Patents

Literature

43results about How to "Increase biogas production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-biological removal and recovery of nutrients from waste

InactiveUS20100193416A1Enhance productionHigh qualityWaste water treatment from animal husbandryTreatment involving filtrationCounter currentDissolved nutrients

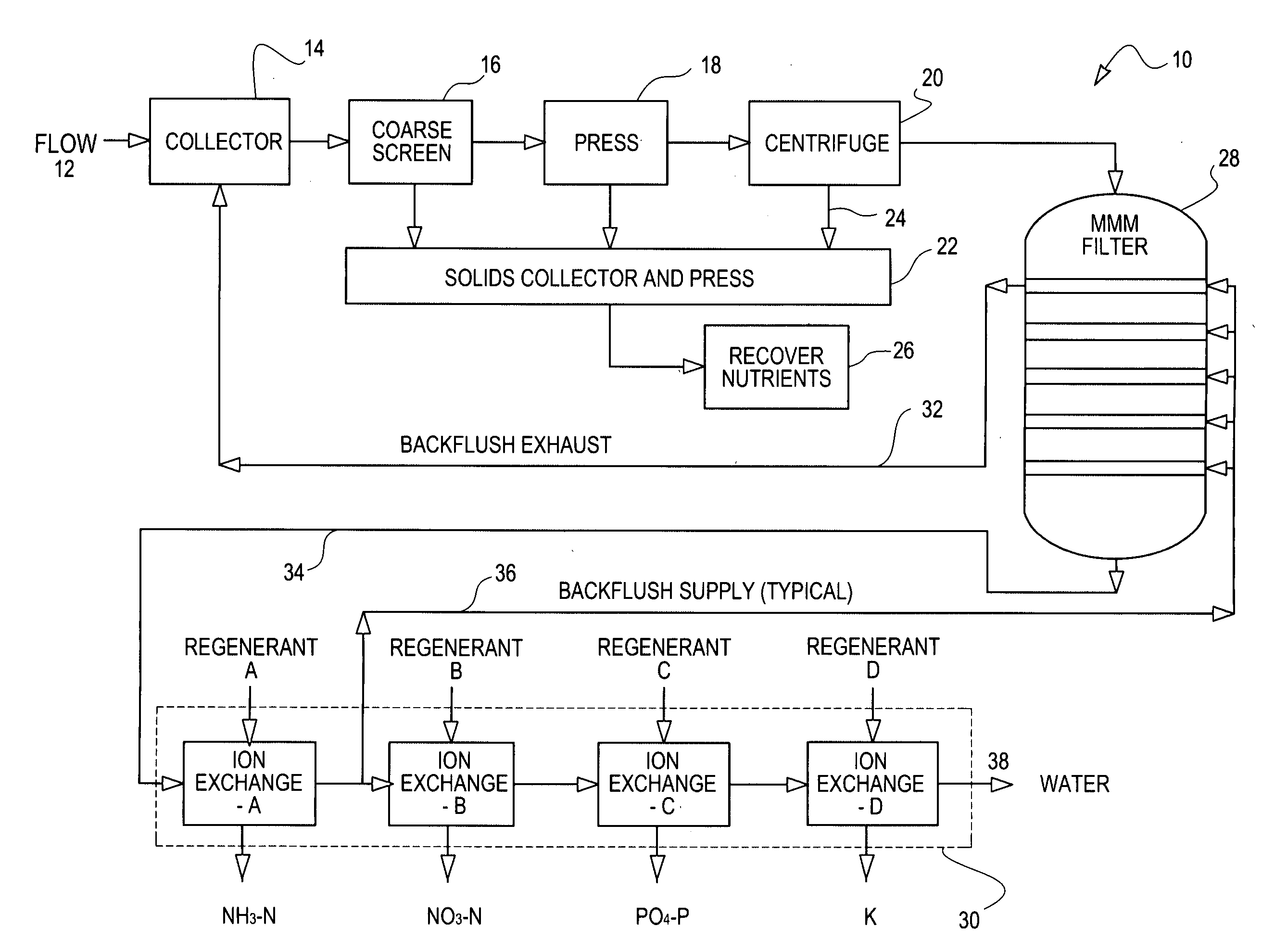

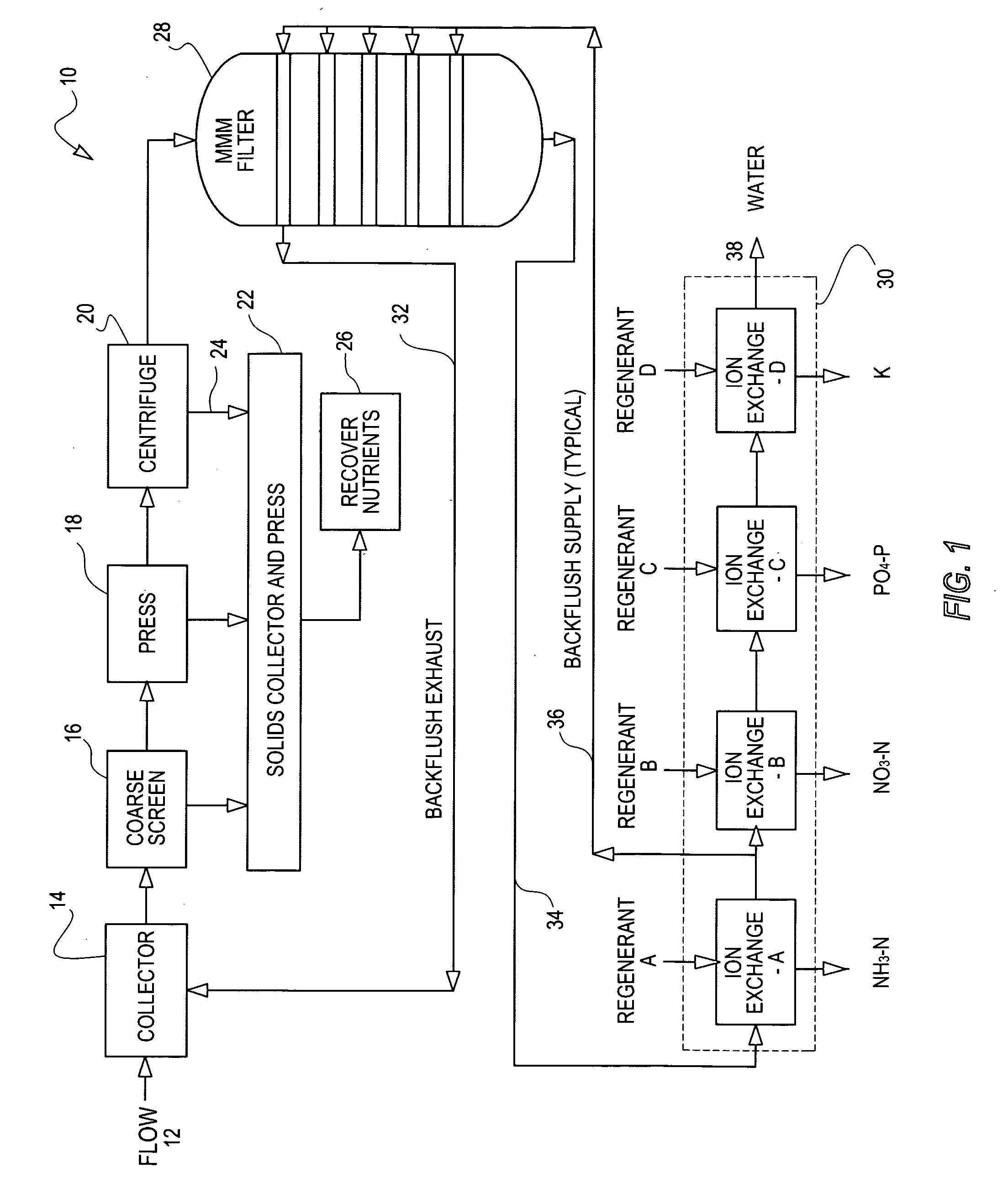

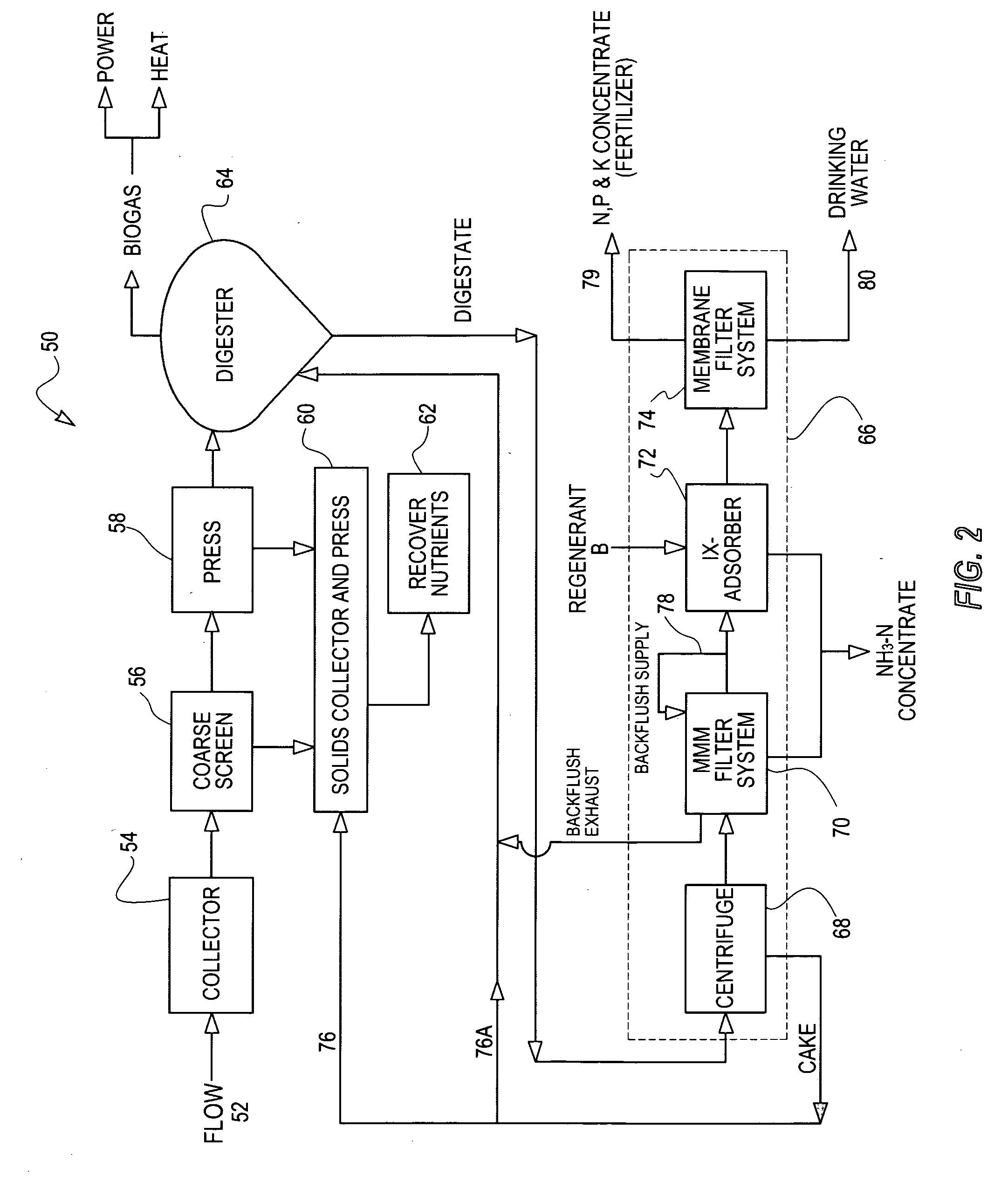

An integrated process that includes liquid-solids separation and filtration system that treats swine or dairy feeding operations residual waste (manure flushwaters) for recovery of solid and dissolved nutrients for reuse and recycling of water from these wastes for a variety of uses. The system includes a coarse liquid / solids system to remove coarse material and multi stage, multimedia filter system that includes a set of modules. Each module includes screen assemblies and filter media sandwiched between the screen assemblies. A plurality of control assemblies is associated with each of the modules. The control assemblies include at least one external valve and are in fluid communication with a corresponding module to control flow through the corresponding module. The control assemblies selectively control fluid in each of the modules between at least one of: a forward flow through the screen assemblies to treat an influent flow, a bypass flow to bypass at least one of the modules, and a reverse flow provided through at least one of the modules.

