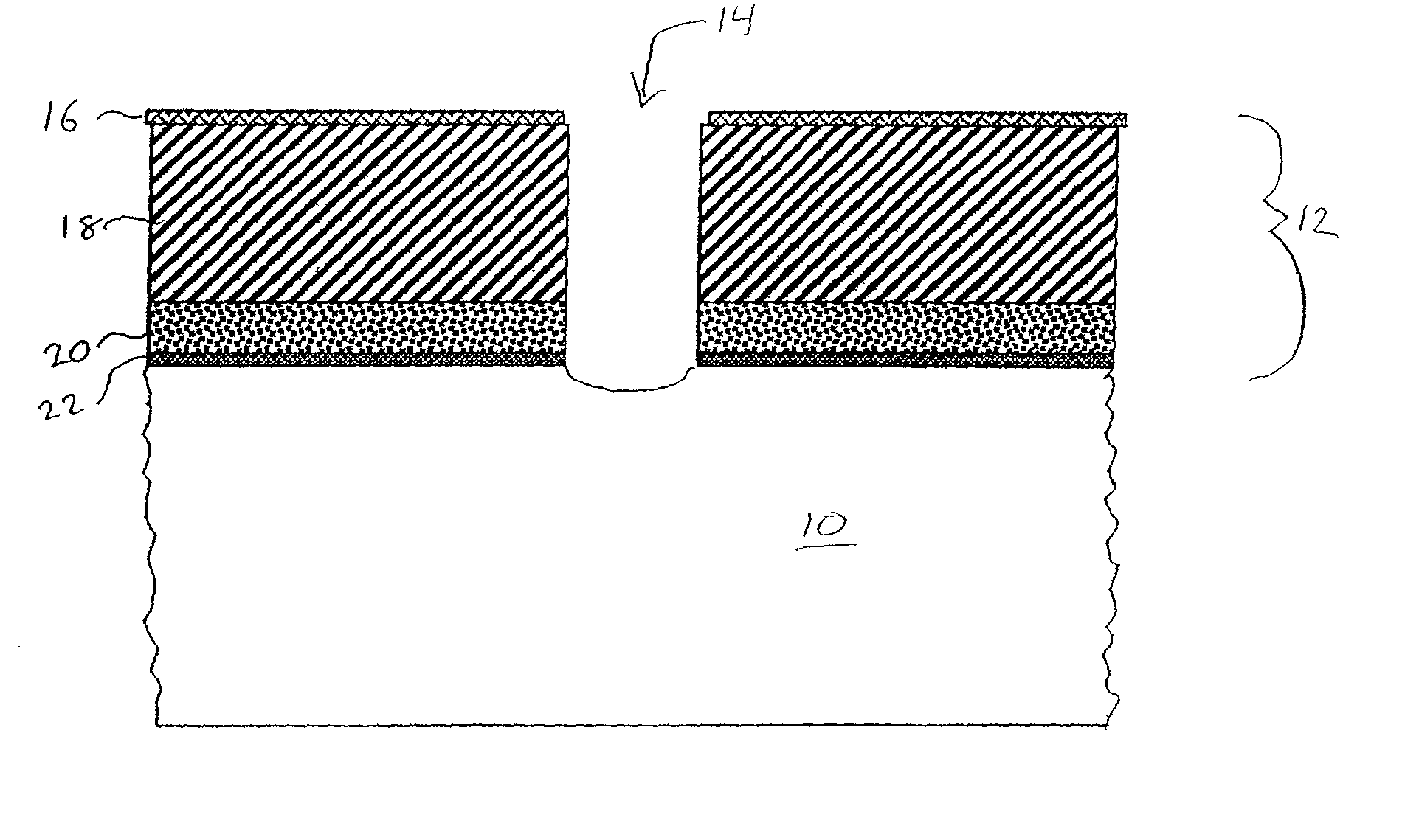

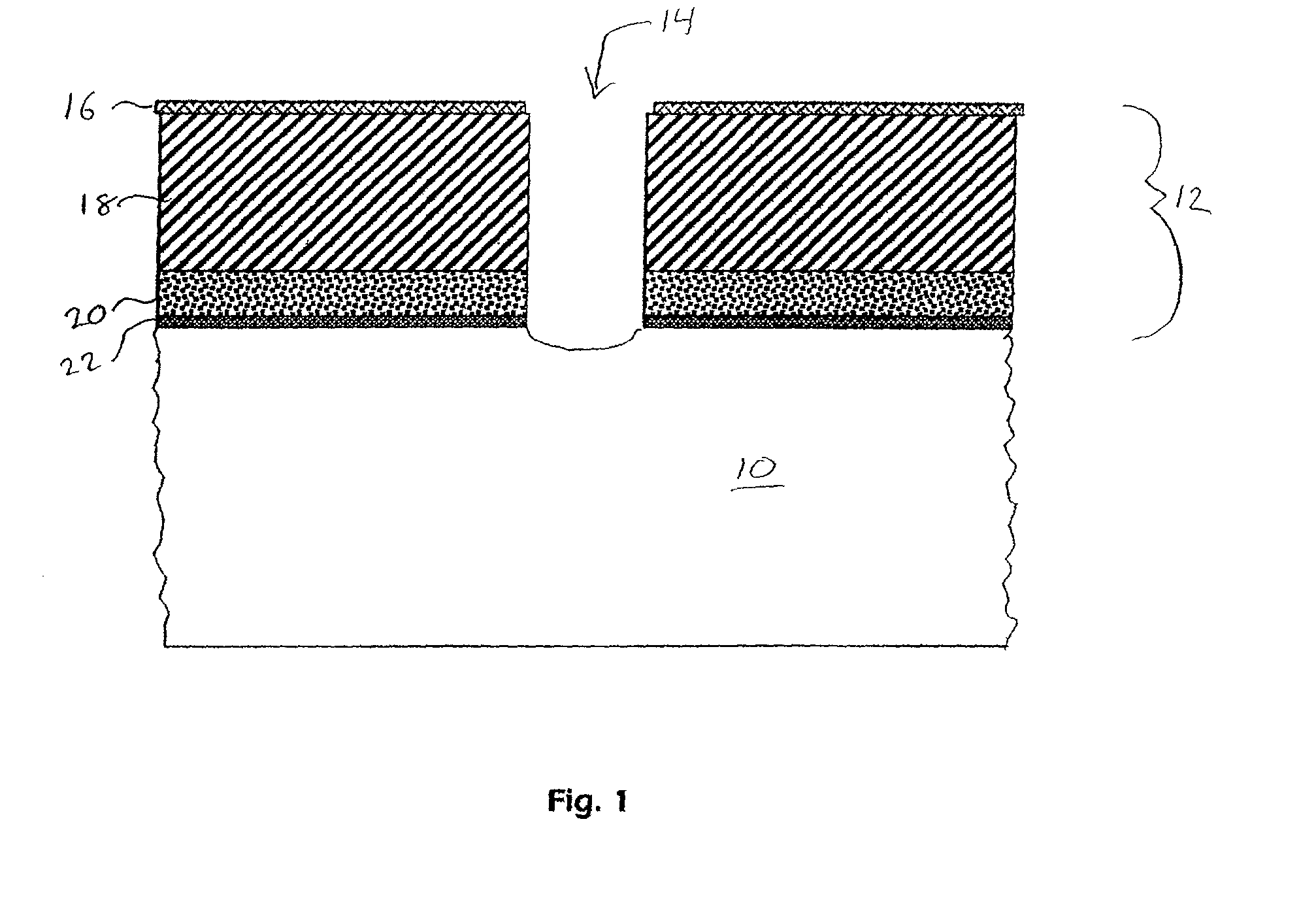

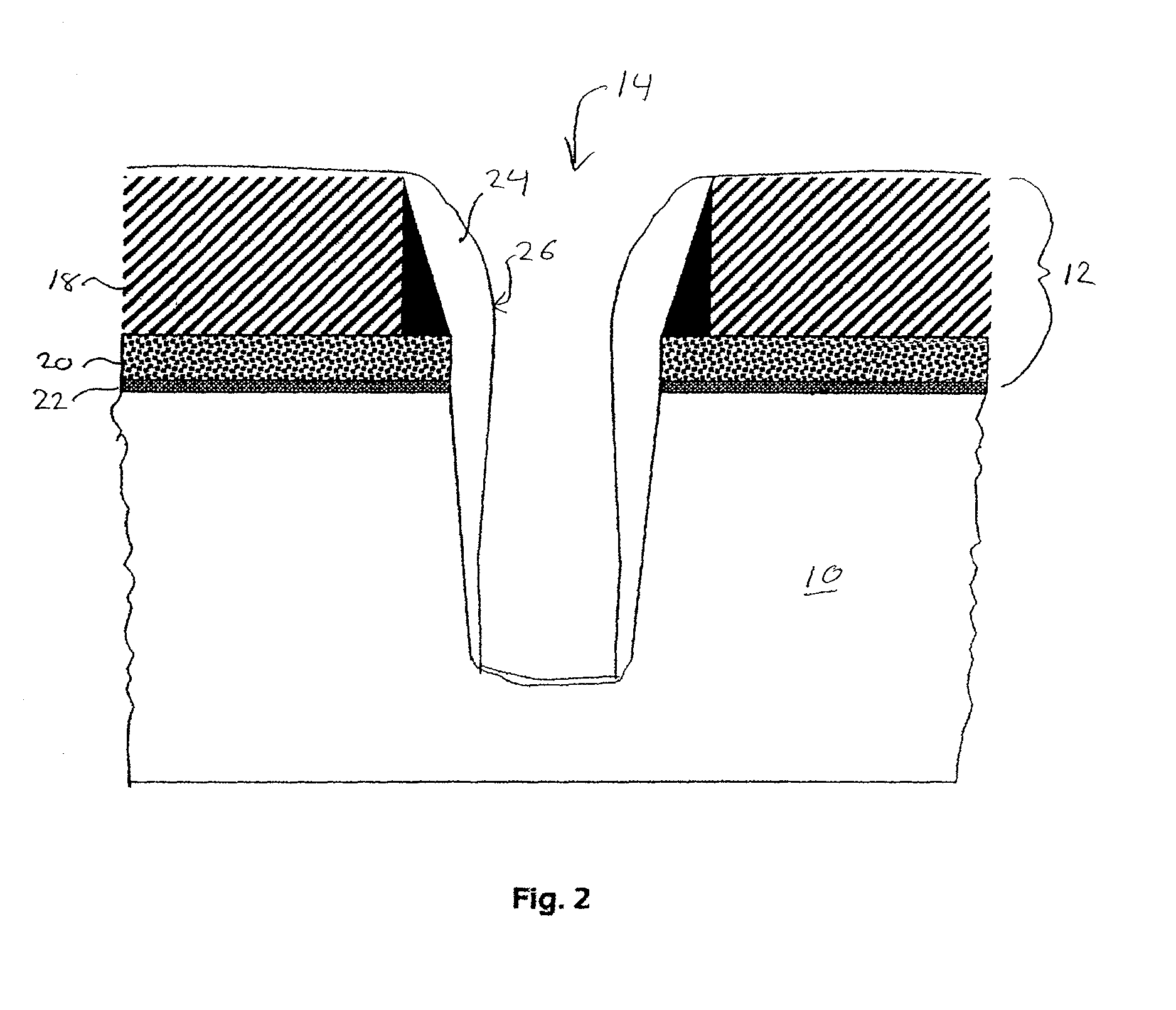

Method of etching high aspect ratio openings

InactiveUS20020179570A1High aspect ratioIncrease the wall areaDecorative surface effectsSemiconductor/solid-state device manufacturingSilanesThinning

A method of etching a deep, high aspect ratio opening in a silicon substrate includes etching the substrate with a first plasma formed using a first gaseous mixture including a bromine containing gas, an oxygen containing gas and a first fluorine containing gas. The etching process with the first gaseous mixture produces a sidewall passivating deposit, which builds up near the opening entrance. To reduce this buildup, and to increase the average etching rate, the sidewall passivating deposit is periodically thinned by forming a second plasma using a mixture containing silane and a second fluorine containing gas. The substrate remains in the same plasma reactor chamber during the entire process and the plasma is continuously maintained during the thinning step. Holes of a depth greater than 40 times the width may be produced using repeated cycles of etching and thinning.

