Coil type heat exchanger

A heat exchanger and coil type technology, applied in the field of heat exchange, can solve the problems of insignificant economic benefit of heat recovery, easy blockage of the heat exchanger flow channel, large temperature difference at the hot end of the heat exchanger, etc., and achieves a small occupied space. , The effect of strong pressure bearing capacity and sufficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

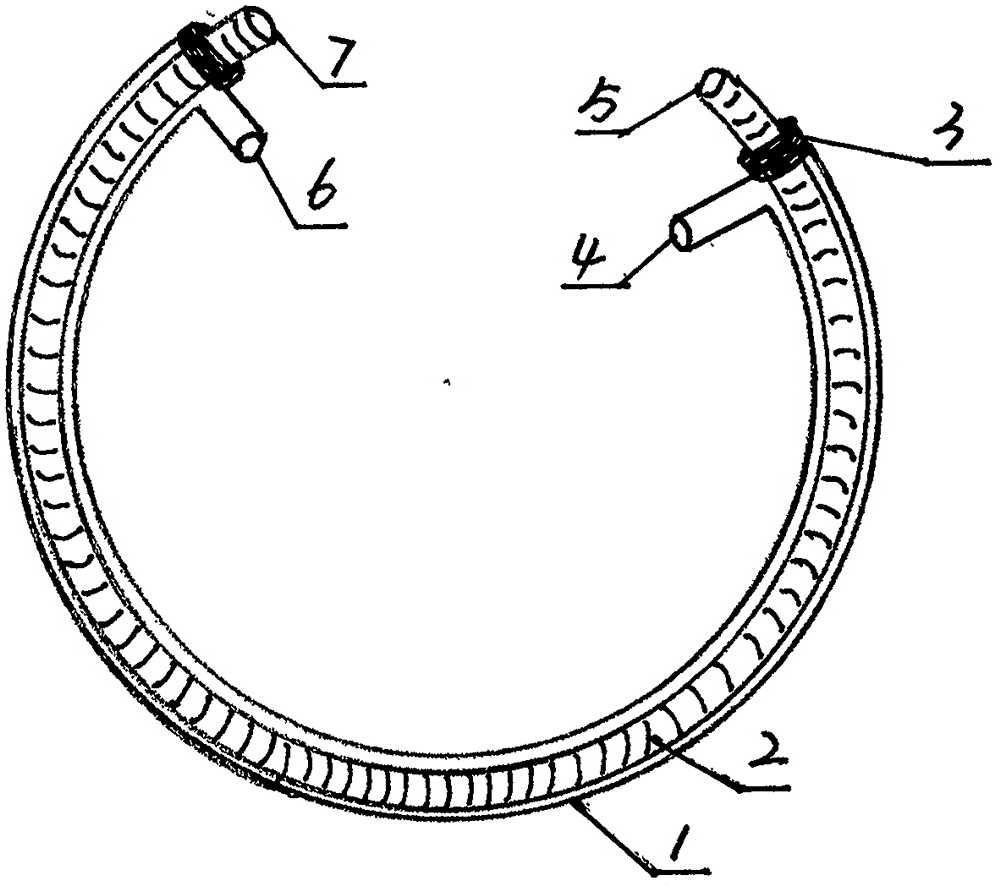

[0017] A coiled tube heat exchanger according to the present invention comprises a coiled tube 1 and a metal bellows 2, and is characterized in that: a metal bellows 2 is installed in the coiled tube 1, and the two ends of the metal bellows 2 The openings are exposed outside the openings at both ends of the coil tube 1, and the openings at both ends of the coil tube 1 and the outer wall of the metal bellows 2 are sealed by injection molding, hot melting, welding or colloid. The other end of the metal bellows 2 is equipped with a second interface 6, one end of the metal bellows 2 is opened as the third interface 7, and the other end of the metal bellows 2 is opened as the fourth interface 5, the cavity space between the inner wall of the coil 1 and the outer wall of the metal bellows 2 and The first interface 4 and the second interface 6 form the first flow channel, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com