Owner:FILTERSURE

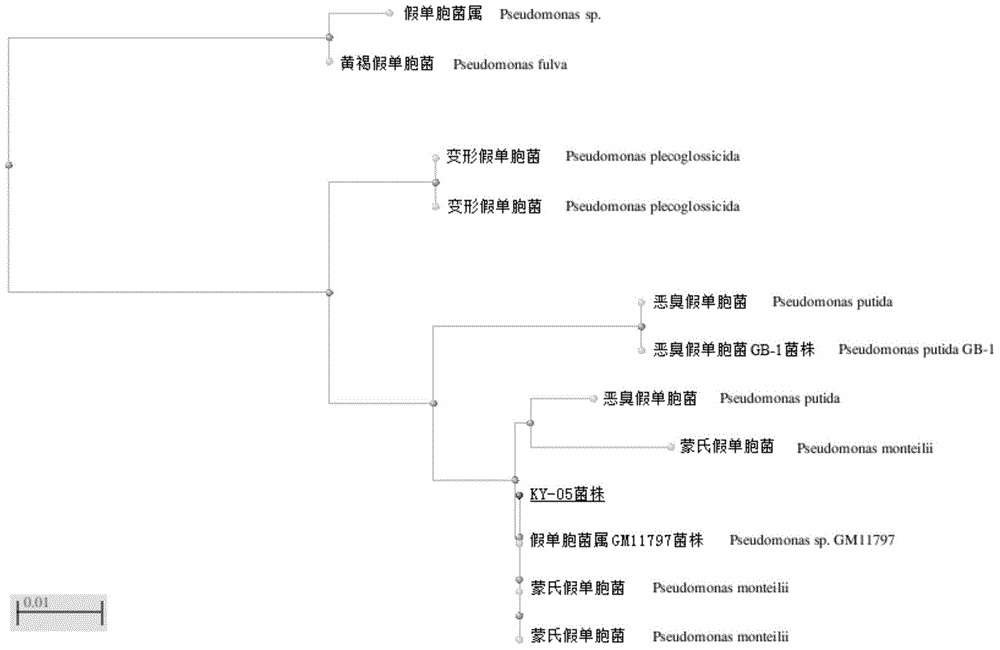

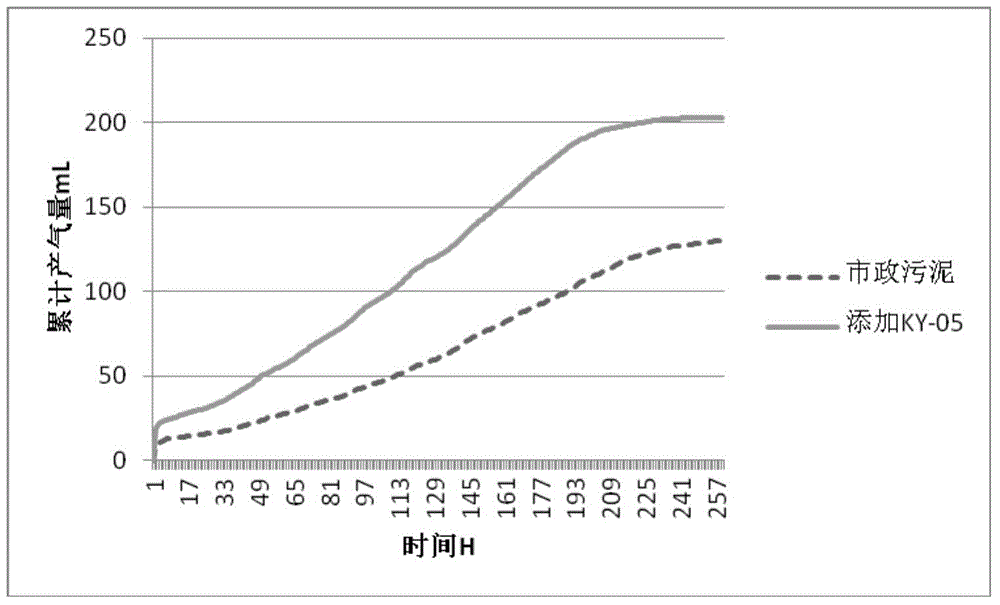

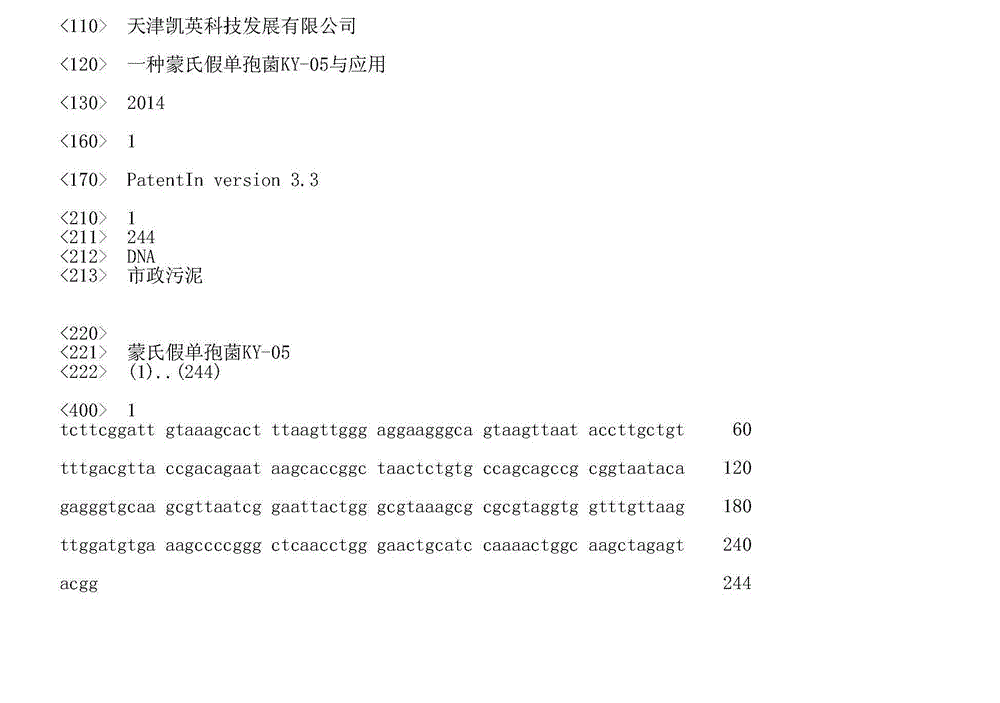

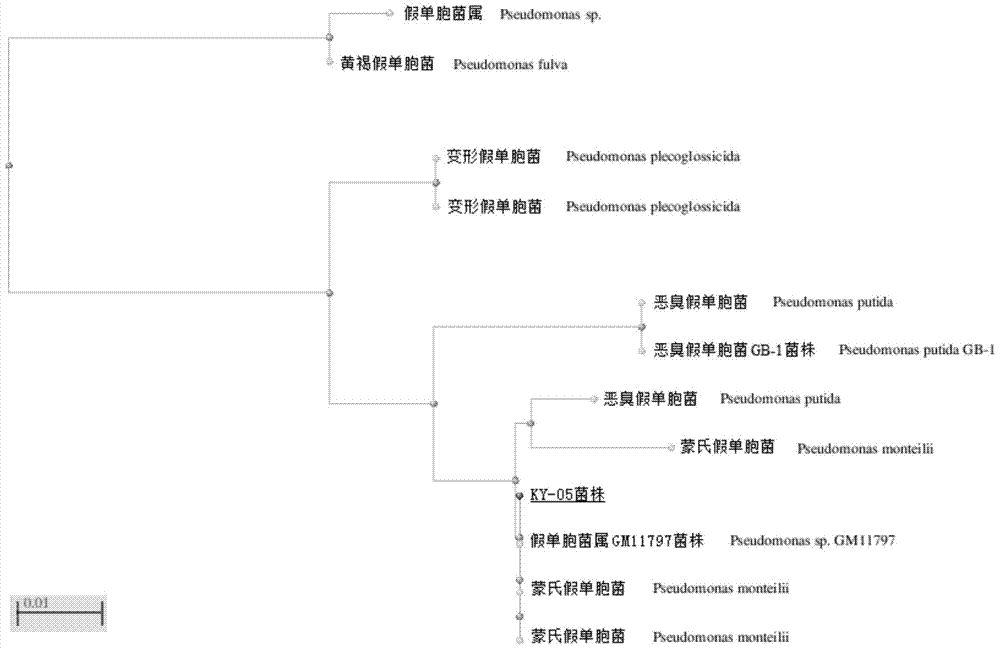

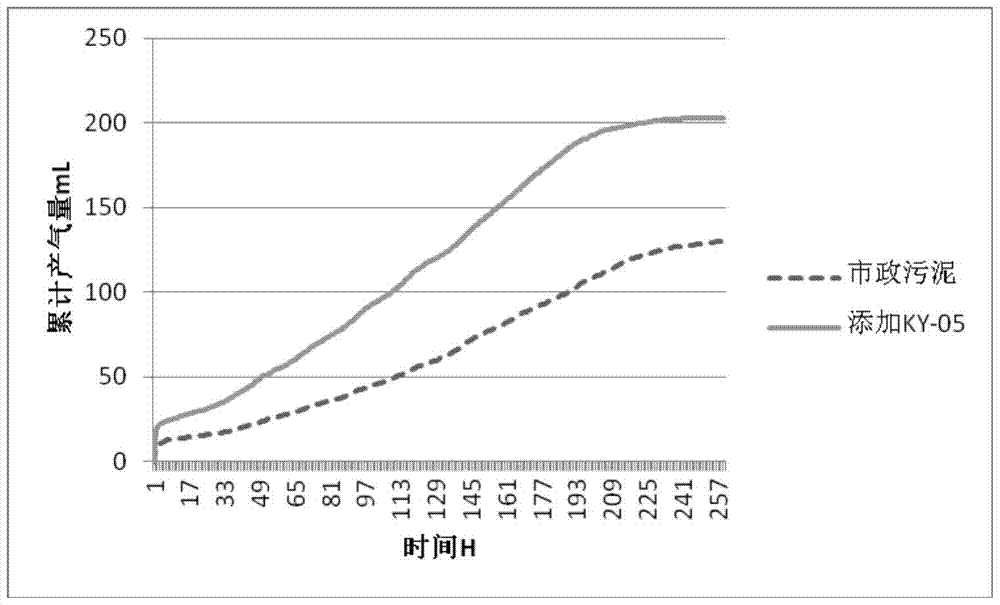

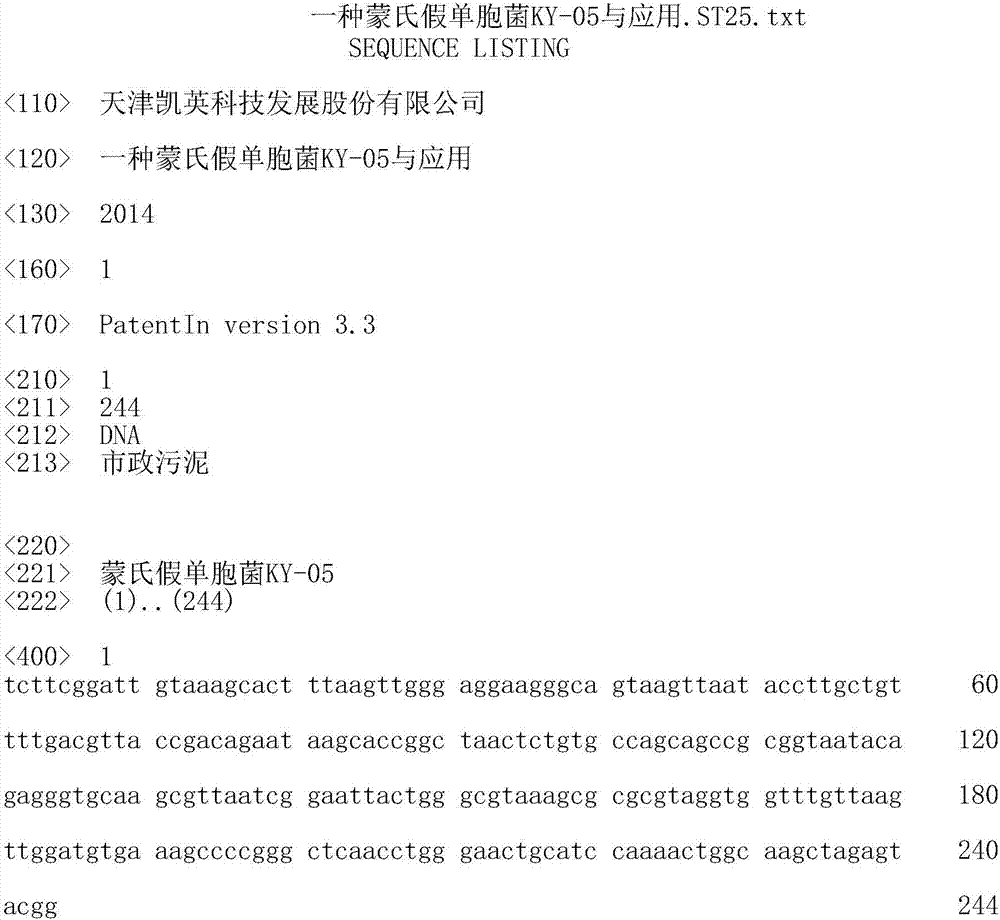

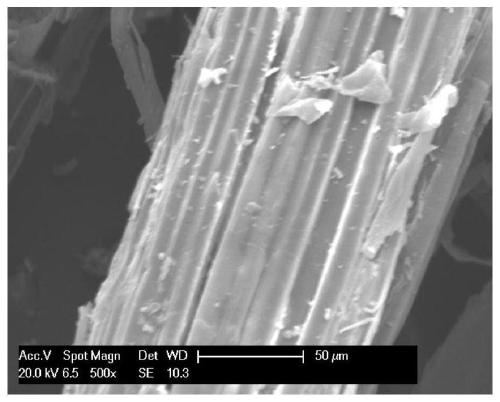

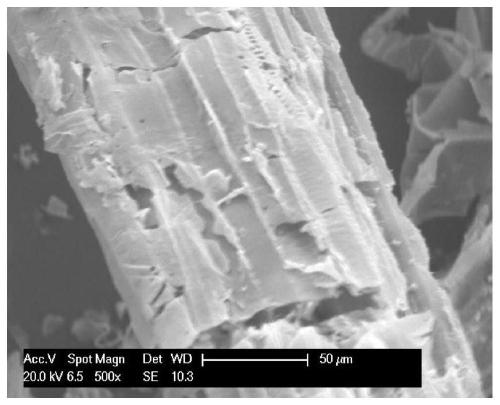

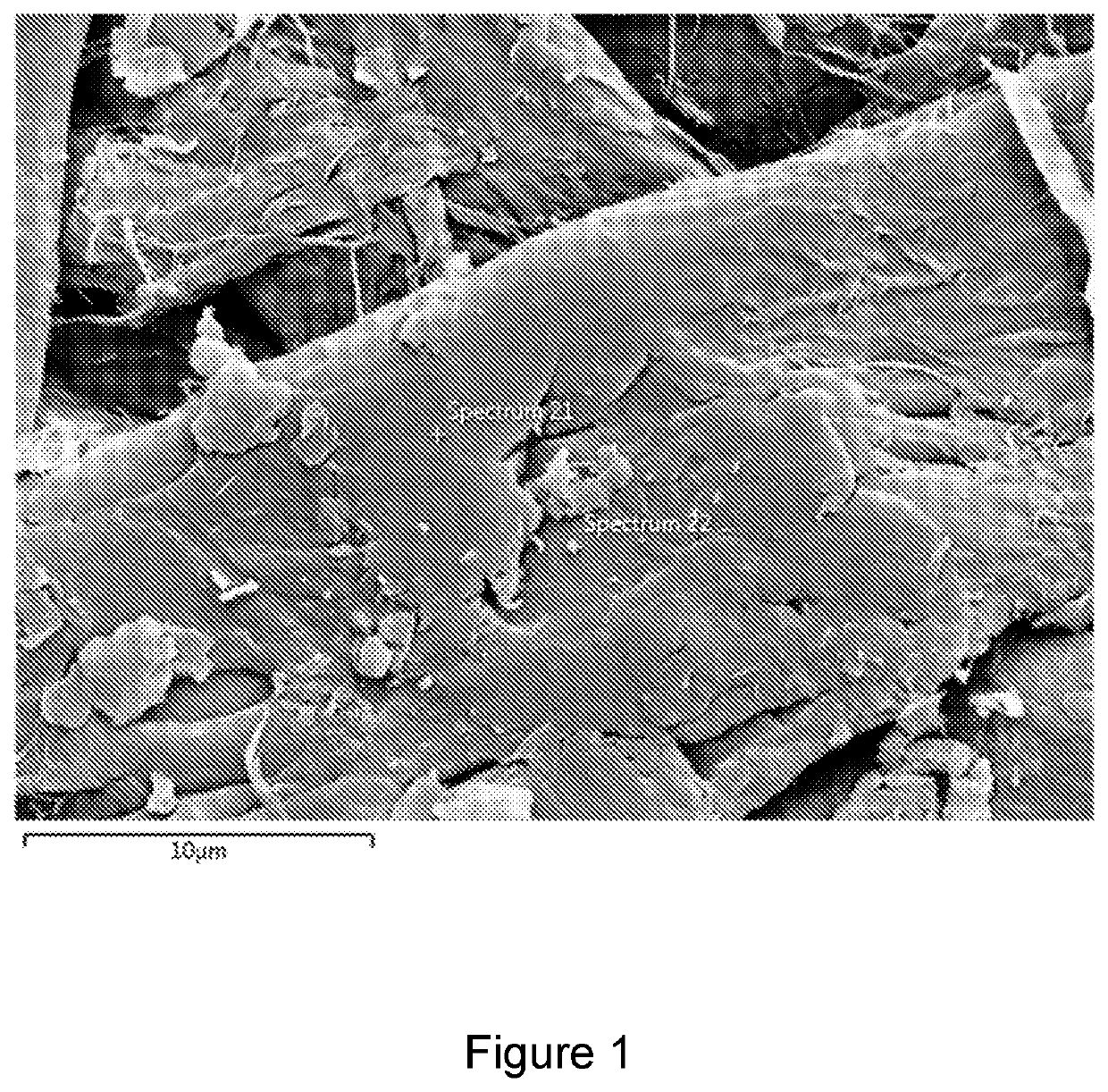

Pseudomonas monteilii KY-05 and application thereof

ActiveCN104630098AIncrease biogas productionHigh speedBacteriaMicroorganism based processesCelluloseCellulose degradation

The invention provides a Pseudomonas monteilii KY-05 with the collection number of CGMCC No.10172, which has cellulose degradation capacity. The Pseudomonas monteilii KY-05 has an enhancement effect on the biogas yield and anaerobic reaction start speed in the existing sludge anaerobic digestion technique, can be used for developing the microbial preparation for enhancing anaerobic digestion gas production efficiency, is gradually subjected to practical application and popularization in sludge plants, and has wide application prospects.

Owner:TIANJIN CARING TECH DEV

Marsh gas engineering inoculum and preparation method thereof

ActiveCN104805125AIncrease productionHigh yieldBacteriaGas production bioreactorsMicroorganismMixed culture

The invention discloses a marsh gas engineering inoculum and a preparation method thereof, and aims to solve the problems of low anaerobic fermentation speed, long fermentation period and poor marsh gas engineering gas productivity and engineering running efficiency in the conventional marsh gas engineering. Organic waste sludge or biogas slurry is taken as a raw material, and a special marsh gas engineering inoculum is prepared through mixed culture and a fixed anaerobic fermentation microbial flora according to an anaerobic fermentation principle and a microbial ecology principle. Compared with the prior art in which an inoculum is prepared by culturing single strains respectively and mixing proportionally, the preparation method has the advantages that the inoculum is prepared through mixed culture of sludge or biogas slurry is stable in micro-ecology; moreover, the marsh gas engineering fermentation period can be remarkably shortened, the marsh gas yield is increased, and the marsh gas engineering economical benefit is increased.

Owner:马力通

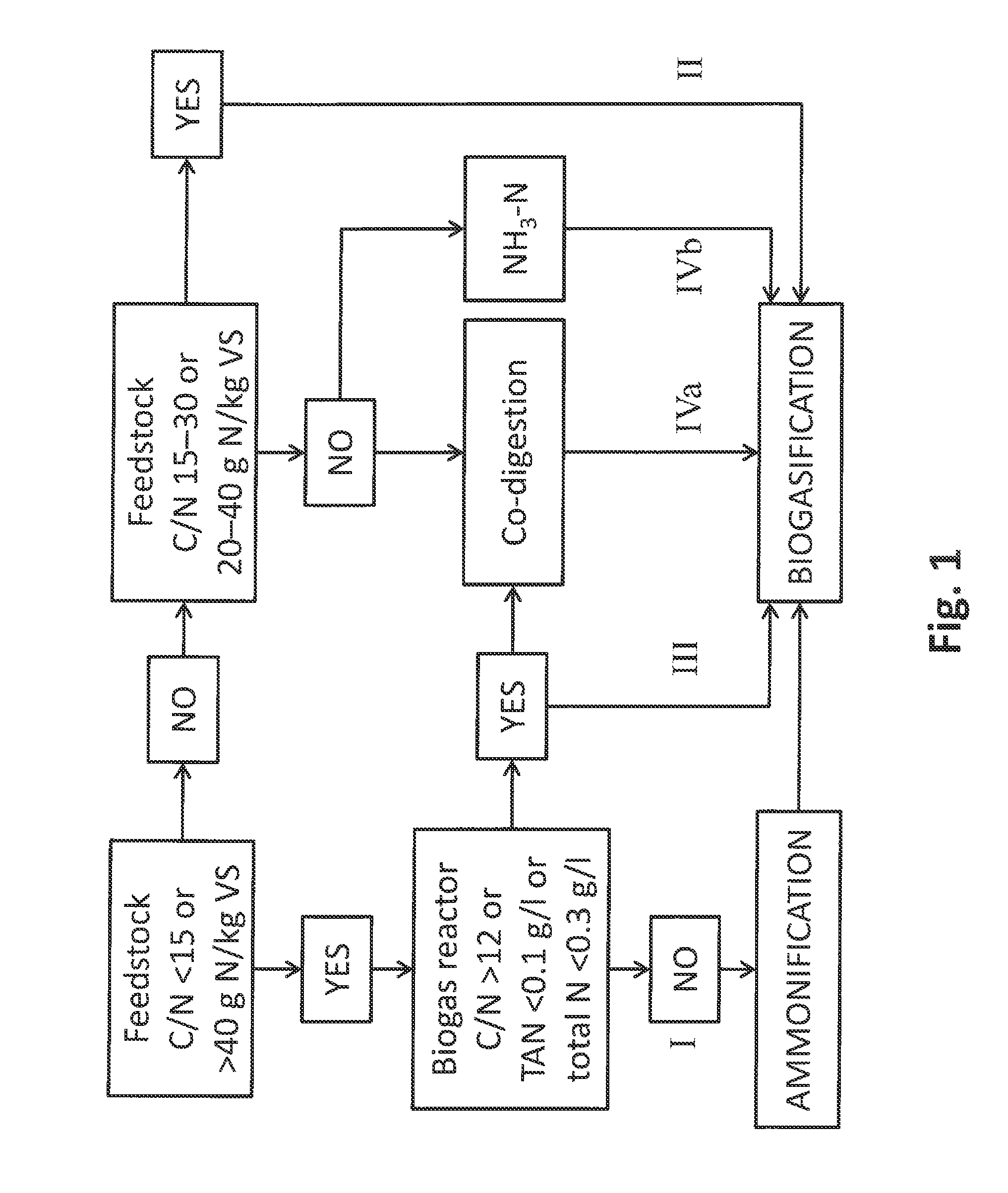

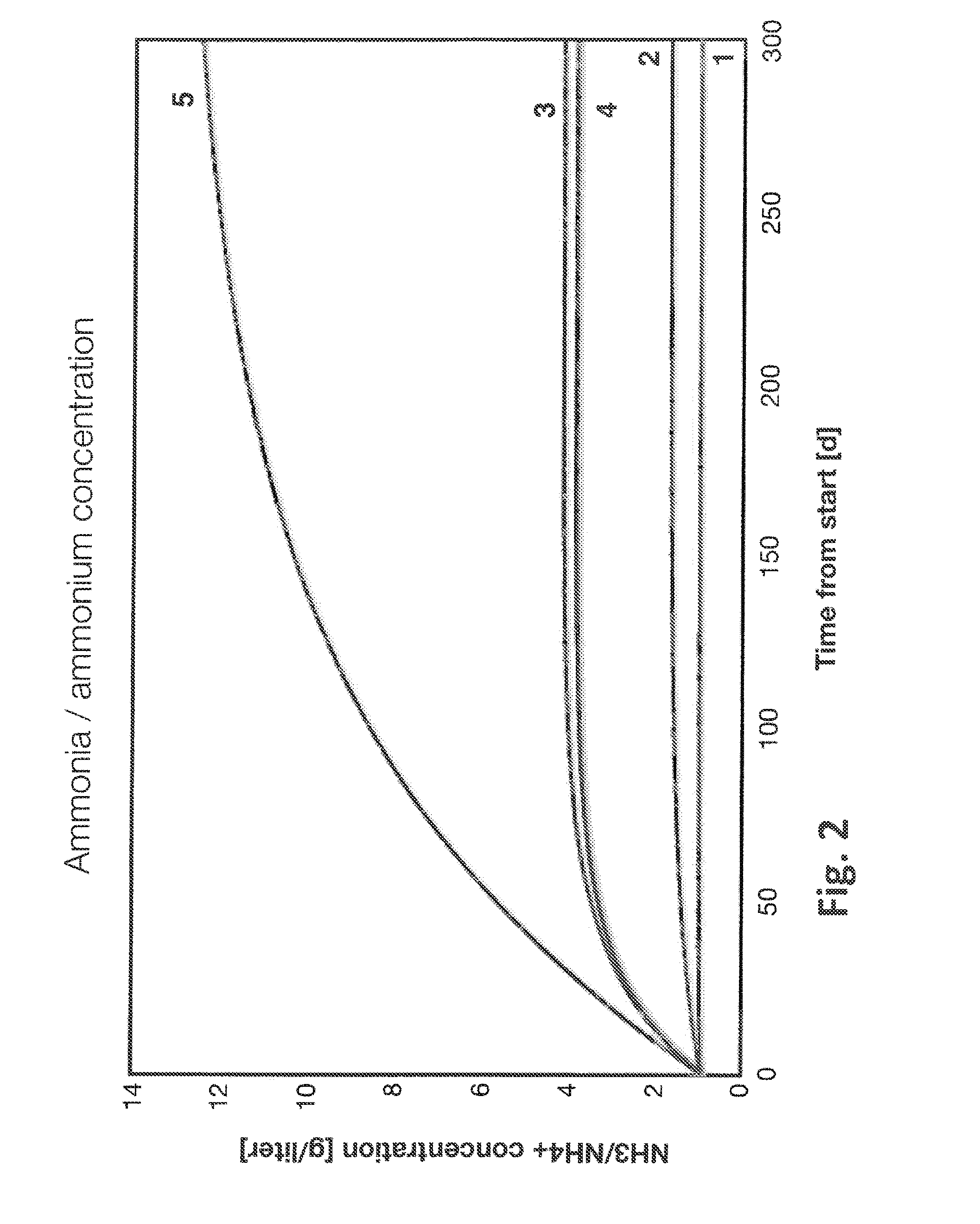

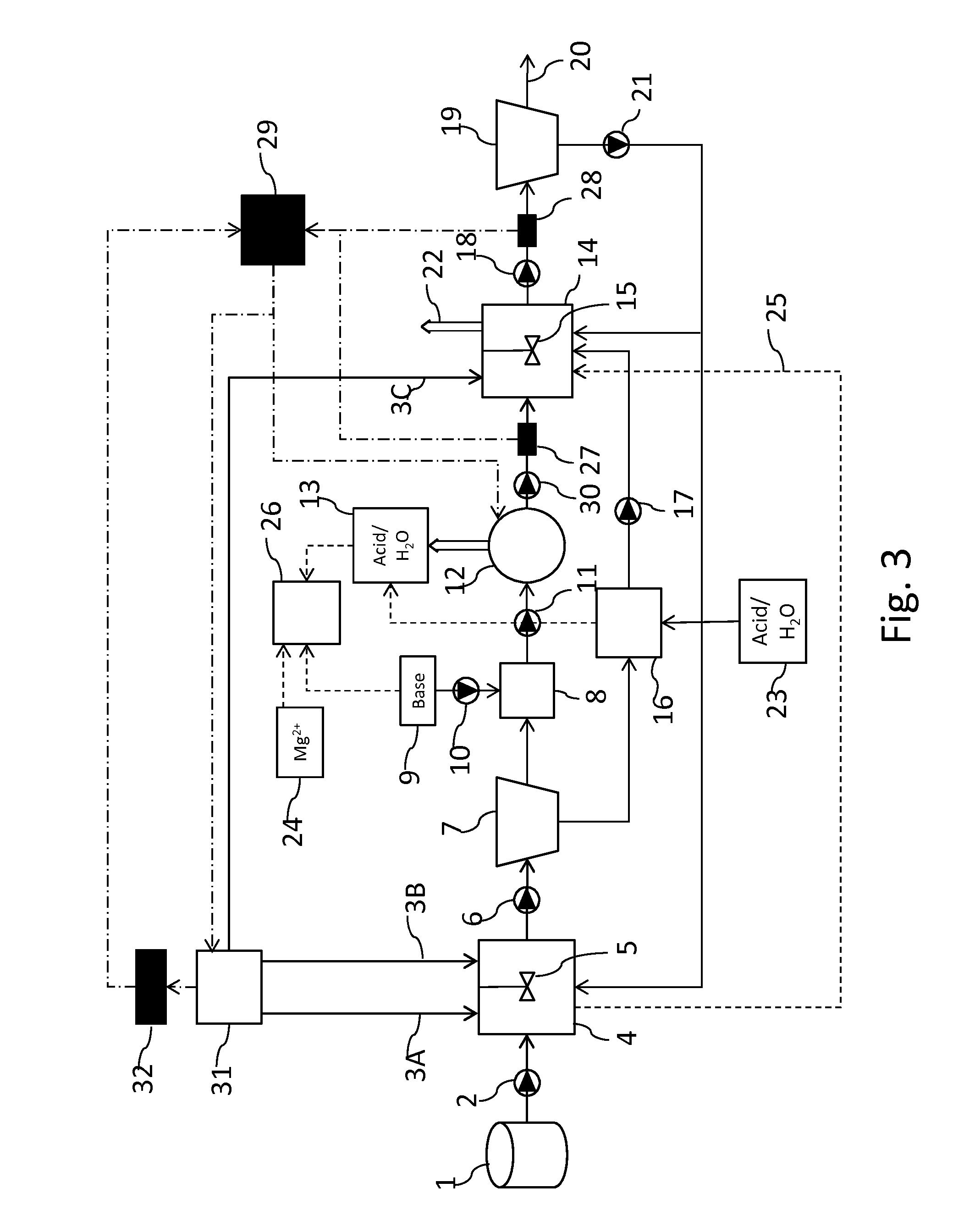

Biogas process with nutrient recovery

ActiveUS20150275234A1Increase biogas productionImprove concentrationBioreactor/fermenter combinationsBiological substance pretreatmentsAmmoniacal nitrogenMicroorganism

The invention is a method of two-phase anaerobic digestion where monitoring and adjusting the nitrogen status (carbon to nitrogen molar ratio, i.e. C / N molar ratio or total or ammoniacal nitrogen content) enables maintaining optimum conditions during the process. The method improves the use of a variety of feedstock materials or facilitates monodigestion of one feedstock. Especially the introduction of nitrogen rich feedstock materials in the process is amended. A community of hydrolyzing and acidogenic microorganisms in the first phase digester performs ammonification i.e. release of organic nitrogen as ammonia. Nitrogen and phosphorus are removed and recovered from the digestate which then undergoes biogasification in the second phase of the process. Reject water from biogasification can be recycled within the process.