Owner:INFINEON TECH AG +1

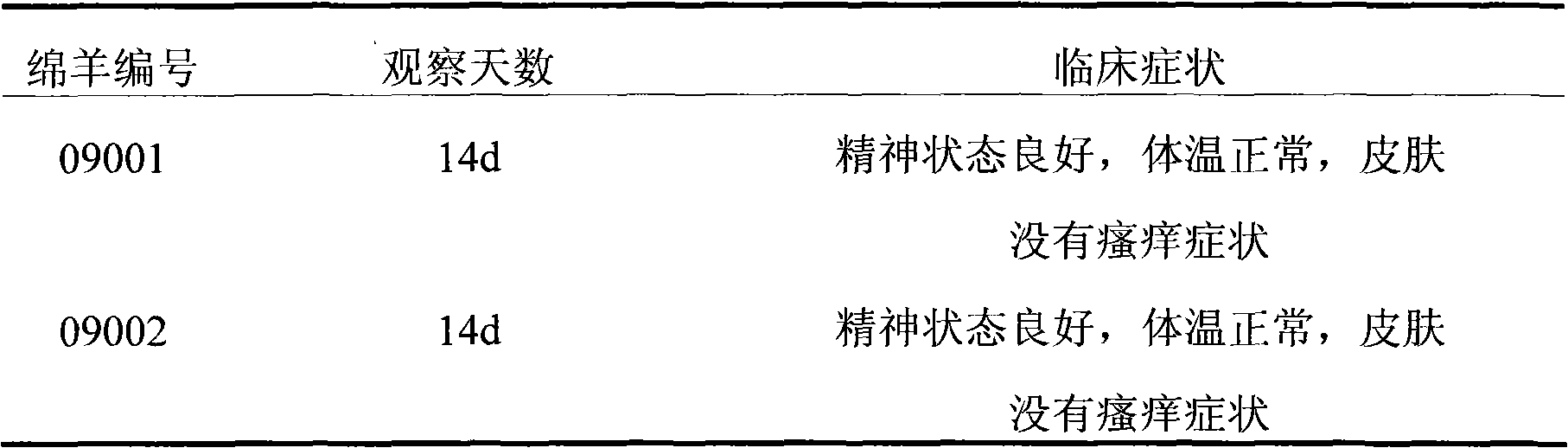

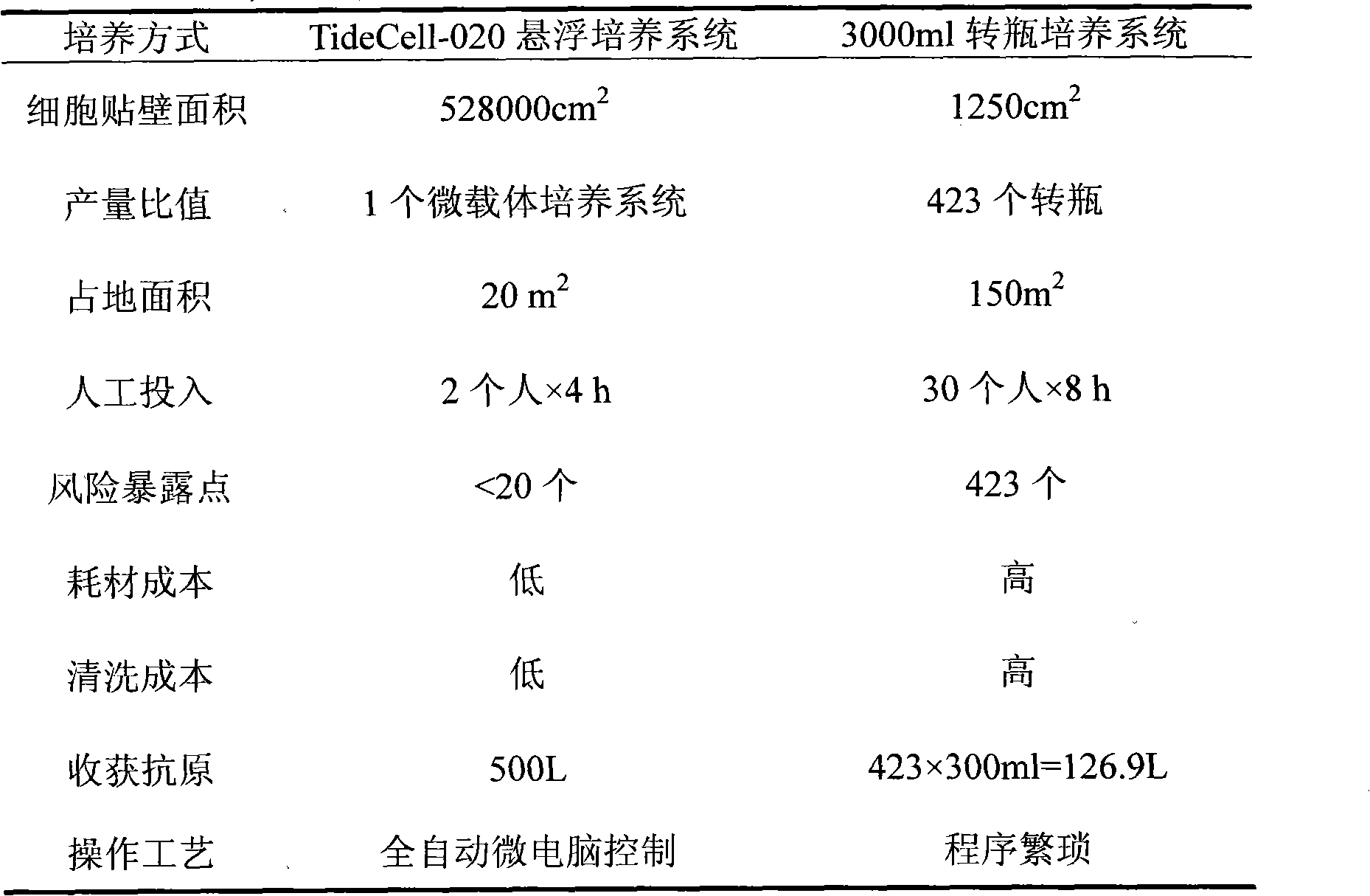

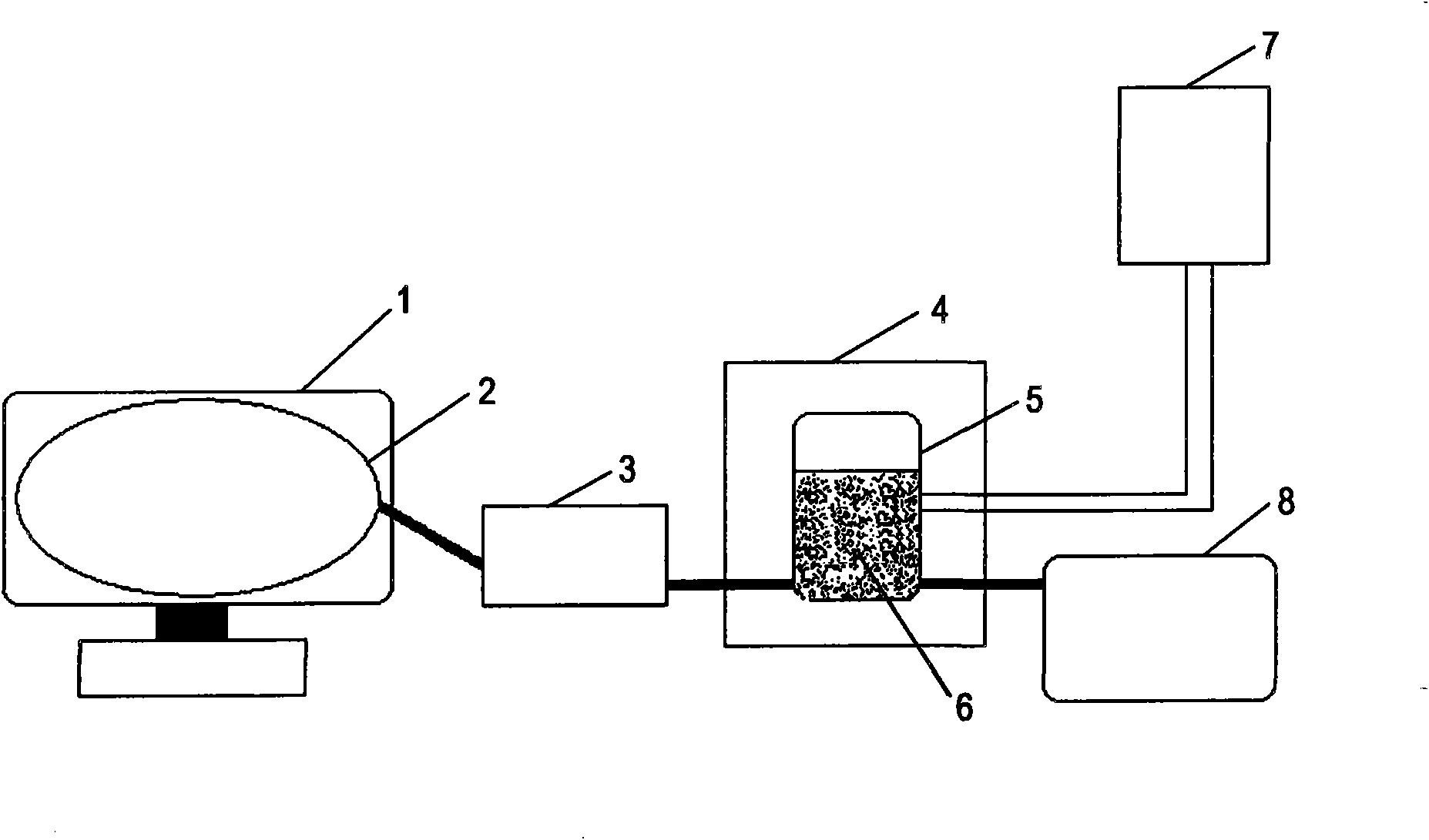

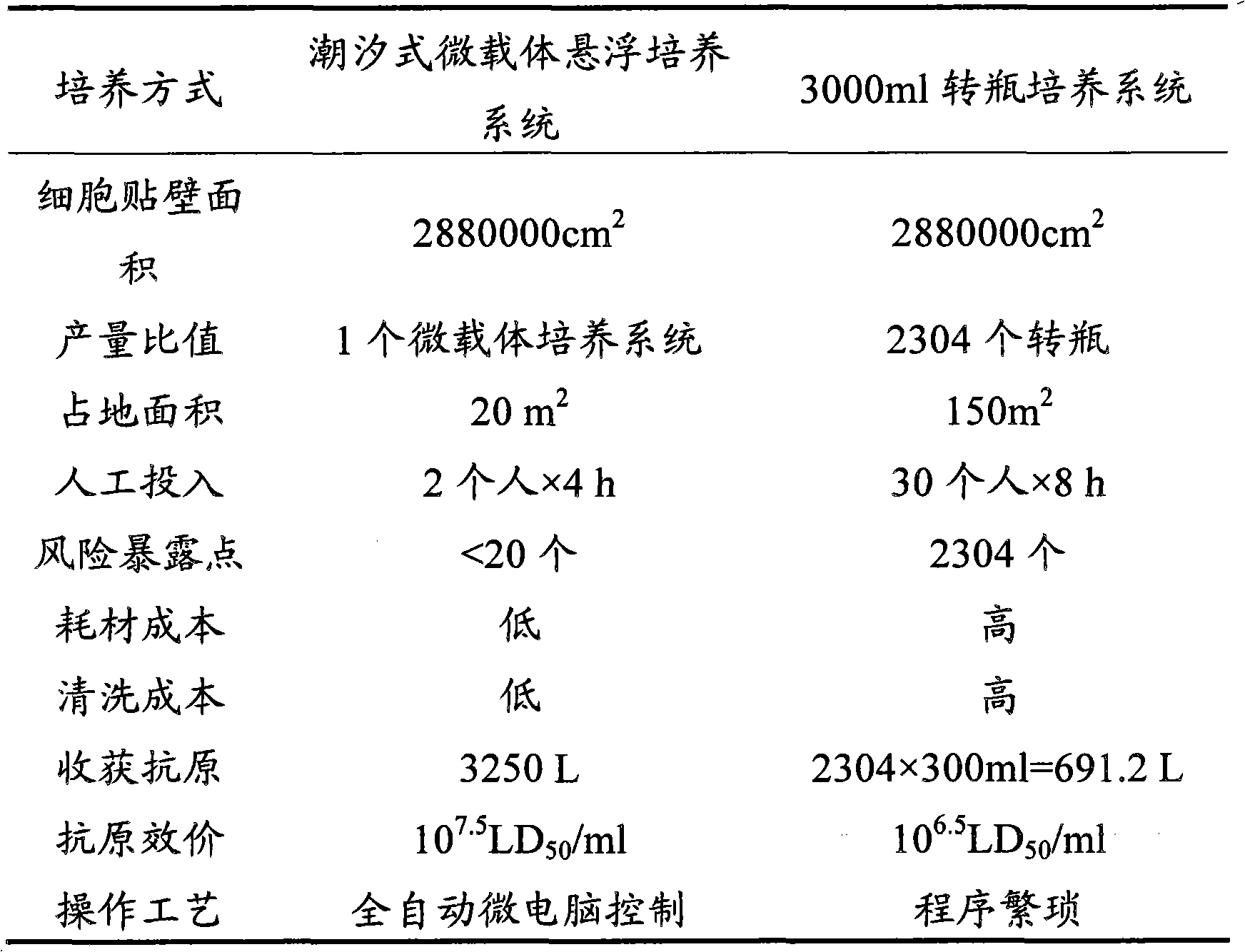

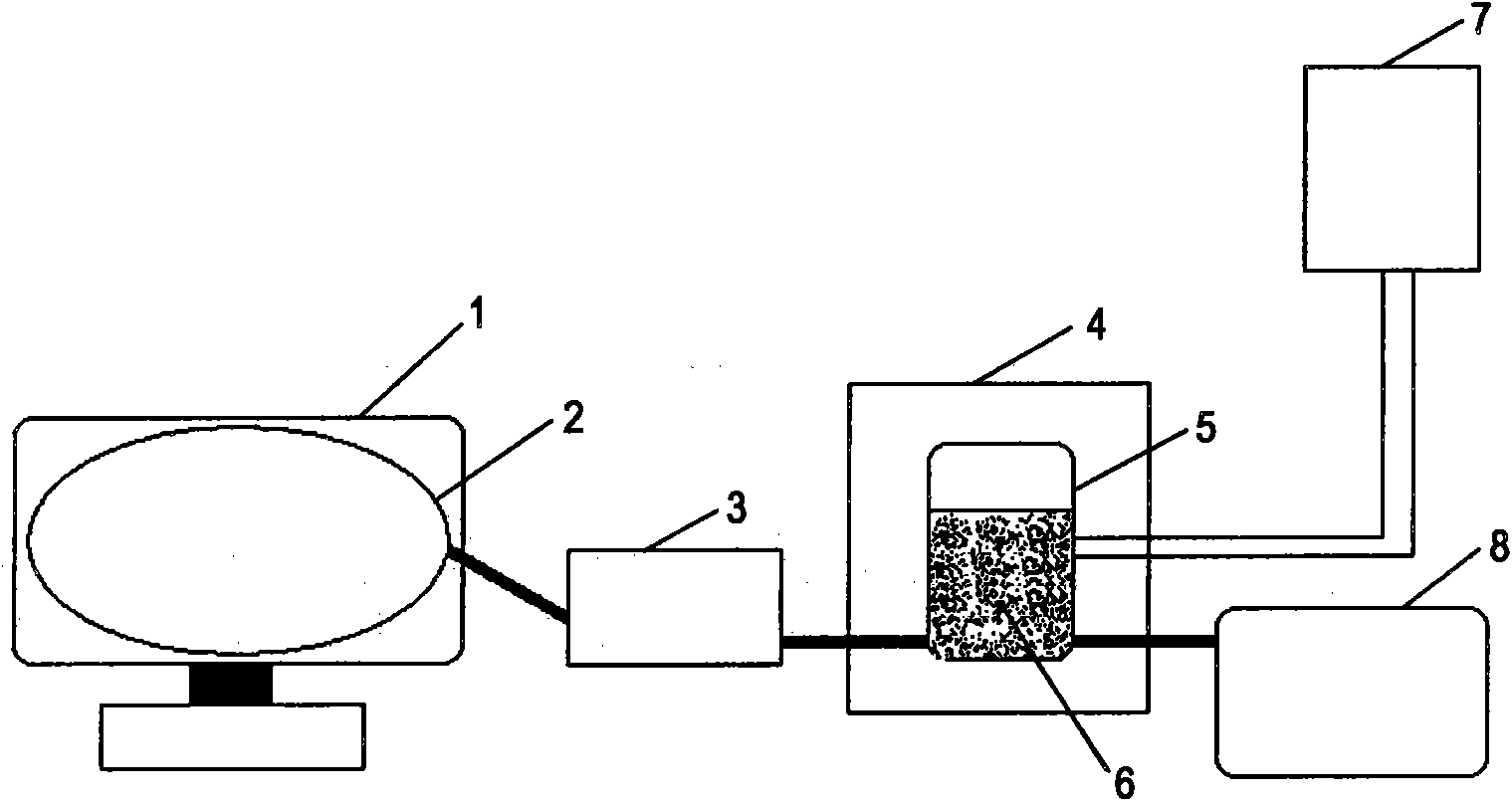

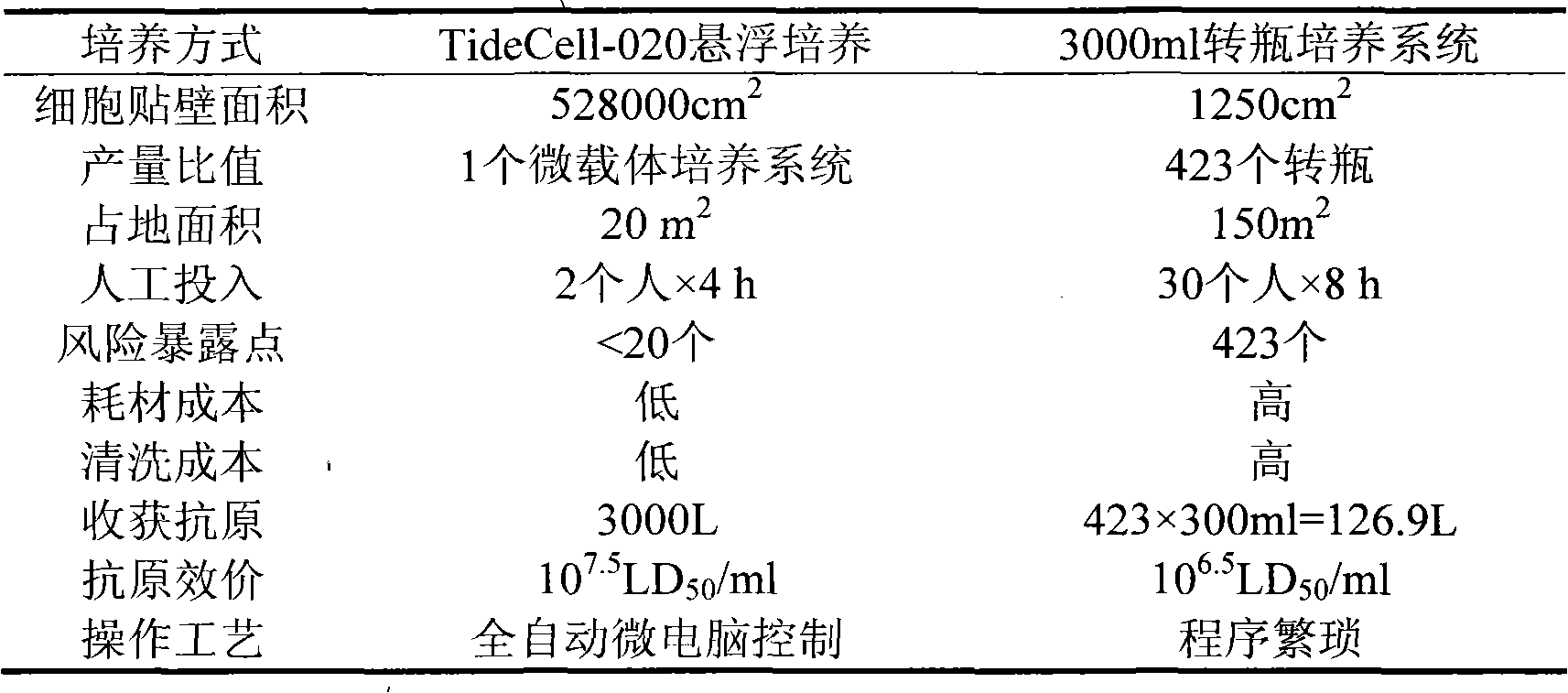

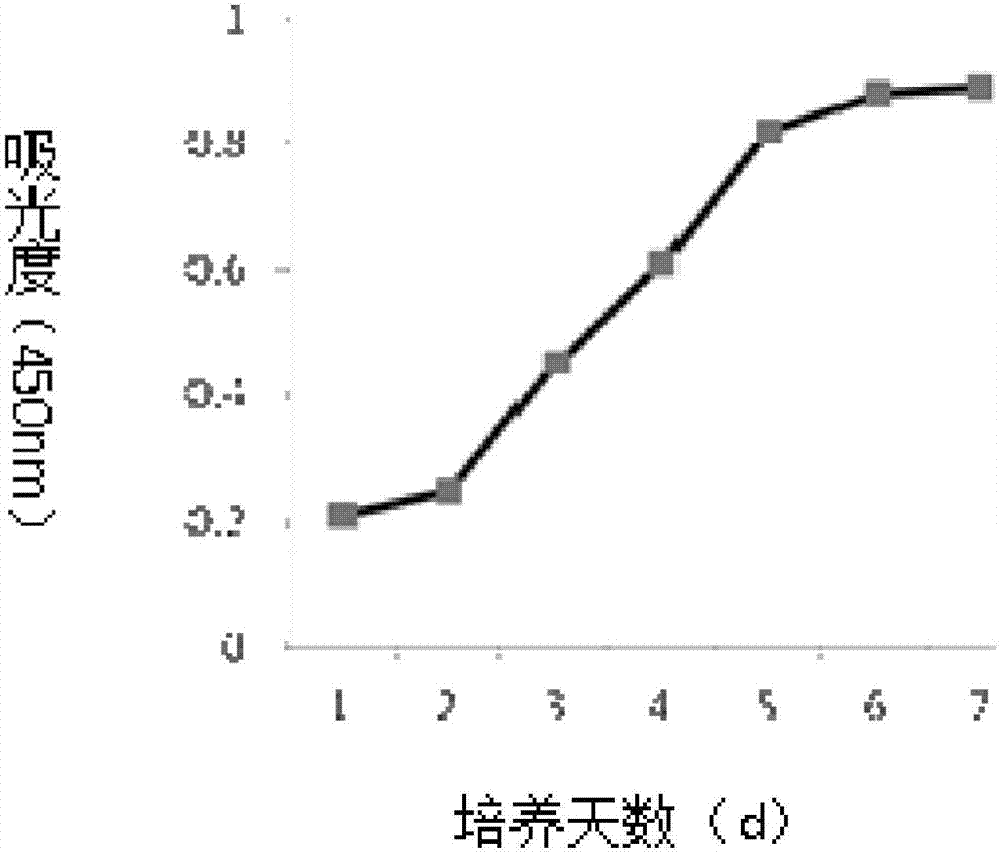

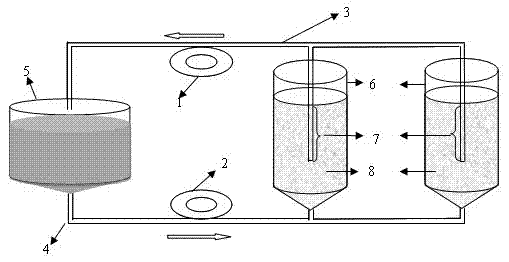

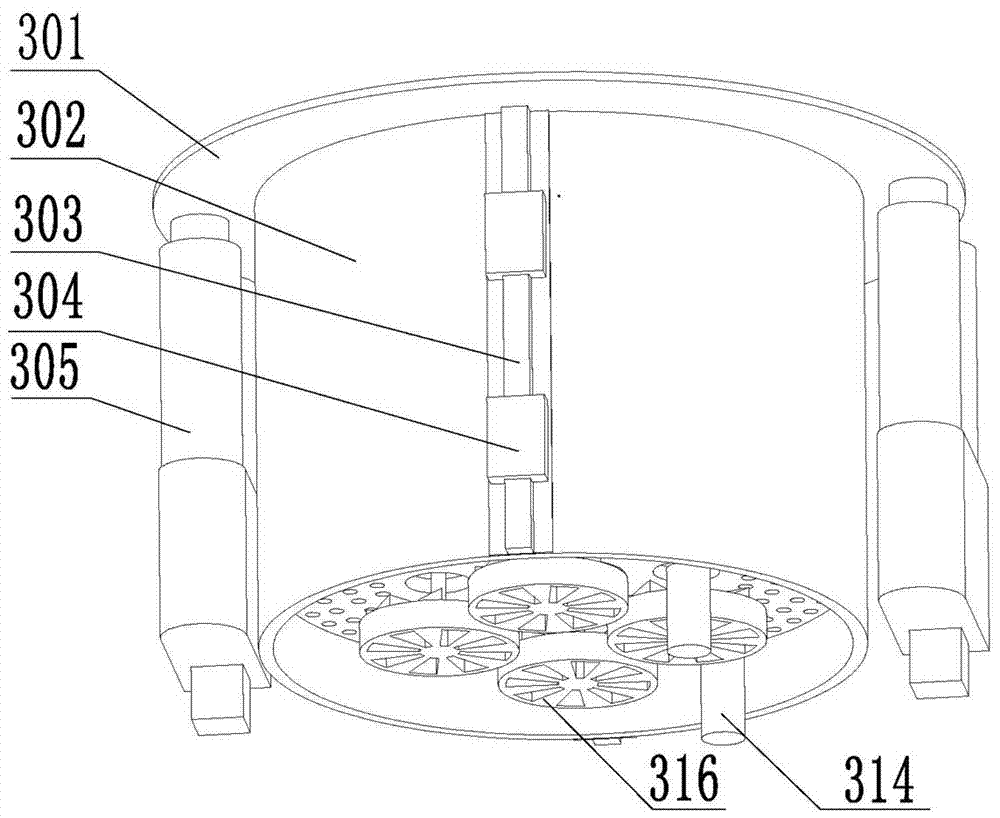

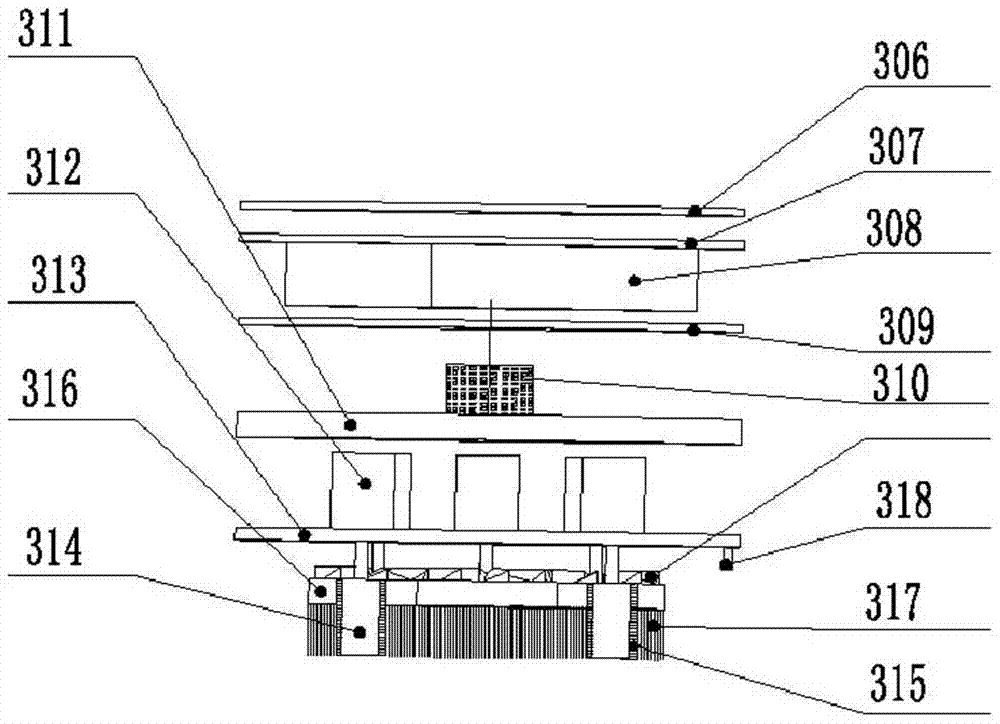

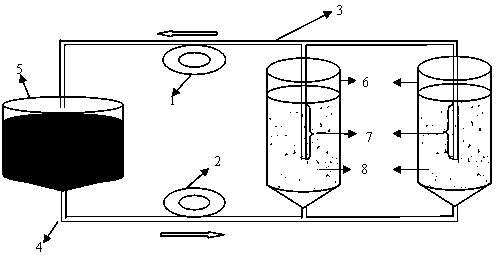

Method for mass production of pseudorabies virus vaccine

InactiveCN101804203ASolve the problems of low production output, high labor intensity and high costExpand production scaleAntiviralsTissue/virus culture apparatusFiberPolyester

The invention discloses a method for mass production of pseudorabies virus vaccine, comprising the following steps: (a) adding netty polyester fiber which serves as a carrier into a bioreactor provided with a tide type micro-carrier suspension culture system and inoculating cells for producing vaccine; (b) inoculating pseudorabies virus vaccine when the culture cell grows to a certain intensity, so that the cells are infected by the pseudorabies virus vaccine; (c) reproducing the virus in great numbers under appropriate conditions; (d) harvesting the virus when cytopathic rate reaches above 70%; (e) carrying out freeze thawing on the harvested virus for once or twice to lead the cells to completely come off and disperse and then adding freeze-drying protective agent, evenly mixing the mixture, packaging the mixture in fixed volume and freeze-drying.The method of the invention has the advantages of good stability, explicit process control indicators, good controllability, easy operation, large process scale and the like.

Owner:PU LIKE BIO ENG

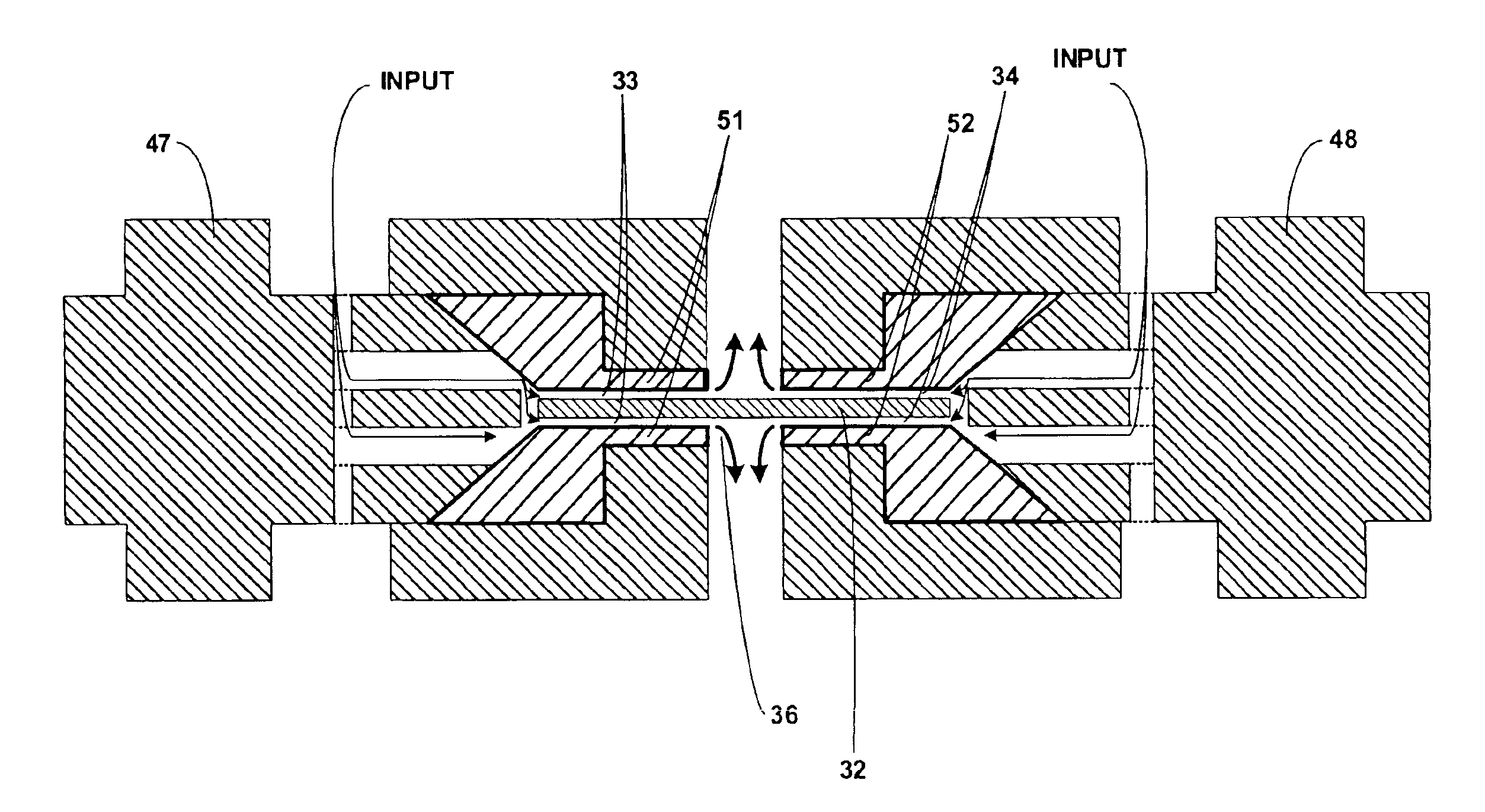

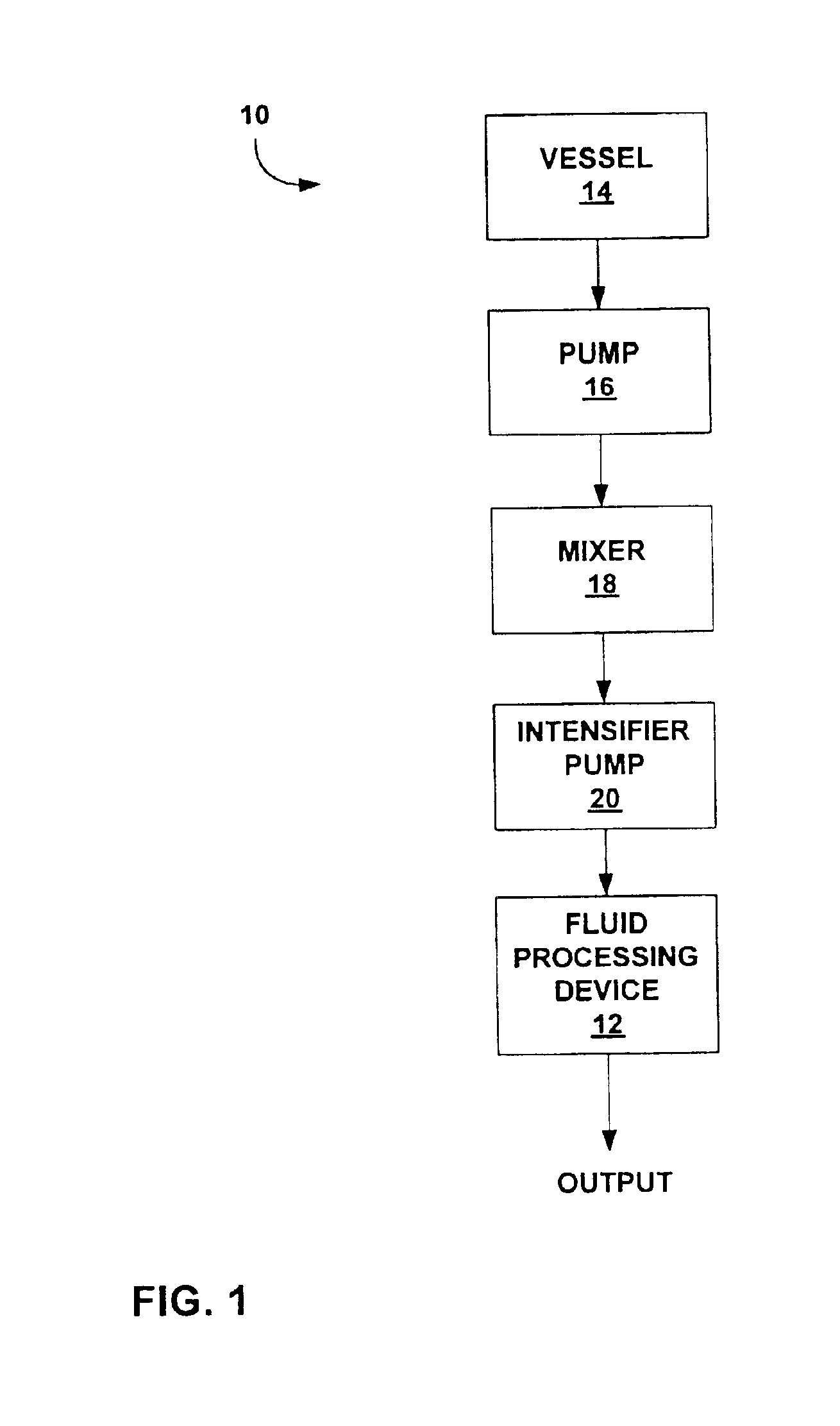

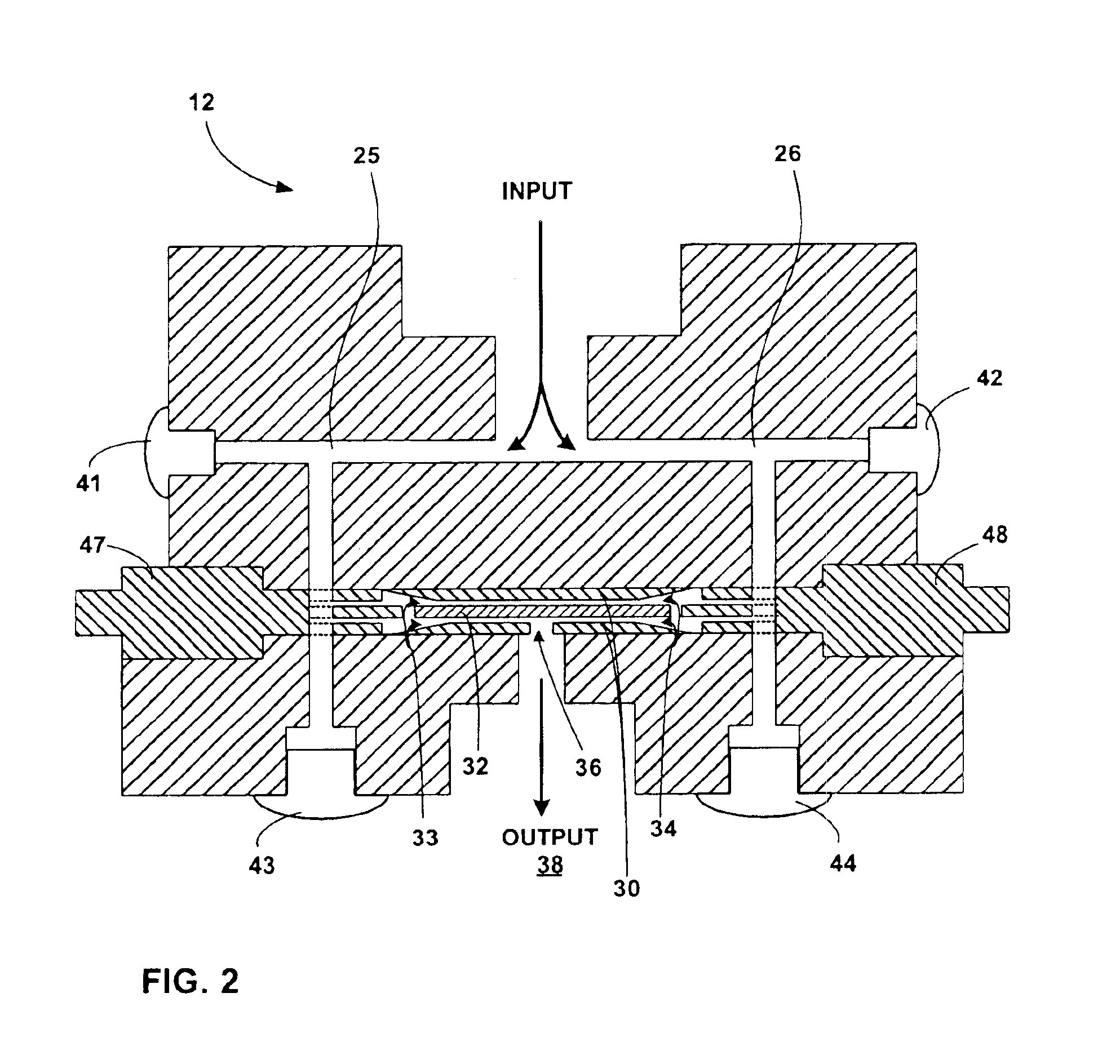

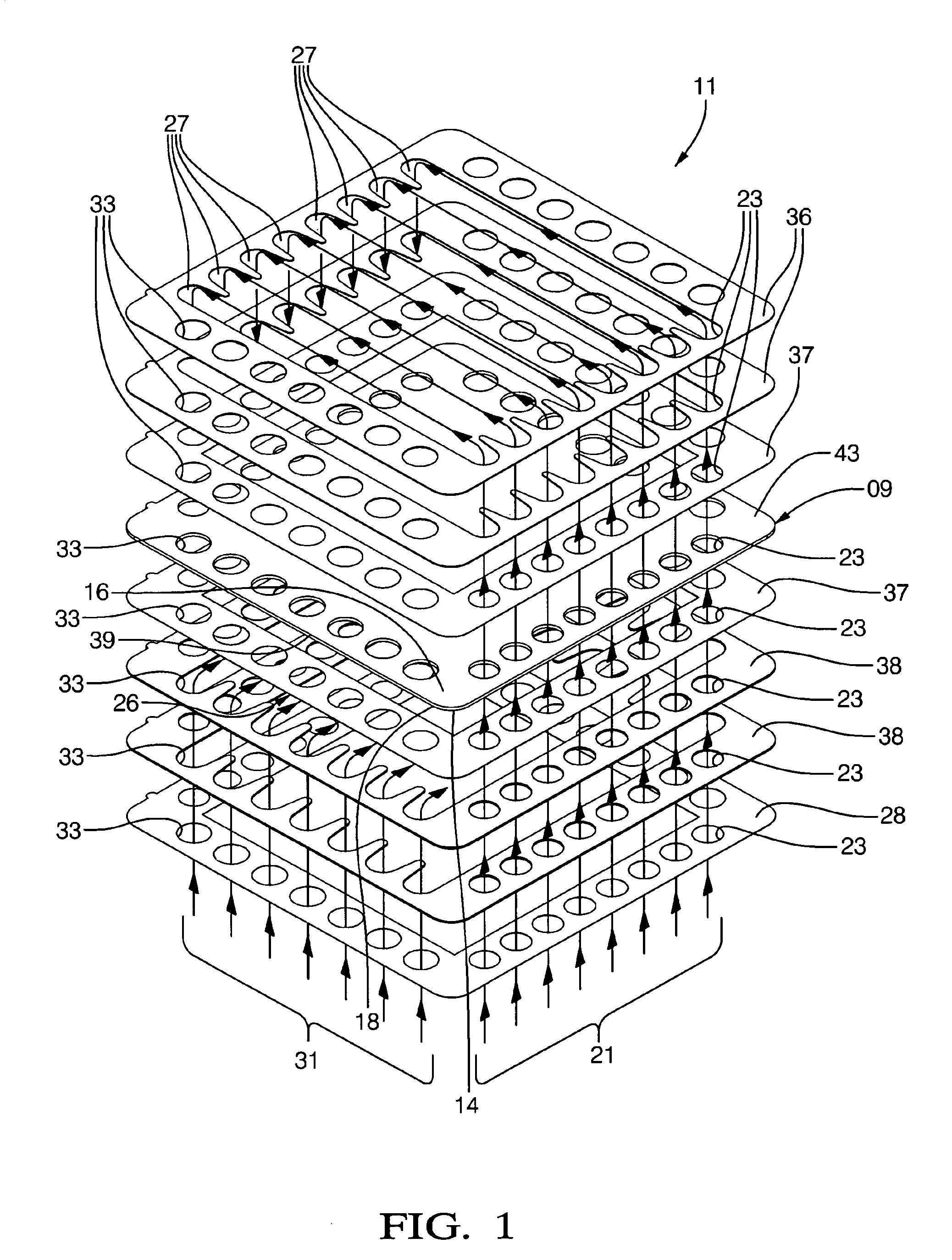

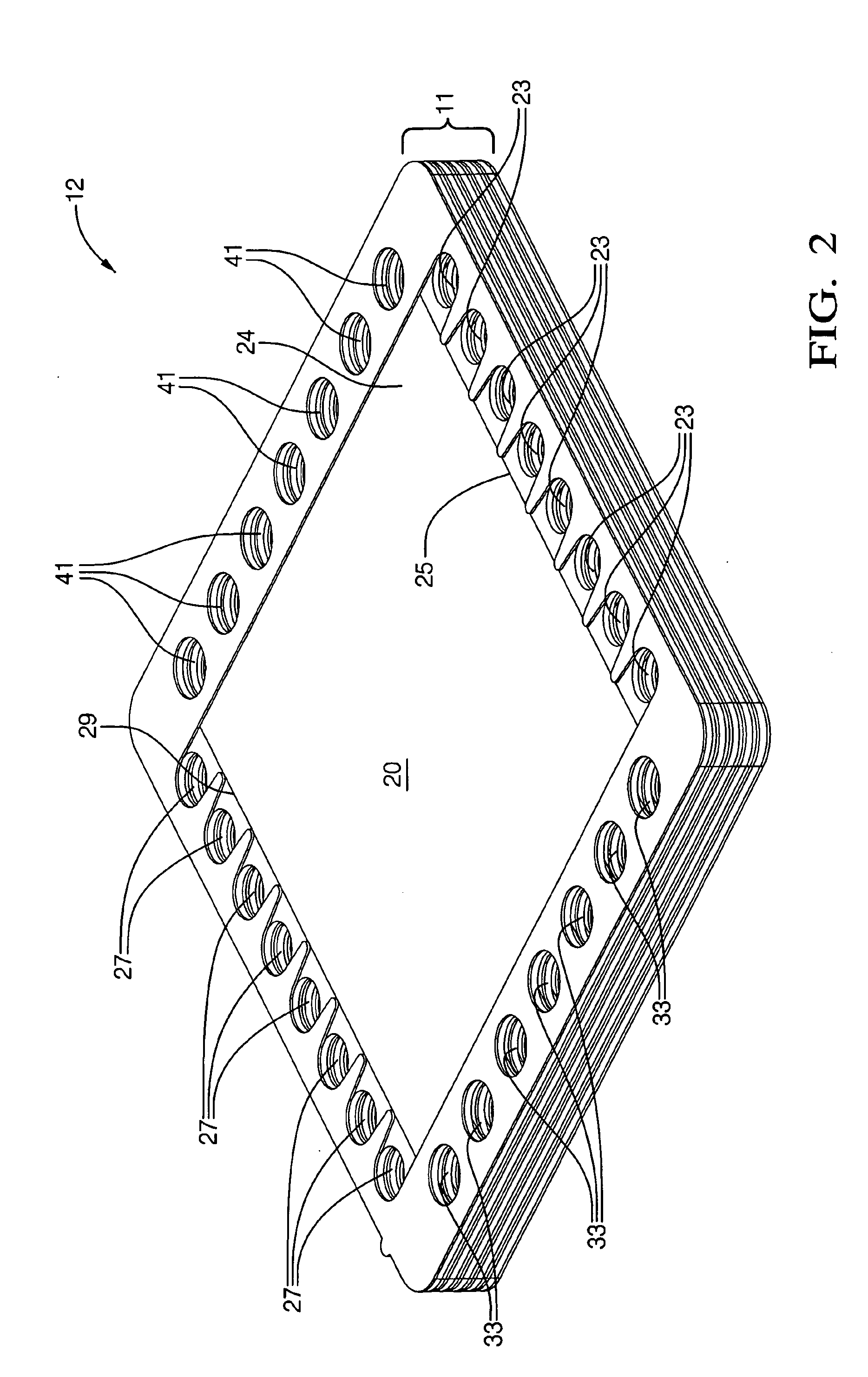

Fluid processing device with annular flow paths

InactiveUS6923213B2Restore balanceEasy for industrial productionShaking/oscillating/vibrating mixersFlow mixersEngineeringHigh pressure

The invention is directed to a high pressure fluid processing device for shearing particles in a fluid mixture. The fluid processing device makes use of annular flow paths. For example, a fluid mixture can be separated into two flow paths which are introduced to first and second annular flow paths on opposite sides of a flow path cylinder. The two annular flow paths flow toward one another through the cylinder, and meet one another within the cylinder. An outlet extends through the cylinder where the two annular flow paths collide allowing the fluid mixture flowing down the annular flow paths to be expelled through the gap.

