Method for producing biogas through anaerobic fermentation of degradation straw raw material

A technology for anaerobic fermentation and biogas production, which is applied in fermentation, waste fuel, biological sludge treatment, etc., can solve problems such as waste of resources, and achieve the effect of small inoculum amount, simple process and easy access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

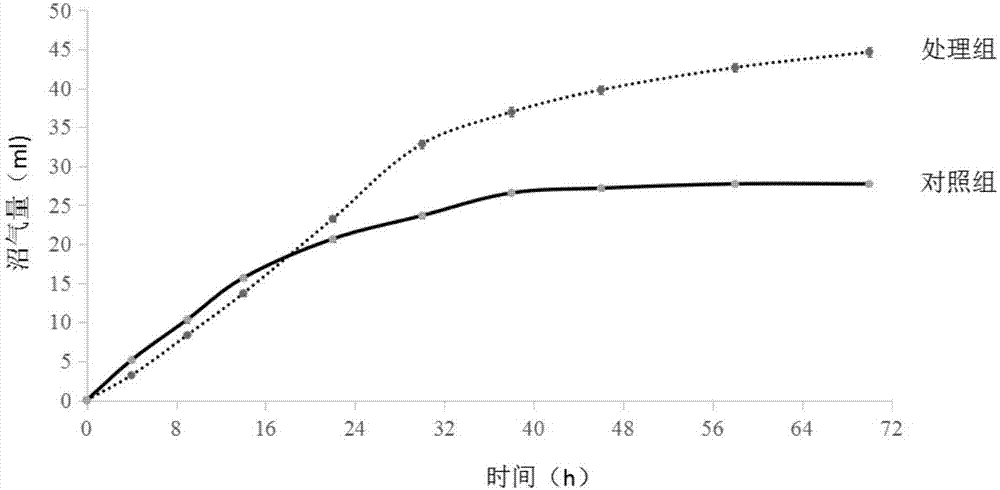

[0025] Example 1 Research on anaerobic fermentation of wheat straw to produce biogas