Owner:DUCTOR

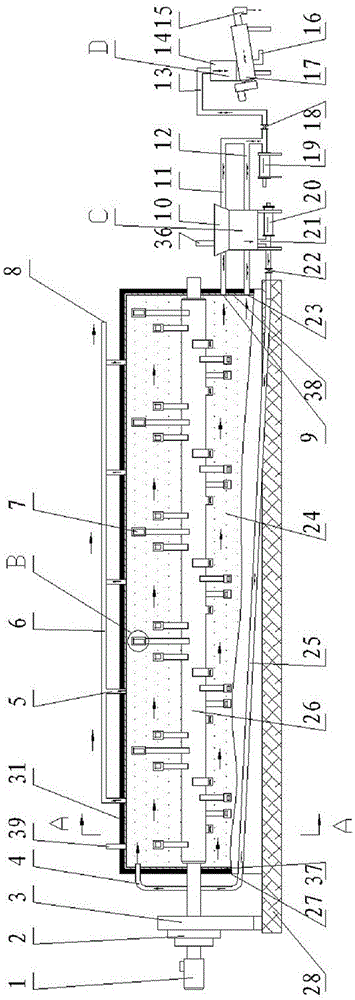

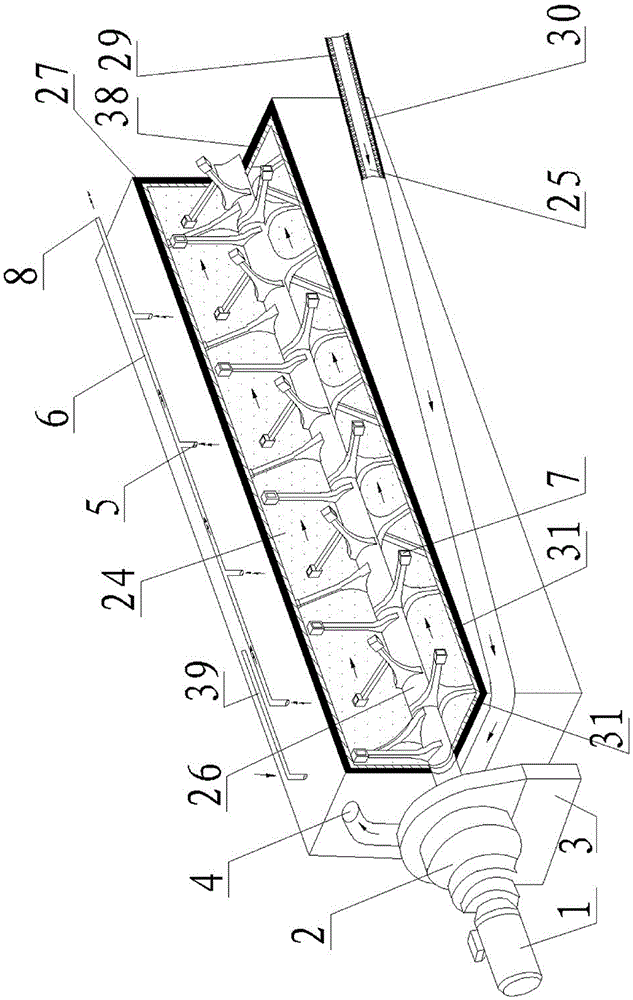

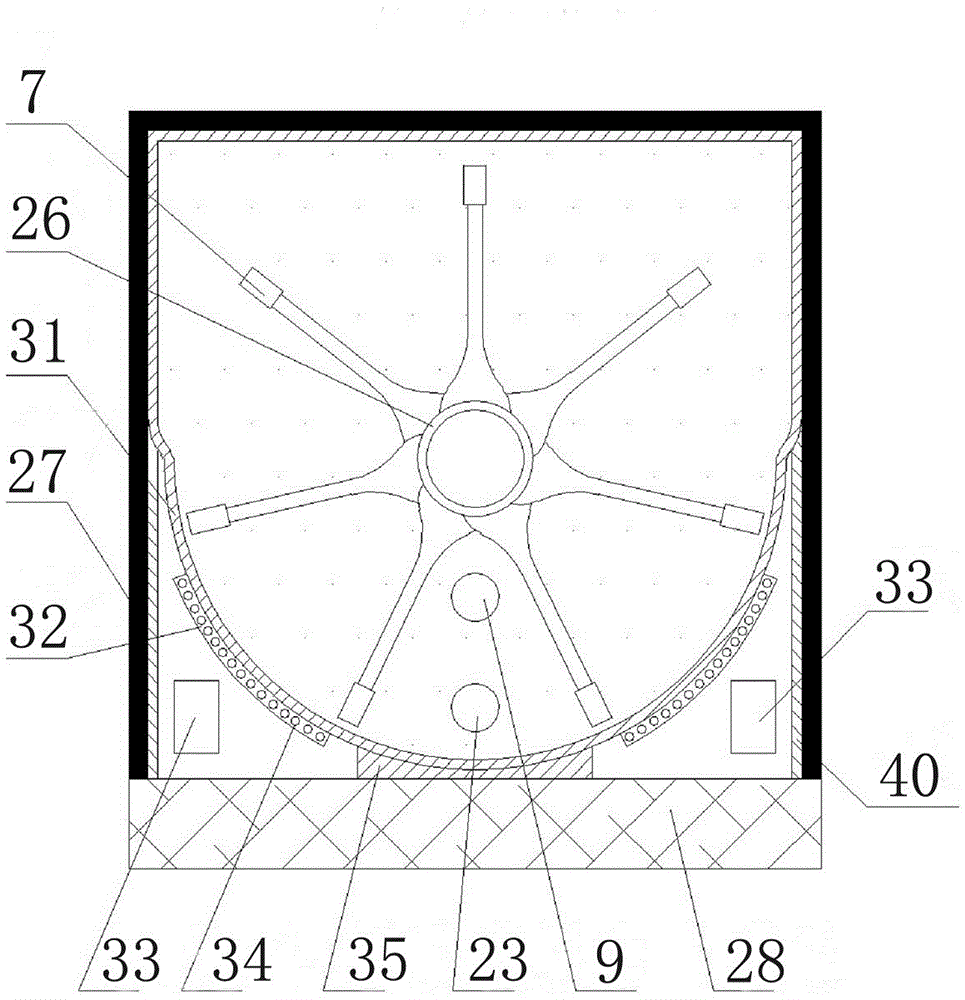

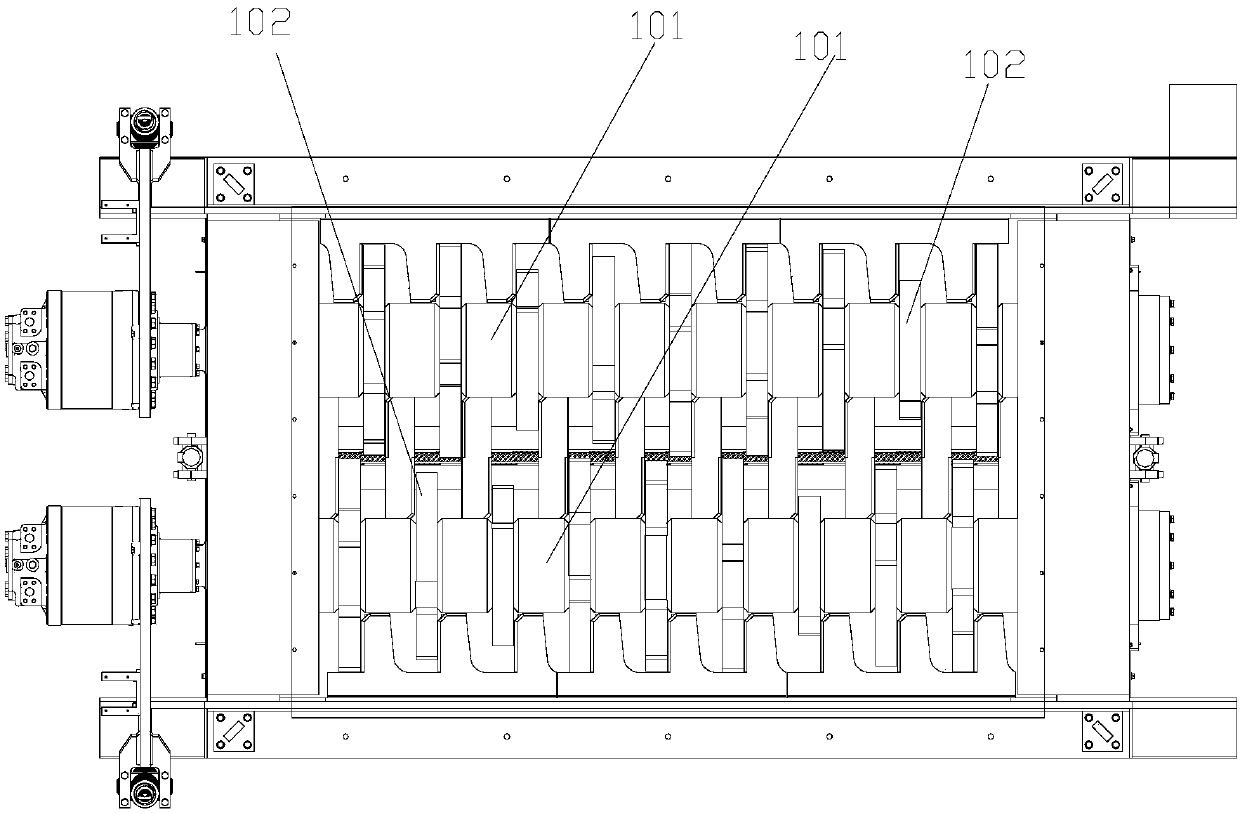

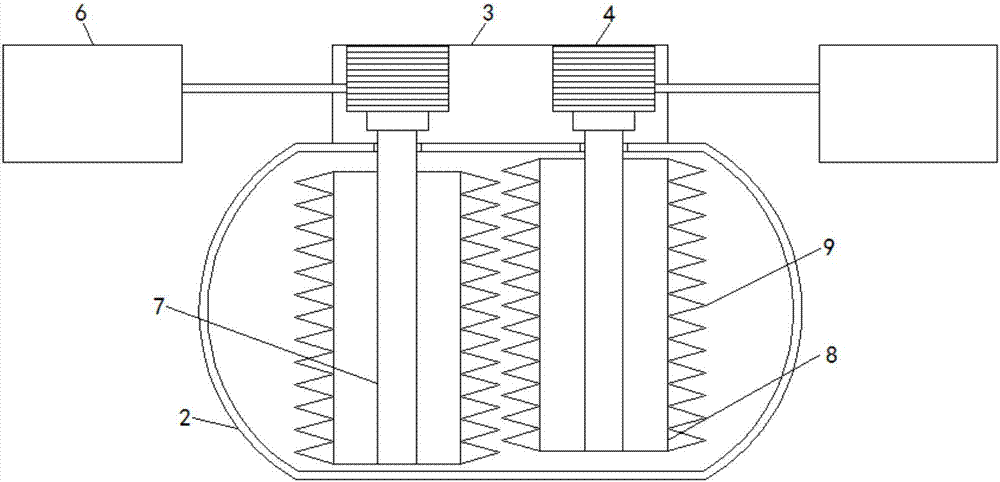

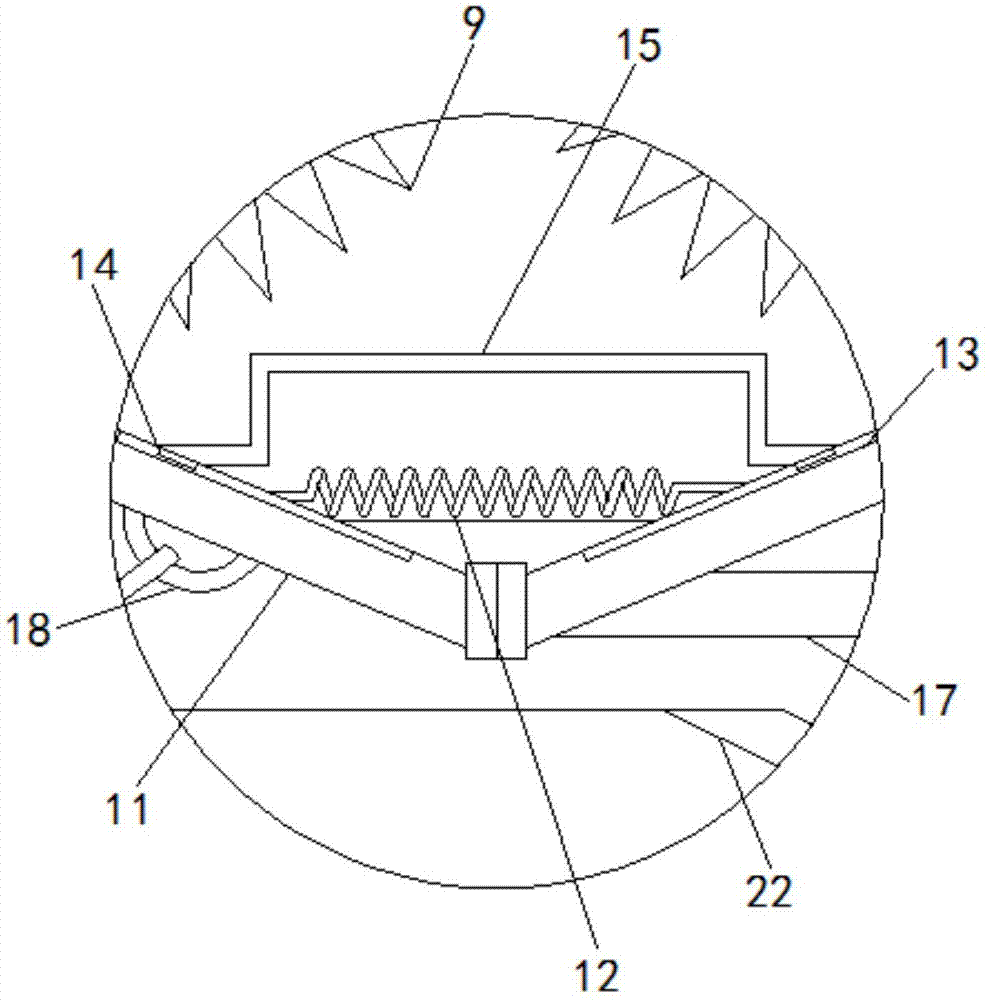

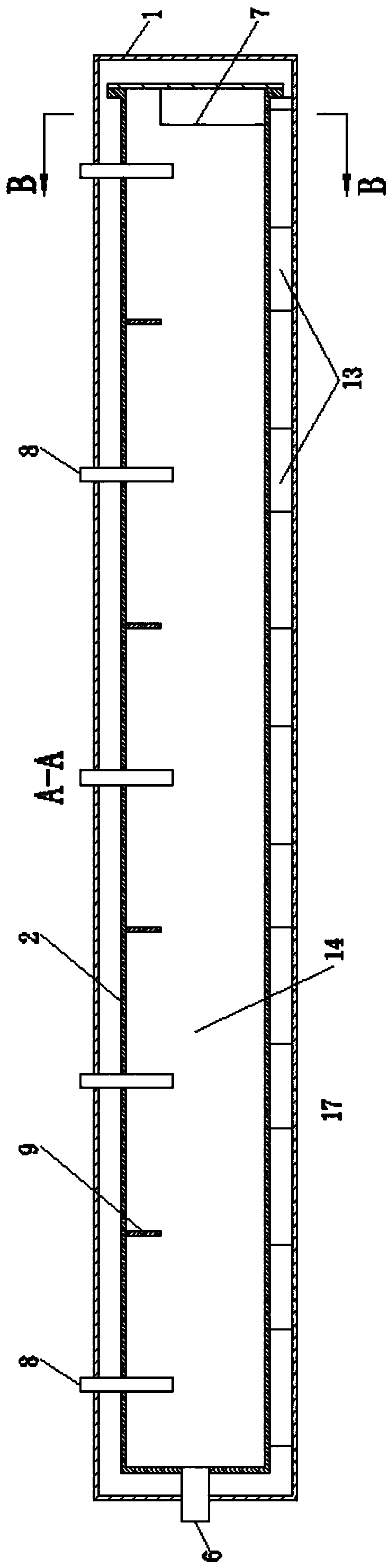

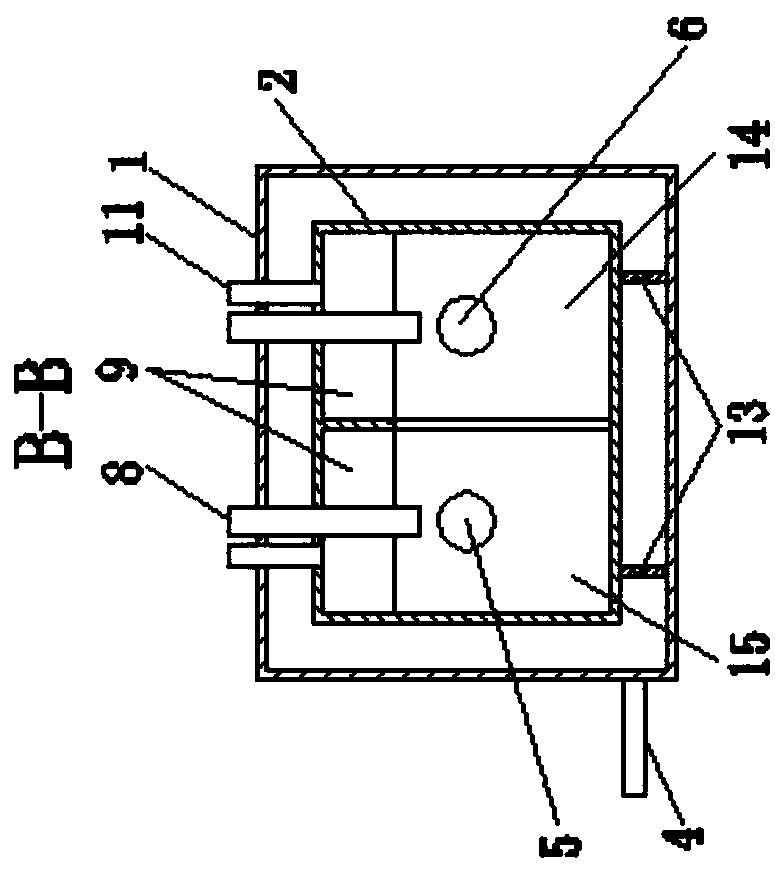

Large horizontal tunnel kiln spiral continuous dry-type anaerobic fermentation equipment

InactiveCN105462821ASmooth feedingIncrease productionBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasRadial surface

The invention discloses large horizontal tunnel kiln spiral continuous dry-type anaerobic fermentation equipment and belongs to the technical field of high temperature dry-type fermentation. The equipment comprises a tunnel kiln inner cavity fixed to an equipment foundation, wherein a heat exchange plate with a steam heating pipe is mounted in an arc-shaped outer cavity, and insulating layers are arranged on the outer portions of the tunnel kiln inner cavity and a tunnel kiln inner cavity supporting wall; a stirring and pushing spindle rotating at a low speed is mounted in the tunnel kiln inner cavity and drives tens of stirring and pushing blades to rotate, the stirring and pushing blades are mounted on the radial surface of the outer circle of the spindle and distributed according to a spiral track in the axis direction, and reaction materials mixed with biogas slurry enter one end of the tunnel kiln inner cavity through a feeding solid pump and a feeding pipe with a spiral material preheating coil and are pushed towards an upper biogas residue and slurry discharge port and a lower biogas residue and slurry discharge port in the axial direction and delivered into a solid-liquid separator through a discharging solid pump. The equipment has the advantages of a dry-type fermentation process, the reaction materials can be fed continuously, a large amount of biogas can be obtained, and the equipment is suitable for treatment of ropy organic materials in municipal refuse.

