Cracking assistant for improving low-carbon olefin concentration

A technology of low-carbon olefins and additives, which is applied in the field of cracking additives to increase the concentration of propylene in catalytic cracking liquefied gas, and can solve the problems of high yield of propylene dry gas and coke, low propylene selectivity, and limited range of propylene concentration. , to achieve the effect of reducing dry gas and coke yield, increasing yield and increasing octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

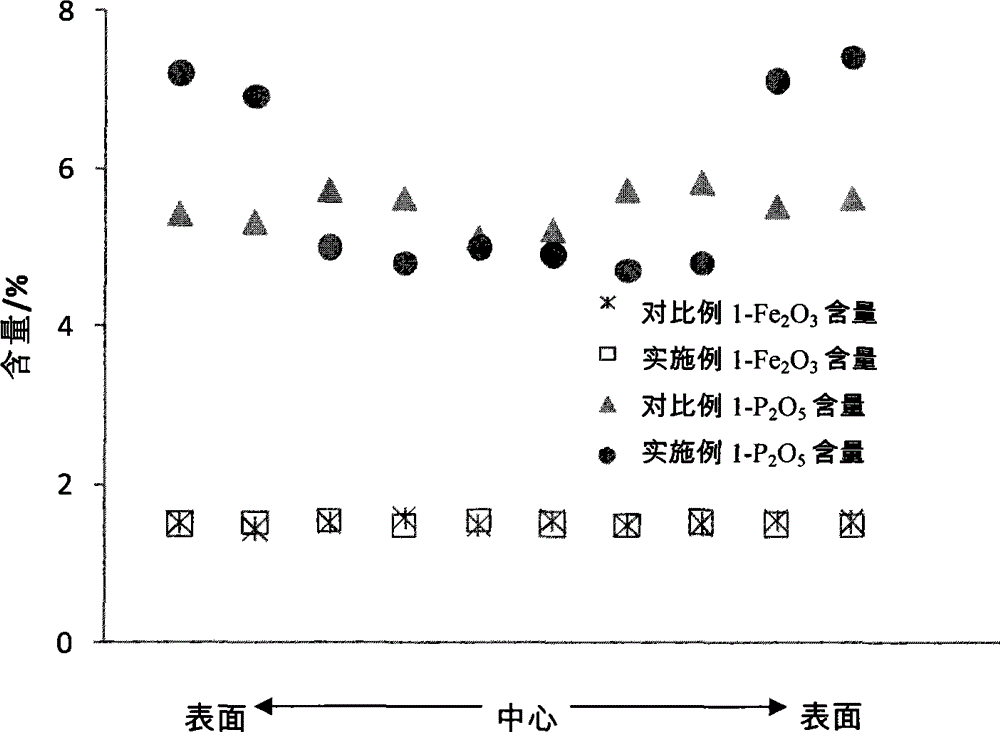

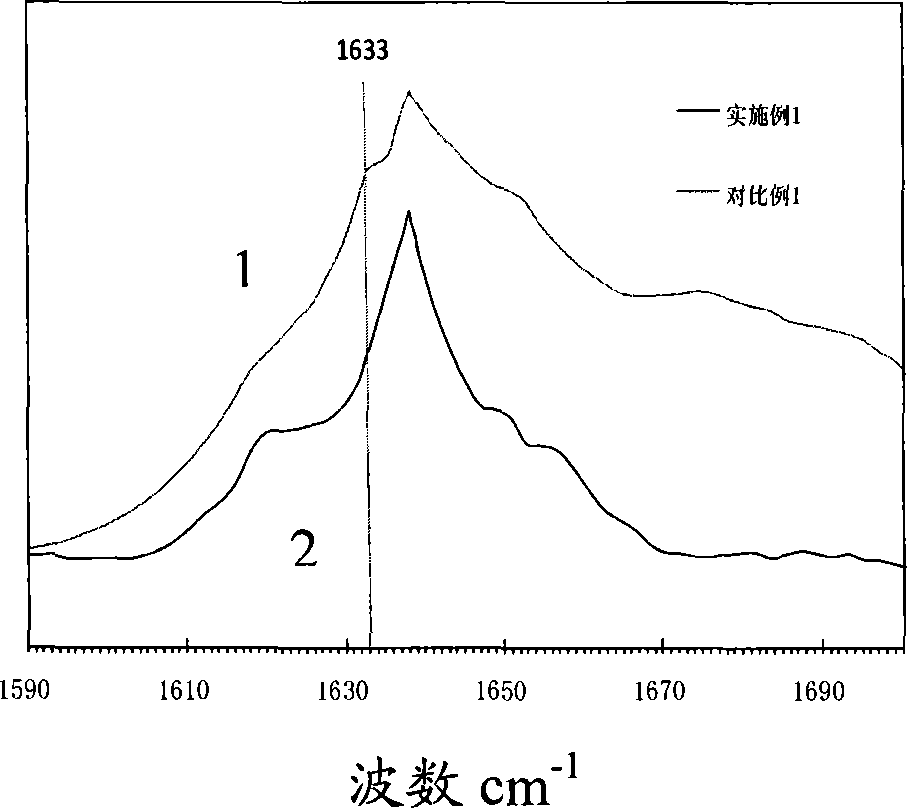

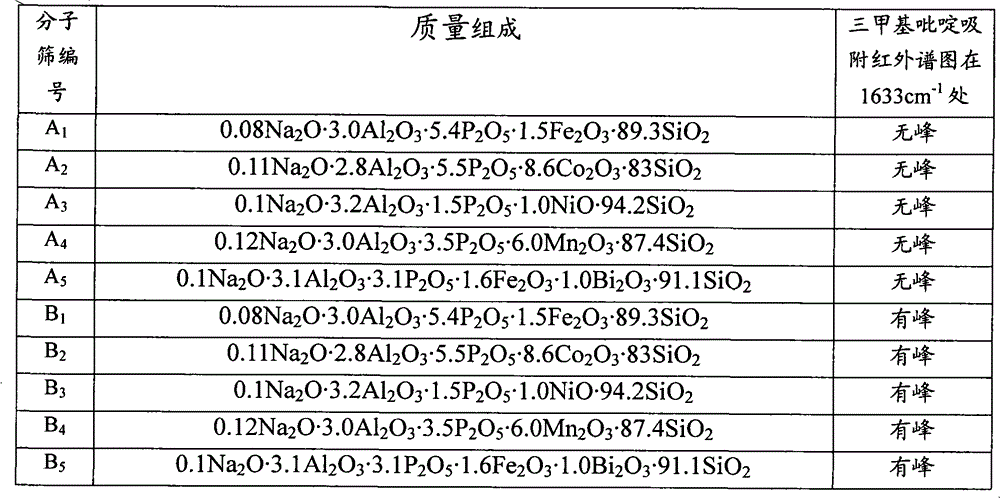

[0038] 5kg NH 4 Cl was dissolved in 100kg of water, and 10kg (dry basis) of crystallization product ZSM-5 molecular sieve (produced by Sinopec Catalyst Qilu Branch Company, produced by amine method, SiO 2 / Al 2 o 3 =50), after exchanging at 90°C for 0.5h, filtered to obtain a filter cake; 0.56kg H 3 PO 4 (concentration 85% by weight) and 0.81kgFe(NO 3 ) 3 9H 2 O was dissolved in 9kg of water, and the impregnating solution was mixed with the filter cake for impregnation, dried, and roasted at 550°C for 2 hours to obtain the sample after the first impregnation; 0.34kg of H 3 PO 4(concentration 85% by weight) is dissolved in 9kg water, this dipping liquid is mixed with the sample after above-mentioned dipping for the first time dipping, oven dry, 550 ℃ of roasting treatment 2 hours, obtain the phosphorus and transition metal modified MFI of the present invention Molecular sieve, denoted as A 1 . Elemental analysis chemical composition (mass) is 0.08Na 2 O·3.0Al 2 o 3...

Embodiment 2