Owner:IMATION

Animal rabies virus and vaccine and production method thereof

ActiveCN101979515AHigh infection efficiencyHigh titerInactivation/attenuationAntiviralsFreeze thawingAdjuvant

Owner:PULIKE BIOLOGICAL ENG INC

Virus and vaccine of porcine reproductive and respiratory syndrome and preparation method of same

ActiveCN101979514AHigh viral titerHigh poison priceViral antigen ingredientsAntiviralsFreeze-dryingCells/microL

The invention discloses a method for preparing virus of porcine reproductive and respiratory syndrome on a large scale. In the method, the virus of the porcine reproductive and respiratory syndrome is prepared in a cell microcarrier suspension culture system by a bioreactor. The method comprises the following steps of: inoculating host cells for preparing the virus to a carrier tank containing culture solution and a microcarrier, and mixing the cells and the microcarrier uniformly to ensure that the cells are attached to the microcarrier; providing sufficient nutrients and appropriate gas environment for the cells under the appropriate culture environment to ensure that the cells are grown until the cells are in an amount which are 10 to 20 times of the inoculation concentration on the microcarrier; preparing virus suspension from the virus of the porcine reproductive and respiratory syndrome by using cell maintenance culture solution to ensure that the suspension is adsorbed to the cells; culturing the virus under the appropriate culture environment; culturing continuously for 2 to 3 days to obtain virus solution; and after the virus solution passes inspection, performing freeze thawing on the virus solution twice at the temperature of -20 DEG C, and inactivating and purifying to prepare an inactivated vaccine of the porcine reproductive and respiratory syndrome or adding a freeze-drying protective agent for freeze drying to prepare a live vaccine of the porcine reproductive and respiratory syndrome. The method has large production scale, high yield of single batch and low production cost.

Owner:PU LIKE BIO ENG

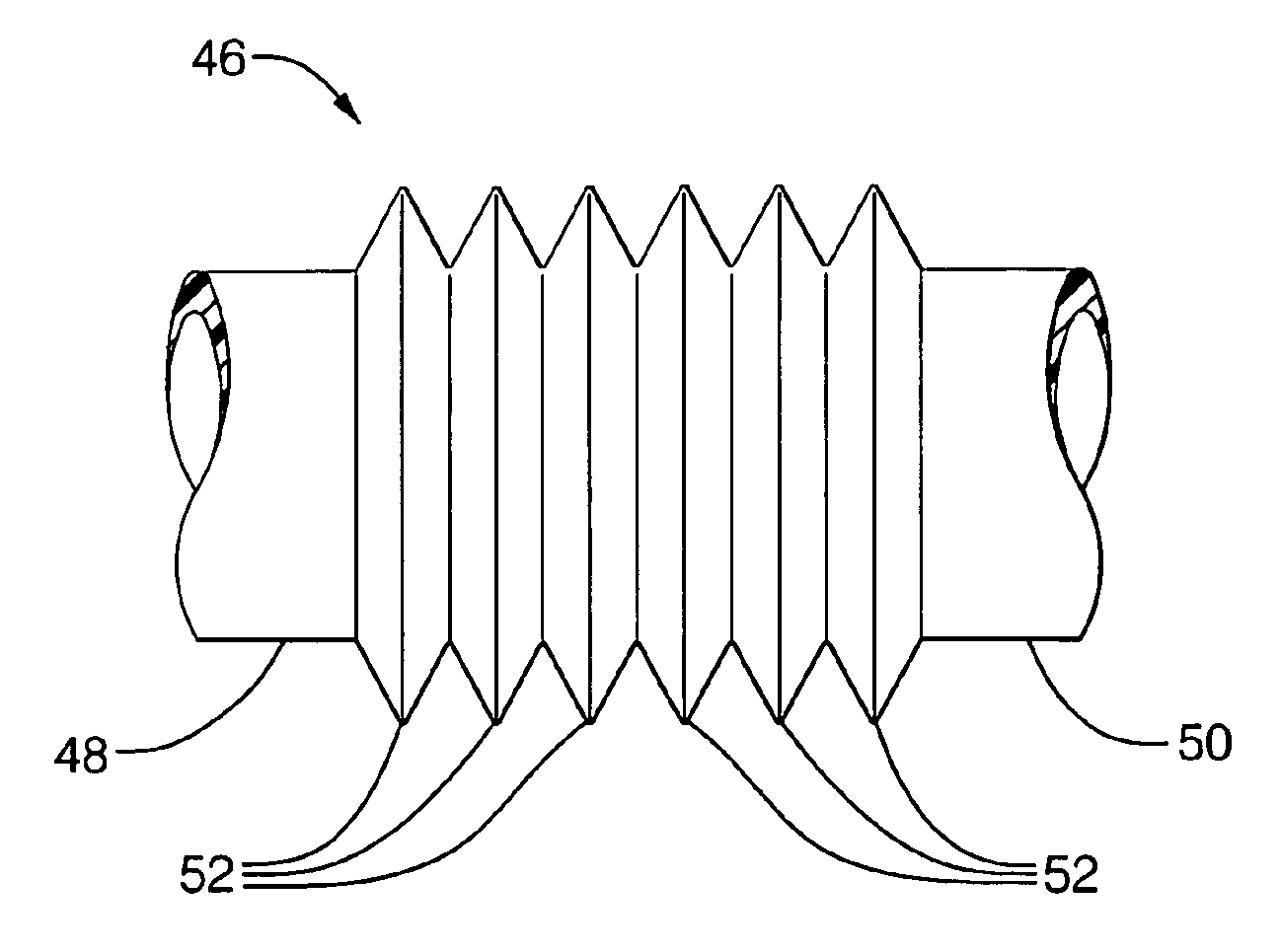

Thermal and vibrational break for high-temperature gas tubes in a solid-oxide fuel cell

InactiveUS7008715B2Increases in lifetimeImprove reliabilityAuxillary drivesFuel cell heat exchangeThermal isolationFuel cells

A fuel cell assembly or system including flexible metal bellows elements in one or more tubes intended for carrying hot gases during operation of the assembly. The bellows elements include a tubing element having plurality of annular corrugated folds. Thermal expansion and contraction of rigid tubes and of the non-tubular elements of the assembly can lead to buckling, cracking, and failure of the tubes and failure of the assembly or system. The flexible bellows elements, having relatively low axial and radial spring rates thus are able to absorb thermal and vibrational dimensional changes in the assembly. In addition, the corrugations provide significant resistance to axial heat flow and large radiant surface area, thus increasing thermal isolation where desired between relatively hot and relatively cold regions of the assembly.

Owner:BAYERISCHE MOTOREN WERKE AG +1

Method for producing rabies virus antigens for animals at a large scale

The invention discloses a method for producing rabies virus antigens for animals at a large scale, which produces the rabies virus antigens at a large scale by utilizing a bioreactor by a cell microcarrier suspension culture system. The method comprises the following steps: inoculating cells for preparing the antigens into a carrier tank containing a culture solution and microcarriers to enable the cells to be attached to the microcarriers; in a proper culture environment, enabling the cells to grow on the microcarriers until the quantity of the cells is 5-40 times more than inoculum density; making rabies viruses into a virus suspension, and enabling the virus suspension to be adsorbed on the cells; culturing the viruses in the proper culture environment by using a cell maintenance culture solution; continuously culturing for 3-5 days and then harvesting a virus solution for the first time, wherein a semicontinuous process is adopted and the ratio of a changed solution is 50 percent; continue culturing for 9-11 days, and harvesting the changed solution once every 24 hours; mixing the harvested virus solution with the virus solution of the bioreactor; and carrying out freeze thawing at the temperature of -20 DEG C and inactivation purification to obtain the rabies virus antigens. The method has large production scale, high single-scale yield and relatively low production cost.

Owner:PU LIKE BIO ENG

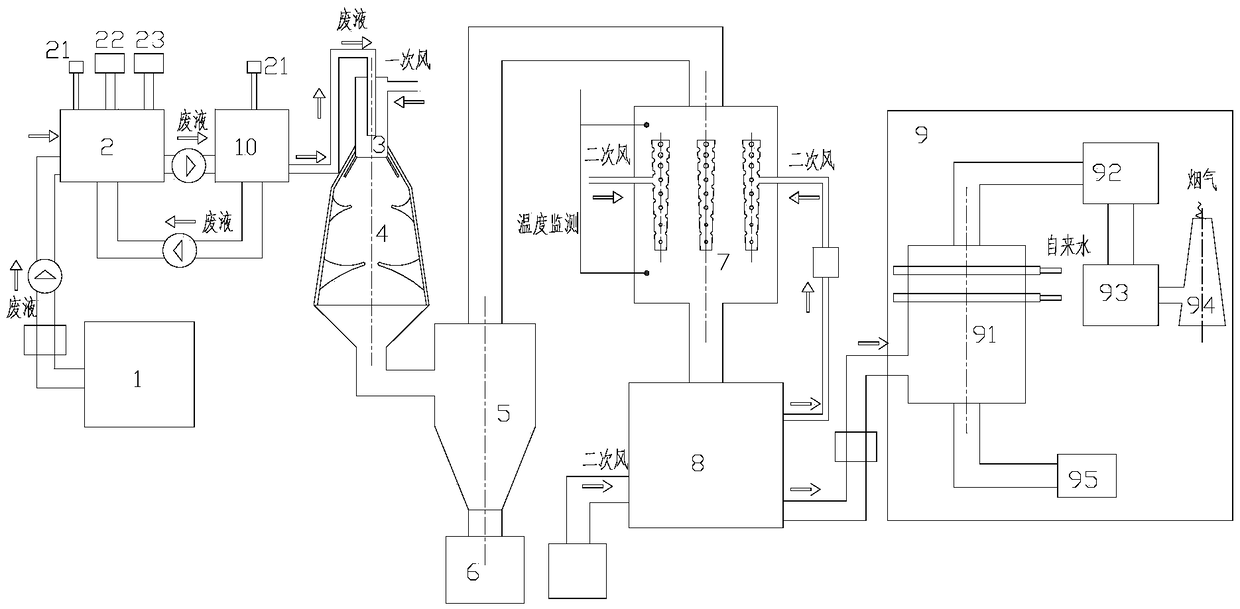

Centralized and real-time processing system for laboratory waste

InactiveCN108773962AExtended service lifeWell mixedSolid waste disposalDispersed particle separationLiquid wasteEvaporation

The invention relates to a centralized and real-time processing system for laboratory waste. A waste liquid neutralizing device is used for neutralizing waste liquid according to the monitored pH value of the waste liquid; a waste liquid caching device is connected with the waste liquid neutralizing device; a premixing device is connected with the waste liquid caching device, an atomizer is arranged on the premixing device, and a primary wind hole for introducing air is formed in the premixing device; a first-stage reaction device is used for carrying out evaporation and cleavage reaction on awaste gas-liquid-solid mixture conveyed from the premixing device; a micro-particle collection device is used for collecting solid micro-particles separated from the first-stage reaction device; other waste gas-liquid mixtures are collected into a second-stage reaction device from an outlet of the micro-particle collection device; a temperature monitoring point and a secondary wind pipe for introducing hot air are distributed on the second-stage reaction device; a signal end of the temperature monitoring point is connected with a control end of an adjusting valve of a secondary wind supply device; and a purifying device is used for purifying secondary-stage products separated from the second-stage reaction device. The centralized and real-time processing system is high in integration level, compact in structure, low in single amount processing cost of waste and high in processing efficiency.

Owner:上海即崇环保科技有限公司

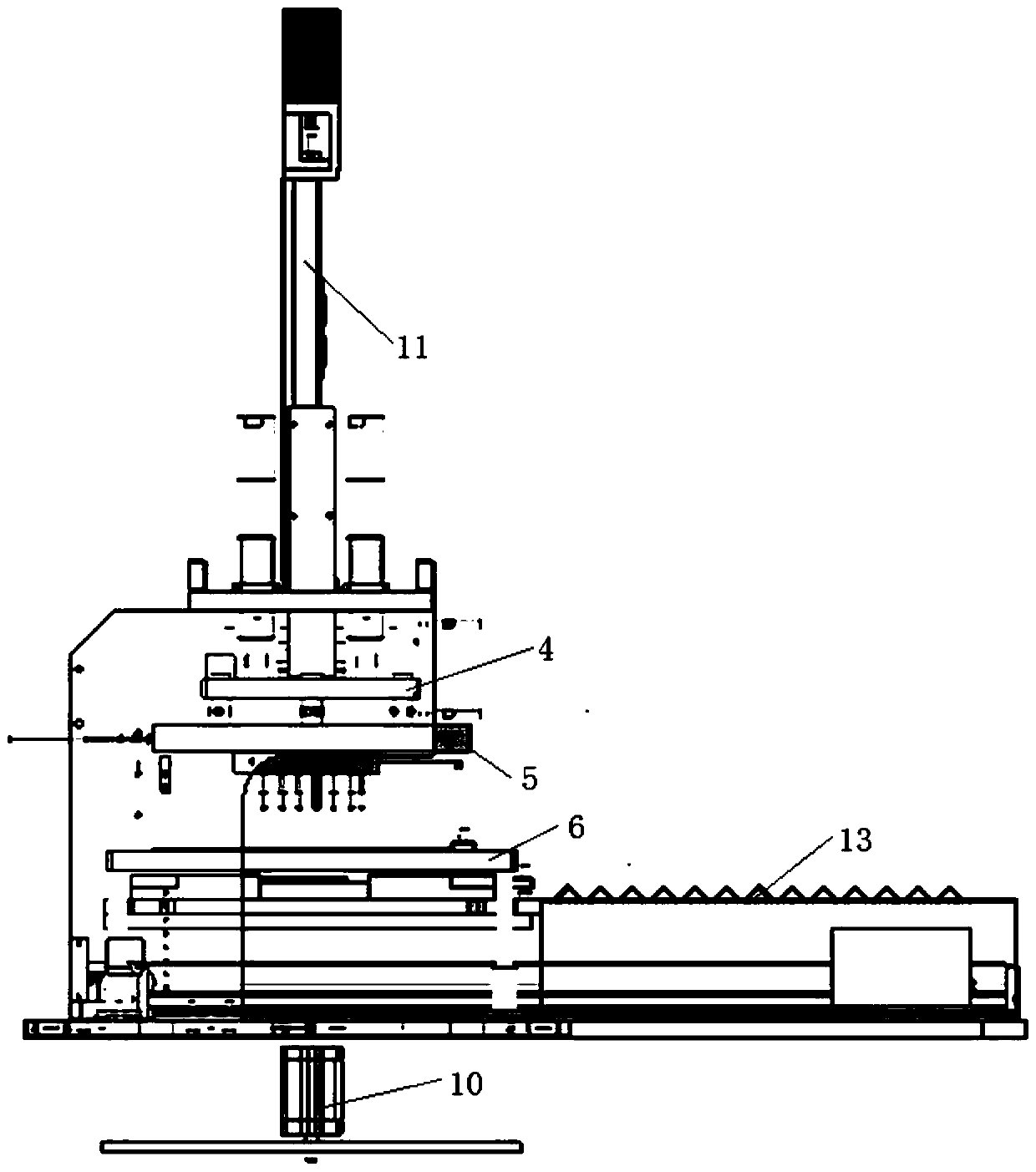

Brushing device applicable to corridor wall surfaces

InactiveCN107366419AQuality improvementEfficient mixingBuilding constructionsEngineeringBrush device

The invention discloses a painting device suitable for the wall surface of a corridor, which comprises a horizontal plate; a track frame is arranged above the horizontal plate; the track frame is provided with horizontal track grooves distributed up and down, and pulleys are nested in the track grooves. The pulley is rotatably connected to the moving frame through the connecting rod; the moving frame is rotatably connected to the brush roller; the left side of the brush roller is provided with a paint spray port. The present invention is provided with interlocking piston barrel, brush roller and paint spray port, so that the paint is evenly sprayed on the brush roller, the effect of roller coating is good, the paint is saved at the same time, and the quality of paint painting is improved; The mixing barrel of the material barrel can efficiently stir and mix the paint, making the paint even and fine, convenient for suction and spraying, and improving the spraying quality of the paint; the invention is provided with triangular wheels and abutting plates, so that the device can be better Climbing steps and fixings increase the mobility of the unit, which in turn increases the efficiency of painting.

Owner:李小婷

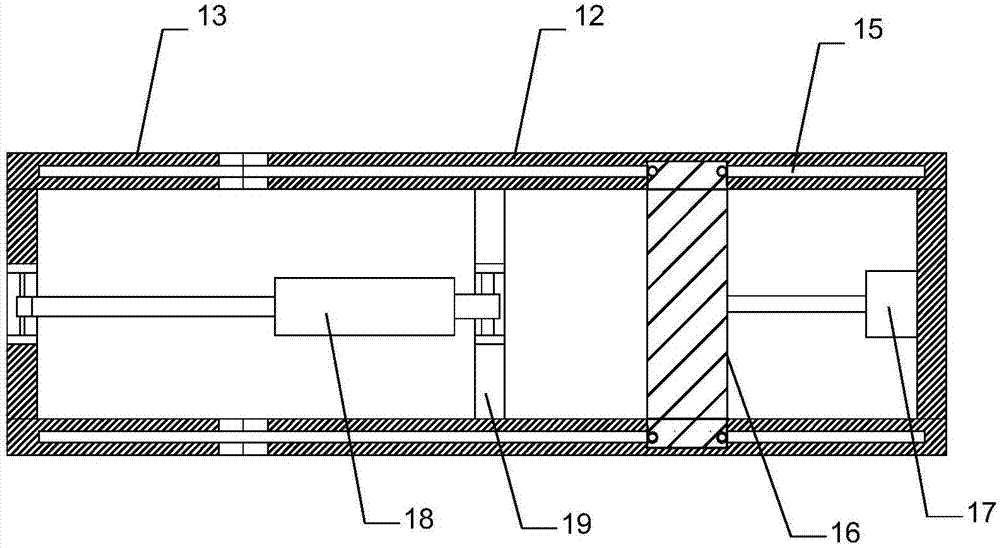

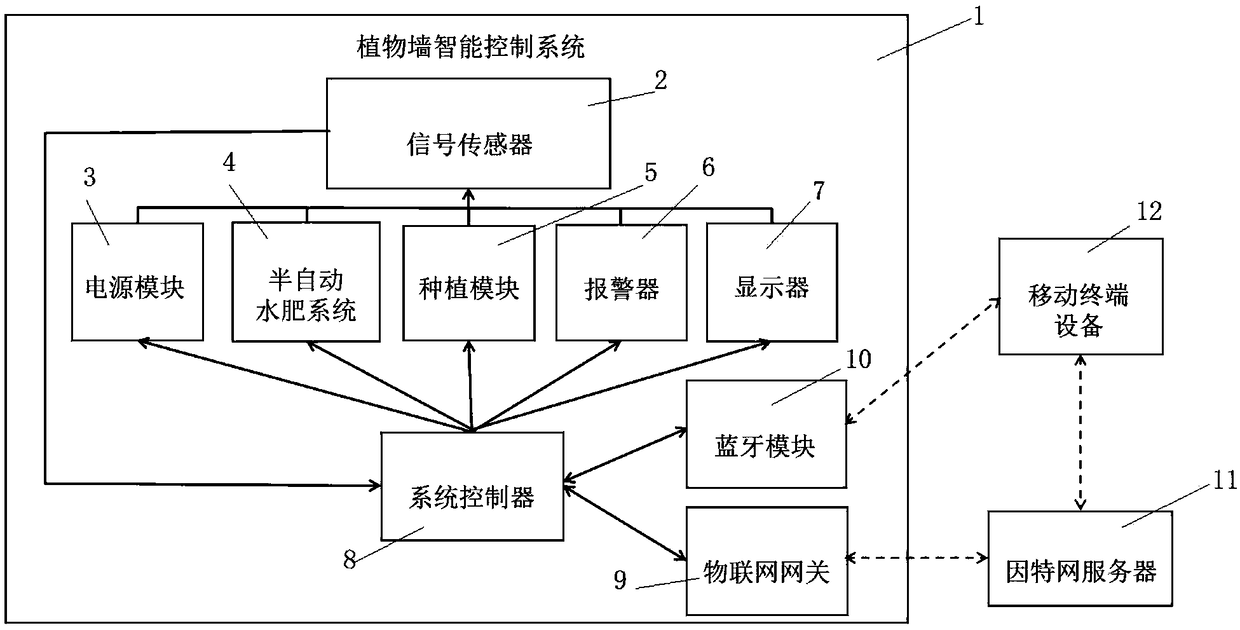

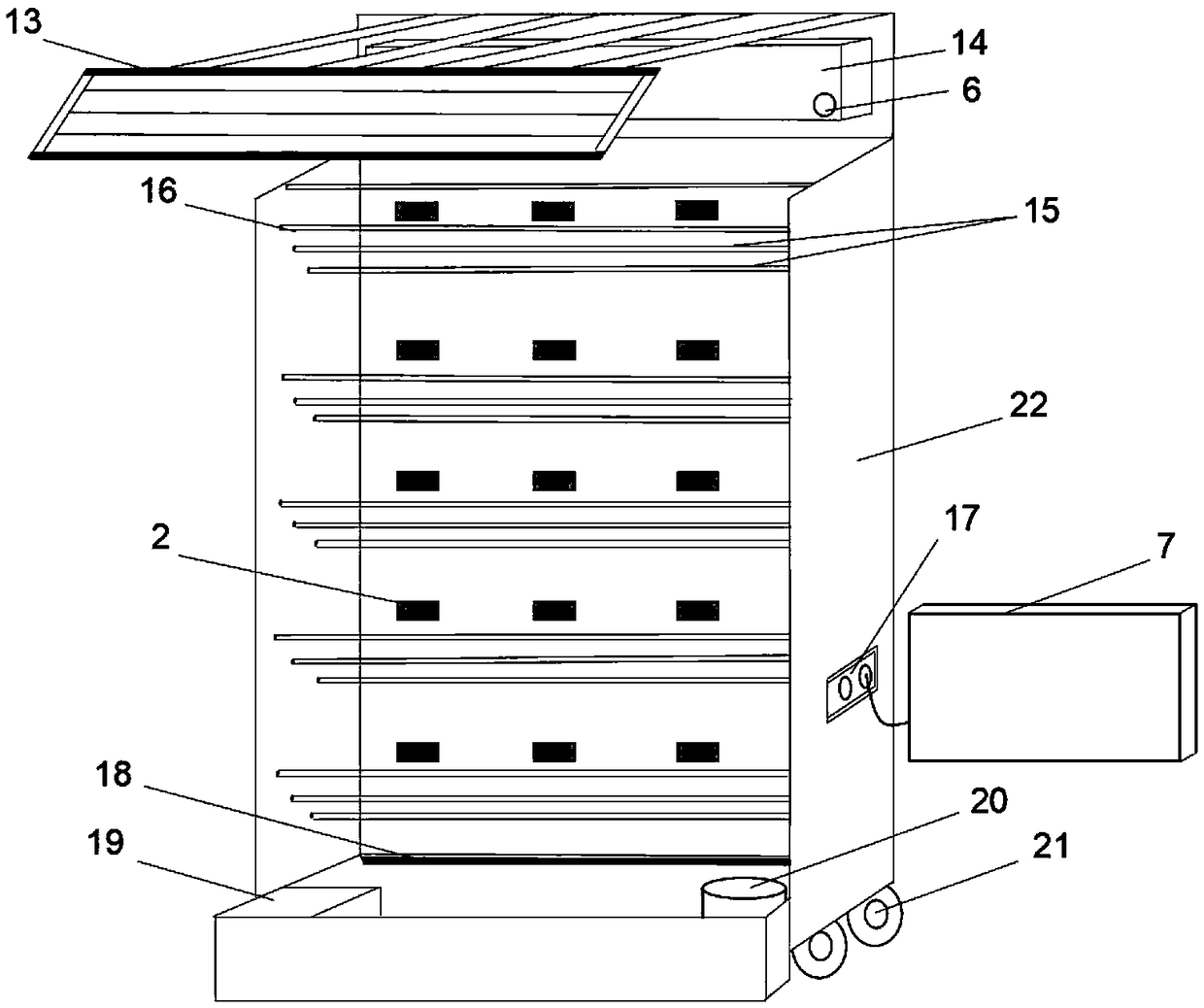

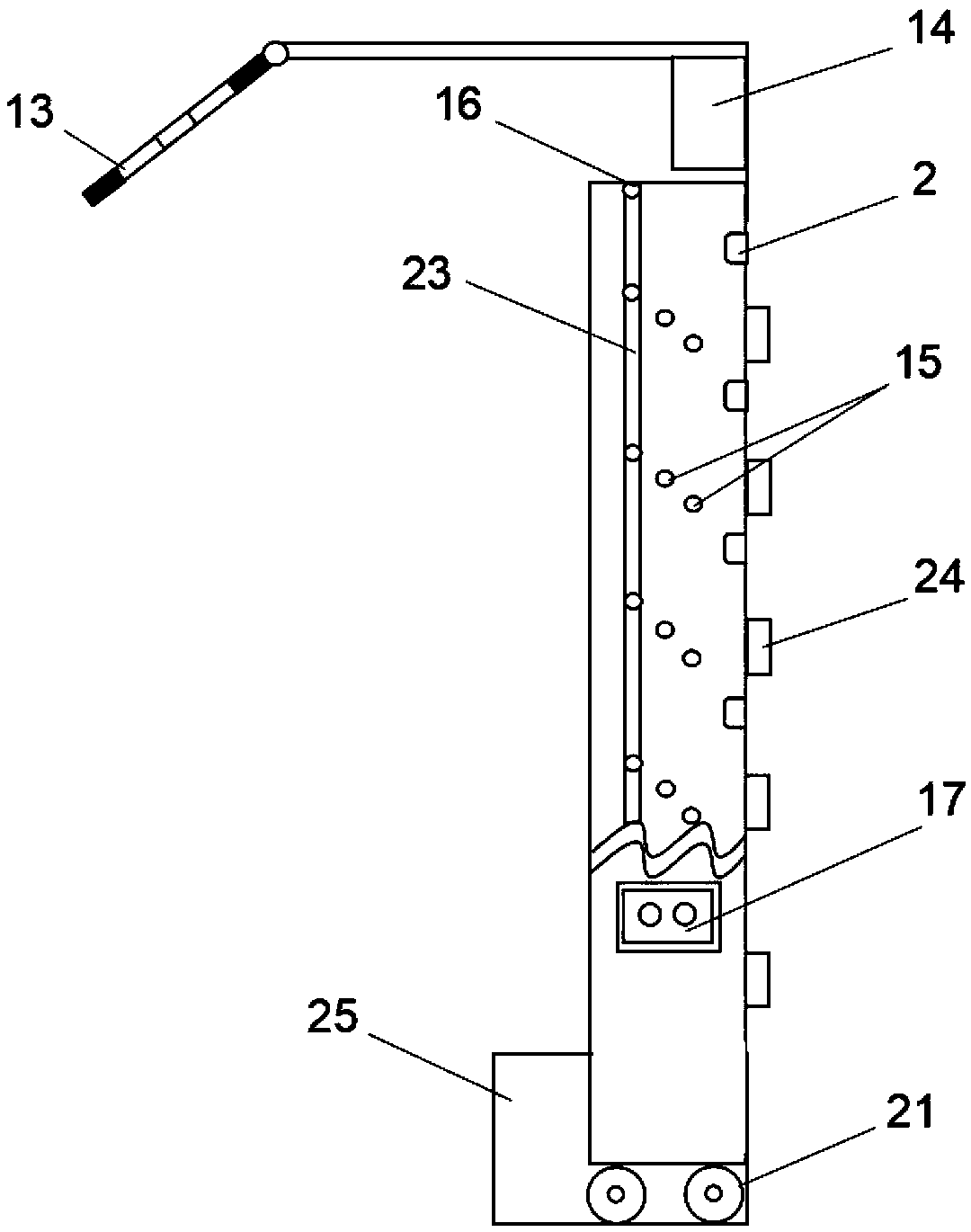

Simple mobile intelligent illumination plant wall device based on internet of things and control method

ActiveCN108925283AGreen smartSave water and electricitySelf-acting watering devicesCultivating equipmentsSemi automaticDisplay device

The invention belongs to the technical field of intelligent internet-of-things plant walls, and discloses a simple mobile intelligent illumination plant wall device based on internet of things, and acontrol method. After relevant information of a power supply module, a semi-automatic water and fertilizer system and a planting module is acquired by signal sensors which are uniformly distributed ina plant wall support frame, a system controller processes the data, and the working stage of a fan, a water tank and an intelligent illumination module is displayed on a display and controlled. Whenthe humidity and temperature are not normal, an alarm gives out sound, a flashing lamp is turned on to give an alarm, and alarm signals are transmitted to a mobile terminal device through a bluetoothmodule or an internet of things gateway. The invention provides the novel intelligent plant wall capable of remotely acquiring the plant wall information at any time and any place and controlling theworking state of the plant wall. Wall bodies with different sizes can be formed by splicing, the whole system is designed by adopting modularization, and the plant wall device is quite convenient to mount and dismount. In addition, the plant wall can be also moved, so that indoor placement and layout are convenient.