Owner:HENAN LIFENG IND CO LTD

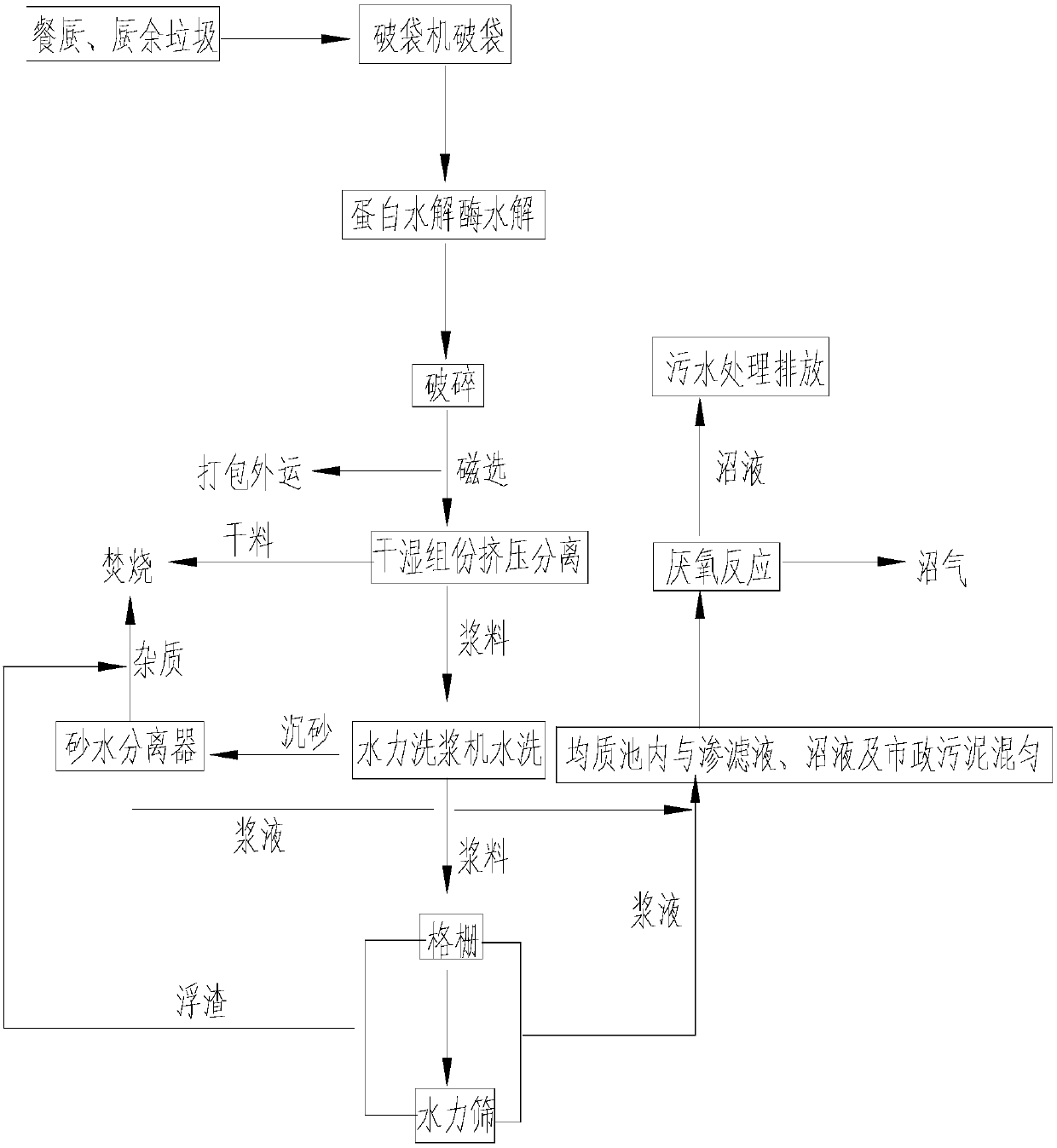

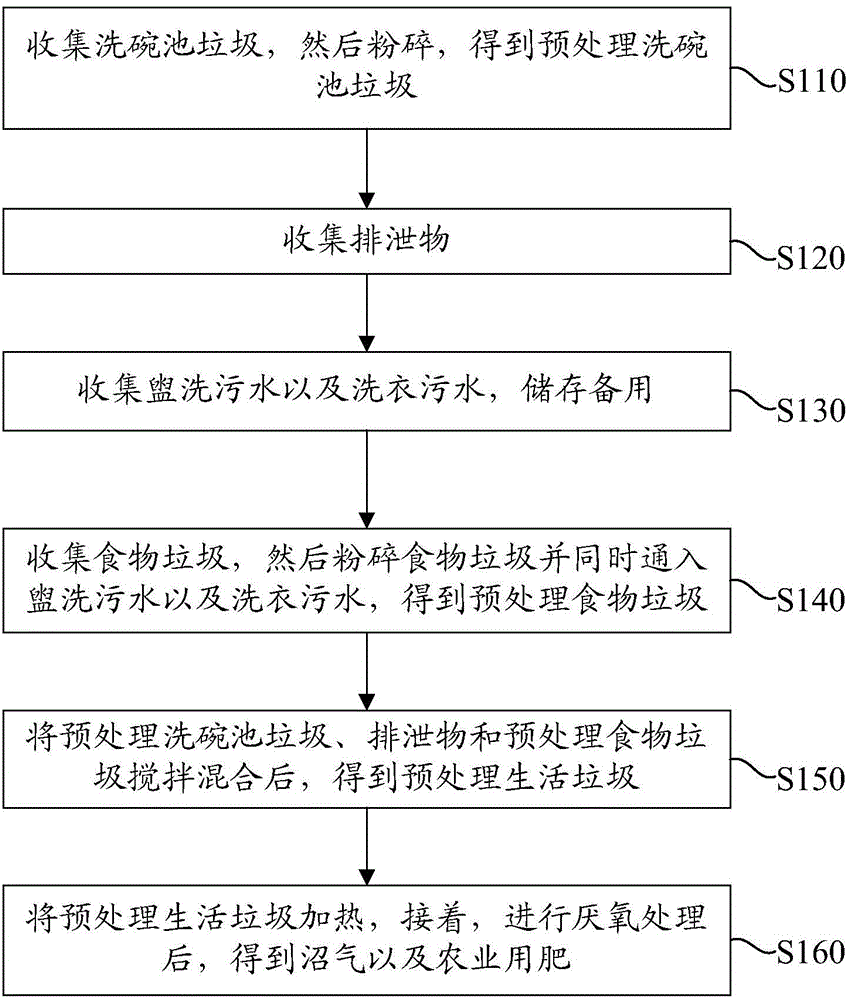

Kitchen waste and food waste treatment method

The invention discloses a kitchen waste (food waste) treatment method which is used for fine treatment and anaerobic digestion of the kitchen waste (food waste). The method mainly comprises three major steps of: enzymolysis pretreatment, solid-solution separation and anaerobic fermentation, wherein the steps are connected through plate chain machines and helixes or pipelines. The major innovationpoint is that an enzymolysis process is added in a kitchen waste (food waste) pretreatment process, and the enzymolysis process can promote hydrolysis of proteins in the crushed kitchen waste (food waste), so that a utilization rate of organic substances and a biogas yield at an anaerobic digestion stage are increased; meanwhile, the method realizes efficient separation of dry and wet materials through a high-pressure extruding mode, and is complete in solid-liquid separation; and moreover, pressure is set for quickly separating out organic substance slurry from the kitchen waste (food waste),so that the separating effect is good, and therefore, the kitchen waste (food waste) treatment method can be widely applied to the kitchen waste (food waste) treatment field.

Owner:浙江旺能生态科技有限公司

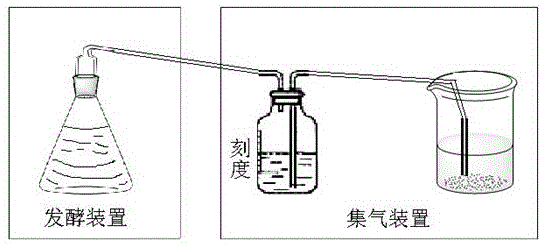

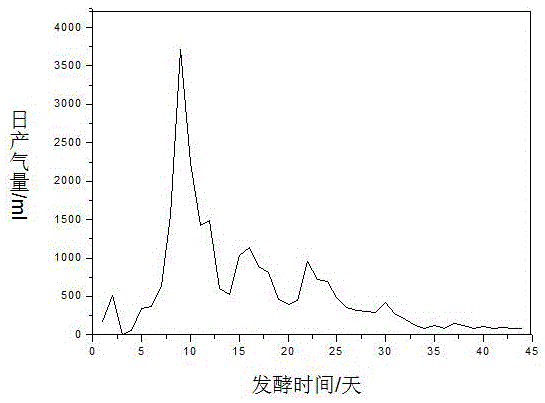

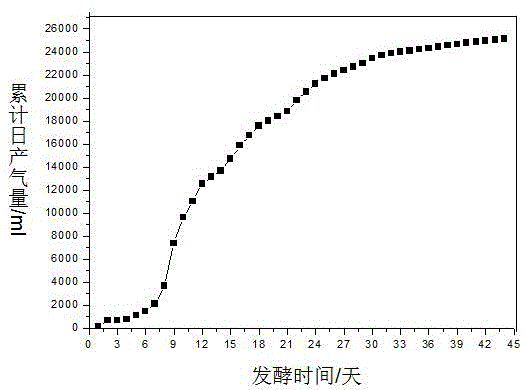

Method for producing biogas from vinasse by high-temperature anaerobic fermentation

InactiveCN105039422AEliminates biological pretreatmentLow costWaste based fuelFermentationPulp and paper industryVinasse

The invention relates to biomass biogas fermentation, particularly a method for producing biogas from vinasse by high-temperature anaerobic fermentation, which comprises the following steps: (1) adding vinasse and inoculum into a fermentation bottle, and mixing; (2) adding water and an alkaline matter into the fermentation bottle to regulate the pH value; (3) after regulating the pH value, putting the fermentation bottle in a high-temperature shaking table, and carrying out fermentation; (4) collecting biogas by a drainage gas collection process in the fermentation process; (5) recording daily biogas yield and accumulative biogas yield, and determining the daily biogas composition by gas phase chromatography; and (6) after the fermentation finishes, calculating the biogas yield per unit volume and the biogas productivity per unit TS in the process of producing biogas from vinasse by high-temperature fermentation. By using the vinasse to produce the biogas by high-temperature anaerobic fermentation, the method has the advantages of high start speed, high gas production rate, energy saving and environment friendliness, and has very high popularization and use value.

Owner:SHANDONG BAOLI BIOMASS ENERGY

Method for planting puelia and producing biogas by puelia as biomass energy

InactiveCN101617599AThe method is easy to learnHigh biogas productionSeed and root treatmentGas production bioreactorsBiogasBiomass

The invention discloses a method for planting puelia and producing biogas by puelia as biomass energy, which belongs to a plant cultivation technology of biomass energy and an application thereof. The invention provides a scientific cultivation method with high yield and easy control, in particular a method for producing biogas by harvested puelia cultivated by scientific approaches of selecting, taking and cultivating seeds, planting, and the like. The puelia planted for 8 months-12 months is used for producing the biogas, and the fresh puelia per ton can produce the biogas of 440 m<3>, wherein the biogas contains 60 percent of methane, and the biogas production rate is 440 m<3> / t*TS. The new puelia seed provided with the invention is a novel puelia seed and is a novel raw material for producing biogas; and the cultivating method of the puelia is simple and easy to learn. The fresh puelia per mu per year can reach 35 tons at maximum by the cultivation method, and the biogas producing amount is high.

Owner:童金阜

Preparation method and application of activated biogas residue hydrothermal carbon

InactiveCN110371971ALarge specific surface areaSmall specific surface areaCarbon compoundsWaste based fuelBiogas productionFermentation system

The invention discloses a preparation method and application of activated biogas residue hydrothermal carbon. The activated biogas residue hydrothermal carbon serves as an additive and is added in theanaerobic fermentation process taking fecal residue and waste water as a fermentation substrate, biogas residue is recycled, and the biogas production efficiency in the anaerobic fermentation processis improved. The preparation method and application of the activated biogas residue hydrothermal carbon have the beneficial effects that the biogas residue is recycled and used for anaerobic fermentation engineering, material circulation is achieved, and meanwhile the high value utilization path of biogas residue is developed; the cost of the preparation method is low, the technology is simple, extra raw material purchasing is not needed, and in the preparation process, the condition is mild, energy consuming is small, and the cost is low; and in addition, the biogas production in the anaerobic fermentation system and the content of methane in the biogas can further be improved, thus the fermentation efficiency is high, the fermentation system is stable, and the problems that existing biogas residue is difficult to consume, and the anaerobic fermentation efficiency of the fecal residue and waste water is low are solved.

Owner:广东广垦畜牧工程研究院有限公司

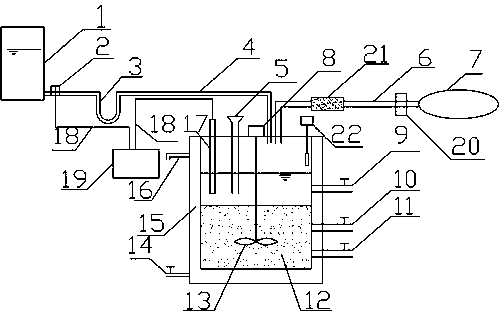

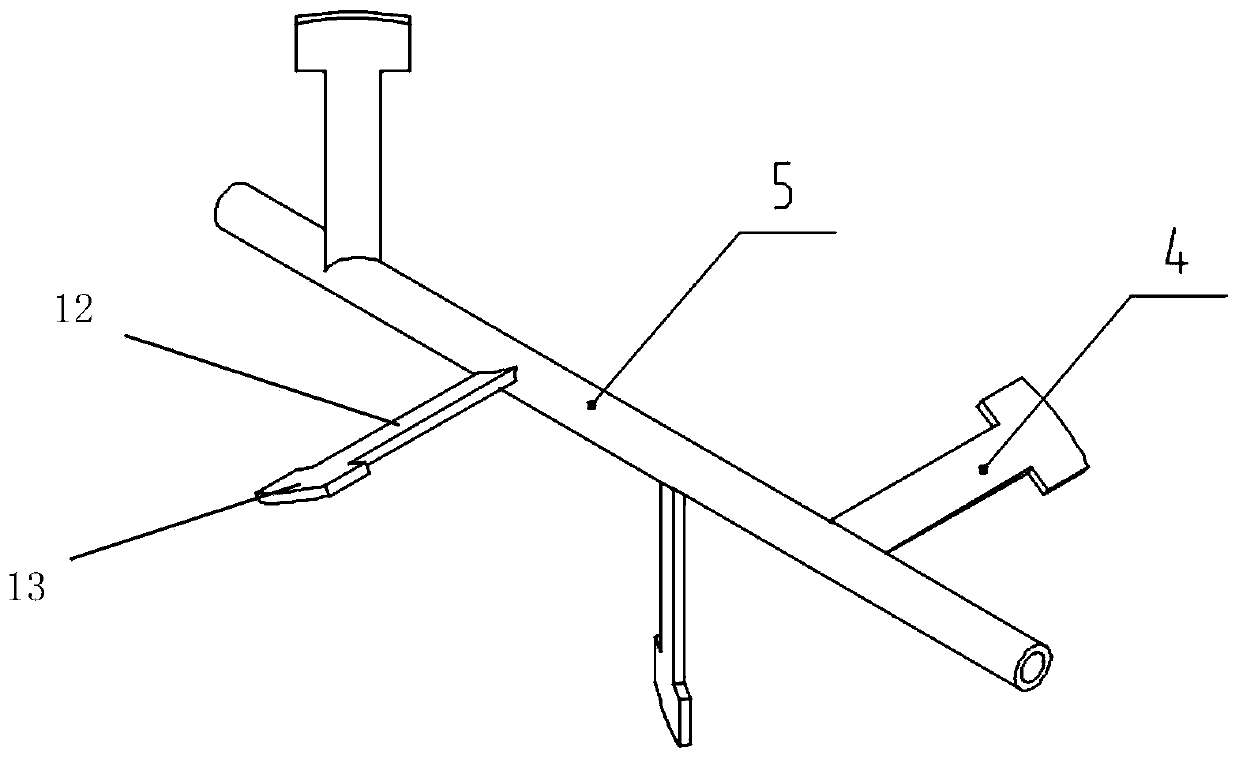

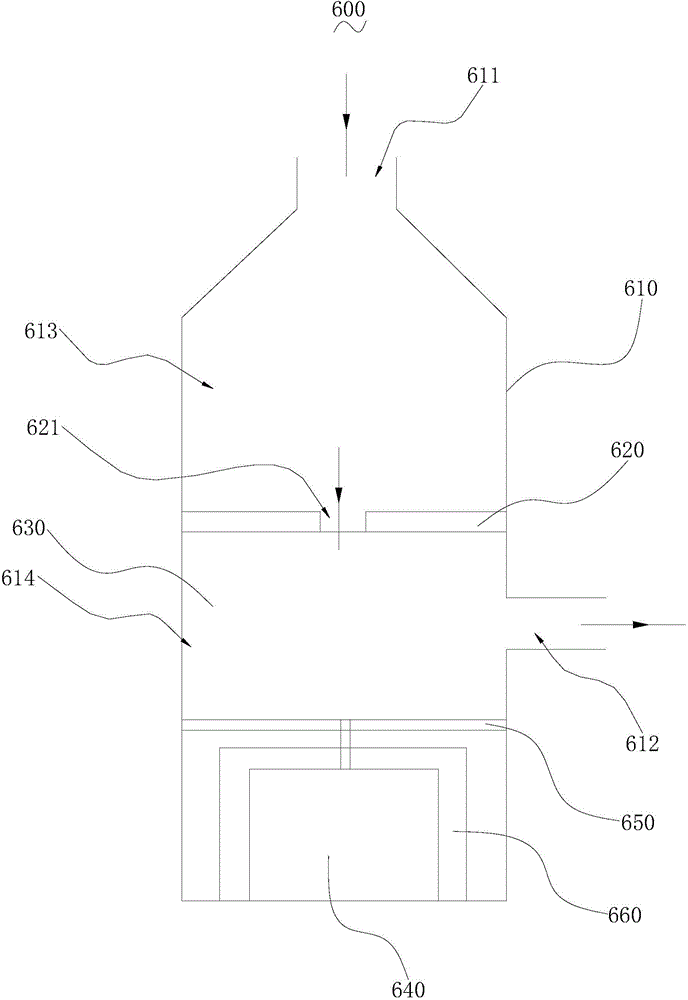

Device for improving yield of methane produced from kitchen waste through anaerobic digestion and method for producing methane

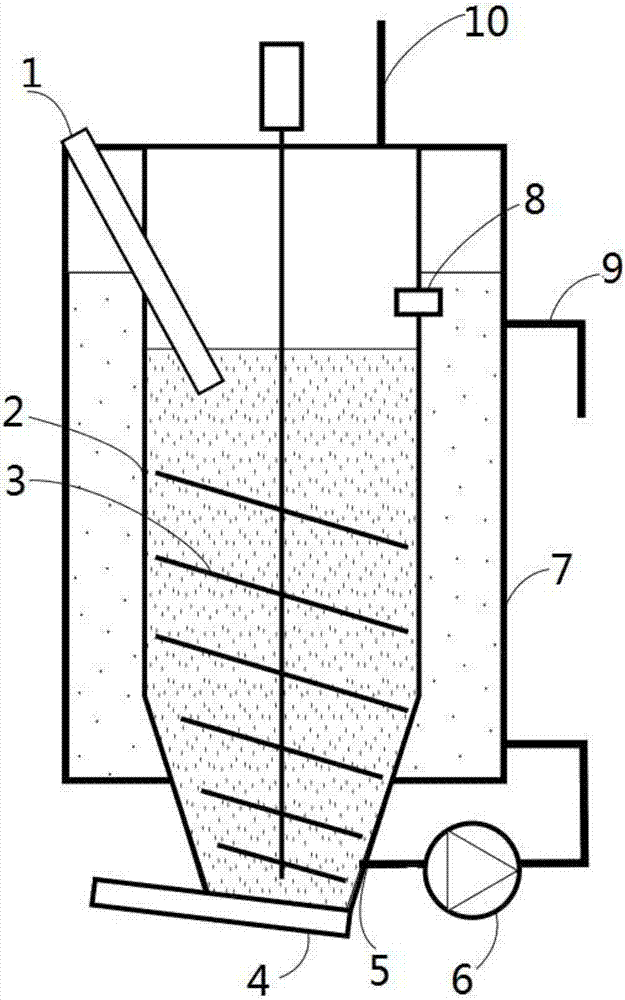

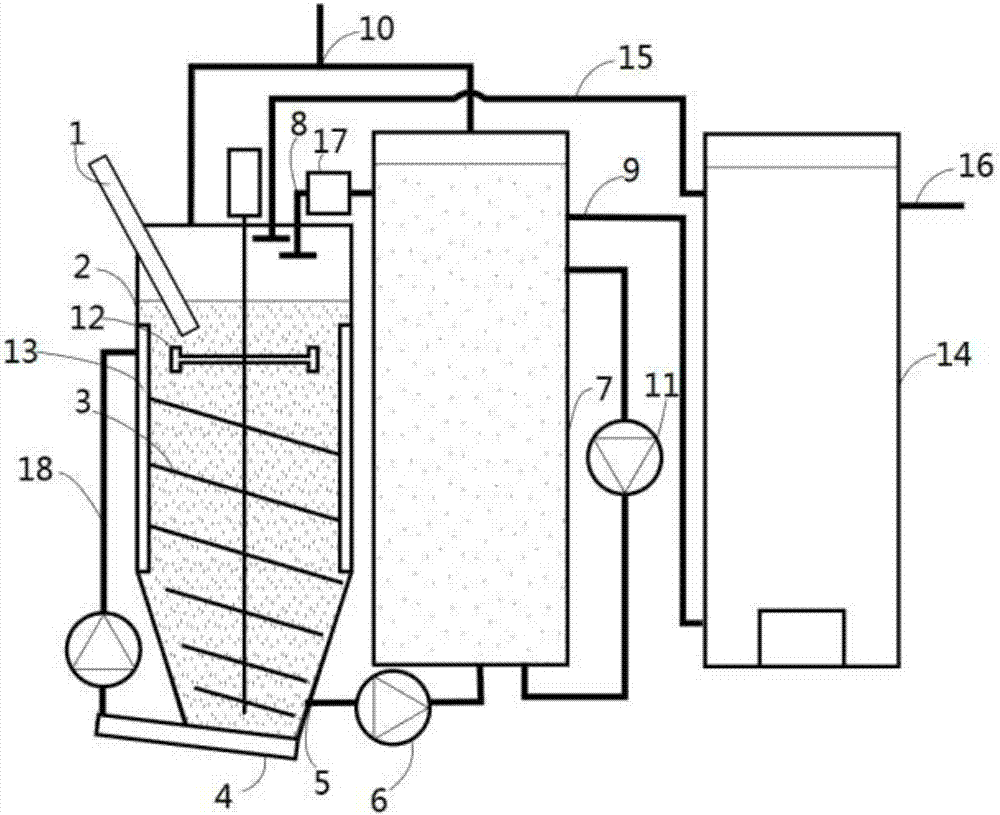

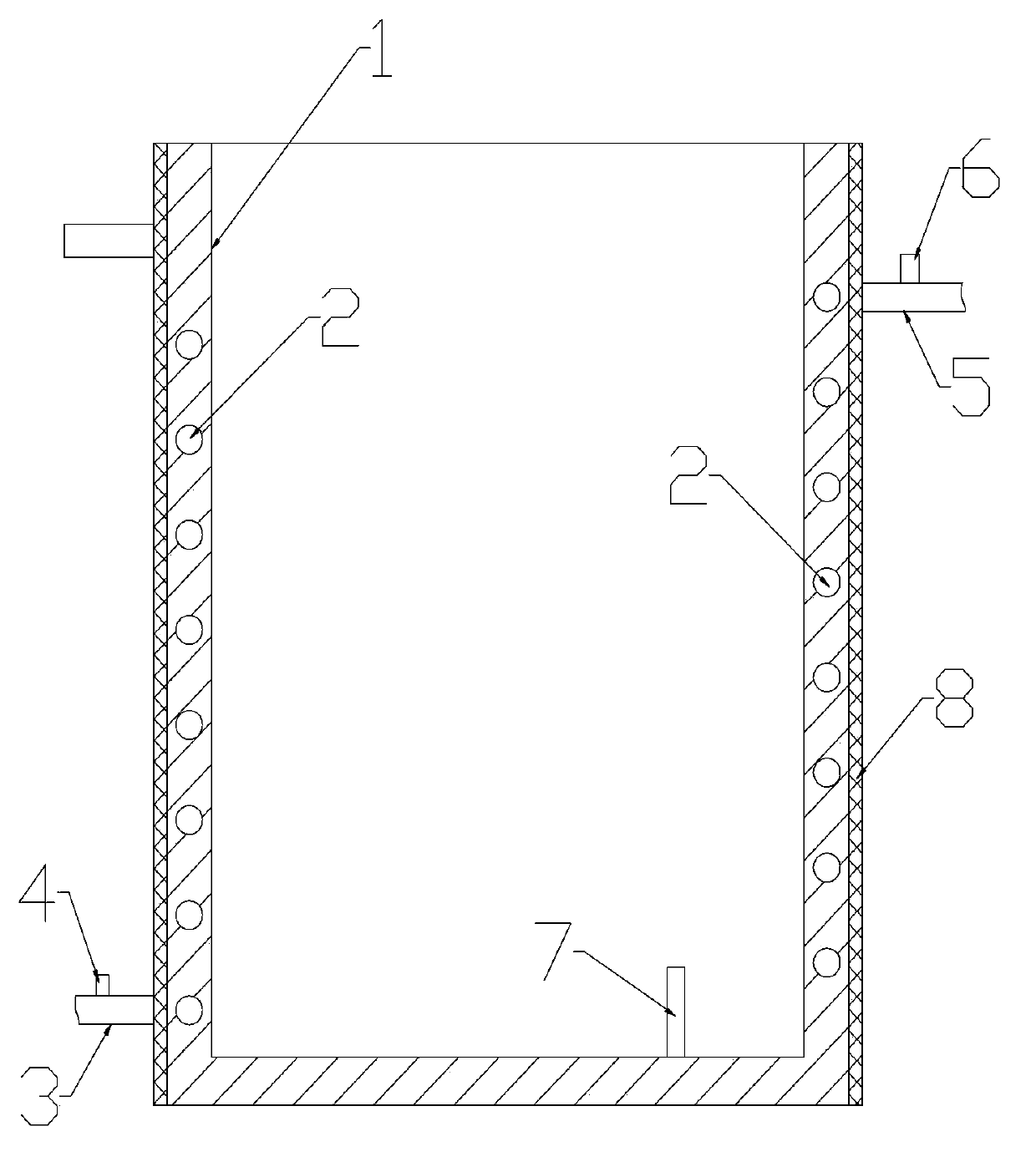

InactiveCN103387936AIncrease biogas productionShort stayBioreactor/fermenter combinationsBiological substance pretreatmentsWater bathsDrive shaft