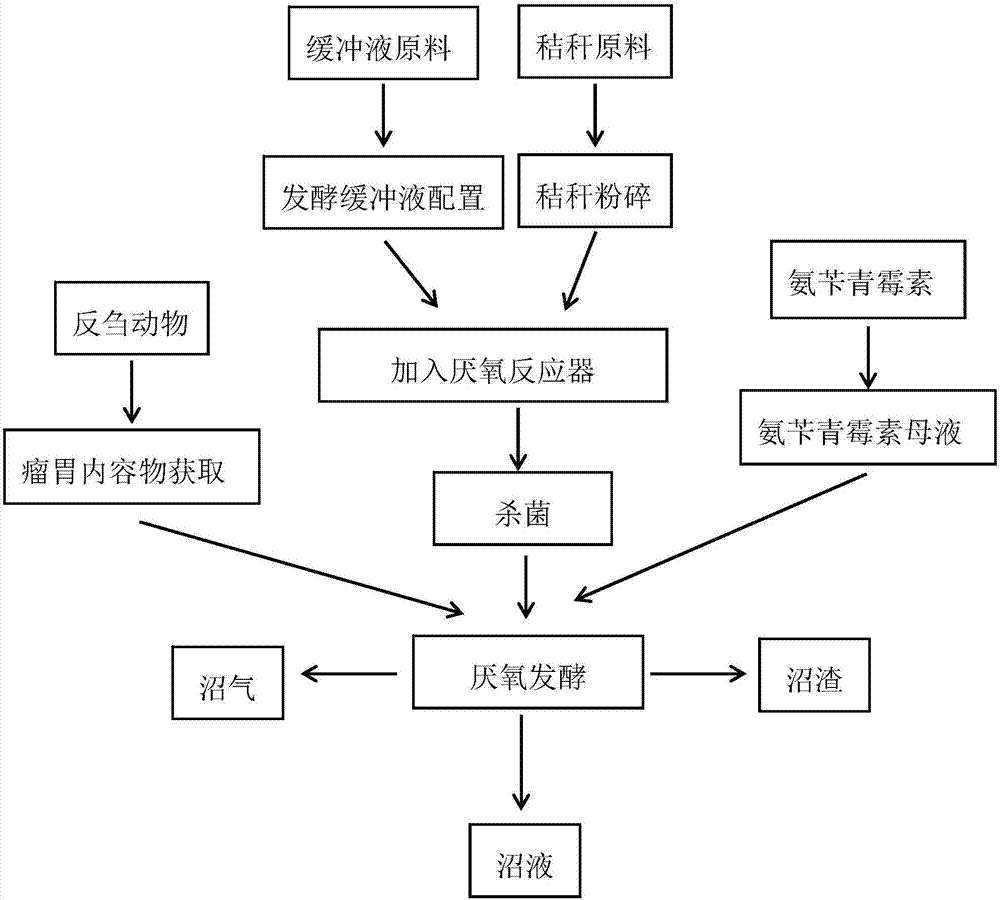

[0026] The wheat straw was crushed into fragments with a length of about 0.5 cm by a pulverizer; the fermentation buffer was prepared according to the formula in Table 1; the mother liquor of ampicillin was prepared; the rumen contents were obtained from the rumen of ruminant cows. Mix 1 g of wheat straw fragments with 90 ml of fermentation buffer and then sterilize, add ampicillin to make the final concentration 2000 U / ml, add 10 ml of rumen content, and ferment anaerobically at 39°C for 72 hours. The conditions of the control group were the same as above, without adding ampicillin. The mass volume ratio concentration of the fermented substance is 1%.

[0027] Table 1 buffer configuration table (1L)

[0028]

[0029]

[0030] After 72 hours of fermentation, the treatment group significantly increased the methane production of the wheat straw anaerobic fermentation system, see figu...

Embodiment 2

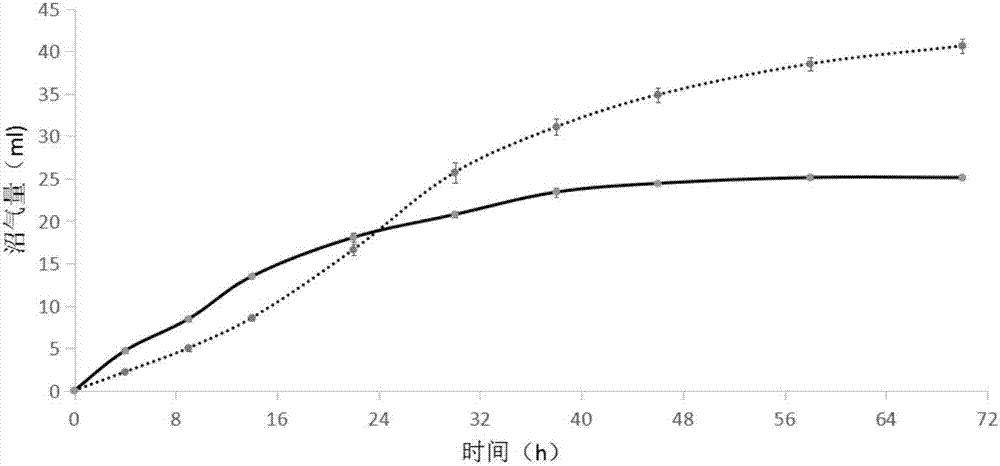

[0042] Example 2 Research on Biogas Production by Anaerobic Fermentation of Rice Straw

[0043] The rice straw is crushed into 0.3cm length fragments by a pulverizer; 1g of the chopped raw material is added to the anaerobic reactor as a fermentation product; 45ml of fermentation buffer is added to the anaerobic reactor; Inoculate the rumen content of 5ml fermented product, described rumen content is taken from the rumen of ruminant dairy cow; Make the final concentration of fermented product be (mass volume ratio) 2%; Add ampicillin in anaerobic reactor, make its final concentration be 1800U / ml; biogas produced by anaerobic fermentation in the anaerobic reactor, the reaction temperature is 38°C; the anaerobic fermentation time in the anaerobic reactor is 72 hours, the above is set as the treatment group, and the control group is the group without adding ampicillin. After 72 hours of fermentation, the treatment group (dotted line) significantly increased the methane production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com