Owner:HUAZHONG UNIV OF SCI & TECH

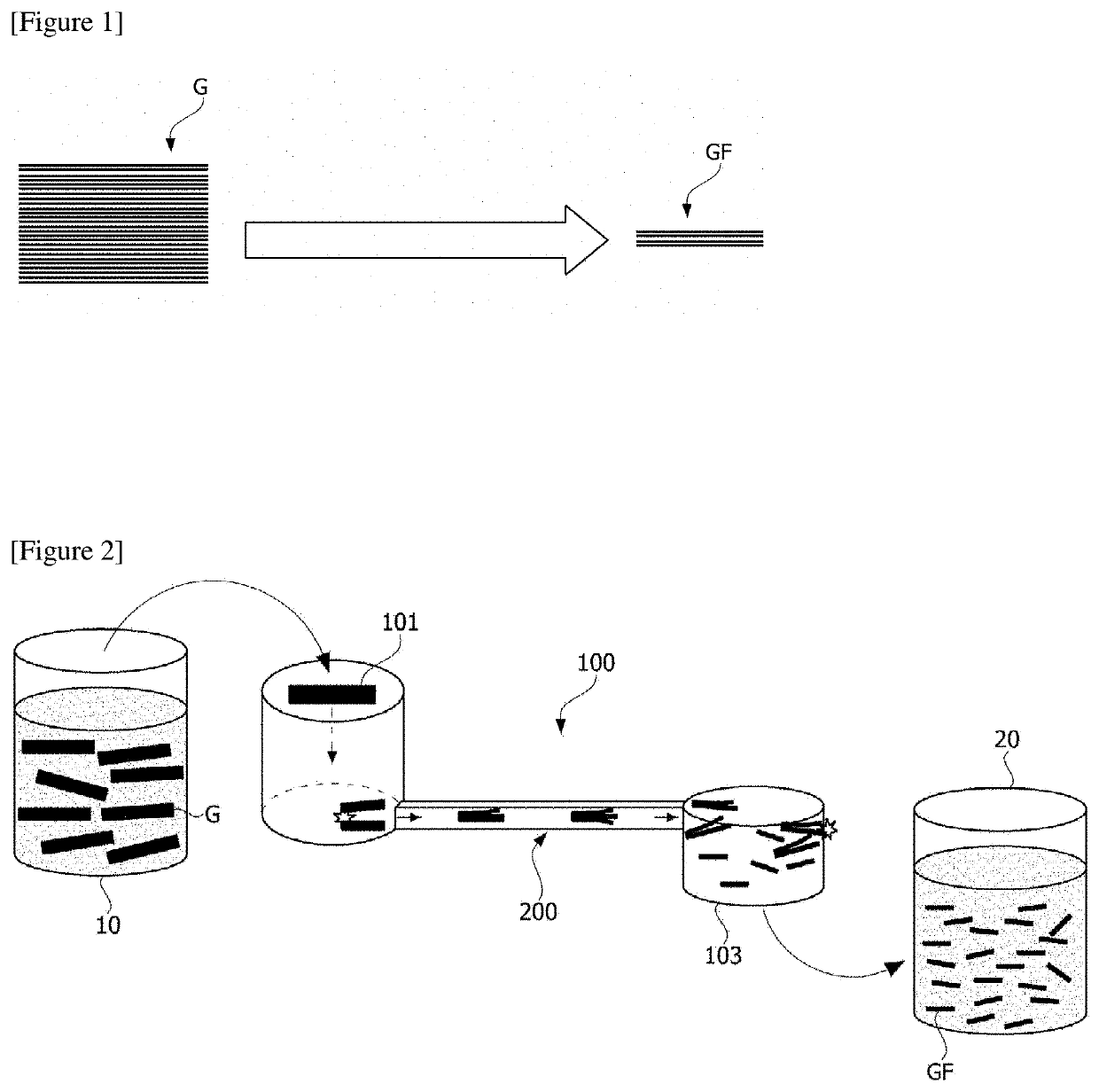

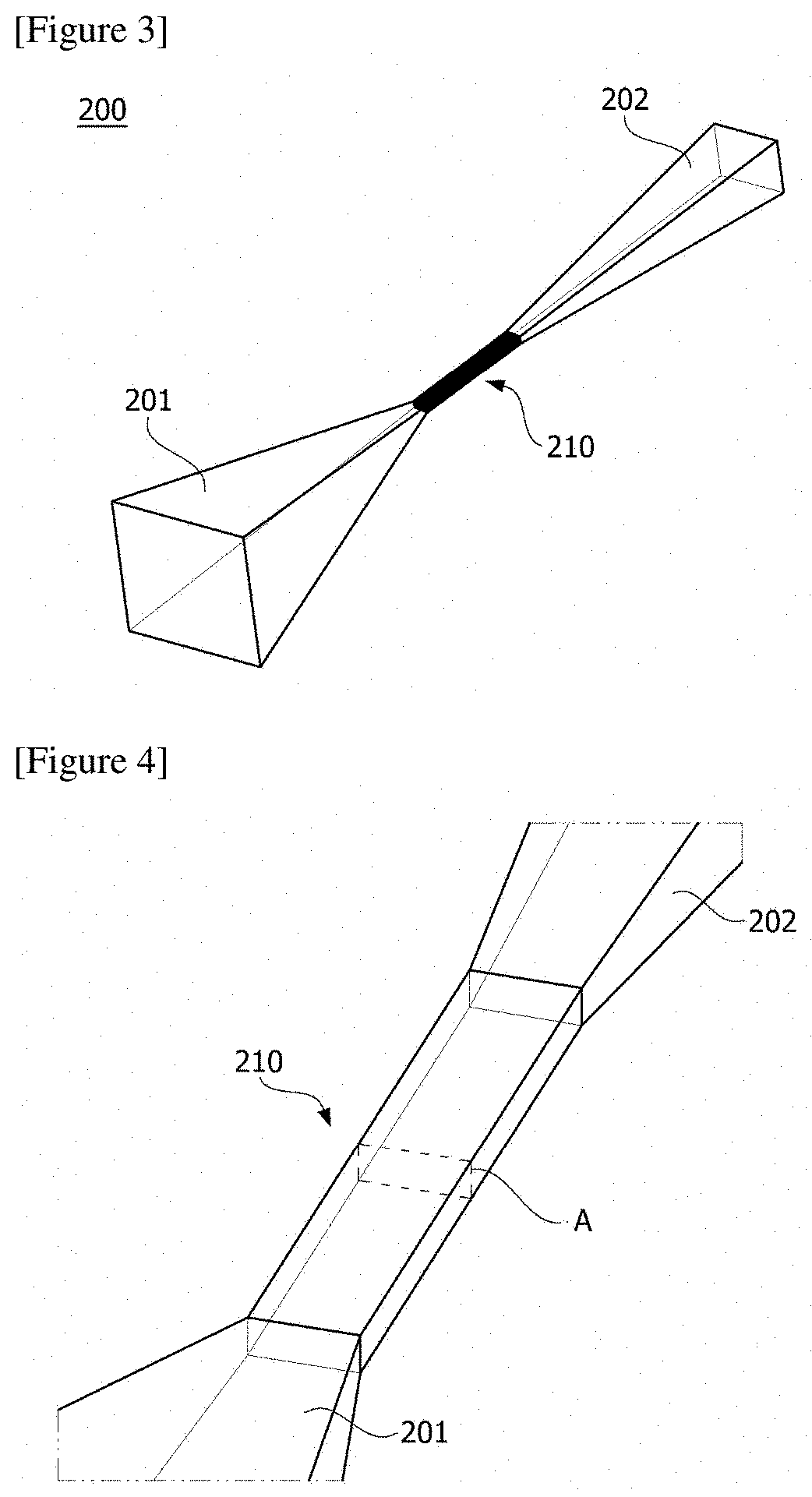

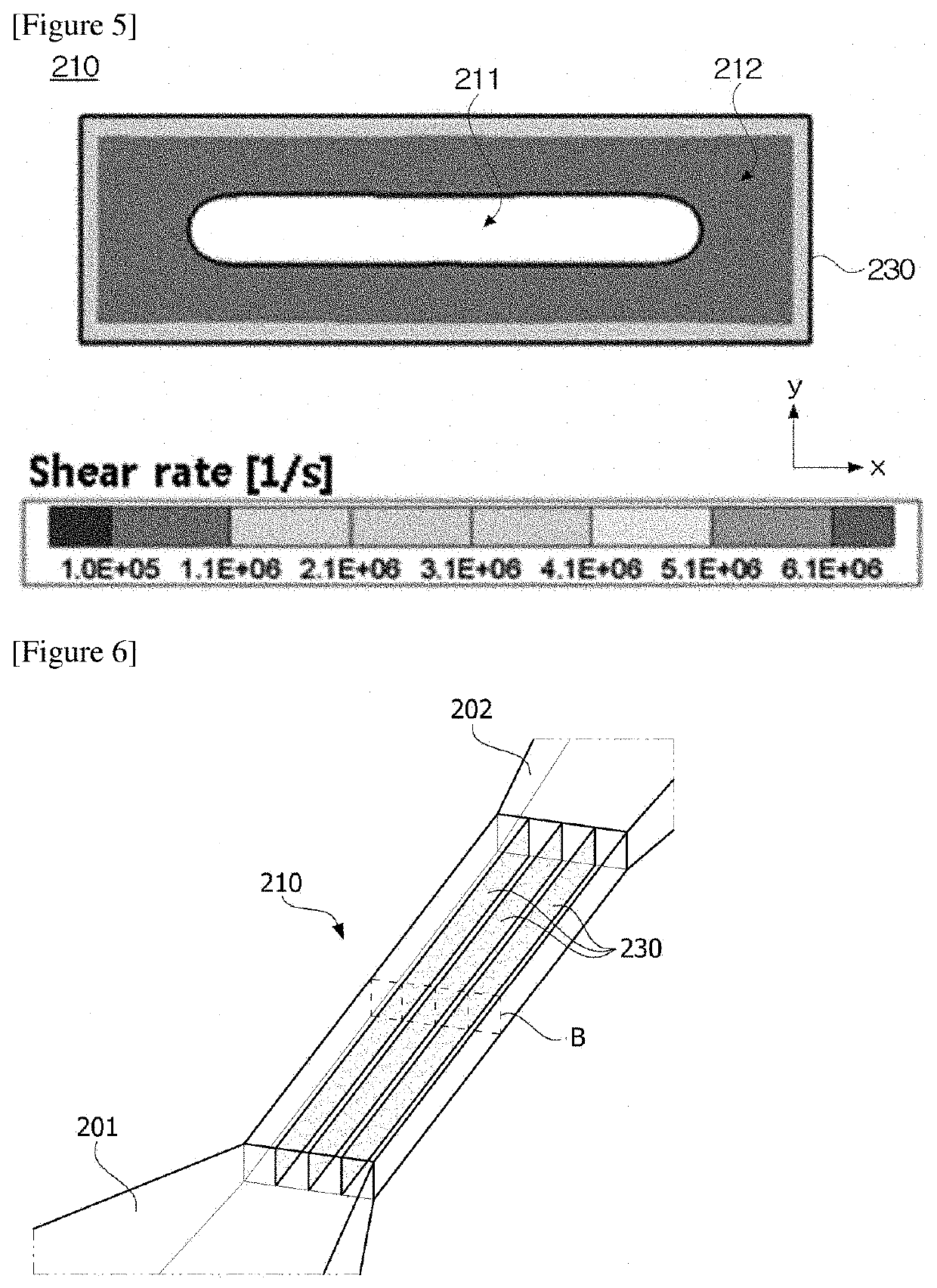

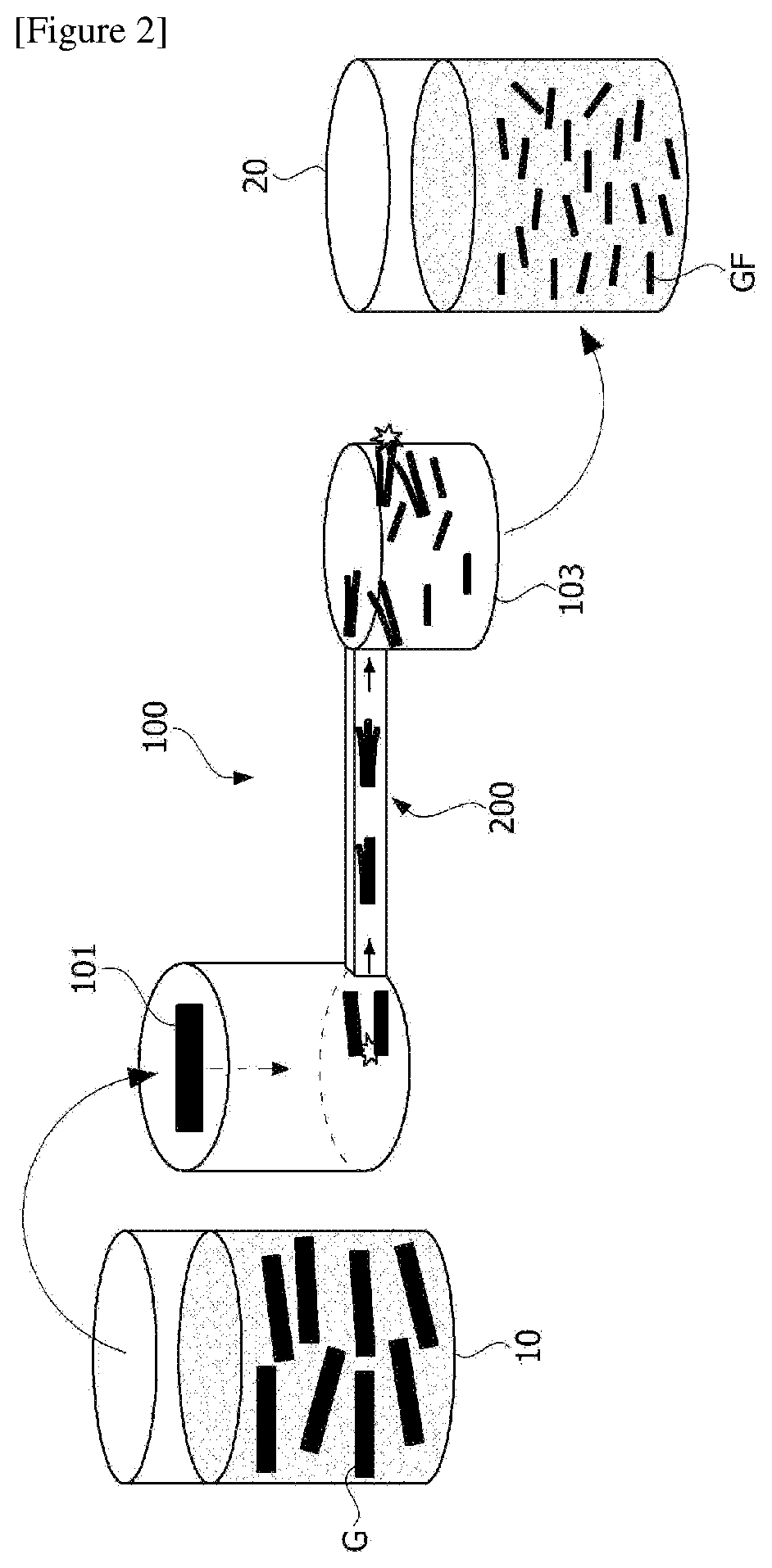

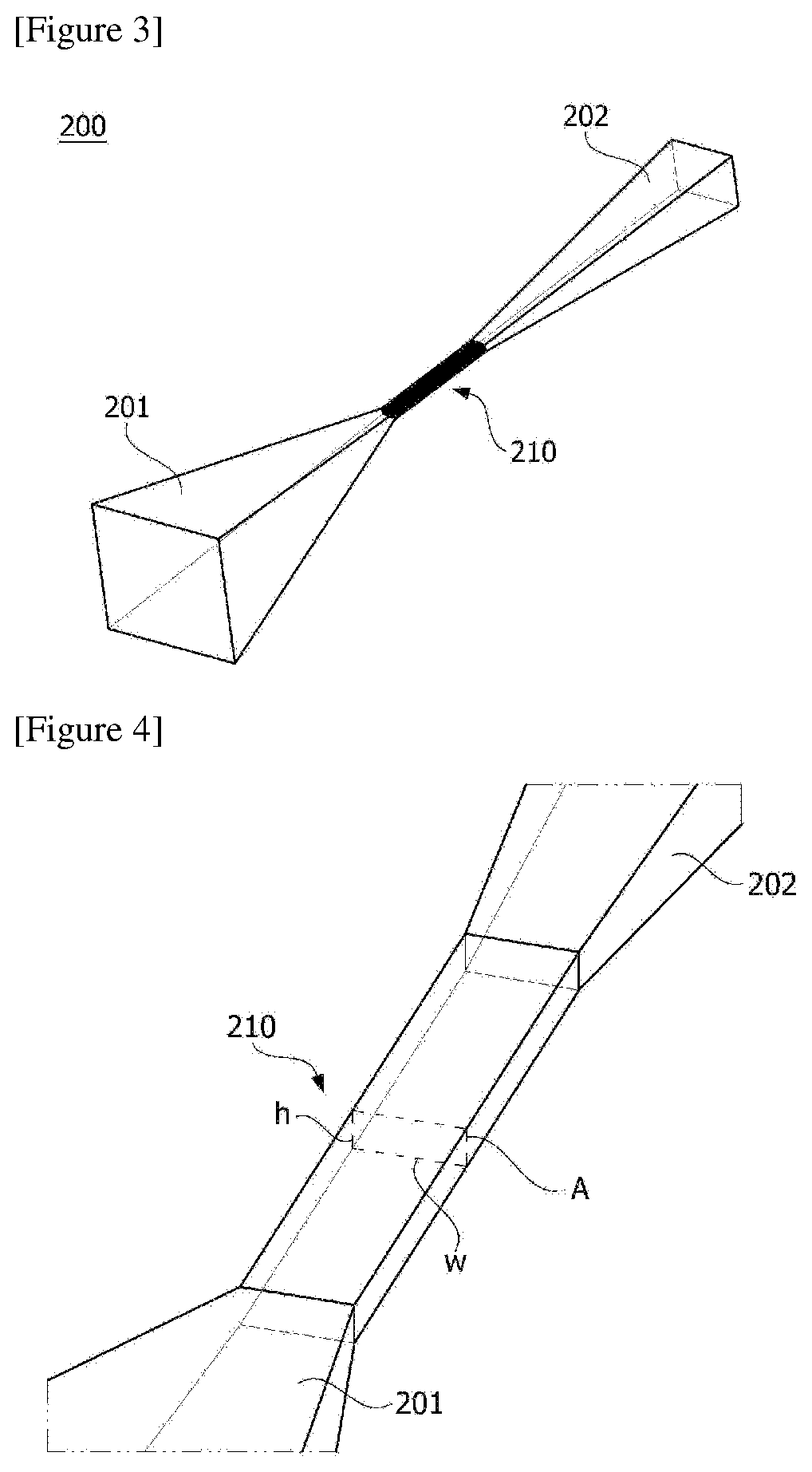

High Pressure Homogenizer And Method For Manufacturing Graphene Using The Same

ActiveUS20200122108A1Improve productivityIncrease effective areaFlow mixersUltra-high pressure processesEngineeringGraphite

The present invention relates to a high pressure homogenizer and a method for manufacturing graphene using the same, and according to one aspect of the present invention, there is provided a high pressure homogenizer comprising a channel module which comprises a microchannel through which an object for homogenization passes, wherein the channel module comprises at least one baffle disposed so as to partition the microchannel into a plurality of spaces and the baffle is provided so as to partition the microchannel into two spaces along the width direction or the height direction.