The invention discloses a device for improving the yield of methane produced from kitchen waste through anaerobic digestion and a method for producing the methane, relates to the technical field of treatment on kitchen waste, and belongs to the technical field of solid waste recycling. A stirring paddle connected with a transmission shaft of an engine is arranged inside a fully-mixing reaction chamber, the outlet end of an alkaline liquor box is connected with one end of an alkaline liquor pipe, the other end of the alkaline liquor pipe is positioned at the upper end face of the fully-mixing chamber, a U-shaped pipe is serially connected onto the alkaline liquor pipe, an electromagnetic valve is arranged on the alkaline liquor pipe between the U-shaped pipe and the alkaline liquor box, a pH electrode probe and the electromagnetic valve are respectively connected with a signal processing and controlling device through a wire, a first sampling pipe, a second sampling pipe and an alkaline liquor discharging pipe are respectively arranged on the side wall of the fully-mixing reaction chamber, a water bath chamber is arranged at the periphery of the fully-mixing reaction chamber, and a recirculated water inlet pipe and a recirculated water outlet pipe are respectively arranged on the side wall of the water bath chamber. Through the device, the purposes of being simple in process and structure, high in automation degree and easy to operate, and capable of increasing the yield of the methane are achieved.

Owner:HOHAI UNIV

Biogas production device with high biomass energy utilization rate

ActiveCN107988050AHigh utilization rate of biomass energyIncrease profitBioreactor/fermenter combinationsBiological substance pretreatmentsEcological environmentNew energy

The invention relates to the technical field of new energy sources and discloses a biogas production device with a high biomass energy utilization rate. The biogas production device comprises a feeding hopper, wherein the bottom of the feeding hopper is fixedly connected with a crushing cylinder; the back surface of the crushing cylinder is fixedly connected with a supporting plate; two crushing motors are fixedly mounted at the top of the supporting plate; opposite sides of the two crushing motors are electrically connected with a power accumulation box. By adopting the biogas production device with the high biomass energy utilization rate, a lot of electric energy is saved and the utilization rate of the new energy sources is improved; the contact area of anaerobic fermentation materialsis enlarged and a proper reaction amount of reactants is controlled; the anaerobic reaction efficiency is improved; meanwhile, the reactants can be sufficiently and effectively mixed and the speed ofanaerobic reaction is improved; reaction temperature which is most suitable for the anaerobic reaction is provided and the decomposition of raw materials is accelerated so that the biogas productionamount is greatly improved and the energy sources are saved; meanwhile, the utilization rate of biomass energy is greatly improved and pollution to an ecological environment is effectively avoided.

Owner:杭州皖云科技有限公司

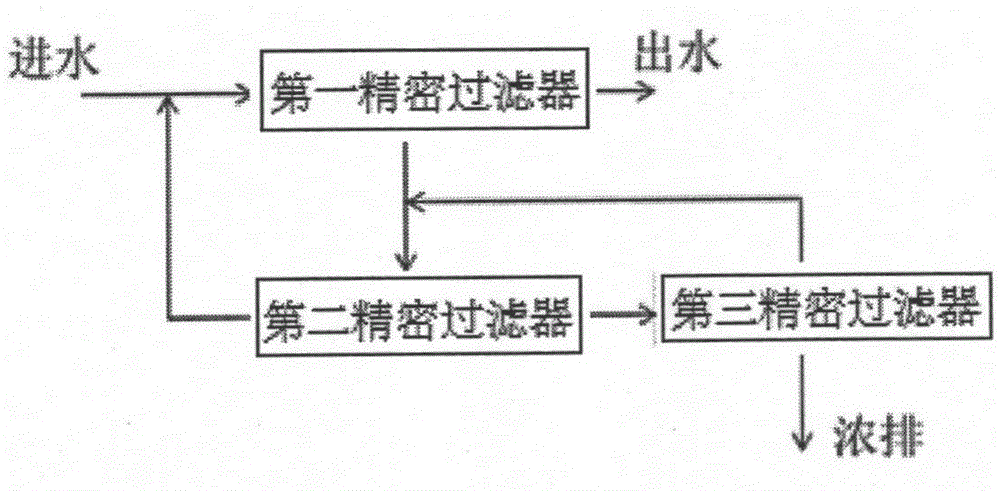

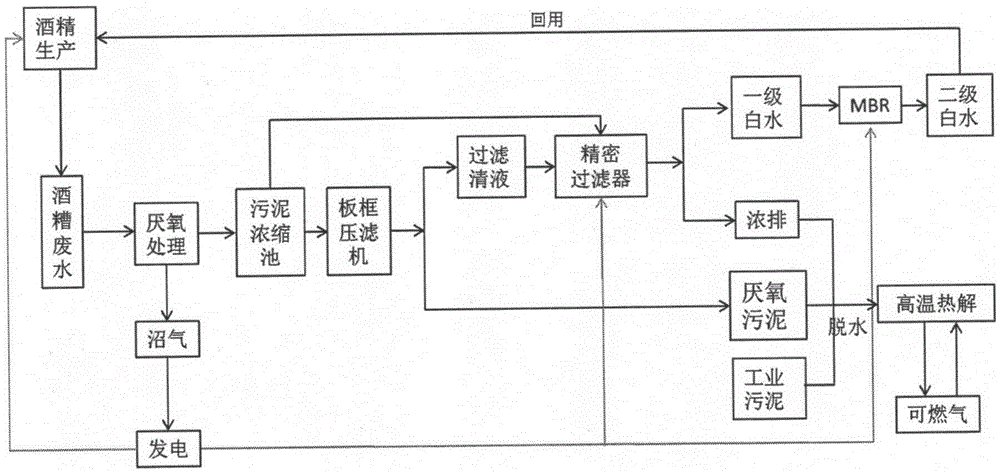

Method for comprehensively treating and utilizing cassava vinasse waste water and industrial sludge

ActiveCN105565598ALow area costLow input costSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisResource utilizationPlain water

The invention provides a method for comprehensively treating and utilizing cassava vinasse waste water and industrial sludge. The method includes: pumping original cassava vinasse waste water into an anaerobic fermentation tank to perform whole-tank high-temperature anaerobic treatment so as to produce biogas; concentrating sludge discharged by the anaerobic fermentation tank, then delivering into a plate-and-frame filter press, and filtering with the plate-and-frame filter press to obtain anaerobic sludge and filtered clear liquid; using a precision filter to perform multistage purification on the filtered clear liquid to obtain first-level plain water and concentrated discharge water, processing the first-level plain water with a membrane biological processing device to obtain second-level plain water which can reach the indexes of production water, and recycling the plain water; mixing the obtained concentrated discharge water and anaerobic sludge with other industrial sludge, dewatering with a dewatering machine, and then conveying to a pyrolyzing furnace for pyrolysis so as to produce combustible gas. The method has the advantages that after the cassava vinasse waste water is subjected to anaerobic fermentation to produce the biogas, self-balancing of energy production and power consumption can be achieved, the water produced after the treatment by the precision filter and a membrane biological reactor can be recycled, resource utilization is achieved, and production cost is lowered.

Owner:CHINA HAISUM ENG

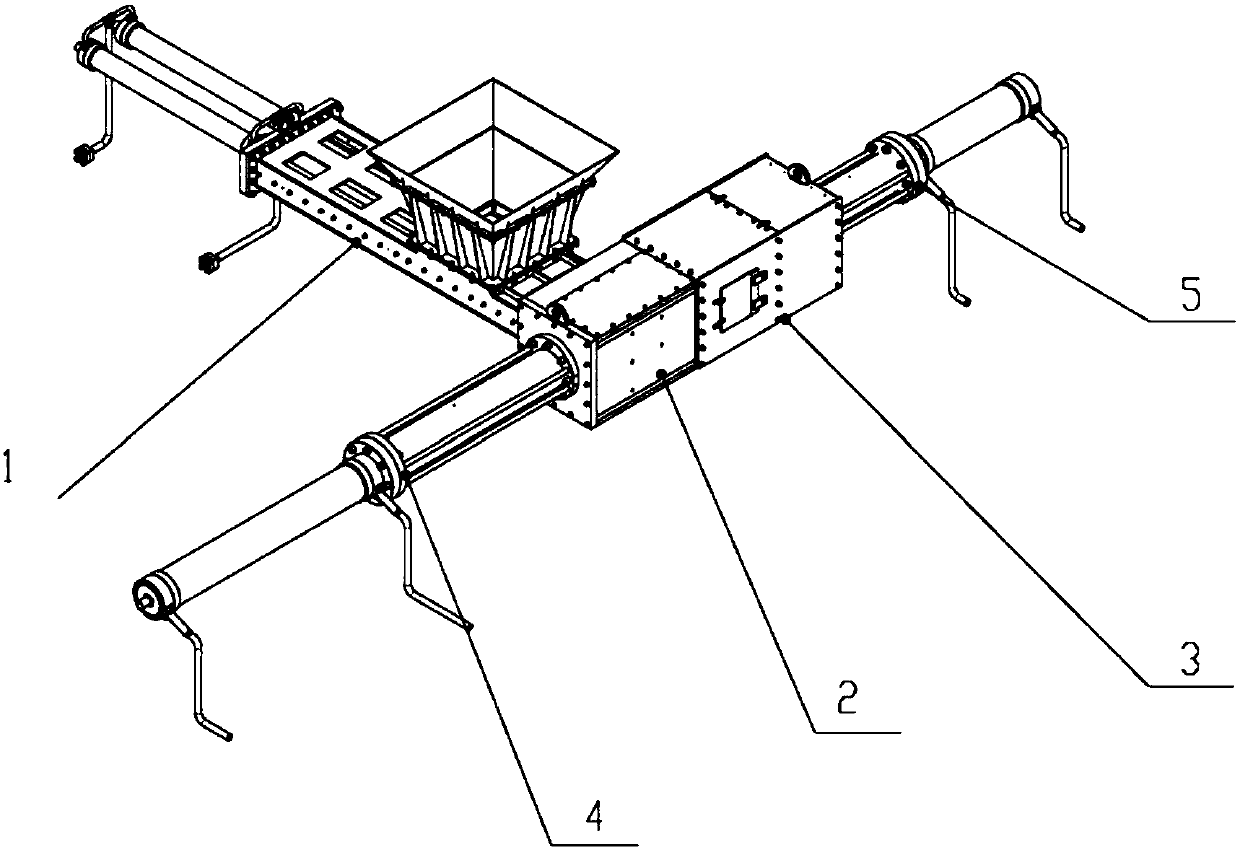

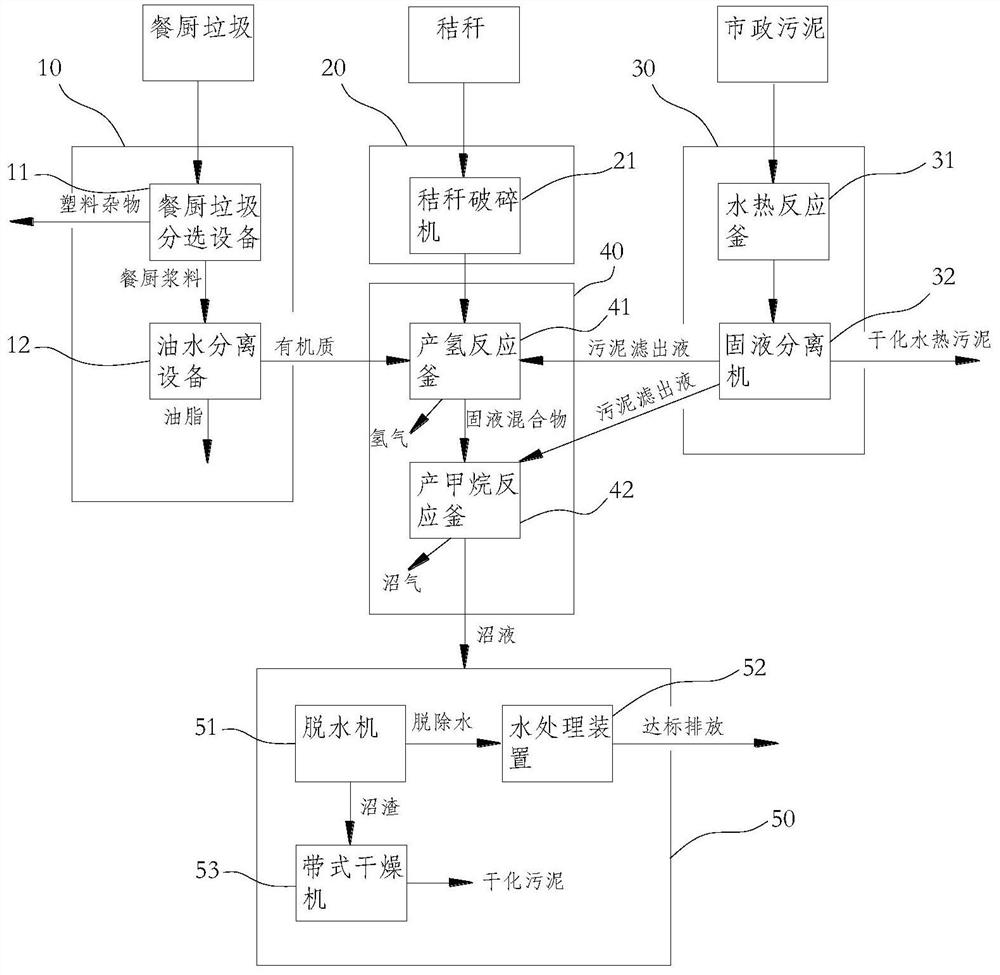

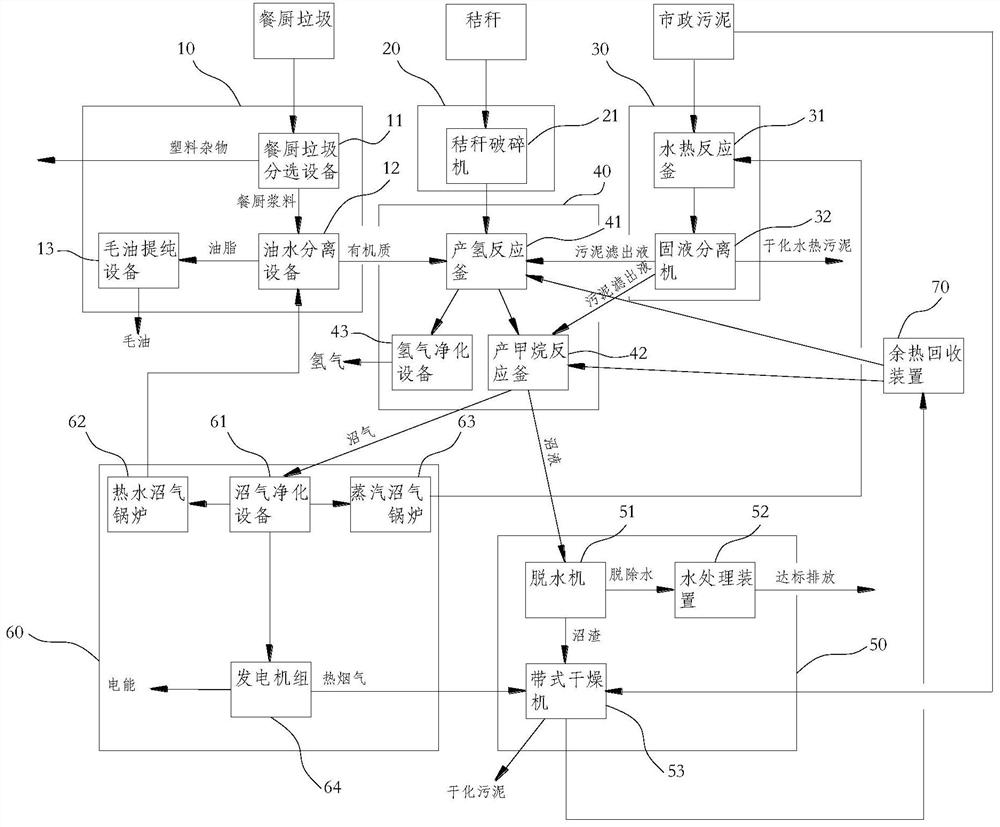

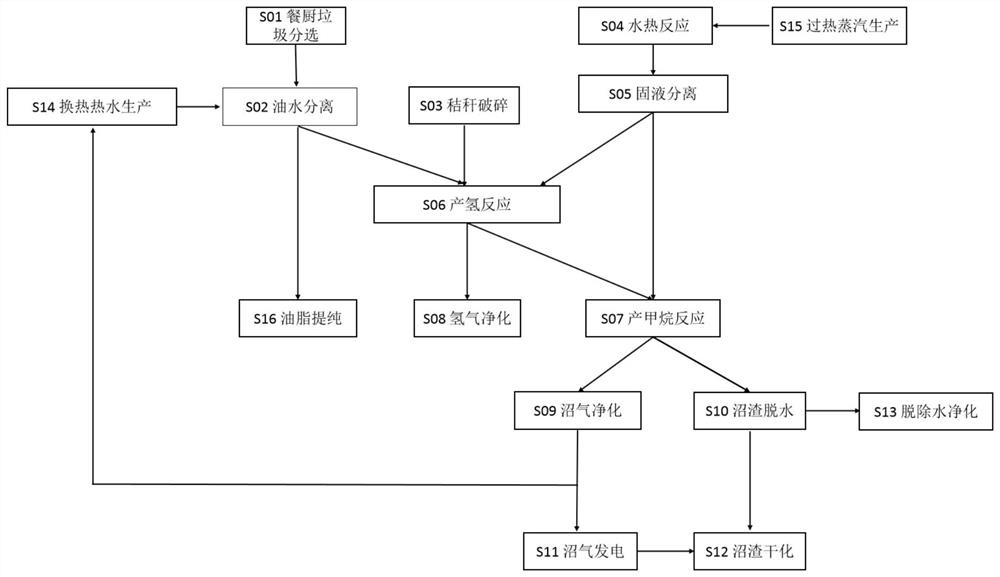

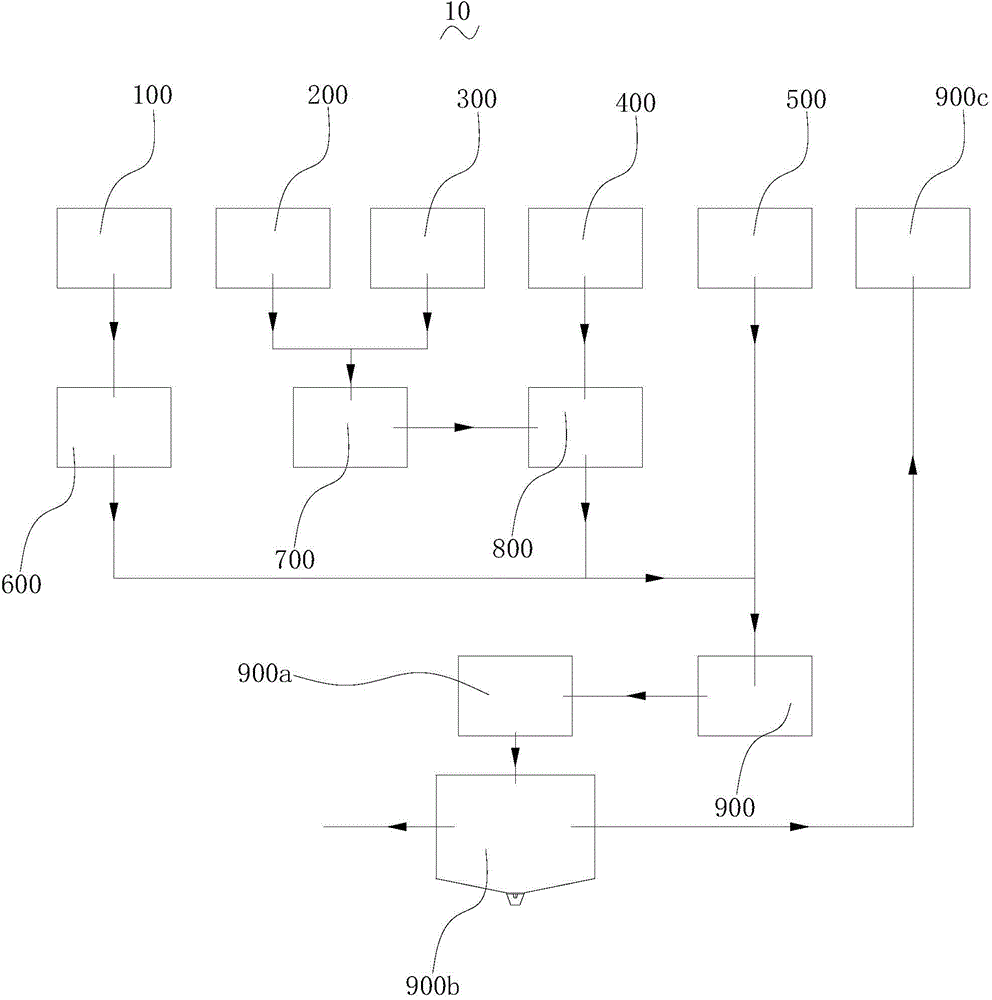

Kitchen waste, straw and municipal sludge resourceful treatment system and method

PendingCN111807660AIncrease biogas productionReduce the burden onSludge treatment by de-watering/drying/thickeningWater treatment compoundsDigestion TreatmentProcess engineering

The invention discloses a kitchen waste, straw and municipal sludge resourceful treatment system and a method. The treatment system comprises a kitchen waste pretreatment device, a straw pretreatmentdevice, a municipal sludge pretreatment device, an anaerobic digestion reaction device and a biogas slurry treatment device. Through the system and the method, the synergistic digestion treatment of the kitchen waste, the straws and the municipal sludge can be realized; the treatment efficiency of the straws and the municipal sludge and the biogas yield are improved; the heat requirement of biogasresidue drying is met, the self-balance of system heat can be realized, the problem of low independent anaerobic digestion efficiency of straws and municipal sludge is solved, harmless and resourceful treatment of kitchen waste is realized, the environmental benefit and economic benefit are high, and the popularization value is very wide.