[0043] 5kg NH 4 Cl is dissolved in 100kg of water, and 10kg (dry basis) of the crystallization product ZSM-5 molecular sieve (produced by Sinopec Catalyst Qilu Branch of Sinopec, synthesized by amine method, SiO 2 / Al 2 o 3 =50), after exchanging at 90°C for 0.5h, filtered to obtain a filter cake; 0.61kg H 3 PO 4 (concentration 85% by weight) and 3kg Co(NO 3 ) 2 ·6H 2 O was dissolved in 9kg of water to obtain an impregnation solution, which was mixed with the filter cake for impregnation, dried, and roasted at 550°C for 2 hours to obtain a sample; 0.32kg H 3 PO 4 (concentration 85% by weight) was dissolved in 9kg water to obtain impregnating liquid, this impregnating liquid and above-mentioned sample were mixed impregnated, oven-dried, 550 ℃ of roasting 2 hours, obtain the phosphorus and transition metal modified MFI molecular sieve of the present invention, write down for A 2 . Elemental analysis chemical composition is 0.11Na 2 O·2.8Al 2 o 3 5.5P 2 o 5 8.6Co ...

Embodiment 3

[0047] 5kg NH 4 Cl was dissolved in 100kg of water, and 10kg (dry basis) of crystallization product ZSM-5 molecular sieve (produced by Sinopec Catalyst Qilu Branch Company, produced by amine method, SiO 2 / Al 2 o 3 =50), after exchanging at 90°C for 0.5h, filtered to obtain a filter cake; 0.15kg H 3 PO 4 (concentration 85% by weight) and 0.38kgNi(NO 3 ) 2 ·6H 2 O was dissolved in 9kg of water, and the impregnating solution was mixed with the filter cake for impregnation, dried, and roasted at 550°C for 2 hours to obtain the first impregnated sample; 0.1kg of H 3 PO 4 (concentration 85% by weight) was dissolved in 9 kg of water, the impregnating solution was mixed with the above-mentioned impregnated sample for the first time, impregnated, dried, and roasted at 550 ° C for 2 hours to obtain the phosphorus and transition metal modified MFI molecular sieve of the present invention , denoted as A 3 . Elemental analysis chemical composition is 0.1Na 2 O·3.2Al 2 o 3 1.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com