Owner:LG CHEM LTD

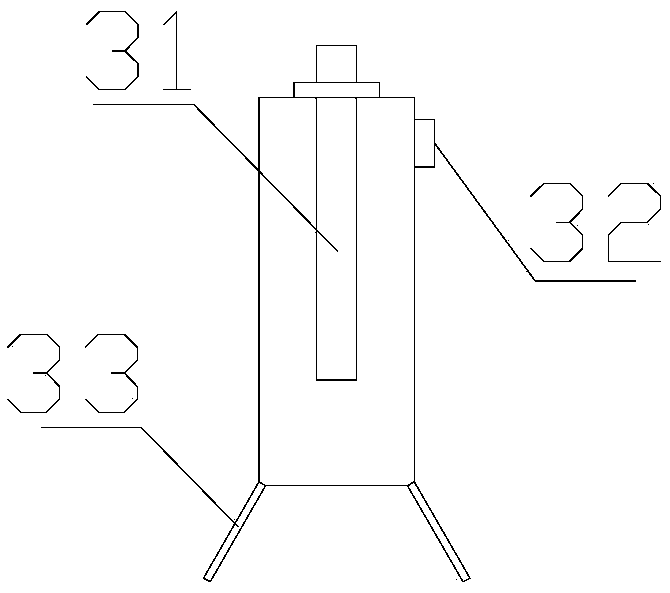

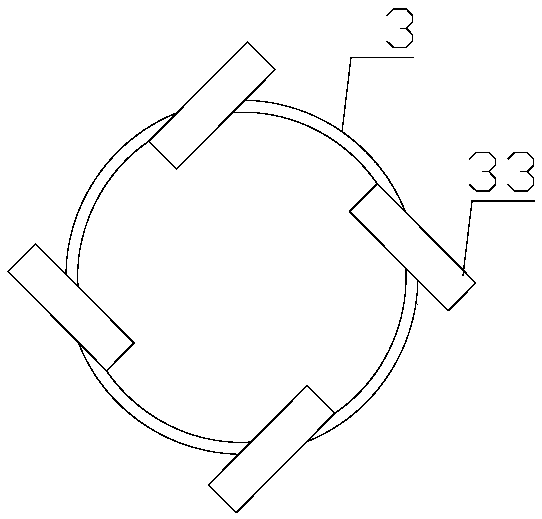

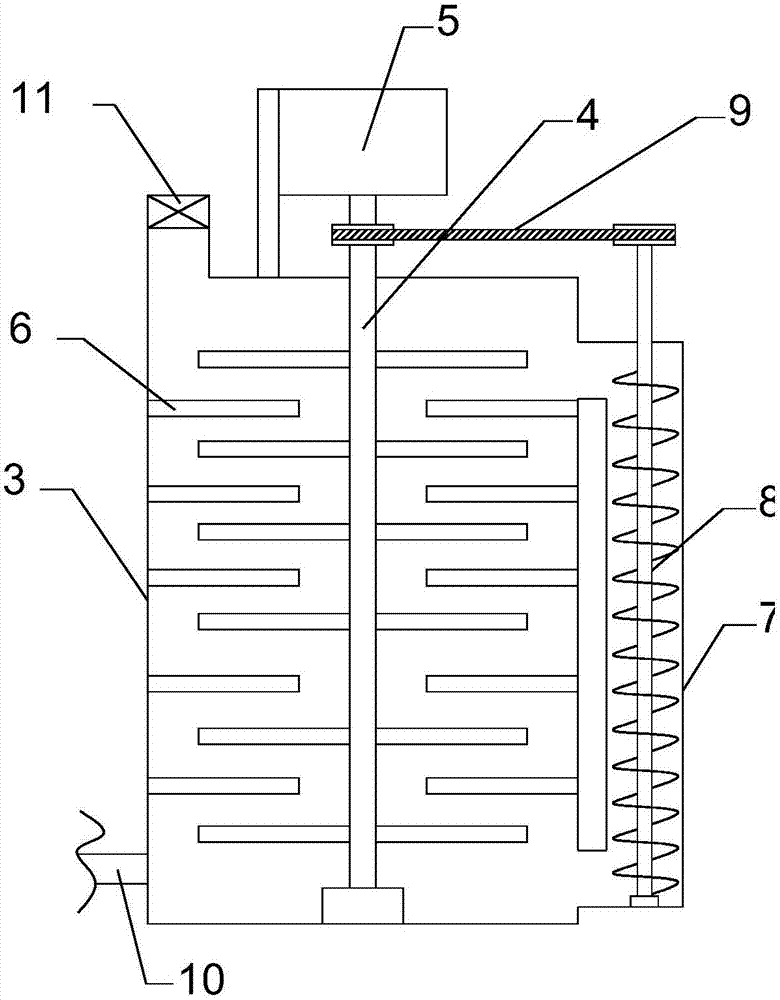

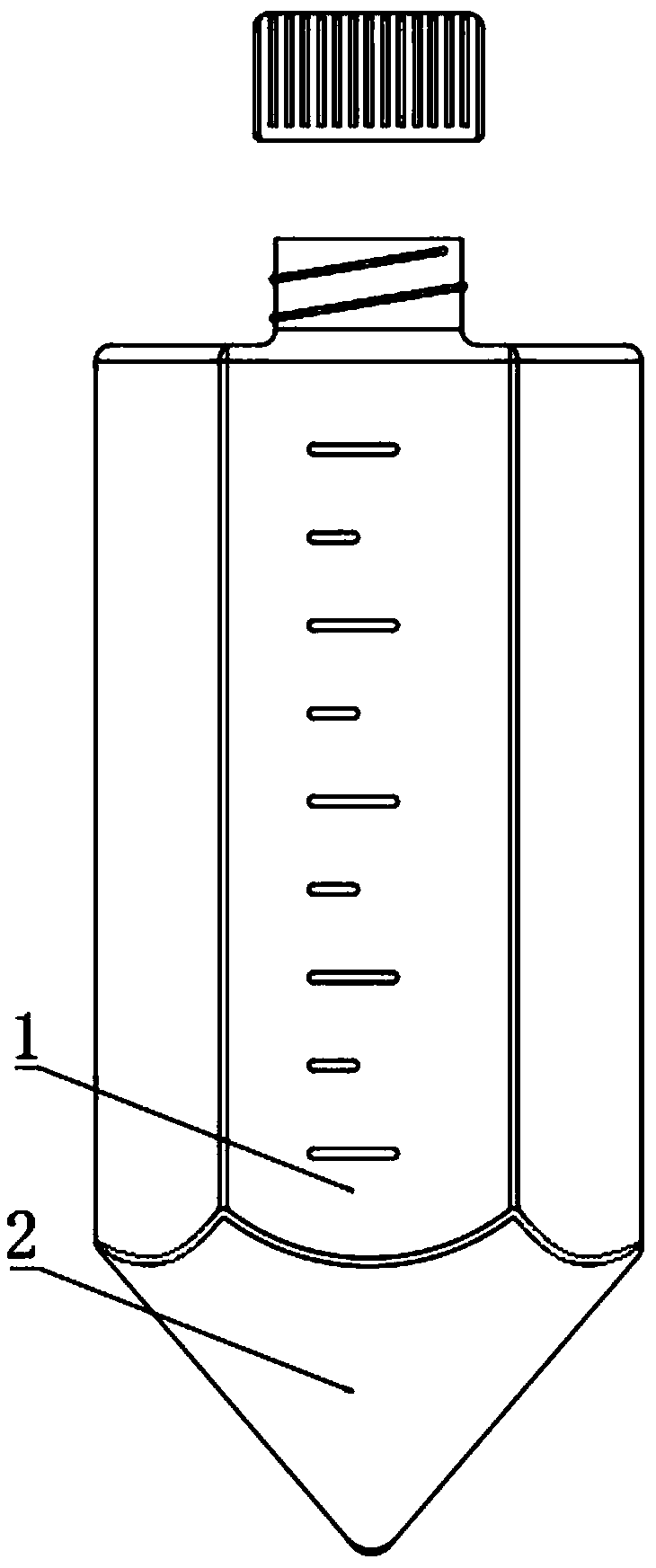

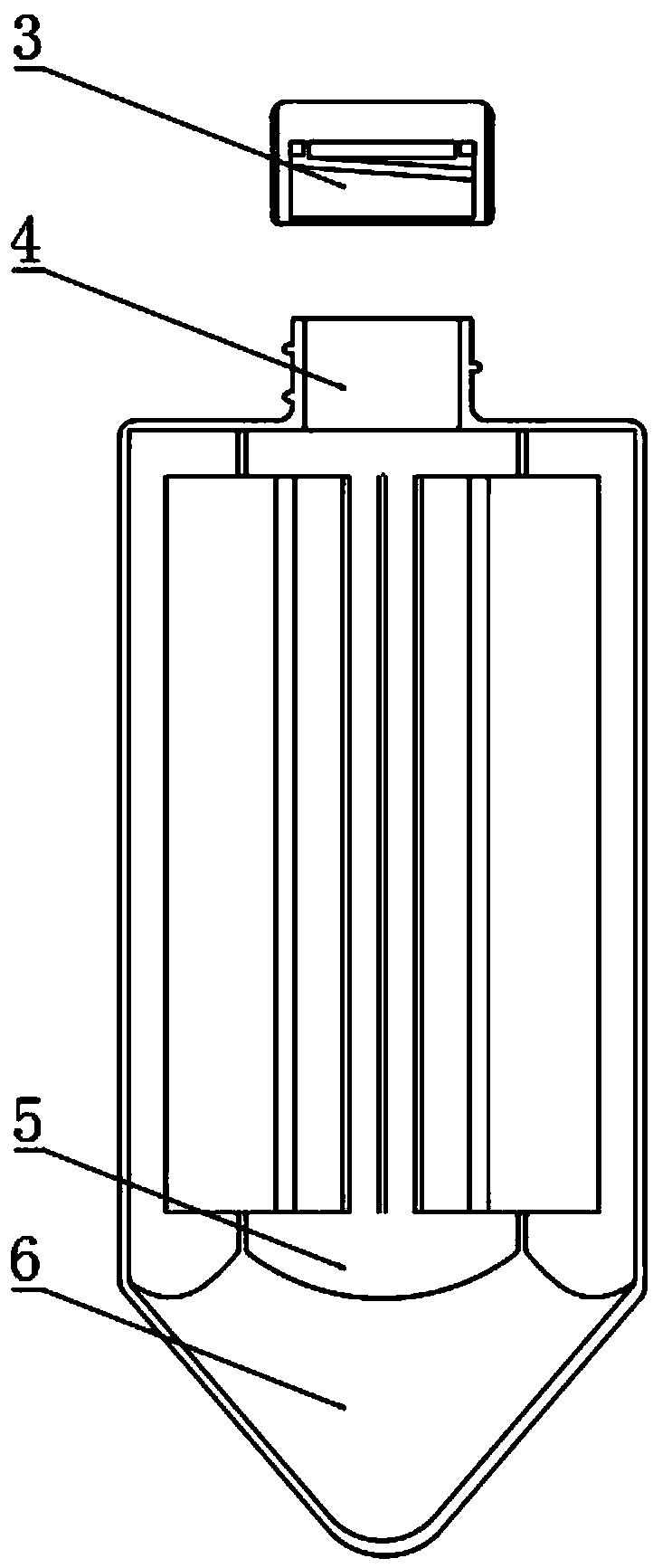

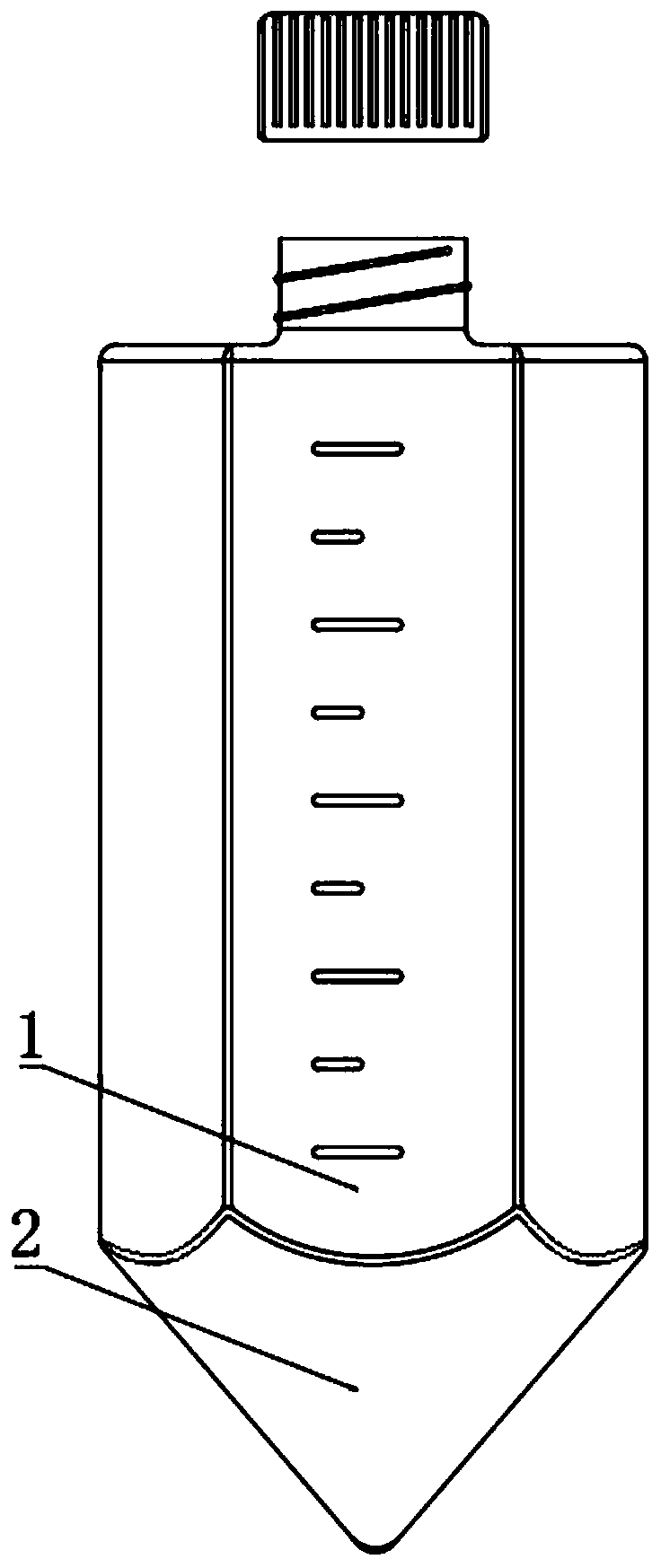

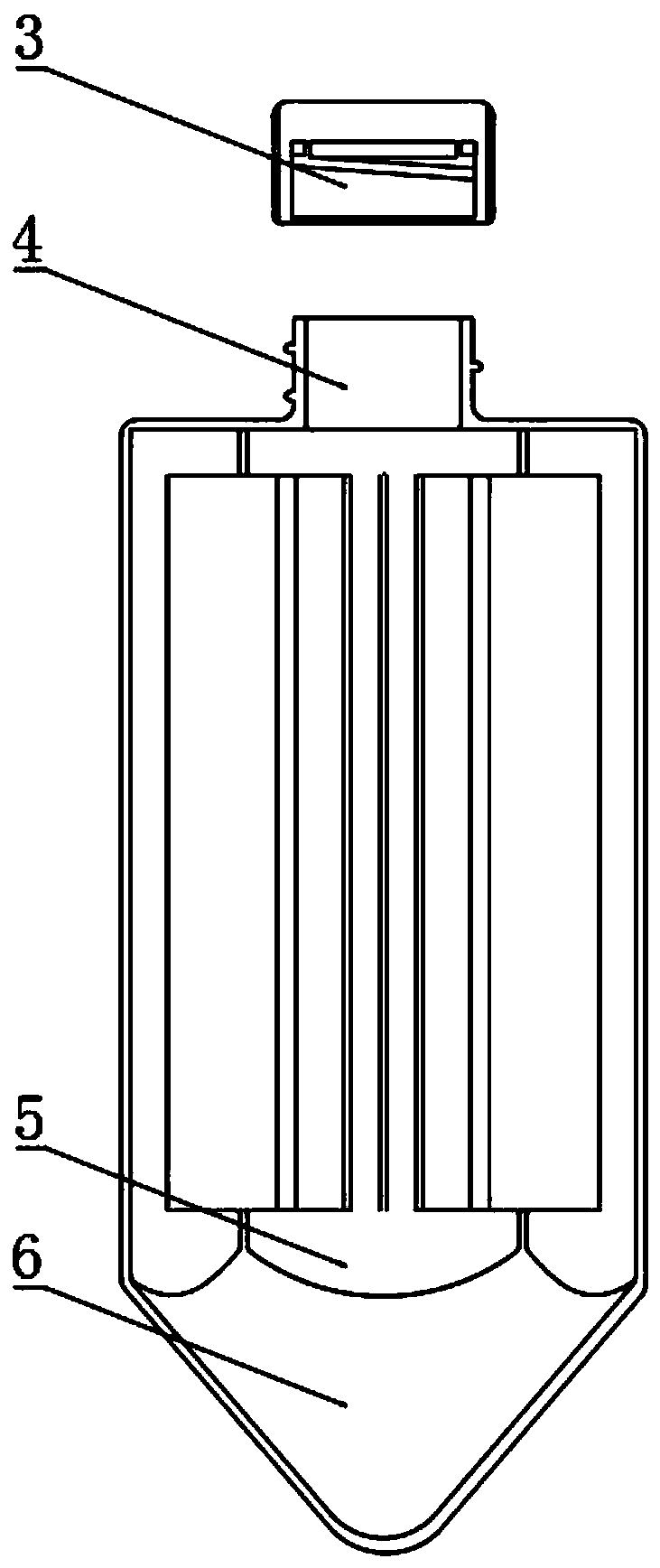

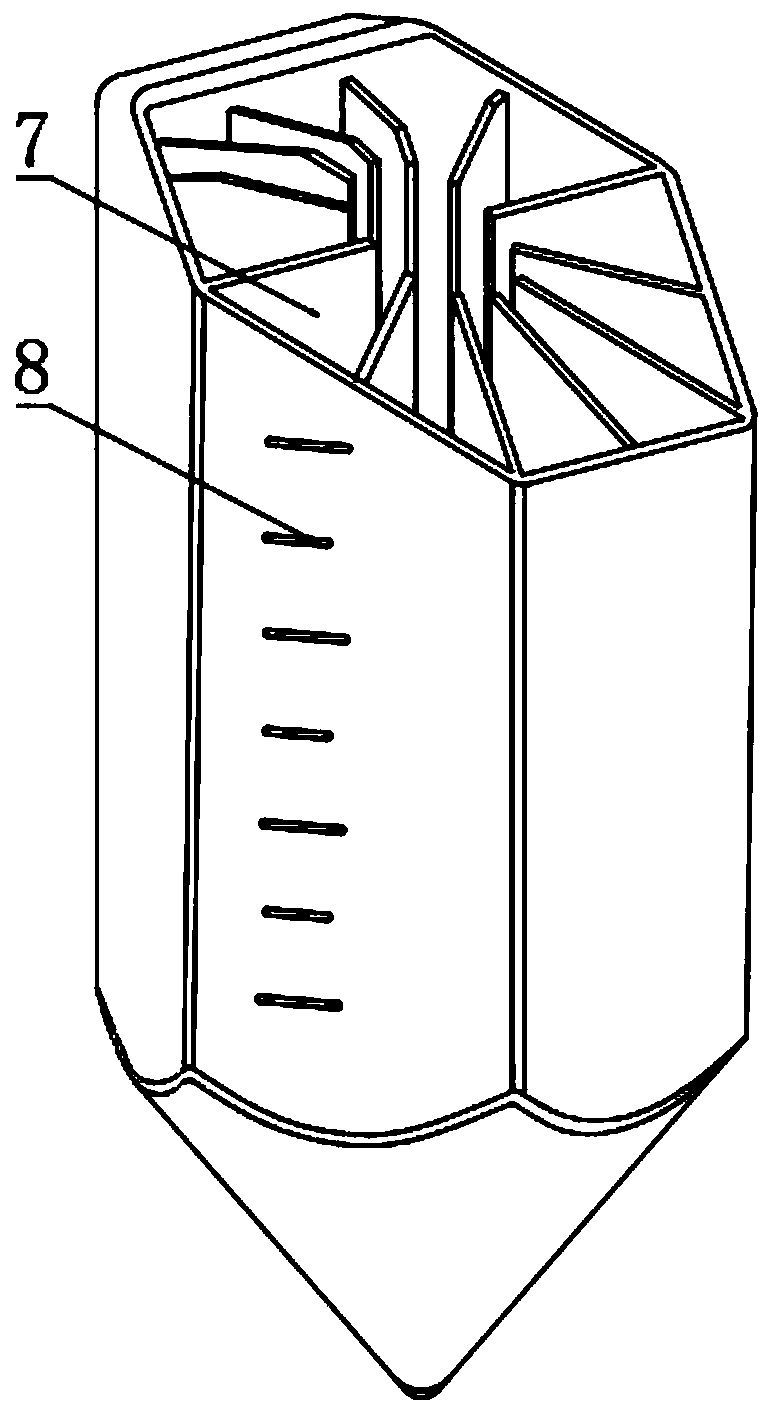

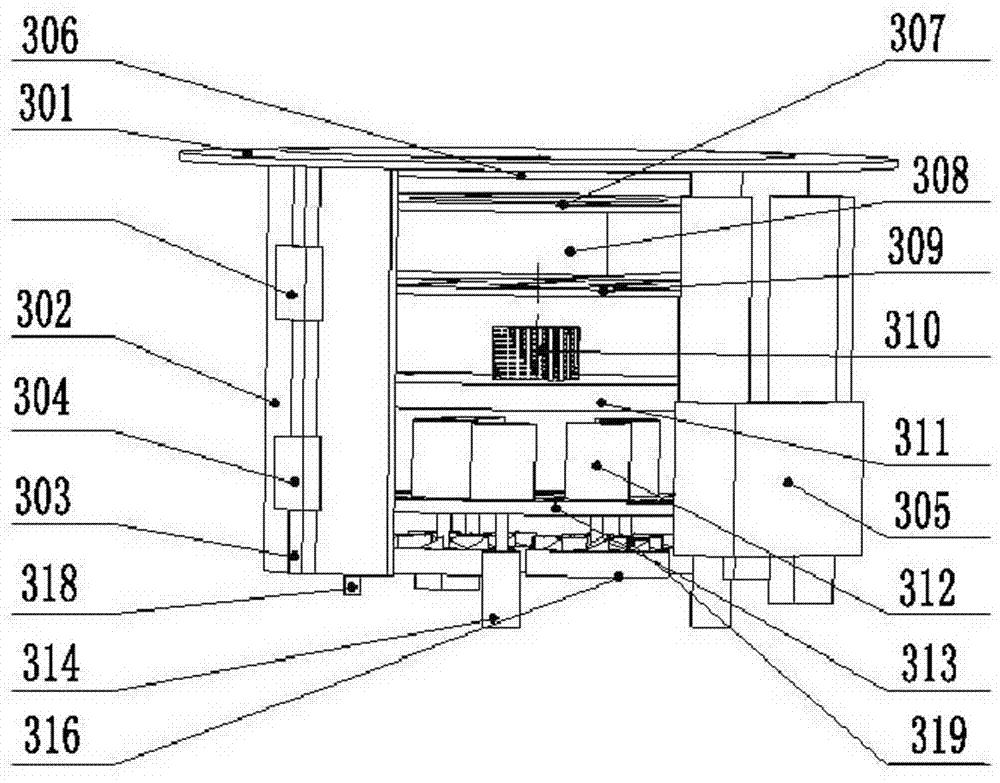

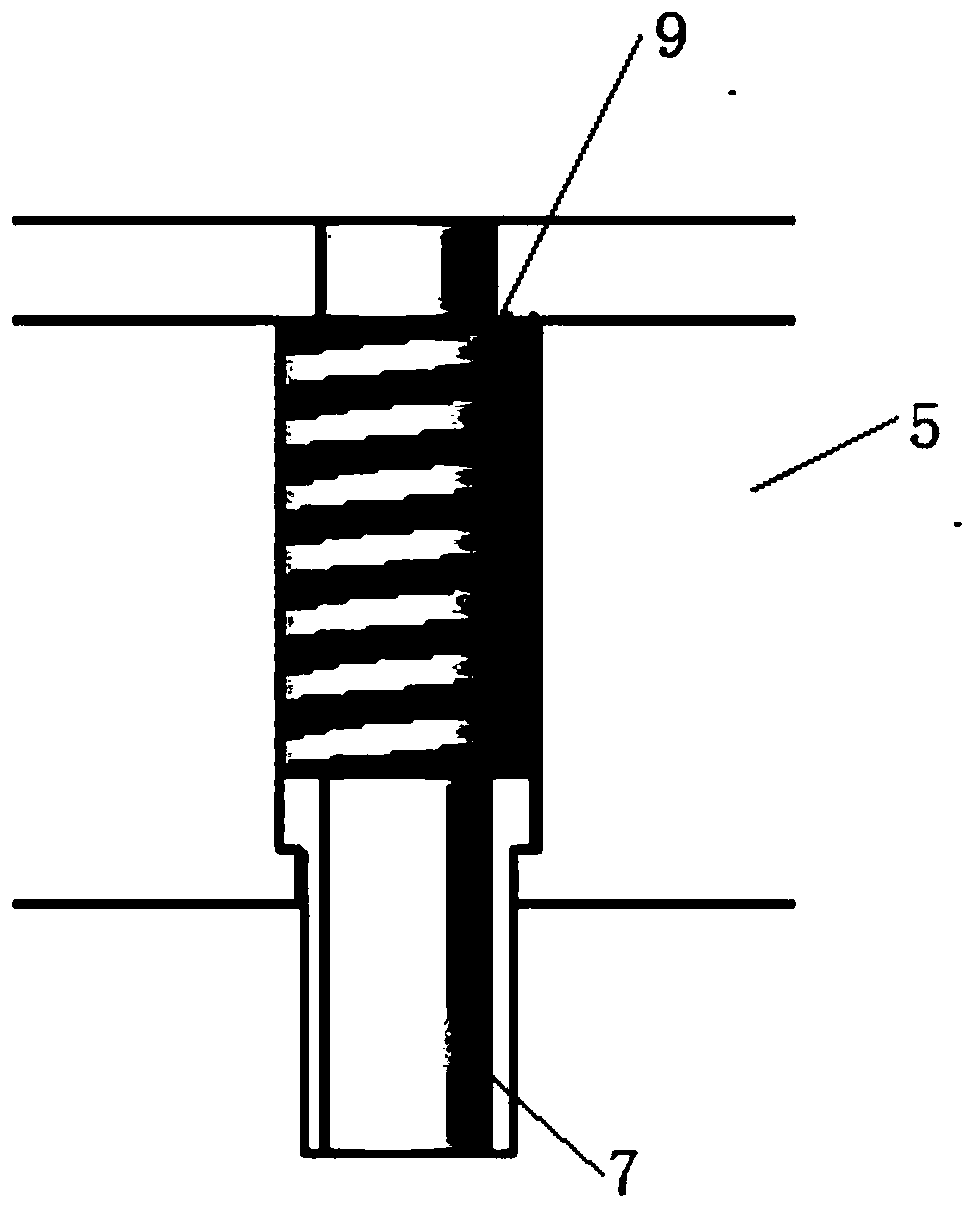

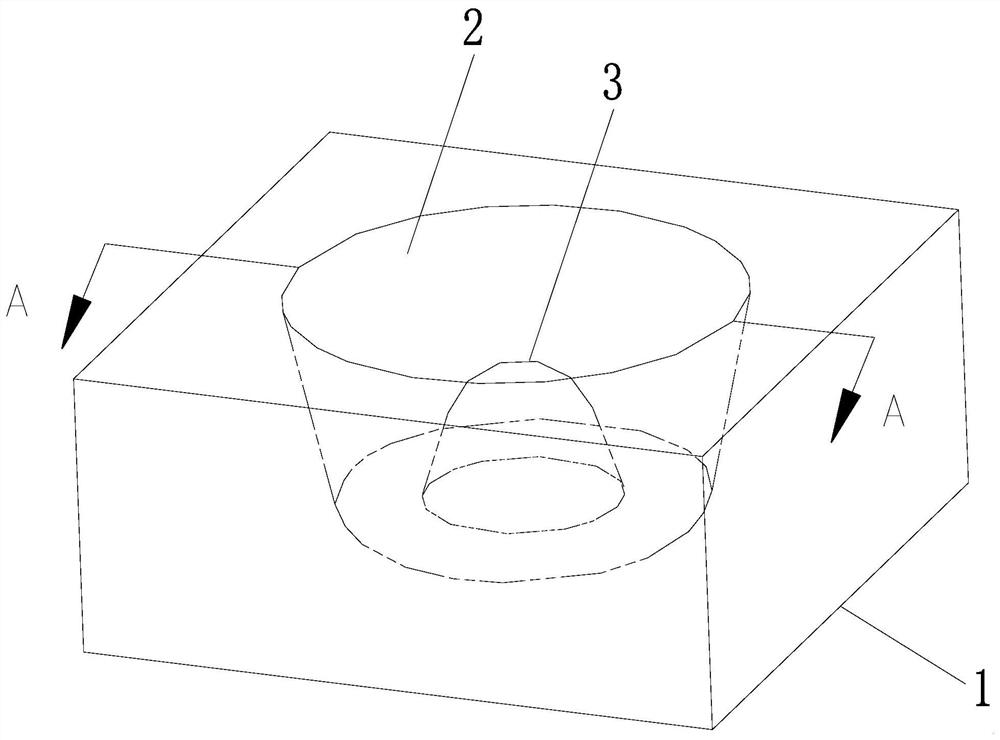

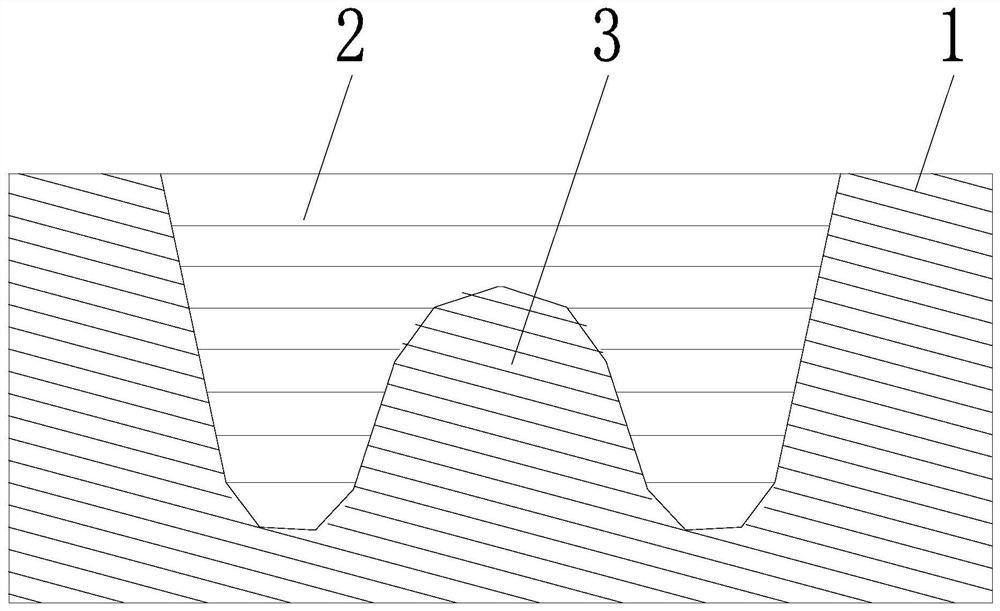

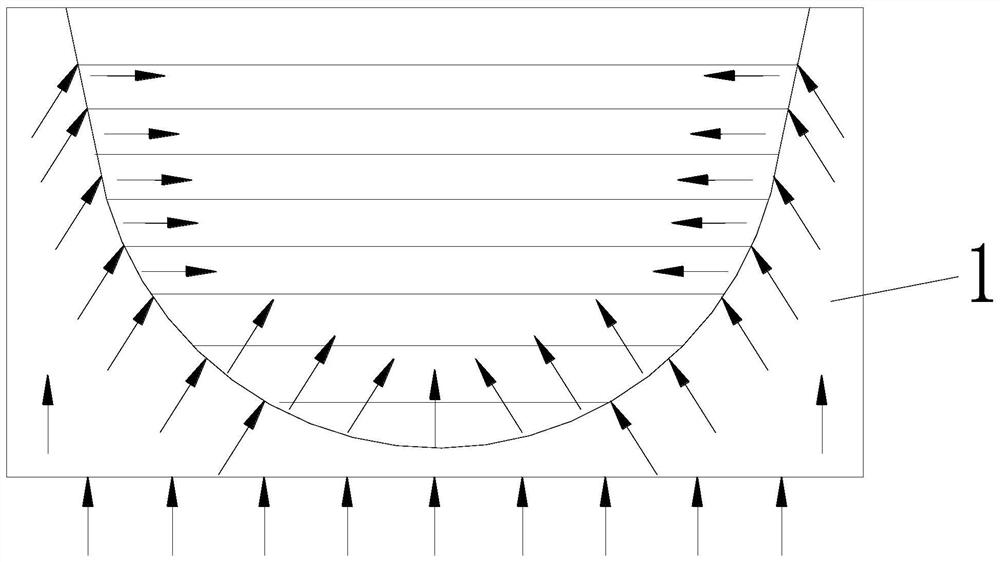

Attached cell culturing container suitable for automatic equipment

InactiveCN109401972AIncrease the wall areaConvenient for compact arrangementBioreactor/fermenter combinationsBiological substance pretreatmentsCentrifugationEngineering

The invention relates to the field of culturing containers, in particular to an attached cell culturing container suitable for automatic equipment. The container comprises a culturing container bottlebody, a fully air-permeable bottle cap and a cell attaching wall panel, the culturing container bottle body comprises a centrifugal bottle bottom collector, a bottle mouth, an inner cell attaching wall, an oblique slope panel and a cell attaching wall panel, the interior of the centrifugal bottle bottom collector is provided with an oblique slope panel, one end of the centrifugal bottle bottom collector is provided with an inner cell attaching wall, the interior of the inner cell attaching wall comprises a plurality of cell attaching wall panels, and a scaling ruler is arranged at the exterior of the culturing container bottle body. The container has the advantages that the container can be used as a single container in the attached cell culturing process for culturing, centrifugation, sample observation, in-process transferring and the like, liquid bottle opening / closing operation, liquid transferring operation, multi-type container storage and multi-type container conversion in thewhole automatic production process are simplified, and the production efficiency and benefits are effectively improved.