Owner:JIANGSU KAIMI MEMBRANE TECH

Method for improving anaerobic fermentation efficiency of antibiotic drug residues containing sporophore

ActiveCN105400704AHigh yieldReduce preprocessing timeFungiFermentationEcological environmentBiochemical engineering

The invention discloses a method for improving anaerobic fermentation efficiency of antibiotic drug residues containing sporophore. The method includes the step of anaerobic fermentation, and the step of culturing the antibiotic drug residues containing sporophore is further included before the step of anaerobic fermentation. Taking cephalosporin C drug residues for example, after the culture step is added, the yield of marsh gas is raised by 50% or more; the method can be further combined with ultrasound, microwave, thermokalite and the like for pretreatment, and the yield of marsh gas is also raised by 50% or more. By means of the method, the problems of recycling of a great number of antibiotic drug residues and environmental pollution can be solved, and the method has great significance in promoting sustainable development of the antibiotics pharmaceutical industry and protecting the ecological environment and has actual economic and social benefits and wide application prospect.

Owner:BIOLOGY INST OF HEBEI ACAD OF SCI

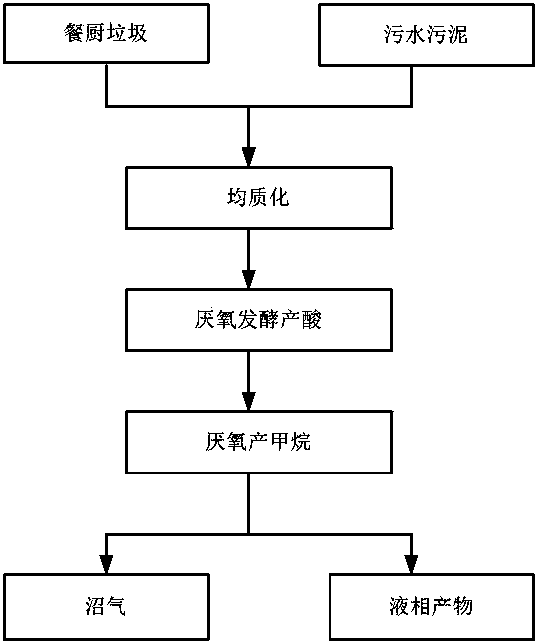

Sewage sludge and kitchen waste treatment device and treatment method

ActiveCN103508643BGuaranteed uptimeStable and homogeneous feedSolid waste disposalWaste based fuelMethane yieldSewage

The invention provides a sewage sludge and kitchen waste treatment device and a treatment method. The device comprises a homogenizing and pulpifying treatment reactor, a sewage sludge pretreatment device and a kitchen waste pretreatment device. The method comprises the following steps that 1, the kitchen waste pretreatment device pretreats kitchen waste and adjusts water content; 2, a dehydrated mud cake pretreated by the sewage sludge pretreatment device and the kitchen waste treated in Step 1 are mixed in proportion, enter the homogenizing and pulpifying treatment reactor for homogenizing and pulpifying treatment, and then become acid production phase feed; 3, the acid production phase feed is added to an acid production phase reactor for hydrolization and acidification, and then becomes acid production phase outlet mud; and 4, the acid production phase outlet mud is added to a methane production phase reactor for anaerobic fermentation, and methane is generated. The sewage sludge and kitchen waste treatment device and the treatment method effectively solve the problems existing in separate treatment of sewage sludge and kitchen waste, and have higher methane yield and organic matter degradation efficiency.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

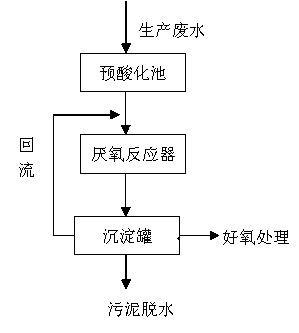

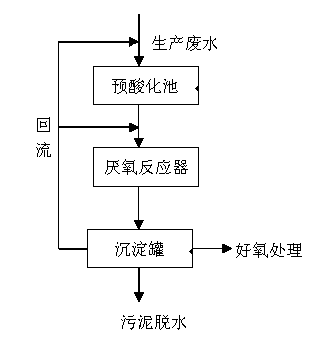

Improved pre-acidifying treatment process of citric acid wastewater

ActiveCN103466791AIncrease varietyReduce shockWaste based fuelTreatment with anaerobic digestion processesChemistryAnaerobic treatment

The invention discloses an improved pre-acidifying treatment process of citric acid wastewater. The process comprises the following step: precipitating overflow effluent of an anaerobic tank through a precipitating tank to obtain supernate which consists of supernate A, supernate B and supernate C, wherein the supernate A is returned and mixed with the citric acid wastewater, the supernate B is returned and mixed with acidified effluent, and the supernate C enters into subsequent steps for aerobic treatment to improve the pH value of effluent of a pre-acidifying pool and increase types and concentrations of microorganisms in the pre-acidifying pool so as to improve the pH of anaerobic inflow and reduce the impact to an anaerobic system, thereby improving the treatment efficiency of an anaerobic processor and the stability of the anaerobic treatment system, and meanwhile improving the removal rate of COD (Chemical Oxygen Demand) and the biogas production as well as lowering the operating cost of enterprises.

Owner:RIZHAO JINHE BOYUAN BIOCHEM

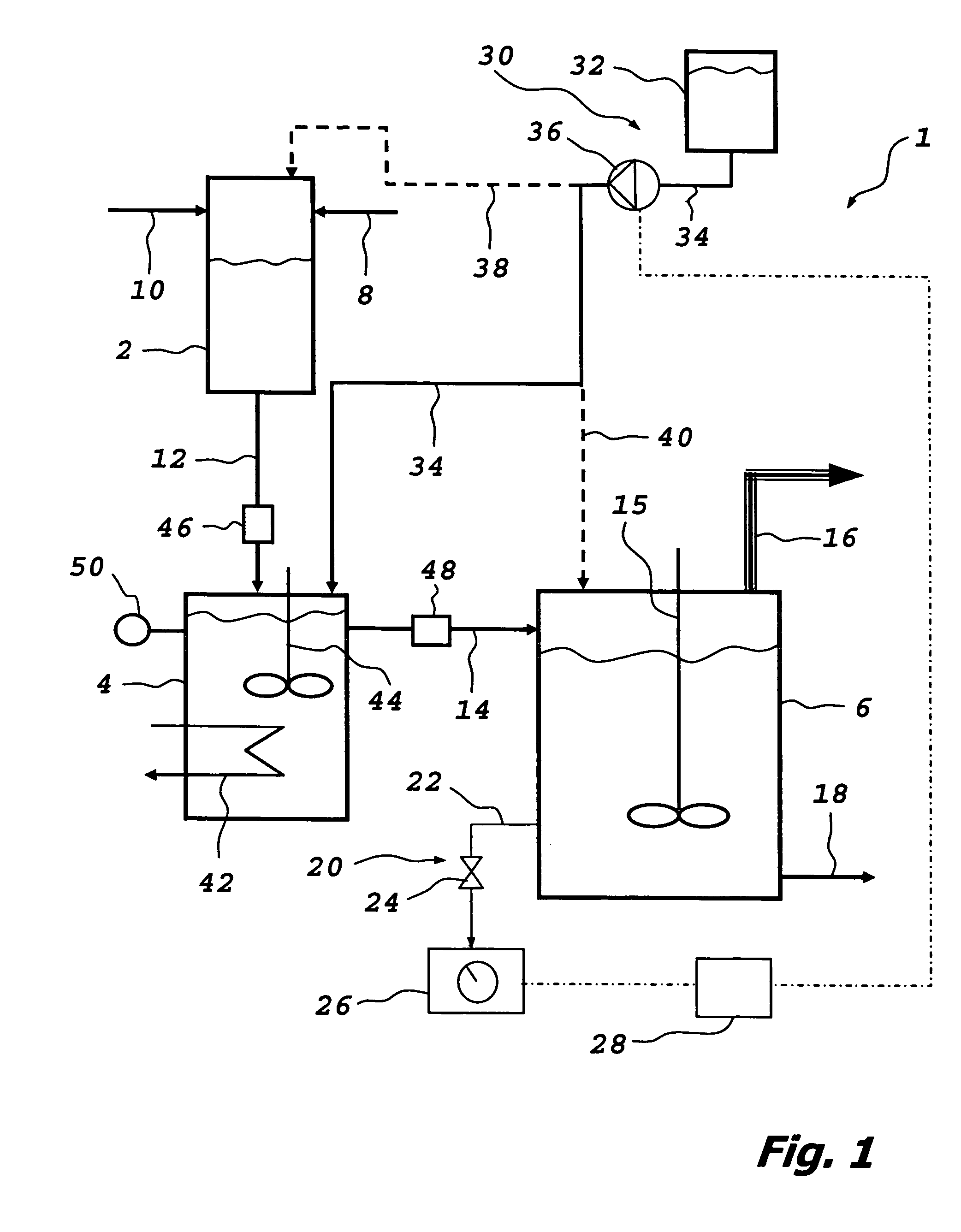

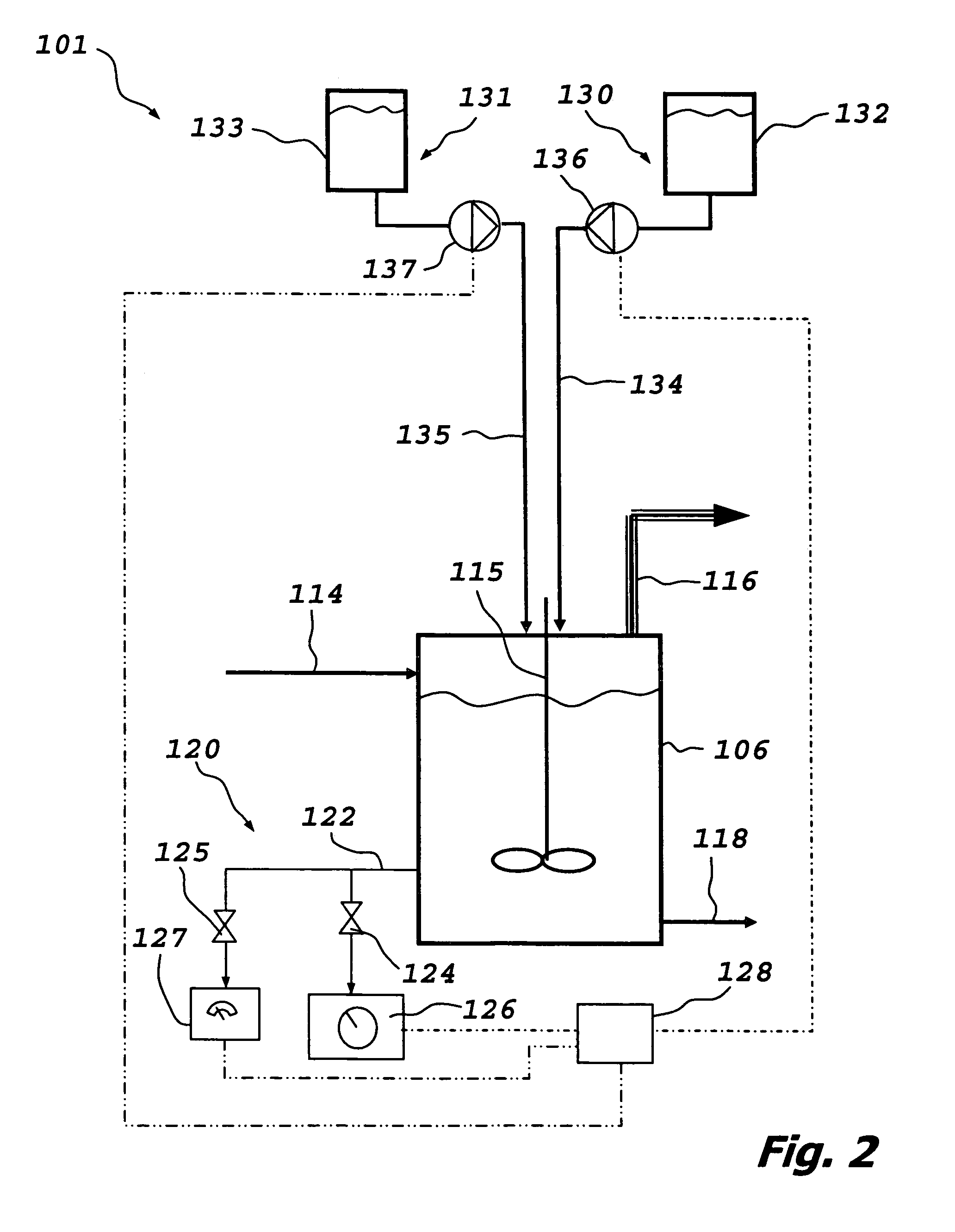

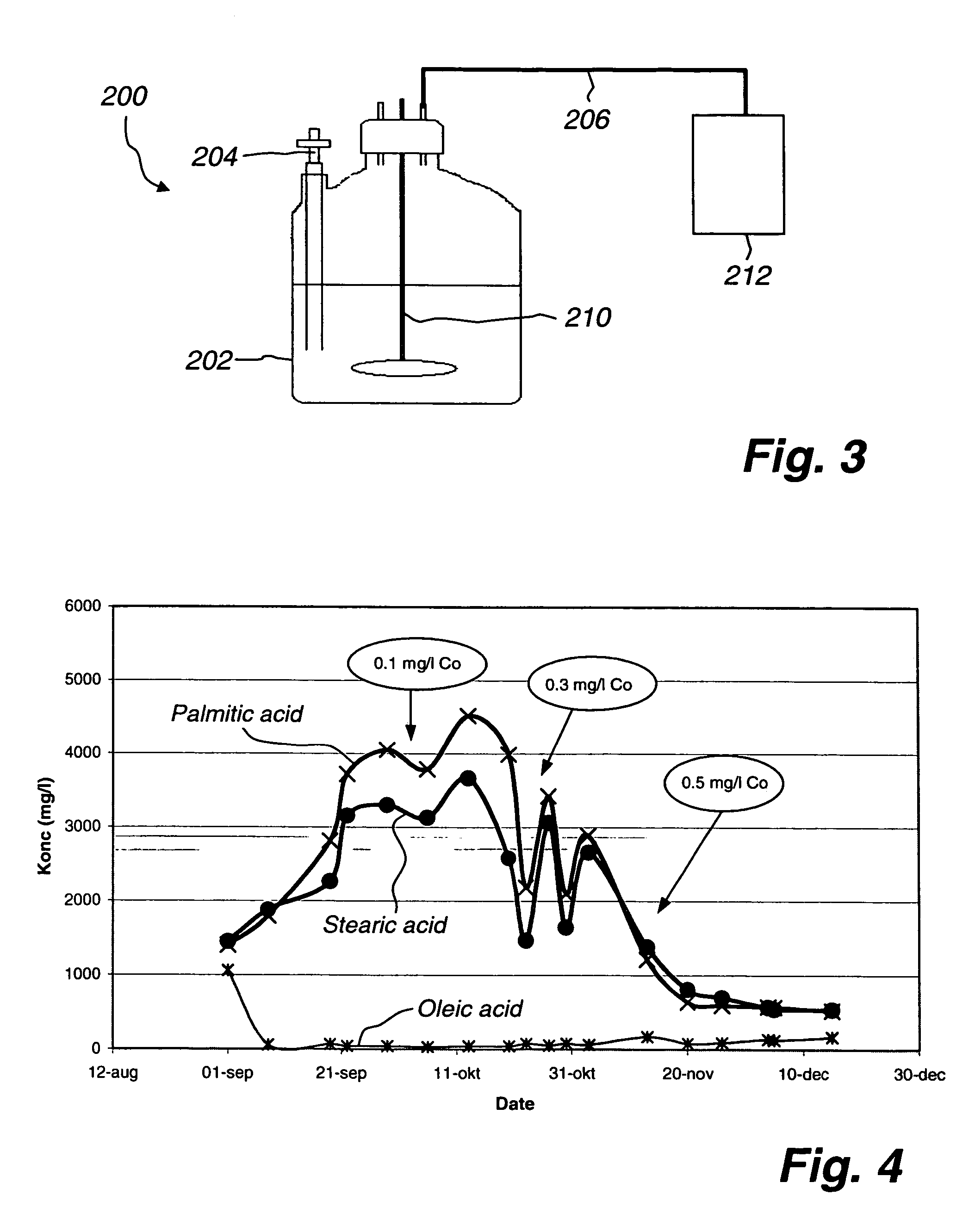

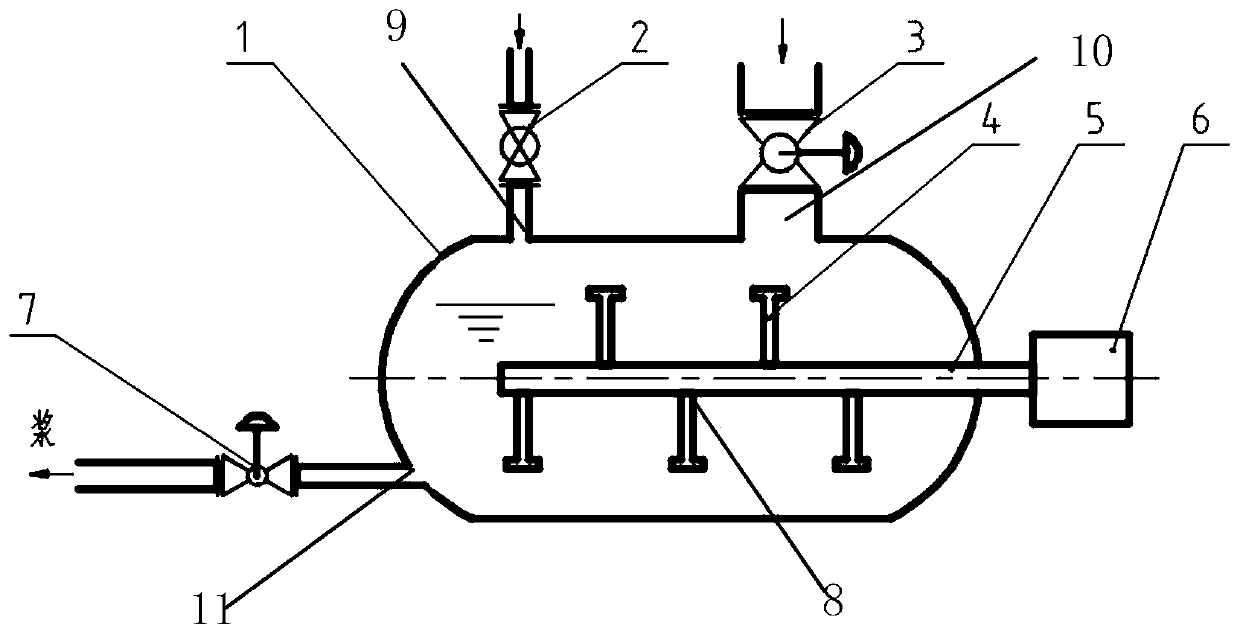

Method, a device and an additive for digesting organic matter

ActiveUS7622286B2Reduce the amount requiredIncrease volumeGas production bioreactorsWaste based fuelBiogenic gasOrganic matter

A method of producing biogas by anaerobic digestion of organic matter includes adding cobalt, iron and hydrochloric acid to an organic matter; bringing the organic matter in contact with biogas-producing bacteria; and digesting the organic matter under anaerobic conditions in a reactor while producing biogas and a digested sludge. A device for producing biogas includes a reactor being adapted for containing the organic matter in the form of a sludge while the sludge is digested. The device includes a feeding device for adding cobalt, iron and hydrochloric acid to the organic matter, and an agitator for mixing the added cobalt, iron and hydrochloric acid with the organic matter. An additive, which is adapted for being added to a device for producing biogas by anaerobic digestion, includes cobalt, iron and hydrochloric acid in an aqueous solution.

Owner:TEKNISKA VERKEN I LINKOPING AB

Method for promoting cellulose anaerobic degradation-based methane production

InactiveCN103409469AReduce pollutionSimple processWaste based fuelFermentationBiotechnologyCellulose

The invention provides a method for promoting cellulose anaerobic degradation-based methane production. The method comprises the following steps of mixing calcium pantothenate and tetrahydrofolic acid according to a certain ratio, adding the mixed solution into a biogas fermentation system with fermentation raw materials, and carrying out biogas fermentation production, wherein the main fermentation raw material is straw cellulose and a volume ratio of the mixed solution of calcium pantothenate and tetrahydrofolic acid to the fermentation system is 1: 500-2000. The method is simple and effective, has a low cost and a wide application range, avoids crop straws retting re-treatment and improves cellulose degradation efficiency and biogas output.

Owner:BIOGAS SCI RES INST MIN OF AGRI

Technology for preparing methane through steam explosion sugarcane leaves dry-method anaerobic fermentation

InactiveCN104073522APromote digestion and utilizationIncrease biogas productionWaste based fuelFermentationBiogasCellulose

The invention relates to a technology for preparing methane through steam explosion sugarcane leaves dry-method anaerobic fermentation, and belongs to the field of agricultural solid waste utilization for energy. The technology comprises the steps as follows: firstly, sugarcane leaves are positioned in a sealed steam explosion device, after introducing saturated steam, the steam explosion pressure is controlled to reduce instantly for obtaining steam explosion sugarcane leaves materials; secondly, a certain amount of pig manure and methane fermentation accelerators, as well as 30% to 40% of inoculum are put into the sugarcane leaves subjected to the steam explosion in sequence as materials of which the C / N is adjusted to 25 to 1 through ammonium bicarbonate and the dry matter density of the materials is adjusted to 22% to 25% through adding water, and then be stirred uniformly and canned for intermediate temperature anaerobic fermentation, and methane is produced. Through adopting the steam explosion method for pre-processing the sugarcane leaves, the internal structure of the sugarcane leaves are damaged effectively so as to generate the breakage and separation of cellulose, hemicellulose and lignin structure, promote the digestion utilization of the fermenting on microorganism of methane in dry-method anaerobic fermentation against the sugarcane leaves, and the fermenting time is shortened by about 15 days, the methane yield is increased by 20%, and besides, the method is simple in technology and low in cost.

Owner:AGRI MACHINERY INST CHINESE TROPICAL ACAD OF SCI

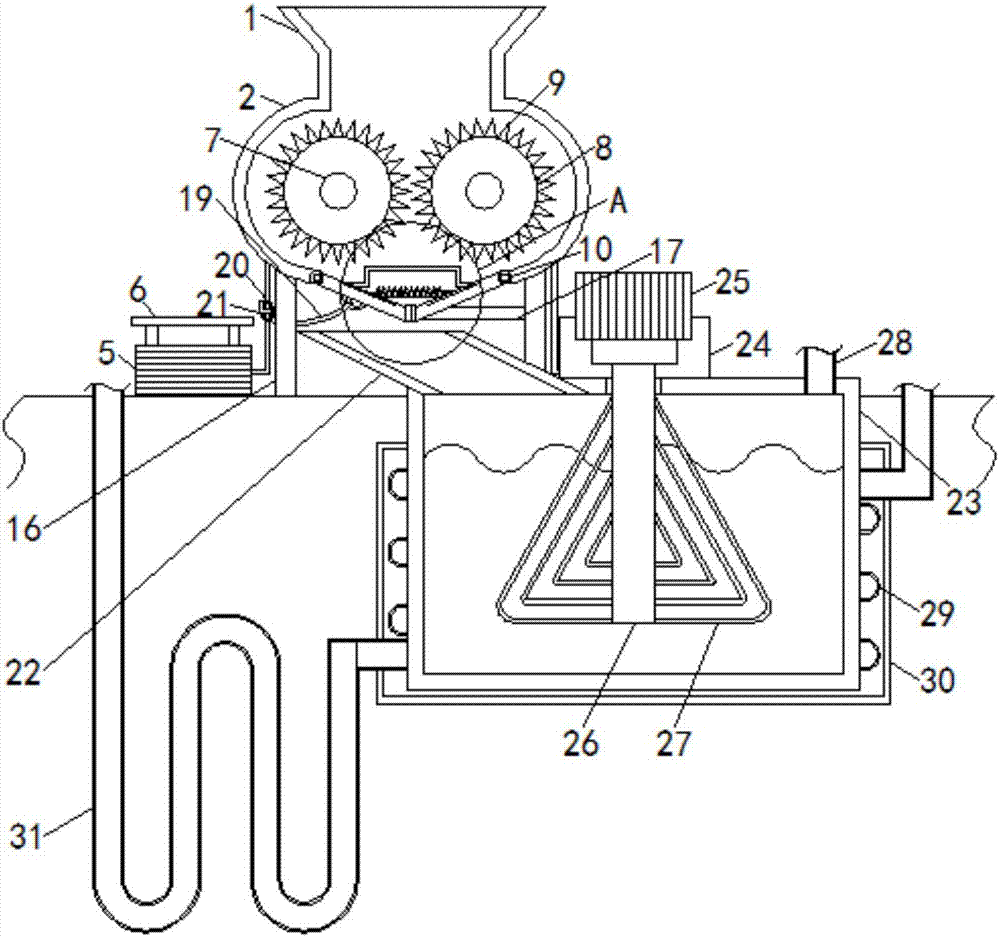

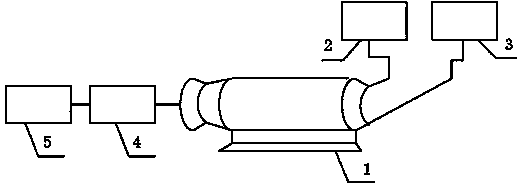

Straw wall-breaking pulping machine and straw wall-breaking pulping method

PendingCN109868212AEfficient wall breakingIncrease biogas productionGas production bioreactorsFermentationBiogasEconomic benefits

The invention discloses a straw wall-breaking pulping machine and a straw wall-breaking pulping method, and belongs to the technical field of biogas fermentation. The straw wall breaking pulping machine comprises a barrel body and a plurality of stirring devices evenly arranged in the barrel body; a steam inlet and a feeding port are formed in the top of the barrel body, and a pulp outlet is formed in the lower end of the barrel body; the stirring device comprises a stirring shaft and stirring blades uniformly distributed on the stirring shaft; each stirring blade comprises a connecting arm fixedly connected with the stirring shaft and a stirring blade arranged at the tail end of the connecting arm; and the length of the stirring blade is greater than the width of the connecting arm. The simple straw wall-breaking pulping machine provided by the invention can realize efficient wall breaking of straws; and meanwhile, the slurry with relatively high biogas yield is obtained through specific process conditions, so that the economic benefit is remarkable.

Owner:QINGDAO HUIJUN ENVIRONMENTAL ENERGY ENG

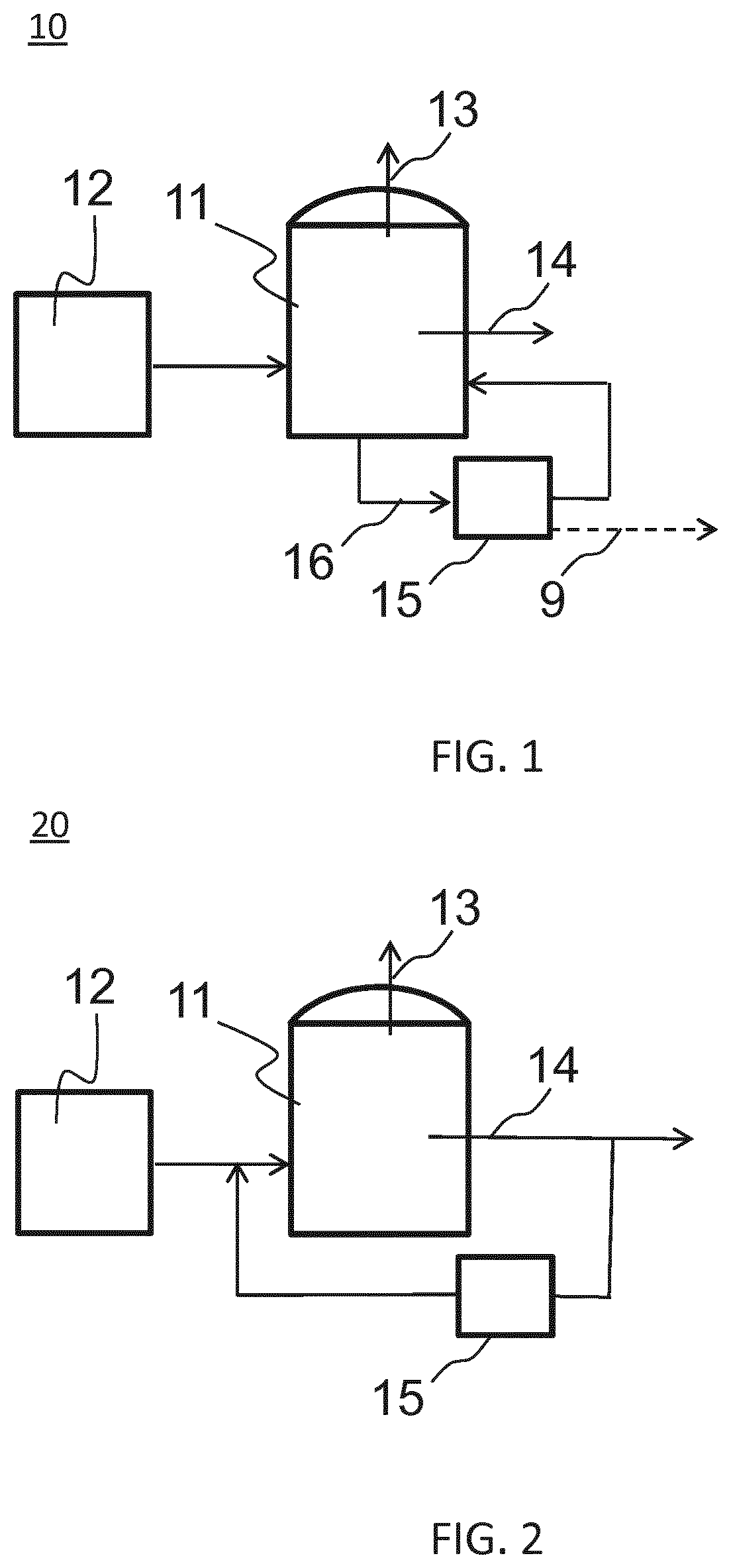

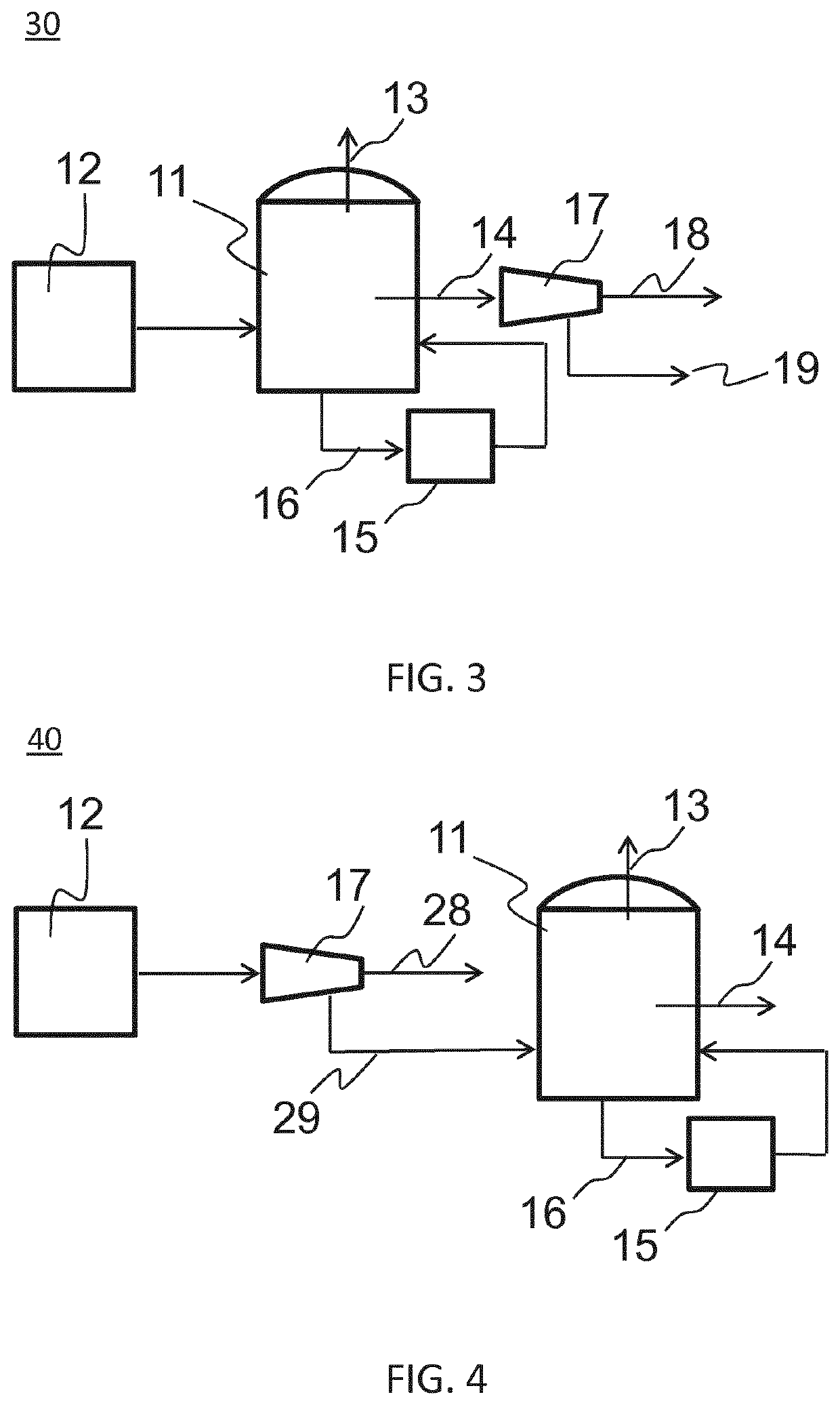

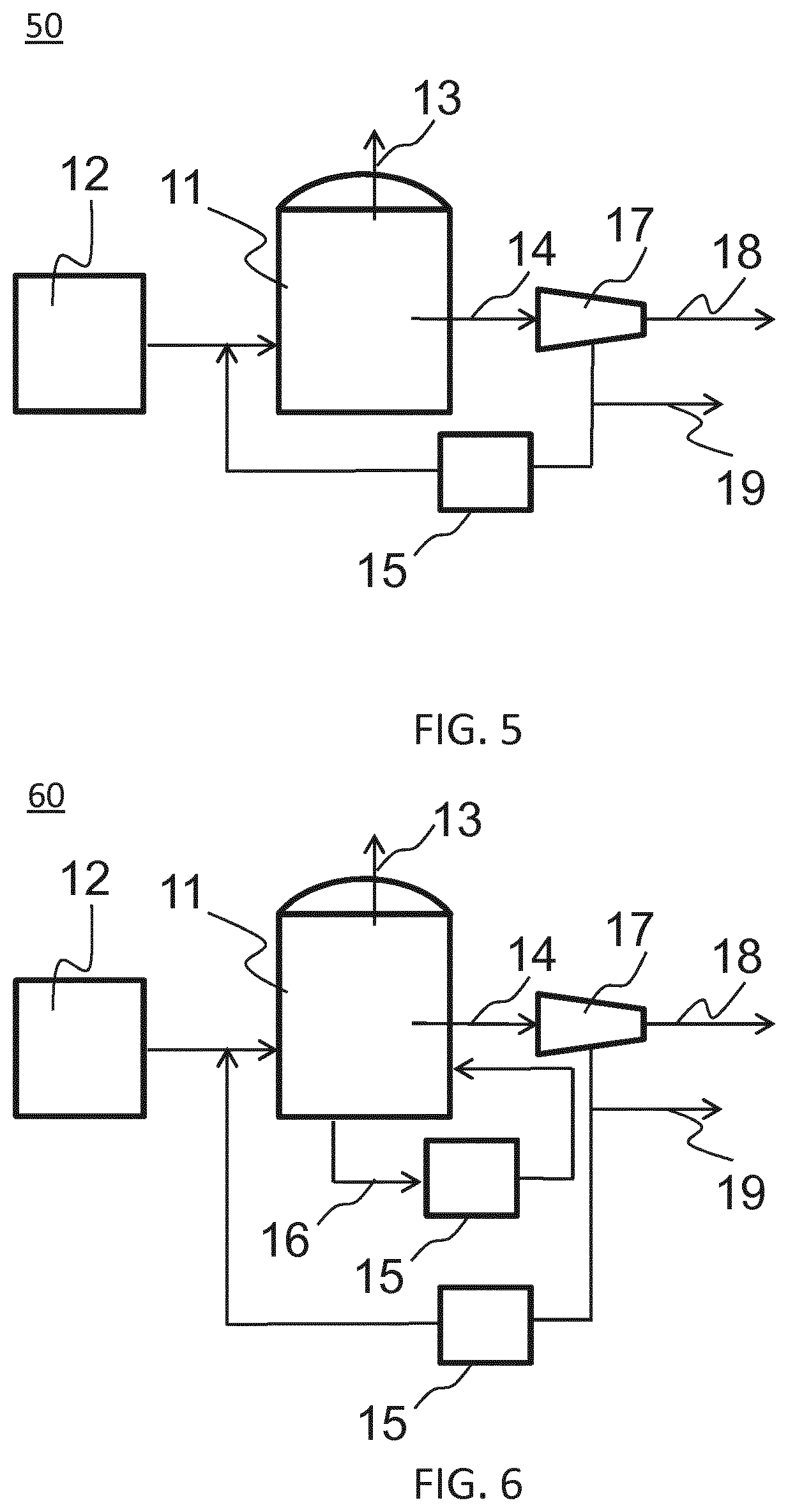

Apparatus and method for refractory organics conversion into biogas

ActiveUS20200165553A1Increase biogas productionLower requirementBioreactor/fermenter combinationsBiological substance pretreatmentsPhysical chemistryDigestate

An apparatus for refractory organics conversion into biogas includes an anaerobic digester configured to be fed with organic material comprising refractory organics and to generate biogas and a digestate comprising at least a part of the refractory organics, wherein the apparatus comprises a device for a controlled partial oxidation of the refractory organics comprising an inlet configured to be fed with refractory organics and means configured to control the residence time of the refractory organics within the device for a controlled partial oxidation, so as to partially degrade refractory organics. A method for refractory organics conversion into biogas carried out using such an apparatus is also provided.

Owner:SUEZ INT

A kind of Pseudomonas monsonii ky-05 and application

ActiveCN104630098BIncrease biogas productionHigh speedBacteriaMicroorganism based processesCelluloseCellulose degradation

The invention provides a kind of Pseudomonas monsonii KY-05, the preservation number is CGMCC No.10172, which has the ability to degrade cellulose; The biogas production rate and anaerobic reaction start-up speed of the process can be improved, and it can be used to develop microbial preparations that enhance the gas production efficiency of anaerobic digestion, and gradually carry out practical application and promotion in sludge plants, with broad application prospects.