Owner:INNOVEL INTELLIGENT TECH CO LTD

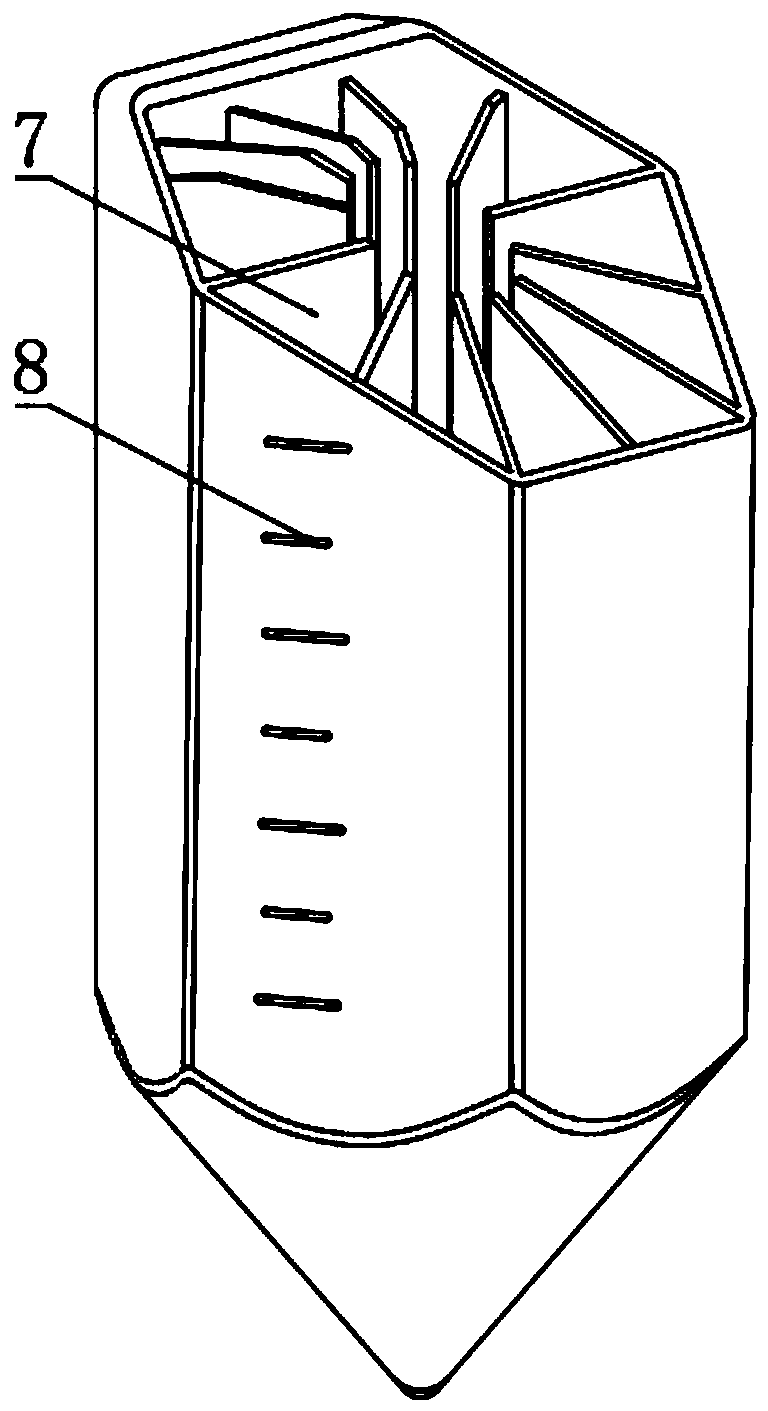

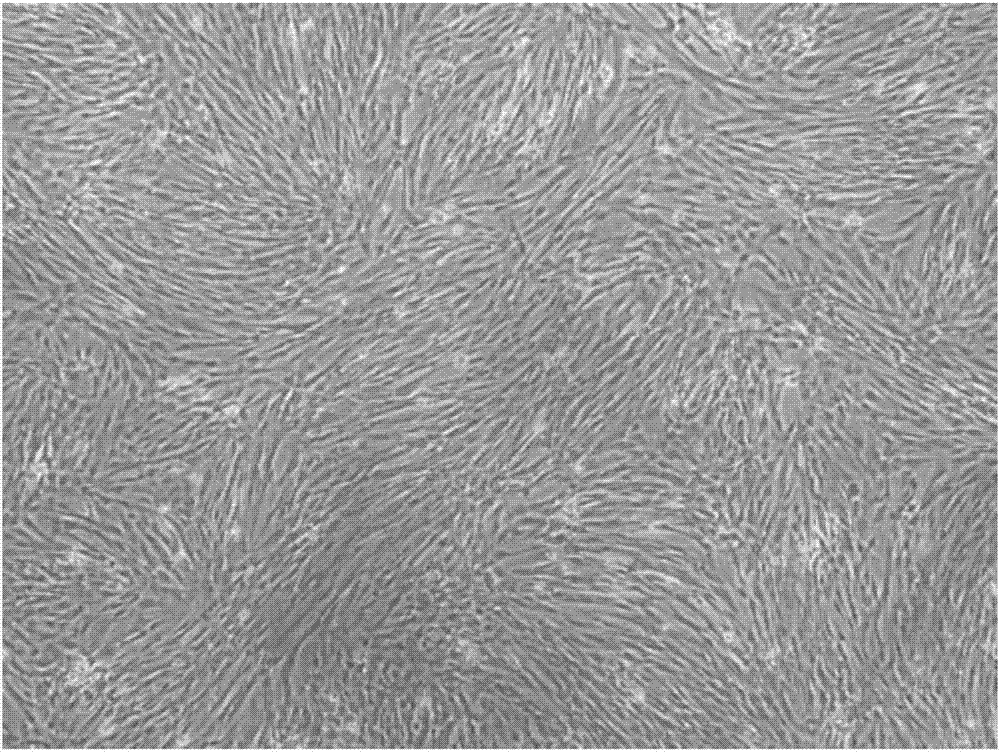

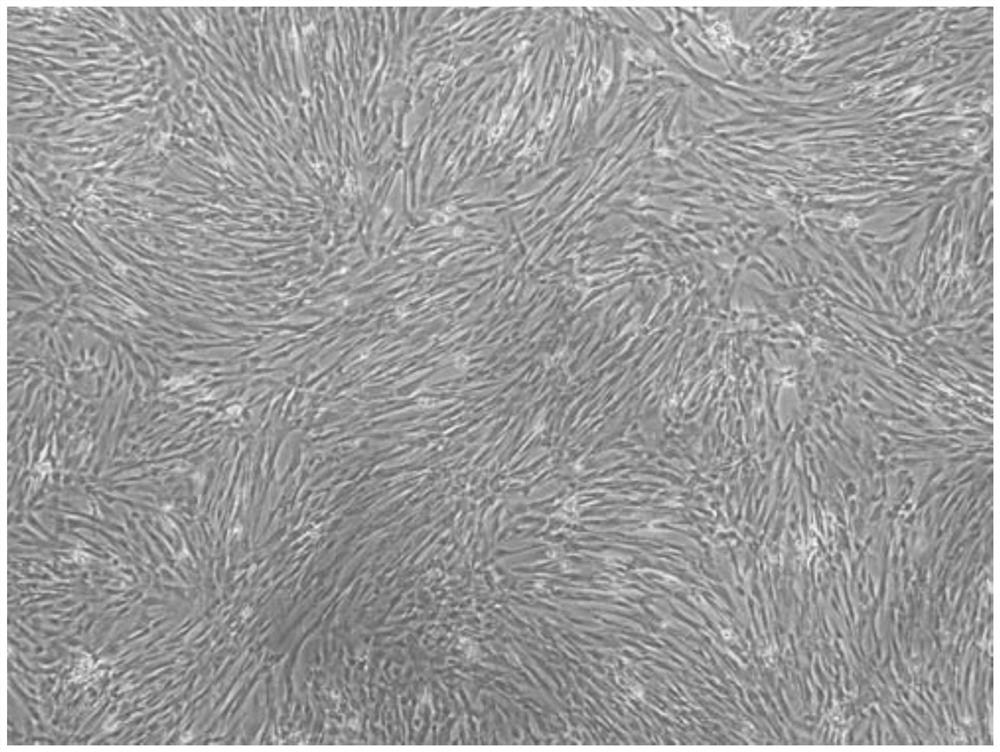

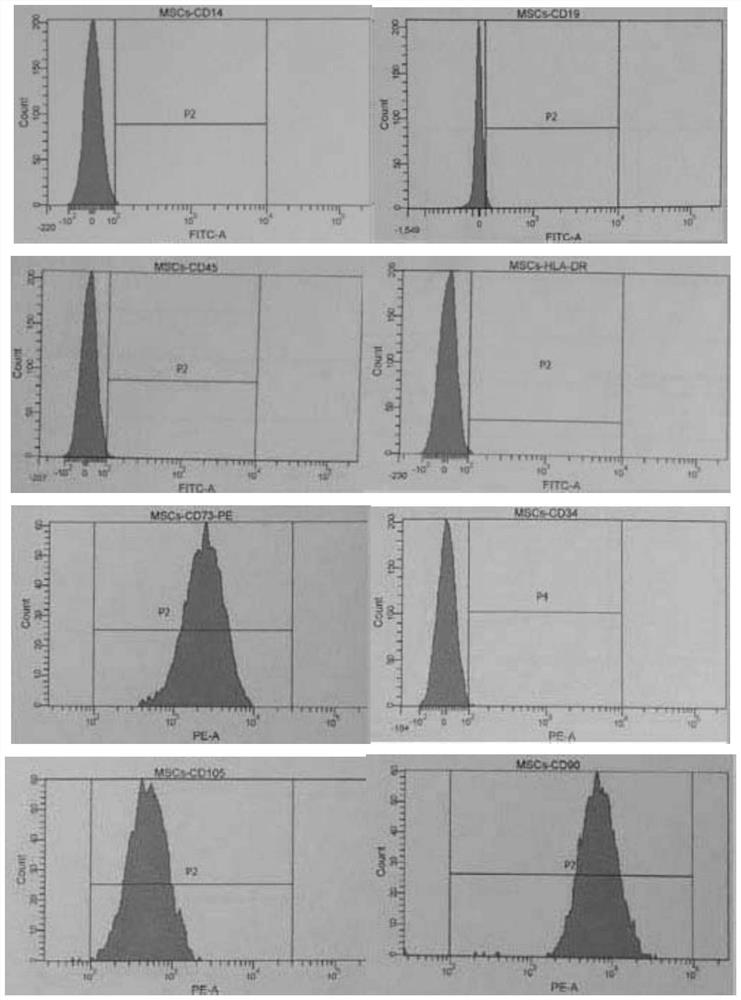

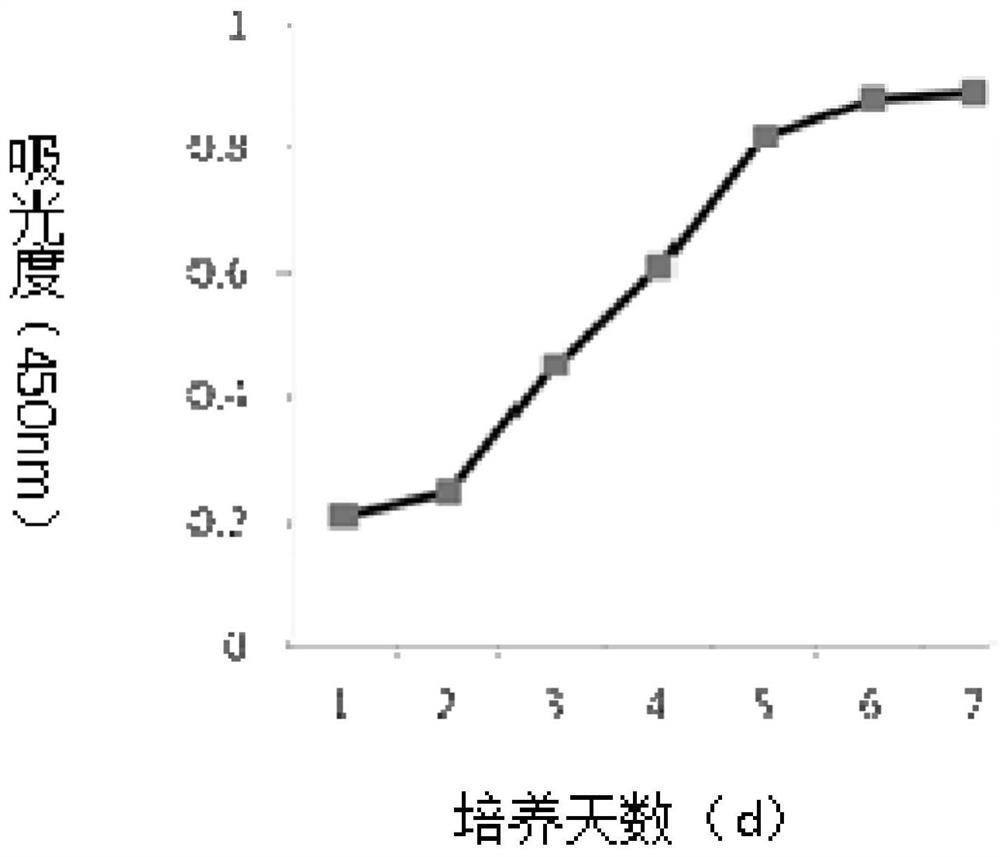

Human placenta chorionic mesenchymal stem cell separation method

ActiveCN107354130AReduce tissue shearing timeIncrease the wall areaCell dissociation methodsSkeletal/connective tissue cellsSaline waterDigestion

The invention discloses a human placenta chorionic mesenchymal stem cell separation method, which comprises: 1) taking healthy human placenta chorionic tissue, cutting into strip blocks, and completely rinsing with physiological saline; 2) adding a proper amount of physiological saline, chopping the chorion into fine particles by using a homogenizer, and rinsing with physiological saline until the solution is clarified; 3) treating again with the homogenizer to achieve micro-particles, and carrying out centrifugation to remove the upper layer blood cells; 4) adding an enzyme to the precipitate, digesting, carrying out centrifugation, and separating the precipitate; 5) carrying out centrifugal washing with physiological saline twice, adding a culture medium to the precipitate, inoculating, and culturing; and 6) discarding the tissue blocks and the culture medium at the 7th day, rinsing the bottom of the culture flask by using physiological saline, adding a fresh culture medium, changing the culture medium every 3 days until the cell fusion degree achieves 80-90%, and carrying out digestion passage with trypsin to obtain the human placenta chorionic mesenchymal stem cells. According to the present invention, the operation is simple and rapid, and the high-quality human placenta chorionic mesenchymal stem cells can be obtained.

Owner:GUANGZHOU WOMEN AND CHILDRENS MEDICAL CENTER

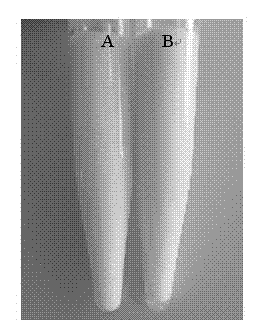

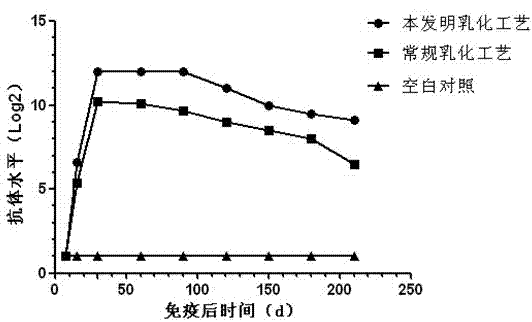

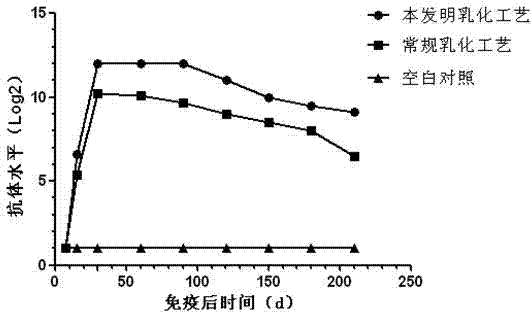

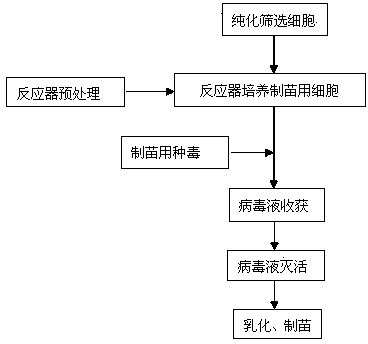

Method for preparing porcine parvovirus inactivated vaccines

ActiveCN103157106AIncreased sensitivityUniform stateAntiviralsRecovery/purificationImmune effectsPublic health

The invention relates to a method for preparing porcine parvovirus inactivated vaccines, and belongs to the field of biotechnology. The method for preparing the porcine parvovirus inactivated vaccines includes the following steps: (1) culturing of cells used for vaccine preparation, (2) virus inoculation and culture, (3) virus liquid harvest, (4) virus liquid inactivation, and (5) vaccine preparation. Seed virus used for vaccine preparation and cells are screened, matching degree between the virus and the cells is strengthened, a riptide perfusion type bioreactor culture system is used for improving multiplication titer and harvest yield of the virus, immune effects are improved through the improvement of an emulsification process and a whole production process does not involve other biosafety and public health problems and is suitable for large scale production.

Owner:RINGPU (BAODING) BIOLOGICAL PHARMACEUTICAL CO LTD

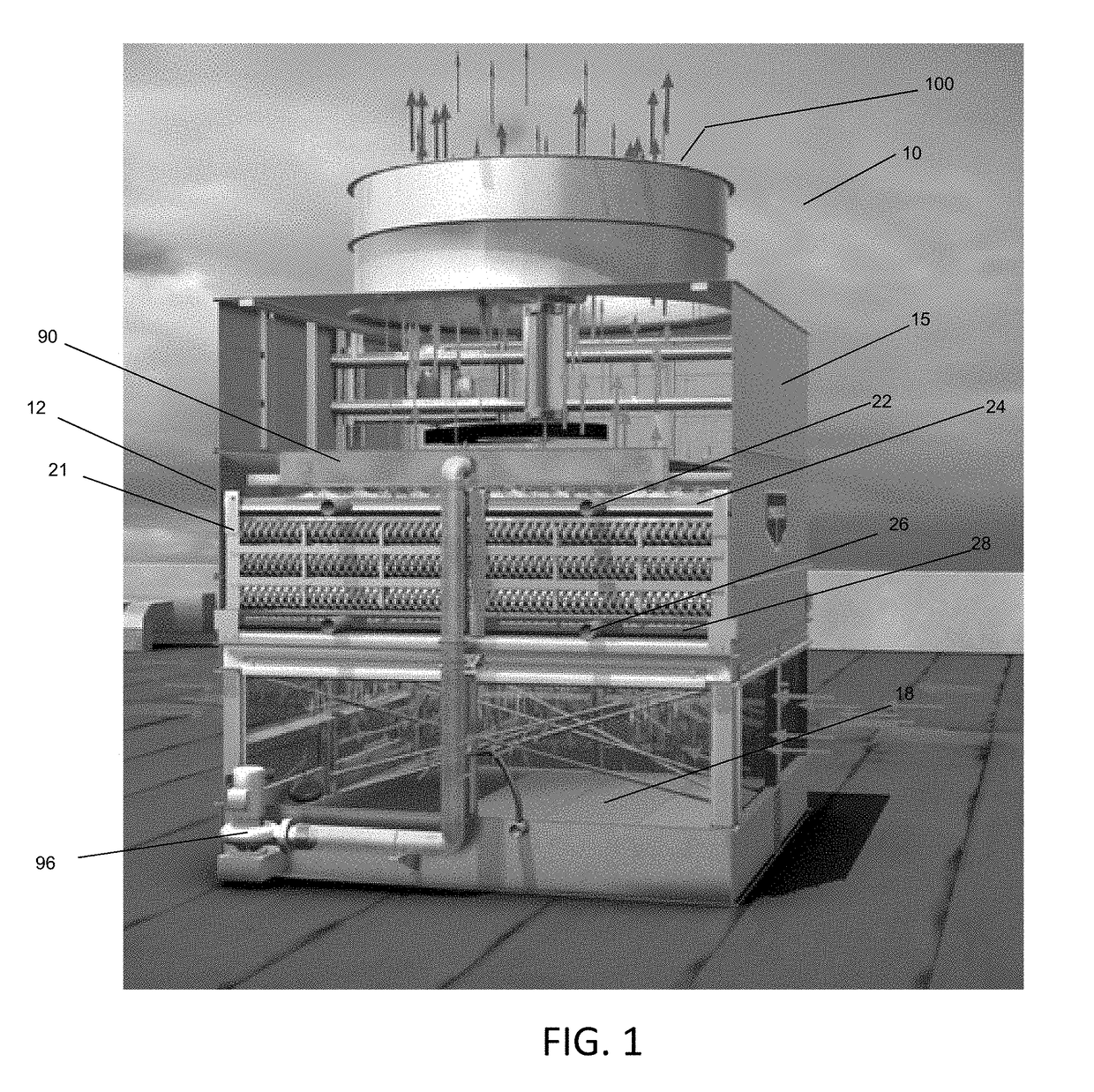

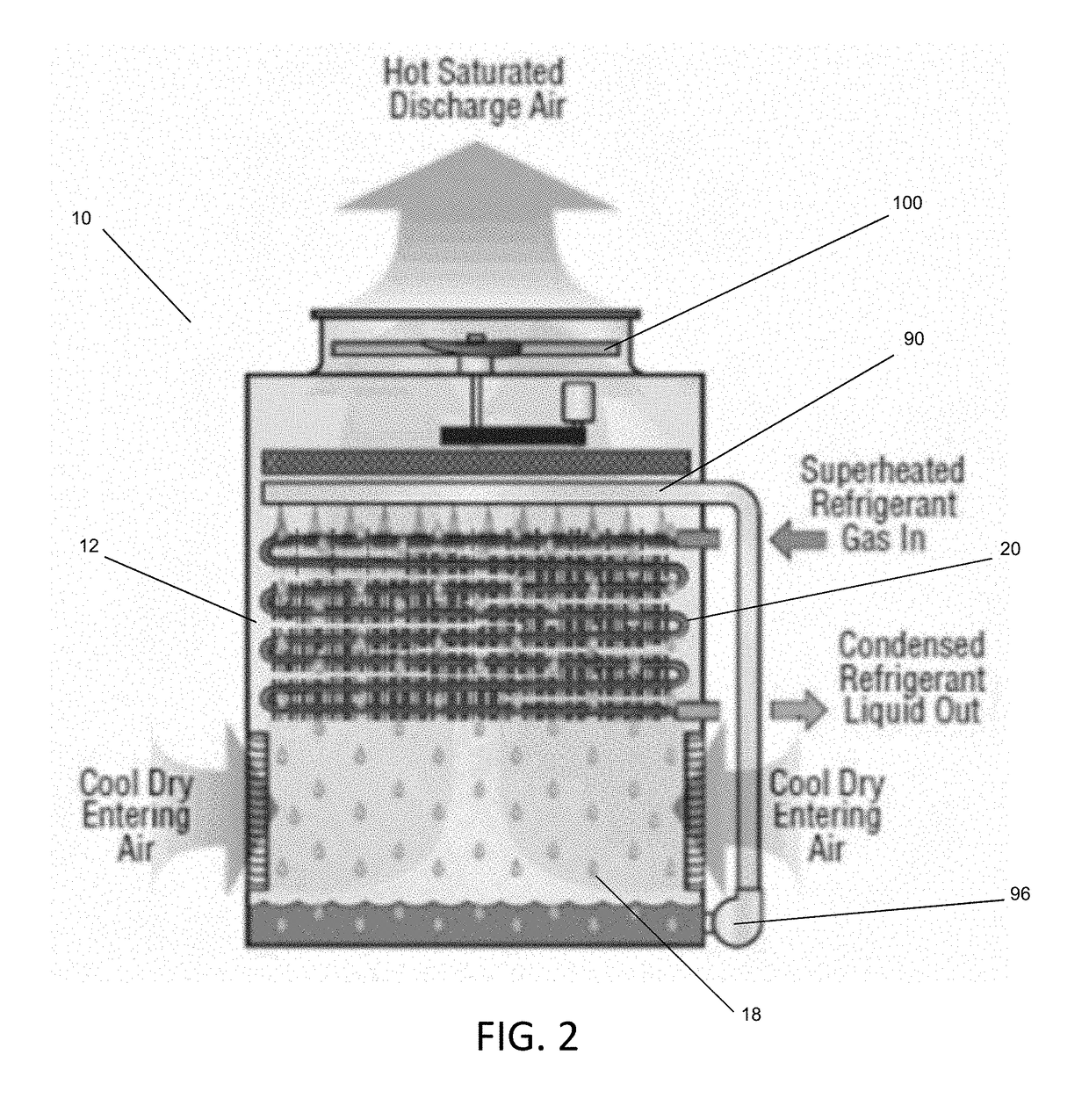

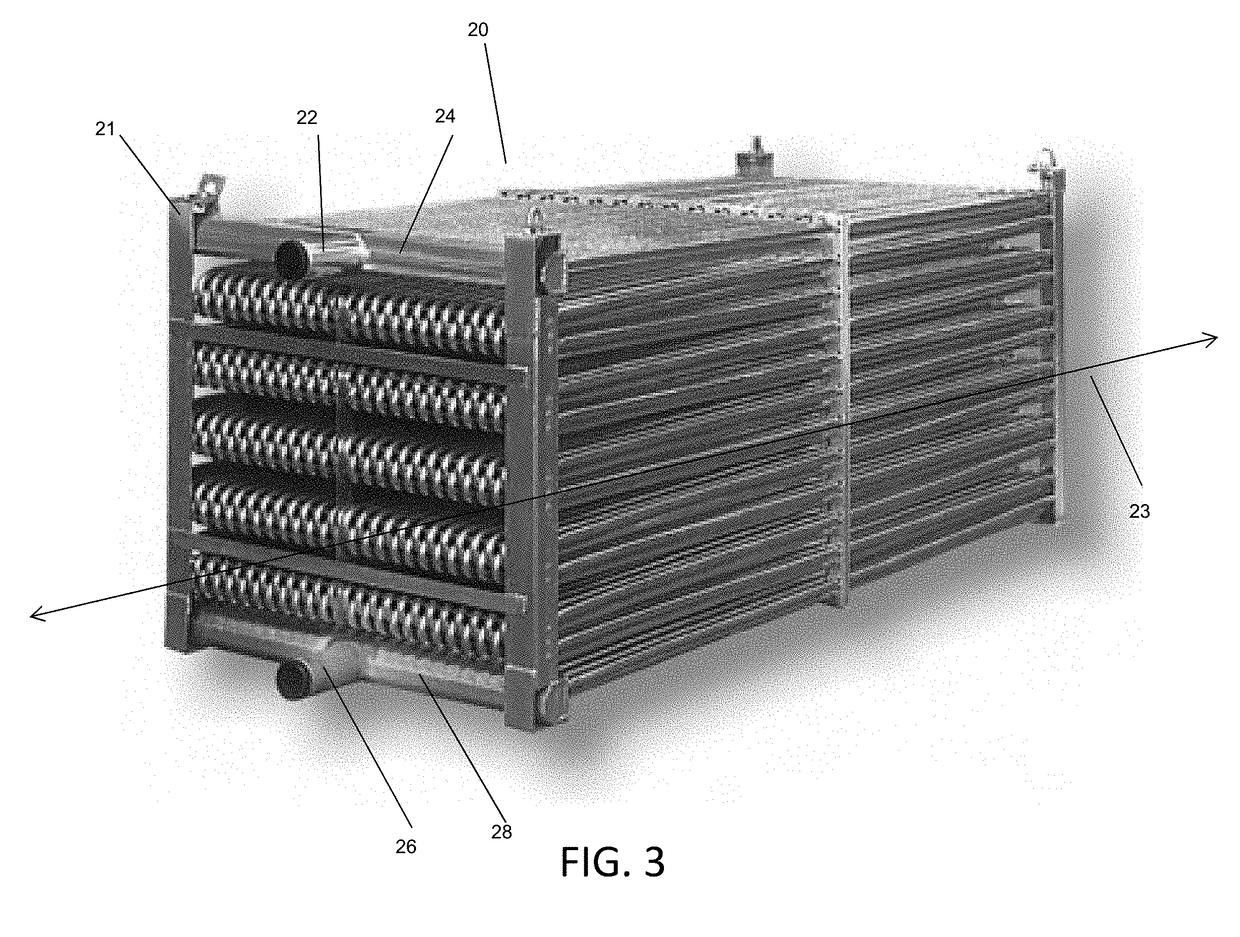

Evaporative refrigerant condenser heat exchanger

InactiveUS20190049163A1Reducing circuit lengthReduces potential travel distanceEvaporators/condensersHorizontal axisEngineering

A coil assembly for an evaporative refrigerant condenser having a plurality of nested pairs of serpentine heat exchange tubes tightly packed adjacent to one-another; each nested pair of serpentine heat exchange tubes having an outer serpentine tube and an inner serpentine tube having an identical number of straight lengths and having parallel vertical and horizontal axes.

Owner:EVAPCO

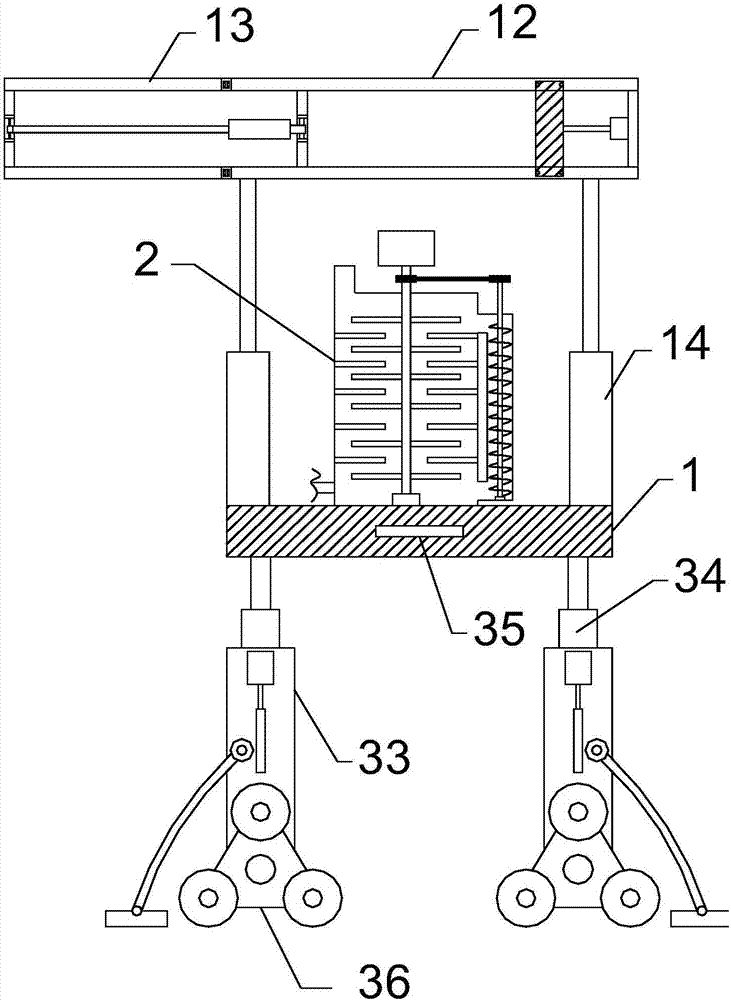

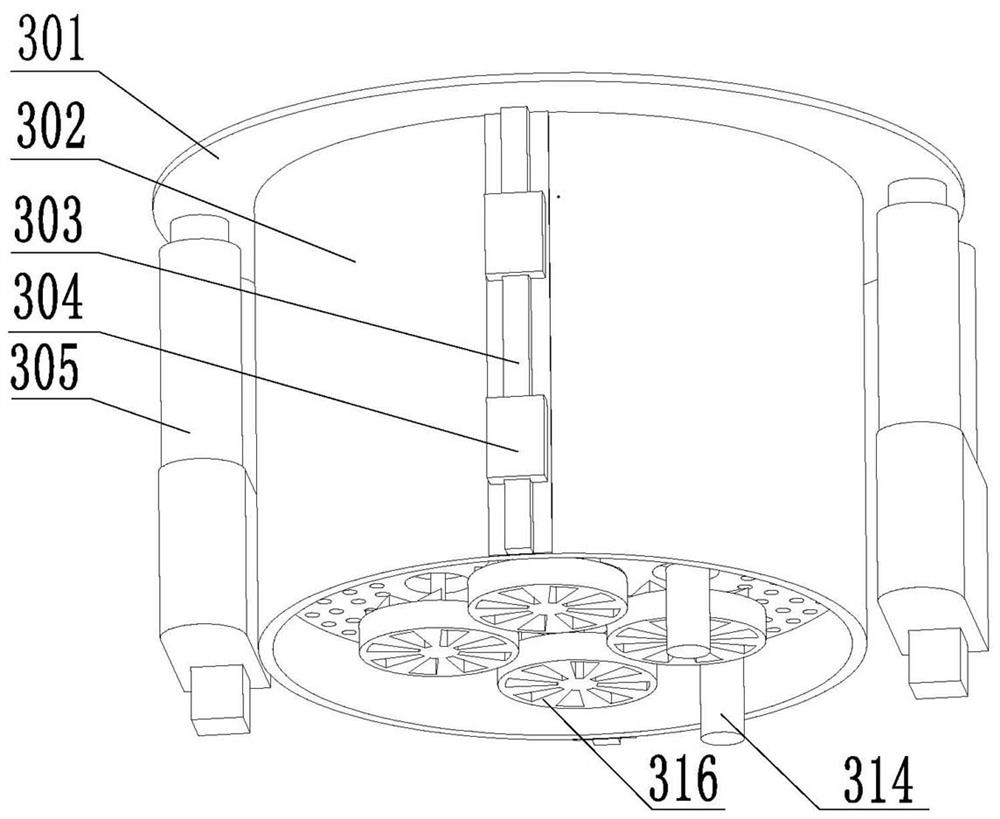

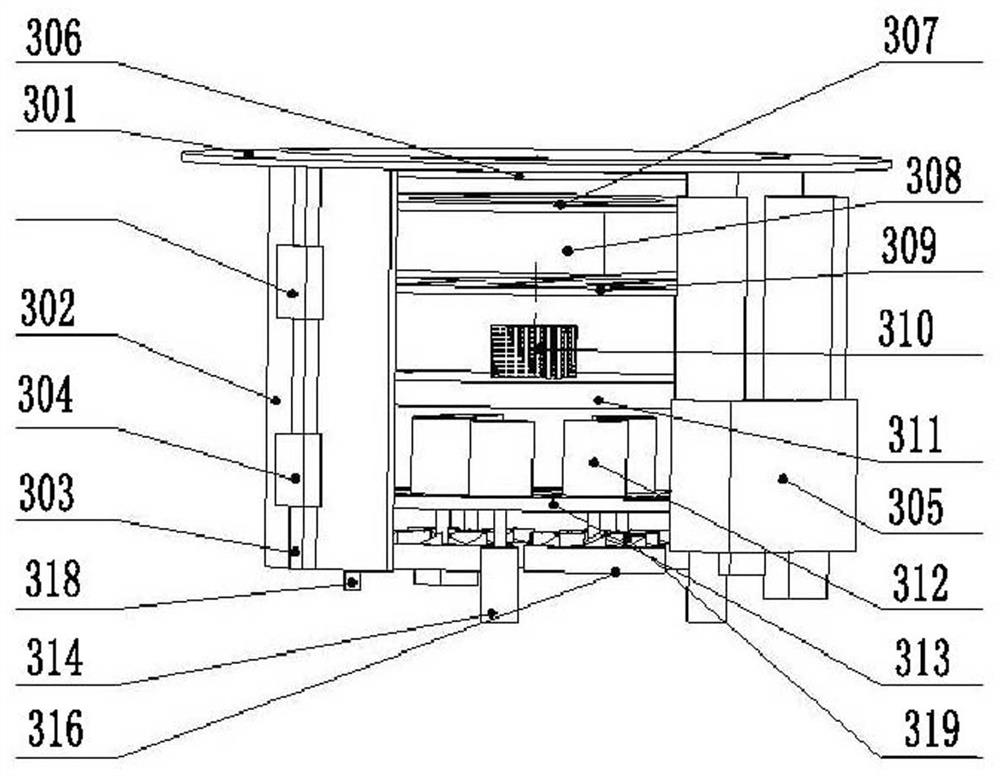

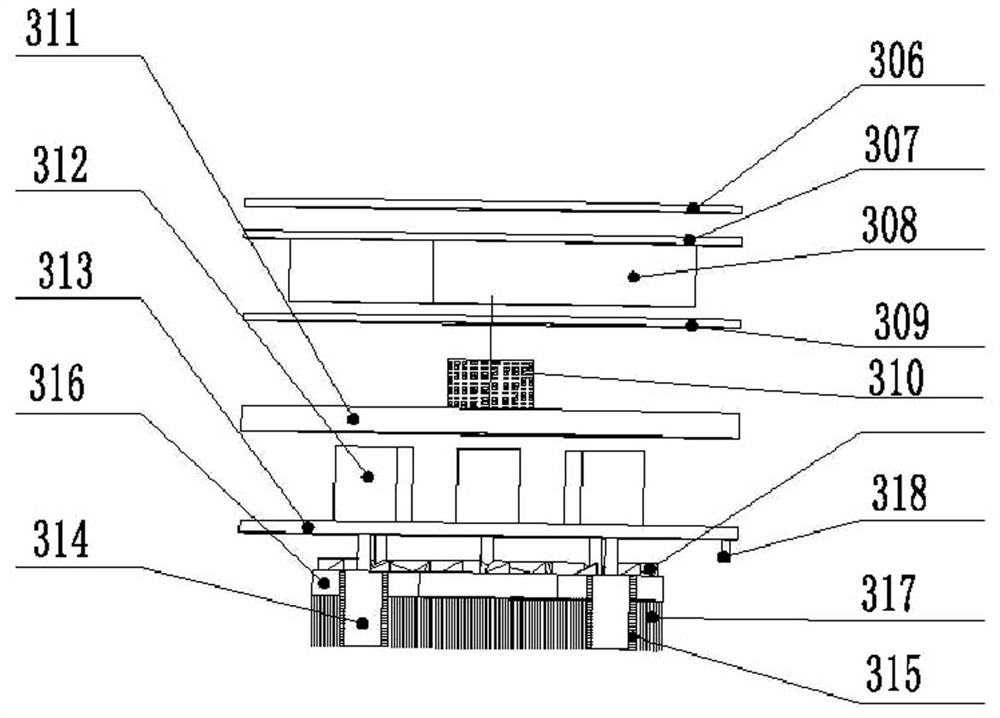

Cluster layout of completely automatic biological product system

InactiveCN109852547AIncrease the wall areaConvenient for compact arrangementBioreactor/fermenter combinationsBiological substance pretreatmentsCentrifugationWhole body

The invention relates to the field of culture containers, especially to a cluster layout of a completely automatic biological product system. The cluster layout of the completely automatic biologicalproduct system comprises a culture container bottle whole body, a fully permeable cap and cell adherent wallboards, wherein the culture container bottle whole body comprises a bottom collector of centrifugal bottles, a bottle mouth, an inner cell adherent wall, a slope board and the cell adherent wallboards, the slope board is arranged in the bottom collector of centrifugal bottles, the inner celladherent wall is arranged at one end of the bottom collector of centrifugal bottles, multiple groups of cell adherent wallboards are arranged in the inner cell adherent wall, and a graduation scaleplate is arranged outside the culture container bottle whole body. According to the present invention, the cluster layout of the complete automatic biological product system can be used as a single container in the process of adherent cell culture, can be used for culture, centrifugation, sample observation, transportation and other operations, the operation of opening / closing the cap, the operationof liquid transporting, storage of multi-type containers and conversion of multi-type containers in the whole process of automated production can be simplified, and the production efficiency and benefit can be effectively improved.

Owner:INNOVEL INTELLIGENT TECH CO LTD

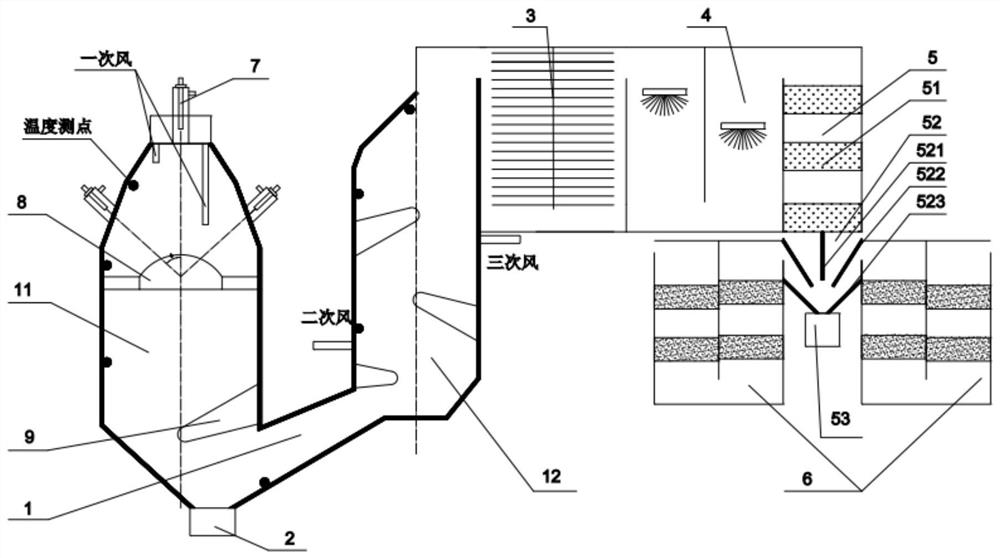

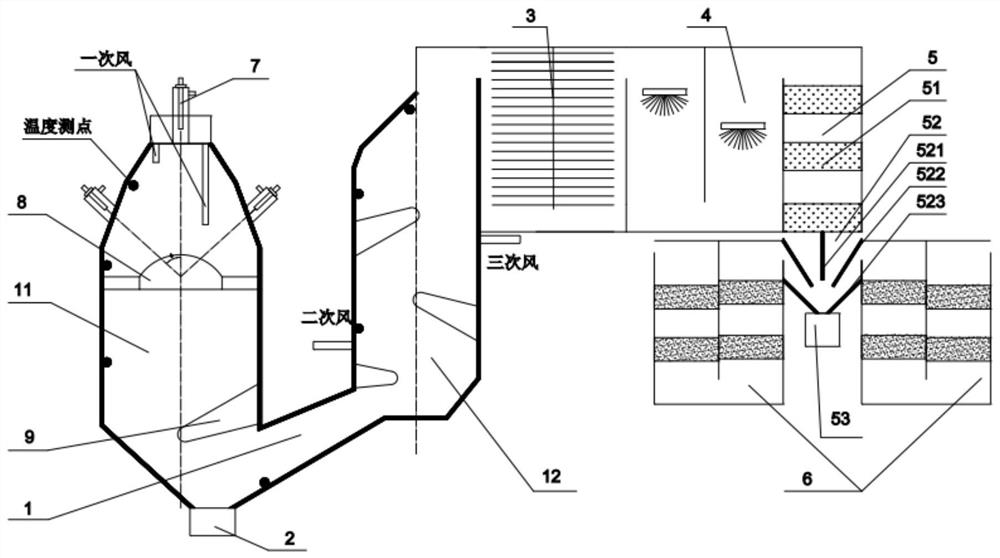

Laboratory organic waste liquid on-site real-time treatment system

ActiveCN112696697AFacilitate staged processingImprove responseCombustion technology mitigationIncinerator apparatusFlue gasProcess engineering

The invention provides a laboratory organic waste liquid on-site real-time treatment system. A waste liquid reaction device (1) comprises a first-stage reaction body (11) and a second-stage reaction body (12) communicated through a channel; the first-stage reaction body (11) is olive-shaped, is internally provided with a flame holder (8) and is filled with primary air and waste liquid; the second-stage reaction body (12) is in a straight eccentric necking shape, the left side of the top is an inclined plane, the right side is a vertical plane, and the section of a top outlet is about 1 / 2-2 / 3 of the section of the middle section; and reactants of the waste liquid reaction device (1) are cooled by a waste heat recovery device (3), quenched and desulfurized by a flue gas quenching and desulfurizing integrated device (4), dewatered by a dewatering device (5) and finally filtered by a flue gas purifying device (6) to remove harmful components. The first-stage reaction body can guarantee a waste liquid reaction space; the second-stage reaction body can guarantee the waste liquid treatment temperature; and the laboratory organic waste liquid on-site real-time treatment system is beneficial to staged treatment of the waste liquid, increases the reactant reaction flow, and ensures the reaction temperature, space and time of the waste liquid.

Owner:TSINGHUA UNIV

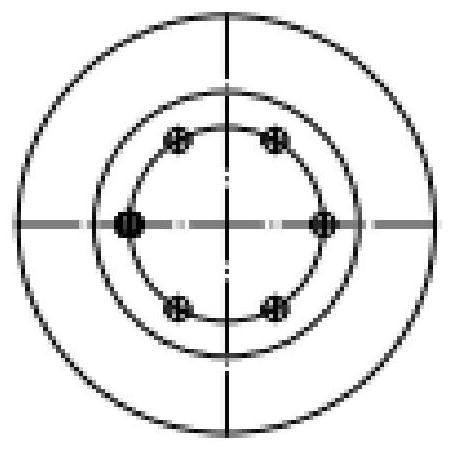

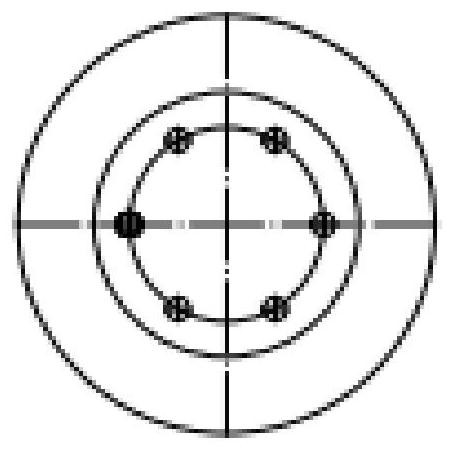

Semiconductor device and production method

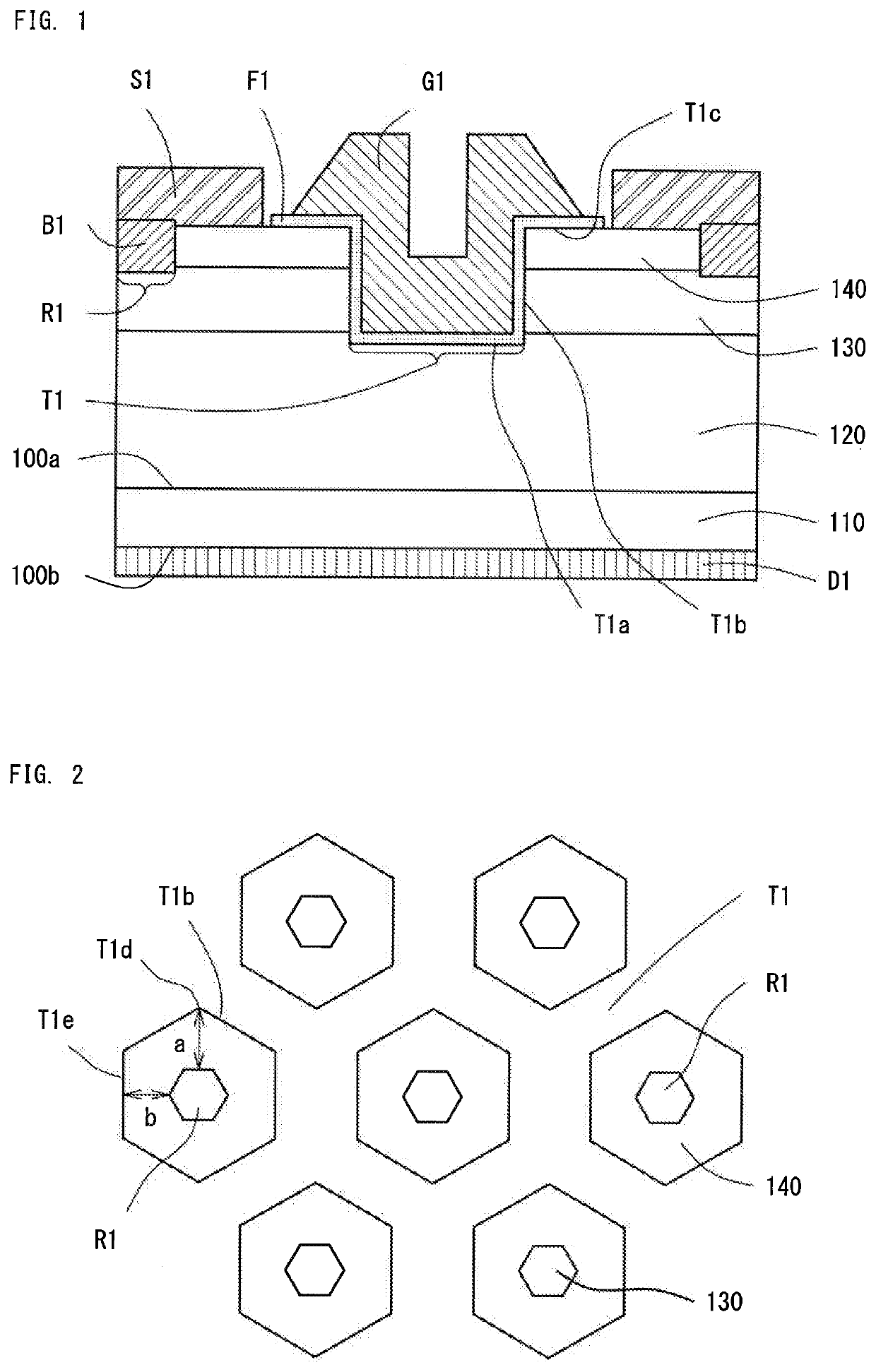

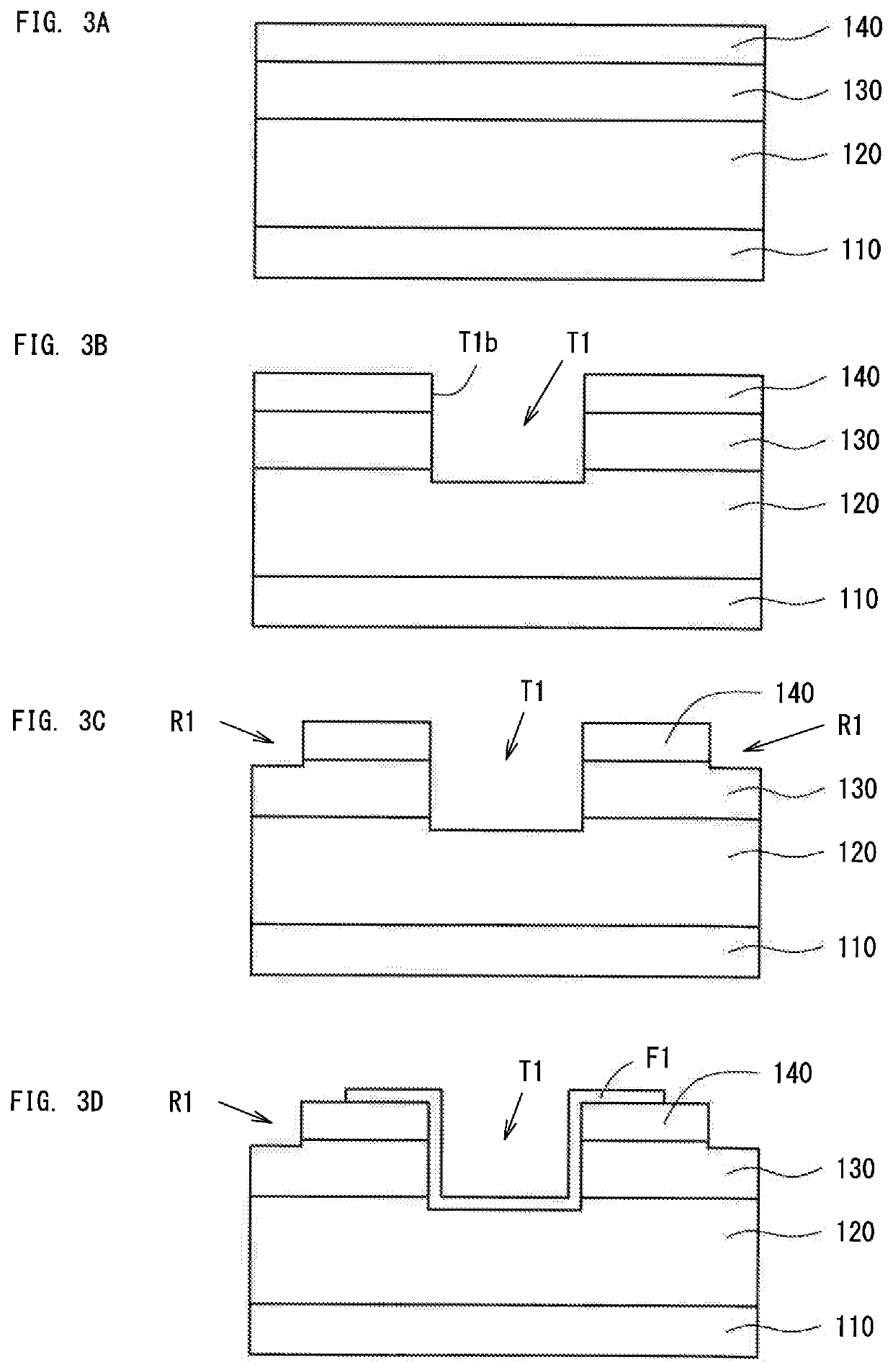

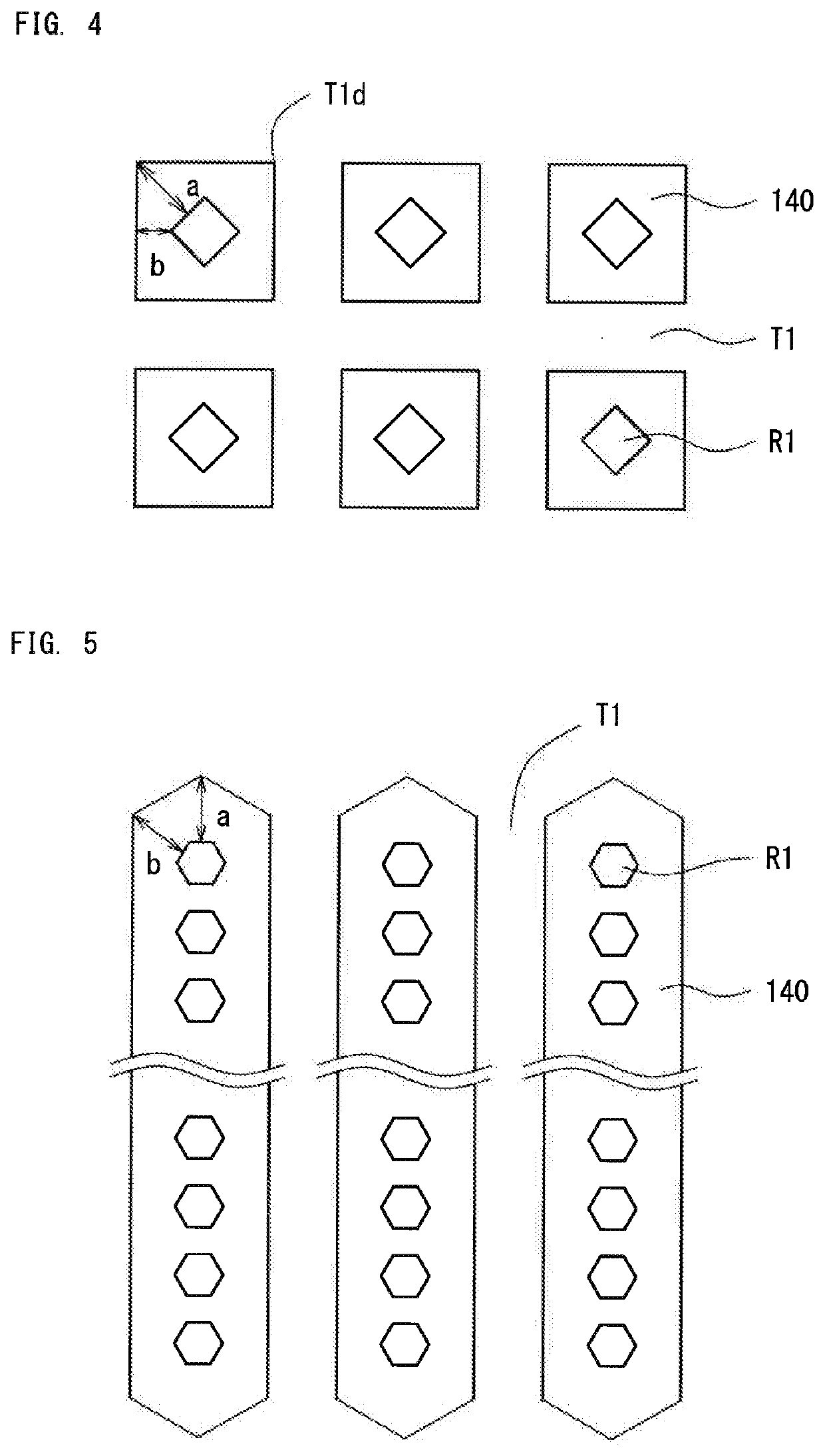

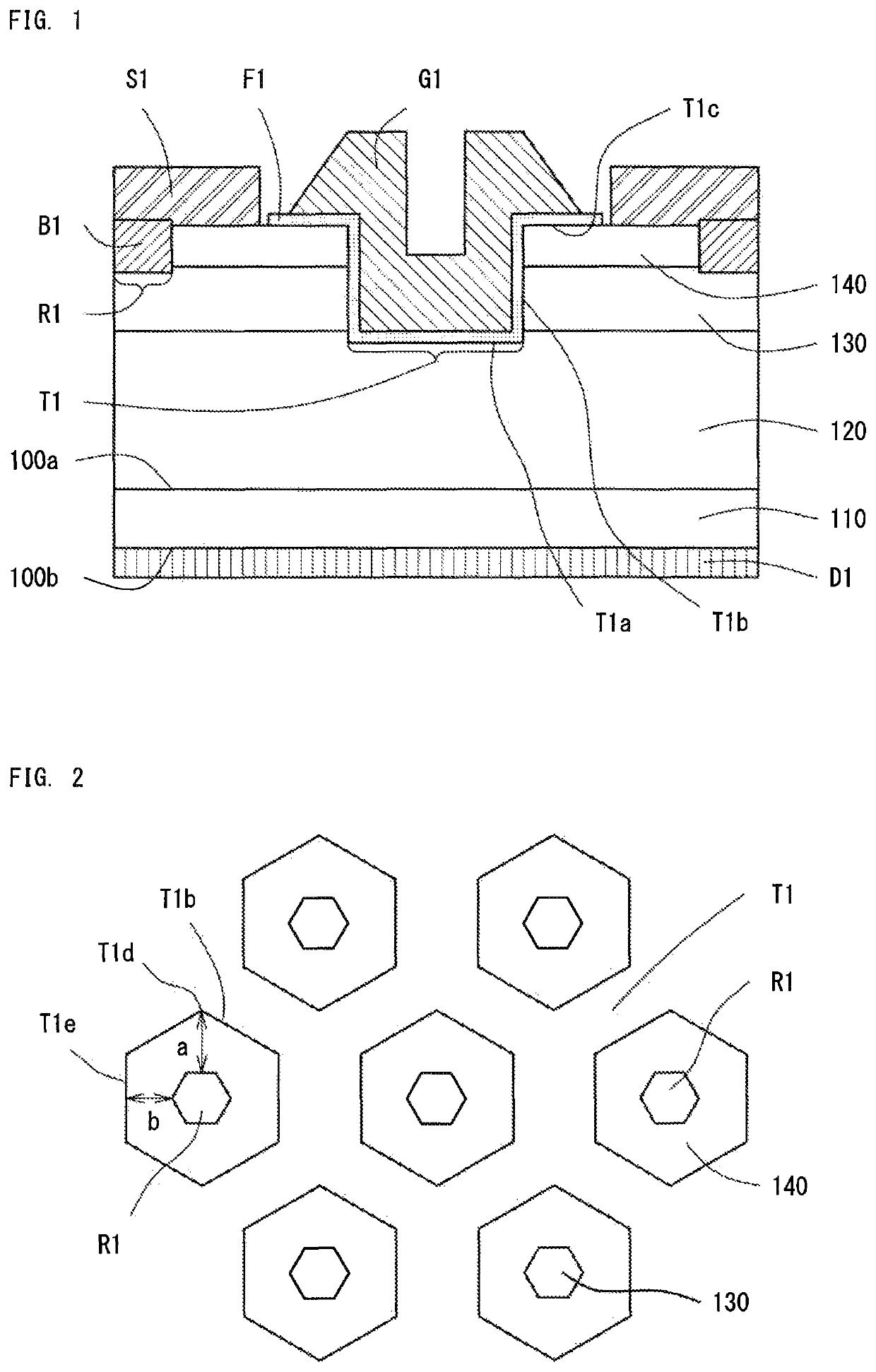

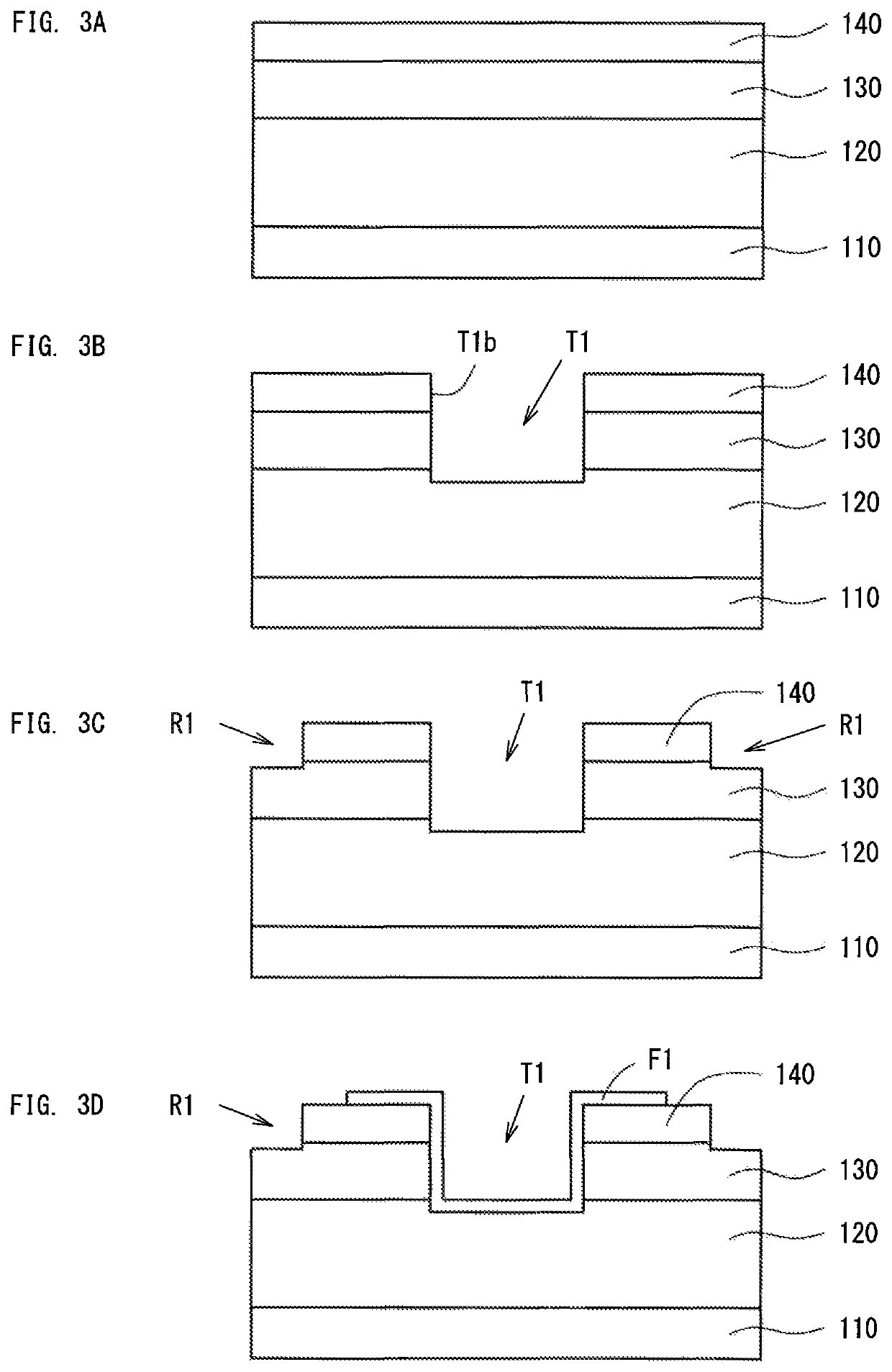

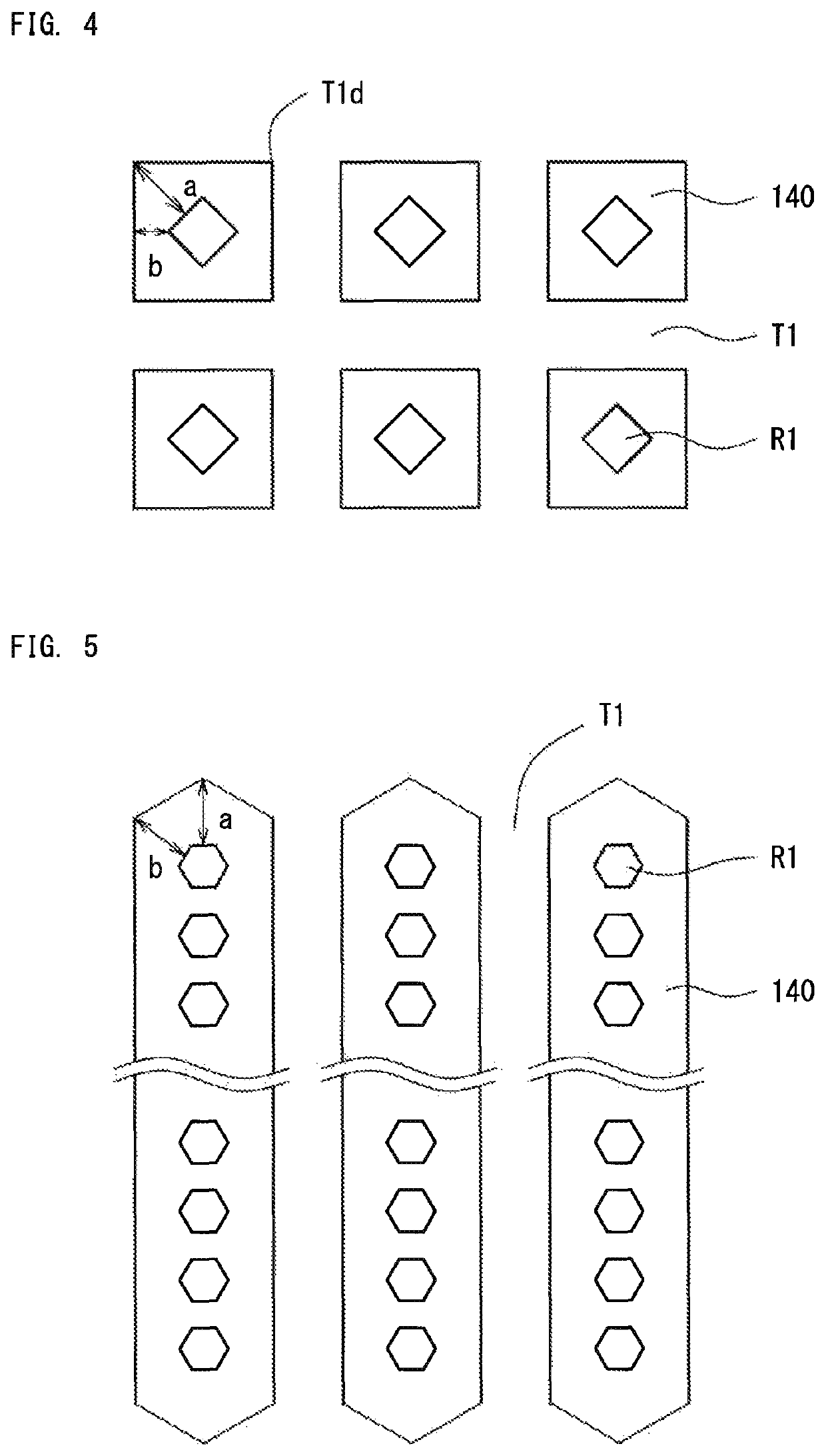

ActiveUS20200287008A1Well formedPrevent current concentrationSolid-state devicesSemiconductor devicesCrystallographyDevice material

The present invention provides a Group III nitride semiconductor device in which current concentration at the corners of the trench is suppressed. The semiconductor device has a pattern in which regular hexagonal unit cells are arranged in a honeycomb pattern. The semiconductor layer is sectionalized into regular hexagonal patterns by the trench. The recess has a small regular hexagonal pattern contained in the regular hexagonal pattern of the semiconductor layer sectionalized by the trench, which is obtained by reducing the regular hexagon of the semiconductor layer with the same center. Moreover, the regular hexagonal pattern of the recess is rotated by 30° with respect to the regular hexagon of the semiconductor layer. The Mg activation ratio is lower in the vicinity of corners of the trench than that in other regions in the vicinity of side walls of the trench of the p-type layer.

Owner:TOYODA GOSEI CO LTD

Dust removal mechanism for highly-folded wall surface

ActiveCN106859483AEfficient cleaningFully automaticSuction filtersSuction nozzlesCircular discElectric machinery

The invention relates to a dust removal mechanism for the highly-folded wall surface, and belongs to the technical field of control devices. The dust removal mechanism comprises a baffle, an outer frame and a drilled base plate which are coaxially arranged; the outer frame is arranged in a hollowed mode, the baffle is installed on the top of the outer frame, the drilled base plate is installed at the bottom of the outer frame, the drilled base plat is provided with through holes, a cylindrical side face brush head and a planar disc brush head are installed on the drilled base plate, and the cylindrical side face brush head and the planar disc brush head both penetrate through the through holes formed in the drilled base plate to be connected with a driving motor. The dust removal mechanism can achieve efficient cleaning of complex wall surfaces such as the highly-folded wall surface, when cleaning is conducted, the device is installed on a wall surface carrying device, that is to say, a full-automatic cleaning on the wall can be achieved. Due to the fact that the design adopts the design idea of directly combining the brush heads with a suction device, the recovery rate to the wall surface dust is guaranteed.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing porcine parvovirus inactivated vaccines

ActiveCN103157106BIncreased sensitivityUniform stateAntiviralsRecovery/purificationImmune effectsPublic health

Owner:RINGPU (BAODING) BIOLOGICAL PHARMACEUTICAL CO LTD

Semiconductor device and production method

ActiveUS11164950B2Prevent current concentrationEfficient removalSolid-state devicesSemiconductor devicesCrystallographyDevice material

The present invention provides a Group III nitride semiconductor device in which current concentration at the corners of the trench is suppressed. The semiconductor device has a pattern in which regular hexagonal unit cells are arranged in a honeycomb pattern. The semiconductor layer is sectionalized into regular hexagonal patterns by the trench. The recess has a small regular hexagonal pattern contained in the regular hexagonal pattern of the semiconductor layer sectionalized by the trench, which is obtained by reducing the regular hexagon of the semiconductor layer with the same center. Moreover, the regular hexagonal pattern of the recess is rotated by 30° with respect to the regular hexagon of the semiconductor layer. The Mg activation ratio is lower in the vicinity of corners of the trench than that in other regions in the vicinity of side walls of the trench of the p-type layer.

Owner:TOYODA GOSEI CO LTD

Method for preparing porcine circovirus 2-type inactivated vaccine

ActiveCN103285385BIncreased sensitivityUniform stateViral antigen ingredientsAntiviralsImmune effectsPublic health

Owner:RINGPU (BAODING) BIOLOGICAL PHARMACEUTICAL CO LTD

A real-time treatment system for laboratory organic waste liquid

ActiveCN112696697BFacilitate staged processingImprove responseCombustion technology mitigationIncinerator apparatusThermodynamicsVertical plane

Owner:TSINGHUA UNIV

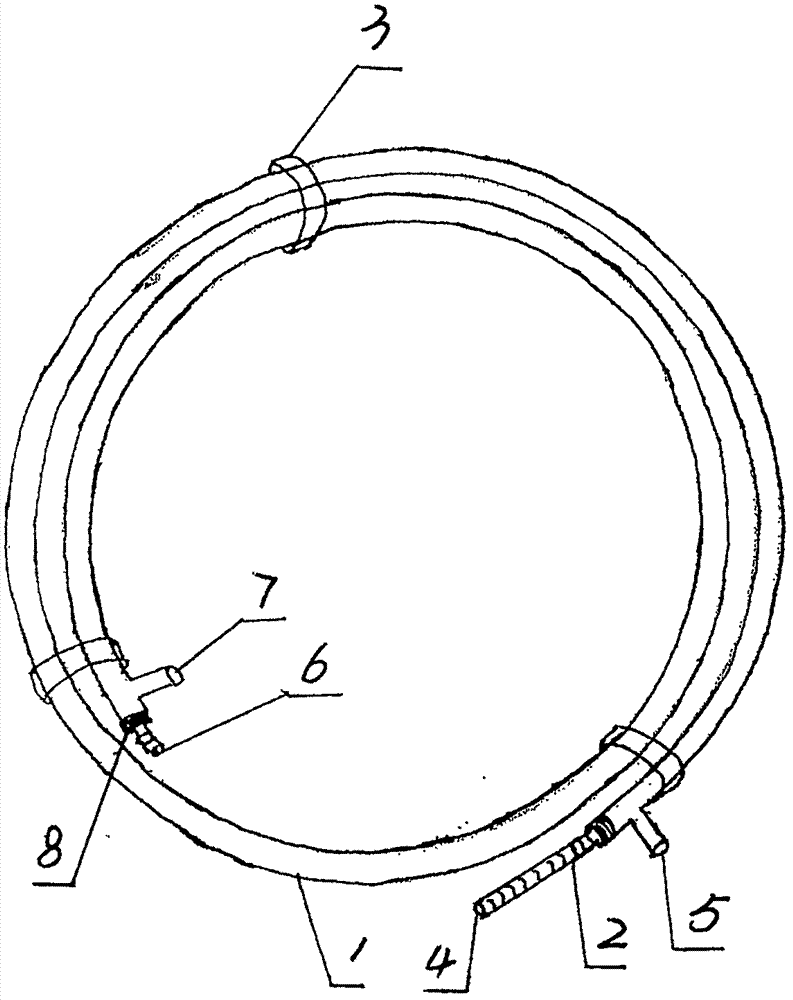

Coil type heat exchanger

InactiveCN106643220AIncrease the wall areaAvoid easy cloggingStationary tubular conduit assembliesTubular elementsPlate heat exchangerEngineering

The invention provides a coil type heat exchanger. The coil type heat exchanger comprises a coil and a metal corrugated pipe. The coil type heat exchanger is characterized in that the metal corrugated pipe with the large caliber is mounted in the coil, openings in the two ends of the metal corrugated pipe are exposed out of openings in the two ends of the coil, and the openings in the two ends of the coil and the outer wall of the metal corrugated pipe are sealed through injection molding, hot melting, welding or colloid; a first joint is mounted at one end of the coil, a second joint is mounted at the other end of the coil, a third joint is the opening in one end of the metal corrugated pipe, and a fourth joint is the opening in the other end of the metal corrugated pipe; the metal corrugated pipe is a copper corrugated pipe or a stainless steel corrugated pipe; and the coil is a rubber coil or a plastic coil. According to the coil type heat exchanger, the runner is long, the metal corrugated pipe with the large caliber is used for flowing of waste hot water, blocking is not likely to happen, the heat exchange efficiency is high, and the coil type heat exchanger can be widely applied to recovery of waste hot water and hot energy generated in household bathing, hairdressing and beauty, large bath centers and industrial production.

Owner:刘洋豪

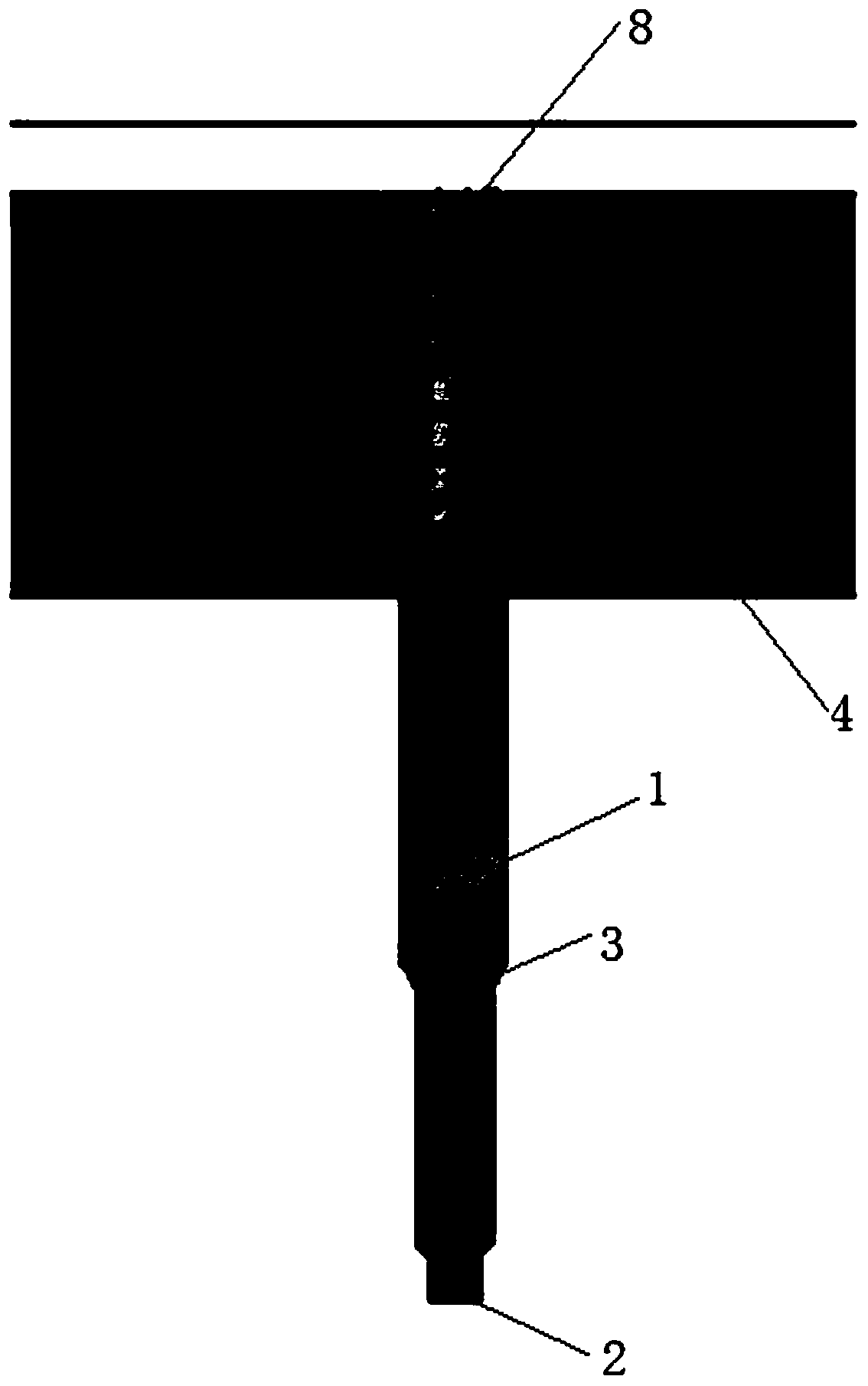

Hot melting machine system and method thereof

InactiveCN111070702AEfficient accumulationEfficient ConcentrationDomestic articlesMetallurgyHot melt

The invention discloses a hot melting machine system and a method thereof. The hot melting machine system comprises a hot melting head, wherein a groove is formed in the bottom wall of the hot meltinghead; a groove shaped step is arranged on the outer wall of the middle section of the hot melting head; the hot melting head is made from uncommon ceramic material; the deformation quantity of the uncommon ceramic material at 200 DEG C is 0.02%; the thermal conductivity the uncommon ceramic material is 115W / (m.K); and the hardness of the uncommon ceramic material is 1200 HV. The hot melting machine system further comprises a heating plate, a prepressing plate and a lower die sequentially arranged from top to bottom. By combining with other structures or methods, the defects in the prior art that when hot melting is simultaneously carried out on multiple points, hot melting heads have position interference to cause poor hot melting effect, and the hot melting heads cannot effectively gather temperature of the hot melting points to cause poor hot melting effect are effectively avoided.

Owner:深圳市松泽自动化设备有限公司

A dust removal mechanism for highly wrinkled walls

ActiveCN106859483BEfficient cleaningFully automaticSuction filtersSuction nozzlesCircular discSuction force

A dust removal mechanism for highly wrinkled walls, belonging to the technical field of control devices, comprising baffles, an outer frame and a bottom plate with holes all coaxially arranged; the outer frame is hollow; the baffle is installed on the top of the outer frame; The perforated bottom plate is installed on the bottom of the outer frame; the perforated bottom plate is provided with through holes; the perforated bottom plate is equipped with a cylindrical side brush head and a flat disc brush head; The disc brush heads all go through the through holes on the bottom plate with holes to connect to the driving motor. The dust removal mechanism can realize high-efficiency cleaning of complex walls such as high folds, and the device can be installed on the wall carrying device during cleaning to realize fully automatic cleaning of the wall. Because this design adopts the design idea of directly combining the brush head and the suction device, the recovery rate of the wall dust is guaranteed.

Owner:ZHEJIANG UNIV OF TECH

A method for isolating human placental chorionic mesenchymal stem cells

ActiveCN107354130BReduce cutting timeShorten the timeCell dissociation methodsSkeletal/connective tissue cellsCulture fluidCulture mediums

The invention discloses a human placenta chorionic mesenchymal stem cell separation method, which comprises: 1) taking healthy human placenta chorionic tissue, cutting into strip blocks, and completely rinsing with physiological saline; 2) adding a proper amount of physiological saline, chopping the chorion into fine particles by using a homogenizer, and rinsing with physiological saline until the solution is clarified; 3) treating again with the homogenizer to achieve micro-particles, and carrying out centrifugation to remove the upper layer blood cells; 4) adding an enzyme to the precipitate, digesting, carrying out centrifugation, and separating the precipitate; 5) carrying out centrifugal washing with physiological saline twice, adding a culture medium to the precipitate, inoculating, and culturing; and 6) discarding the tissue blocks and the culture medium at the 7th day, rinsing the bottom of the culture flask by using physiological saline, adding a fresh culture medium, changing the culture medium every 3 days until the cell fusion degree achieves 80-90%, and carrying out digestion passage with trypsin to obtain the human placenta chorionic mesenchymal stem cells. According to the present invention, the operation is simple and rapid, and the high-quality human placenta chorionic mesenchymal stem cells can be obtained.

Owner:GUANGZHOU WOMEN AND CHILDRENS MEDICAL CENTER

High-pressure homogenizer and method for manufacturing graphene using the same

ActiveUS11242251B2Exfoliation effective region can be increasedImprove productivityFlow mixersTransportation and packagingGraphiteGraphene

Provided a high-pressure homogenizer comprising a channel module comprising a microchannel through which an object for homogenization passes, wherein the microchannel is provided with a first flow channel and a second flow channel sequentially arranged along the direction through which the object passes, the first flow channel is provided with a plurality of first baffles disposed so as to partition the microchannel into a plurality of spaces, the second flow channel is provided with a plurality of second baffles disposed so as to partition the microchannel into a plurality of spaces, and at least one of the first baffles is provided to be positioned between two adjacent second baffles.

Owner:LG CHEM LTD

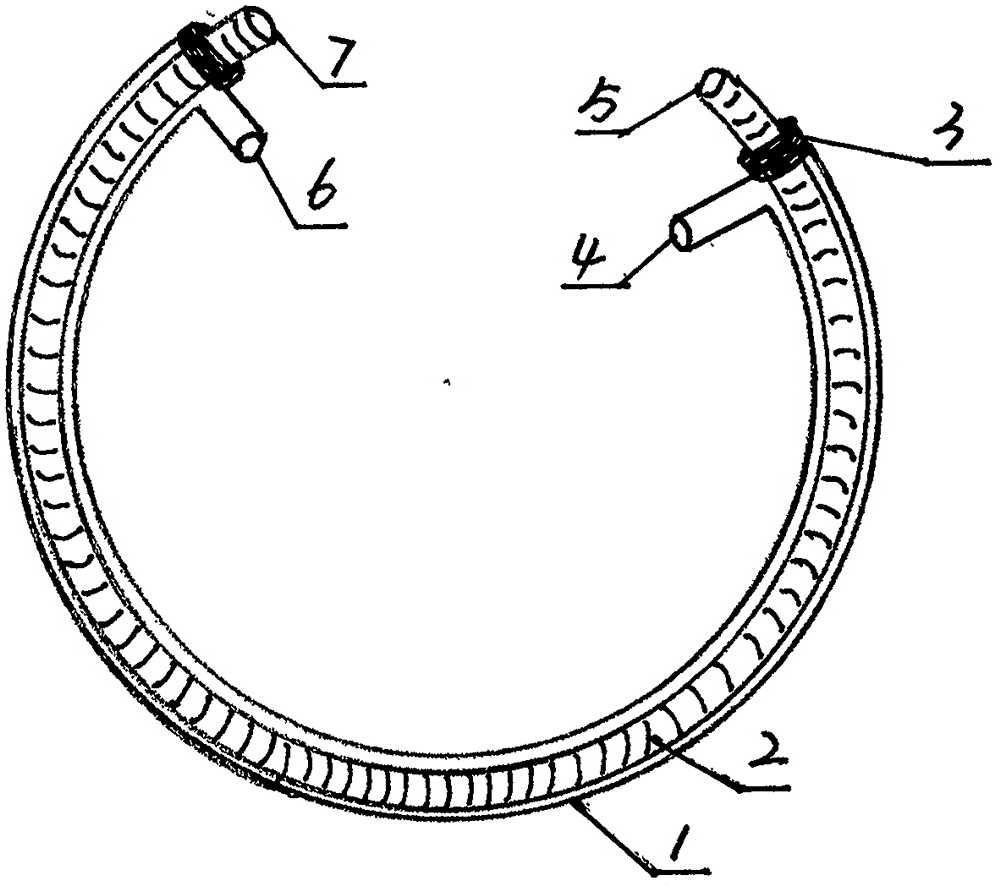

Annular casing pipe type heat exchanger

InactiveCN106918252AIncrease the wall areaAvoid easy cloggingStationary tubular conduit assembliesPlate heat exchangerWater flow

The invention provides an annular casing pipe type heat exchanger. The annular casing pipe type heat exchanger comprises a plastic pipe, a stainless steel corrugated pipe and bundling pieces. The annular casing pipe type heat exchanger is characterized in that the stainless steel corrugated pipe is arranged in the plastic pipe, openings in the two ends of the stainless steel corrugated pipe are exposed out of openings in the two ends of the plastic pipe, and the openings in the two ends of the plastic pipe and the outer wall of the stainless steel corrugated pipe are sealed through injection molding or hot melting or welding or glue; a hole is formed in the pipe wall at one end of the plastic pipe, and a first connector is arranged on the hole in the pipe wall in the manner of injection molding or hot melting or welding or glue; a hole is formed in the pipe wall at the other end of the plastic pipe, a second connector is arranged on the hole of the pipe wall, the opening in one end of the stainless steel corrugated pipe is provided with a third connector, and the opening in the other end of the stainless steel corrugated pipe is provided with a fourth connector; and the plastic pipe provided with the stainless steel corrugated pipe is manufactured into a spiral shape, and the plastic pipe is twisted by the bundling pieces to be shaped into a ring shape. Waste hot water flows through the stainless steel corrugated pipe with the diameter ranging from 10 mm to 70 mm, blockage is not likely to happen, and the heat energy of the waste hot water can be better recycled.

Owner:刘洋豪

Ice making box

PendingCN112710110AIncrease the wall areaImprove ice production efficiencyLighting and heating apparatusIce productionPhysicsAluminium

The invention discloses an ice making box, and belongs to the technical field of ice making equipment manufacturing. The ice making box comprises an ice making box body, the ice making box body is provided with a groove, a convex part is arranged in the groove, the ice making box body selects a metal material as the material, an aluminum material or a copper material is selected as the material of the ice making box body, the convex part is cylindrical or conical, and the average diameter of the convex part ranges from one third to two thirds of the diameter of the groove. According to the ice making box, by arranging the convex part, the wall surface area of cold and water heat exchange is increased, cold conduction is already changed into three-dimensional conduction of the wall surface of the ice making box body and from the convex part to the center of the groove from one-way conduction from the peripheral wall surface of a traditional ice making box to the center of a groove, and the ice making efficiency is greatly improved.

Owner:新东海(佛山)五金电器制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com