Owner:TIANJIN CARING TECH DEV

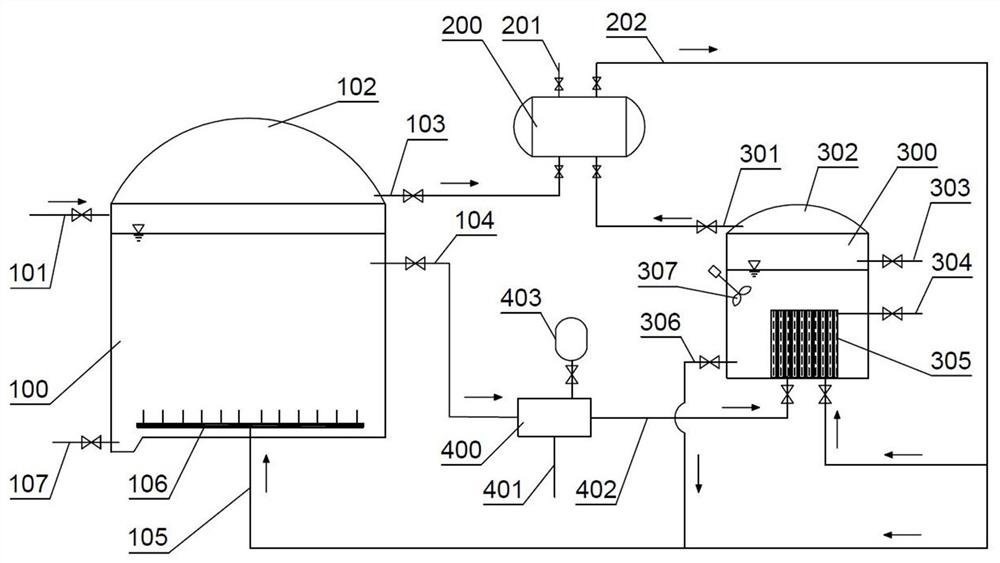

Anaerobic digestion system capable of improving biogas production efficiency

PendingCN114058482AImprove conversion rateIncrease concentrationBioreactor/fermenter combinationsBiological substance pretreatmentsDigestion TreatmentBiogas production

The invention belongs to the technical field of biological fermentation, and discloses an anaerobic digestion system capable of improving biogas production efficiency. The anaerobic digestion system comprises an anaerobic digester, a biogas pressure regulating tank, an anaerobic membrane separator and a solid-liquid separator, wherein the anaerobic digester communicates with a feed pipe, a digester flexible gas storage bag, a discharge pipe, a material distribution pipe and a slag discharge pipe, the digester flexible gas storage bag communicates with a digester exhaust pipe, the biogas pressure regulating tank communicates with a biogas discharge pipe and a biogas backwashing pipe, the solid-liquid separator communicates with a biogas residue pipe, a biogas slurry pipe and a coagulant adding tank, the anaerobic membrane separator communicates with a membrane separator flexible gas storage bag, an overflow pipe, a sludge return pipe, a membrane assembly and a side stirrer, and the membrane assembly communicates with a water outlet pipe. The system of the invention overcomes the problems that digestion treatment on organic materials is incomplete, efficiency is low, operation energy consumption is high, and sulfur components in biogas are not treated independently in the prior art, and is suitable for anaerobic digestion of agricultural waste organic materials to produce biogas.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

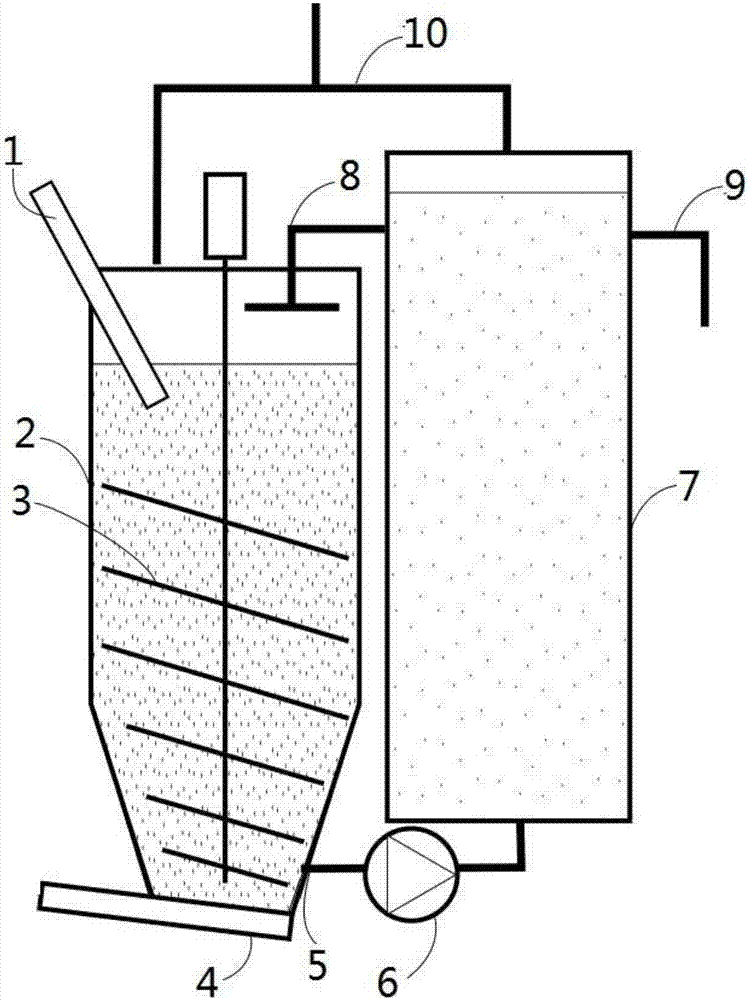

Device and method for fermenting organic matters

PendingCN107034126AFully decomposed organic matterIncrease biogas productionBioreactor/fermenter combinationsBiological substance pretreatmentsInternal energyCirculating pump

The invention discloses a device and a method for fermenting organic matters. The device comprises a feeding device, a first reaction device, an extruding device, a high-solid-content discharging device, a low-solid-content discharging device, a first circulating pump, a second reaction device, a first backflow device, a first discharging device and a collecting device, wherein the extruding device is arranged in the first reaction device, and the first circulating pump is arranged between the low-solid-content discharging device and the second reaction device; the first backflow device is arranged between the first reaction device and the second reaction device, and the first discharging device is arranged at the second reaction device. Through the circular flow of a microbial community remained and fermented in the second reaction device and materials between the first reaction devices, the organic materials can be very sufficiently acidified within a short time; compared with a traditional anaerobic fermentation technology, the method has the advantages that the organic matters are more sufficiently decomposed, and the biogas production is higher.

Owner:ENWISE CO LTD

Ensiling method for improving yield of methane produced through anaerobic fermentation of straw

ActiveCN109880855AIncrease soluble sugar contentInhibit plant respirationWaste based fuelFermentationBiotechnologyAmmonium hydroxide

The invention provides an ensiling method for improving the yield of methane produced through anaerobic fermentation of straw. The ensiling method comprises the following steps that the newly harvested straw is smashed into the length of 0.5-3.0 cm; an ensiling additive A is sprayed to the smashed straw, uniform stirring is conducted, and silage stock is obtained; the uniformly prepared silage stock is placed into a silage pit in layers; the method for filling the silage stock into each layer comprises the steps that each layer is filled with the straw with the thickness of 30-60 cm, the strawis compacted, and an ensiling additive B is uniformly sprayed on the upper surface of the straw; after filling of the silage stock is completed, sealing is conducted to form an anaerobic environment,closed storage is conducted for 30-90 days at the natural temperature of 5-25 DEG C, and ensiled straw is obtained, wherein the ensiling additive A is a calcium peroxide solution, and the ensiling additive B is an ammonium hydroxide solution. By means of the ensiling method, the straw can be prevented from being mildewed and decayed, loss of nutrients in the straw is reduced, and the yield of themethane produced through anaerobic fermentation of the straw is effectively improved.

Owner:HEBEI UNIV OF TECH

Heating-type biogas generating device

InactiveCN103865764AIncrease biogas productionGuaranteed normal useBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasWater pipe

The invention discloses a heating-type biogas generating device which comprises a cylindrical fermentation tank. A water pipe is spirally arranged in the cylindrical surface wall of the cylindrical fermentation tank (1); an electromagnetic valve 1 and a water outlet pipe are communicated with the lower end of the water pipe; and an electromagnetic valve 2 and a water inlet pipe are communicated with the upper end of the water pipe. According to the heating-type biogas generating device, after the water pipe is spirally arranged in the cylindrical surface wall of the cylindrical fermentation tank, the temperature of the fermentation tank can be raised by the way of supplying hot water into the water pipe when temperature is low, thereby increasing the biogas yield and ensuring the normal usage of a user. The heating-type biogas generating device is simple in structure improvement and obvious in improvement effect.

Owner:DEYANG JIALONG MACHINERY MFG

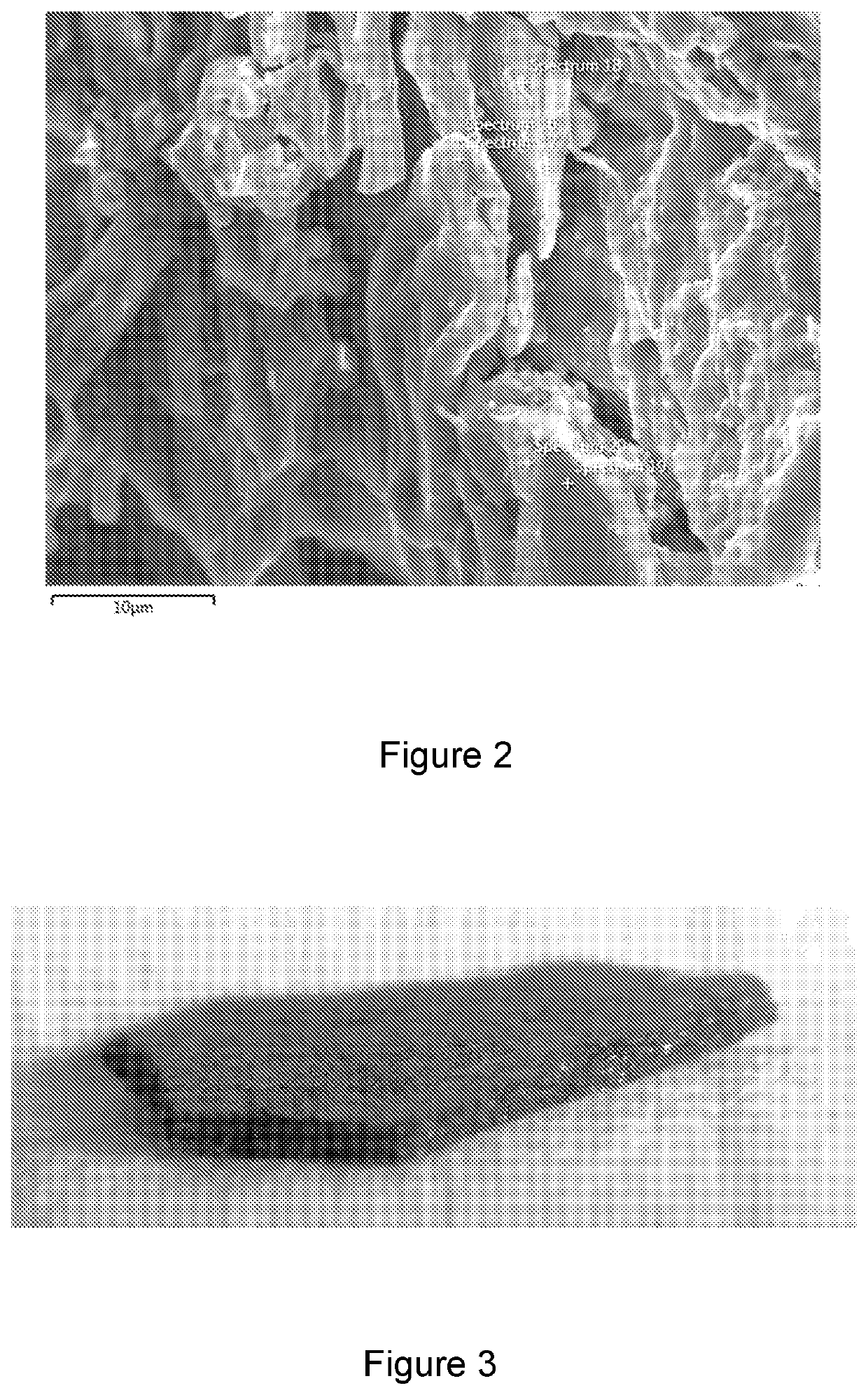

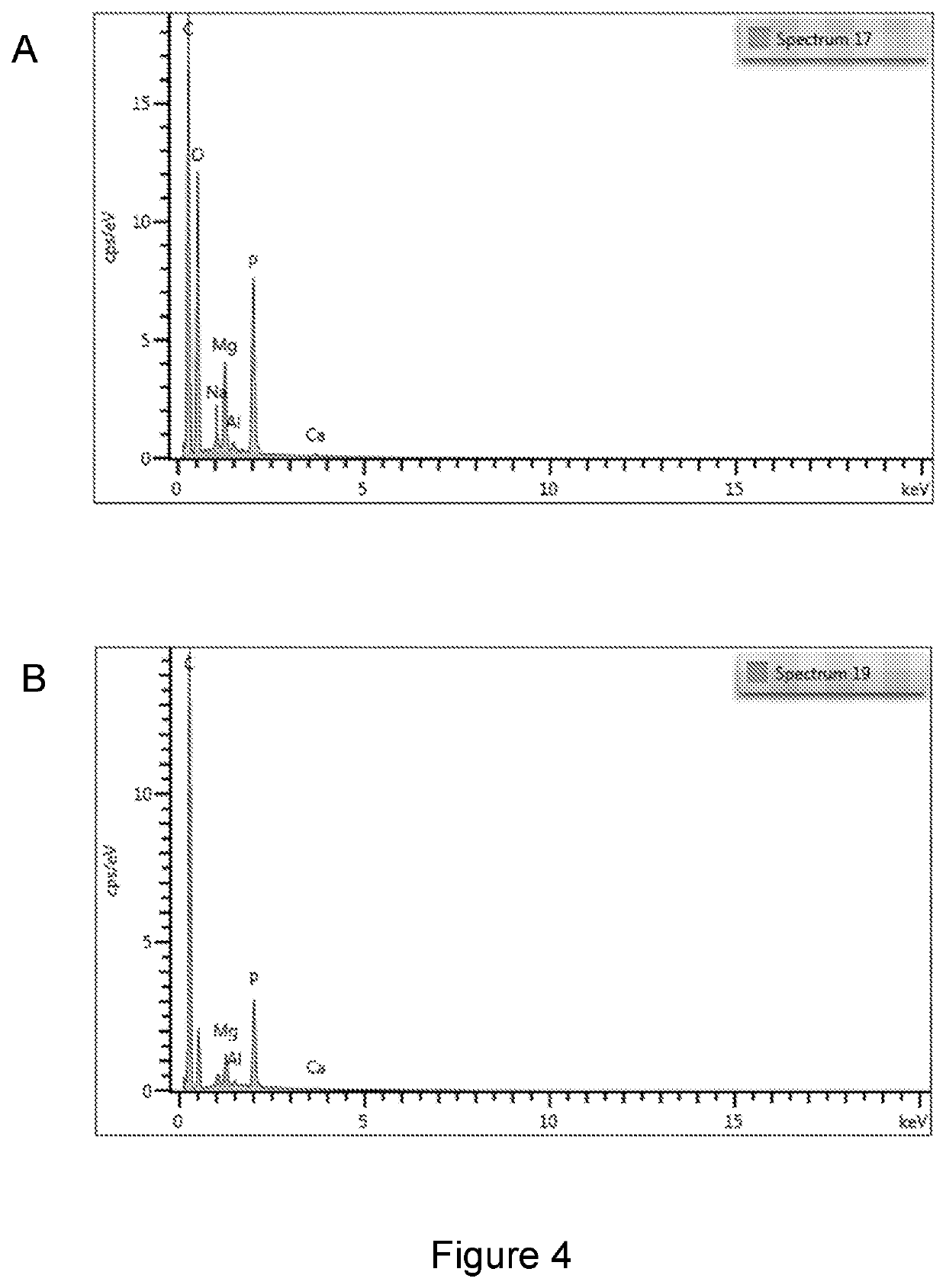

Adsorbent for anaerobic digestion processes

InactiveUS20200071218A1Increase biogas productionImprove adsorption capacityBioreactor/fermenter combinationsBiological substance pretreatmentsSorbentEnvironmental engineering

A particulate carbon adsorbent for use in anaerobic digestion is provided. The particulate carbon adsorbent is substantially planar and comprising between 40-90 wt % carbon. Methods of manufacture of the particulate carbon adsorbent are also provided.

Owner:THE UNIV COURT OF THE UNIV OF EDINBURGH

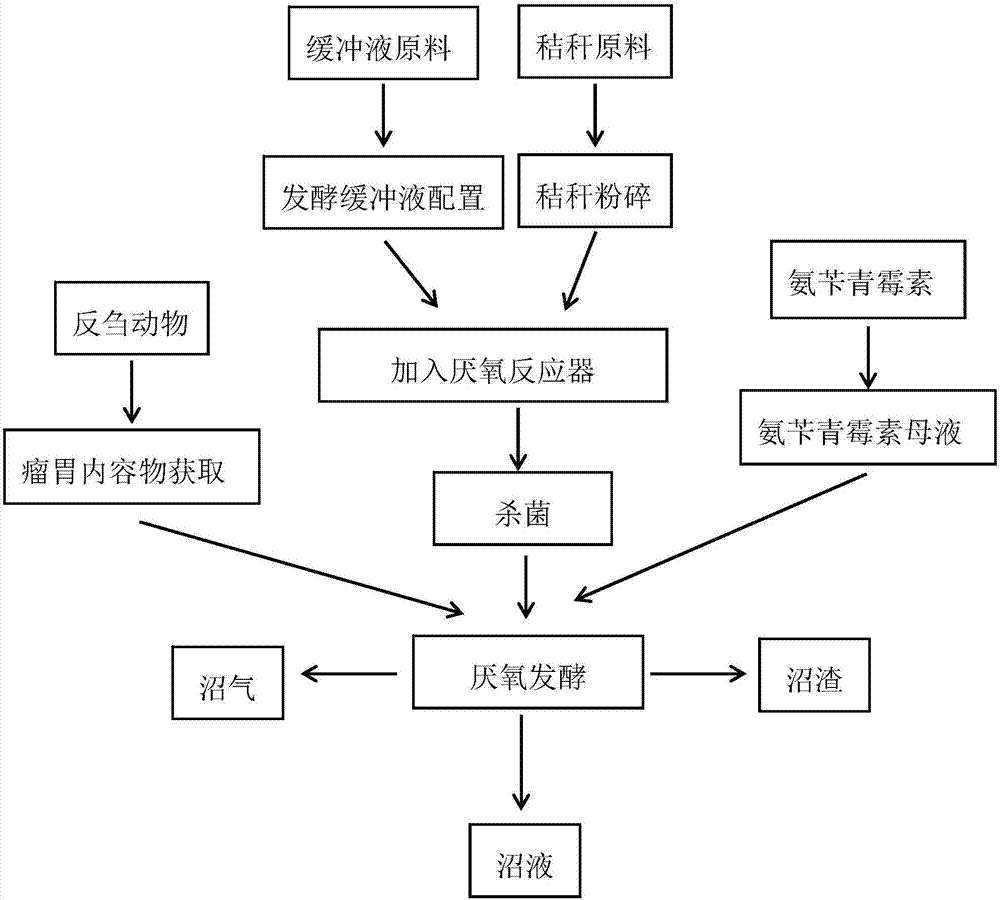

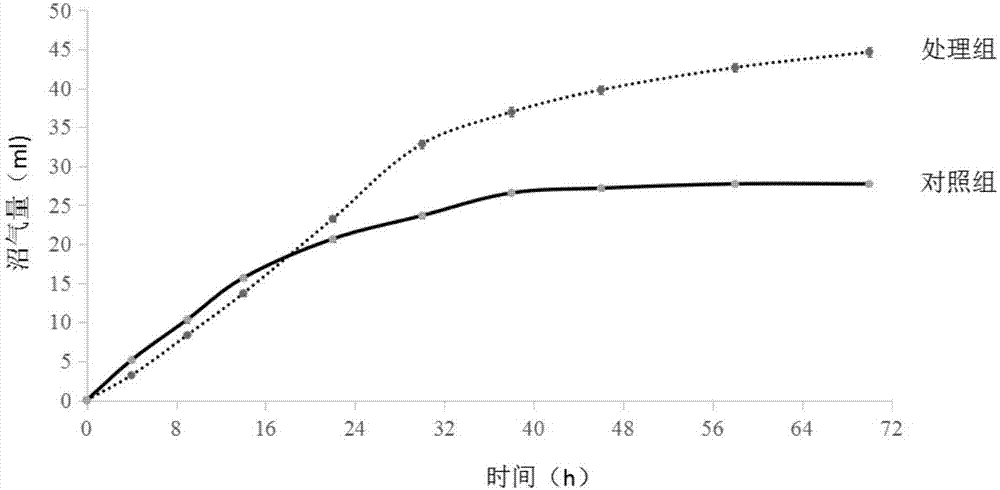

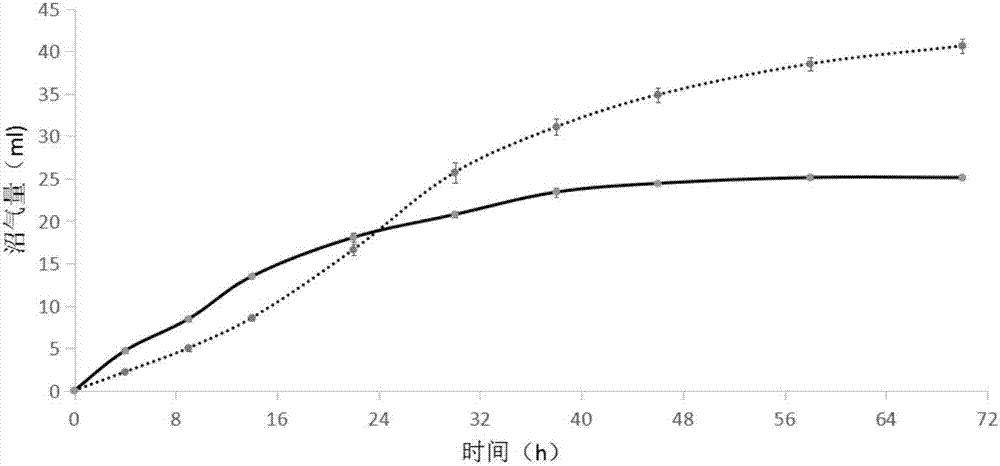

Method for producing biogas through anaerobic fermentation of degradation straw raw material

InactiveCN107164414AIncrease gas yieldRaise the ratioWaste based fuelFermentationAmpicillinReaction temperature

The invention discloses a method for producing biogas through anaerobic fermentation of a degradation straw raw material. The method concretely comprises the following steps: chopping the straw raw material to form 0.3-0.8 cm fragments; adding the chopped fragments into an anaerobic reactor as a fermentation material; adding a fermentation buffer solution to the fermentation material in the anaerobic reactor according to a weight / volume ratio of the fermentation material to the fermentation buffer solution of 1:(45-90); inoculating the anaerobic reactor with an inoculation material according to a weight / volume ratio of the fermentation material to the inoculation material of 1:(5-10) to make the final concentration of the fermentation material be 1-2%; and adding ampicillin into the anaerobic reactor to make the final concentration of the ampicillin be 1800-2200 U / ml, and carrying out fermentation at a controlled reaction temperature of 38-40 DEG C for 48-72 h to obtain the biogas. Compared with the prior art, the method disclosed in the invention has the advantages of effective increase of the yield of the biogas produced from the straw raw material by 55-60%, increase of the proportion of the biogas in cumulative gas production, and increase the biogas yield per unit straw raw material.

Owner:NANJING AGRICULTURAL UNIVERSITY

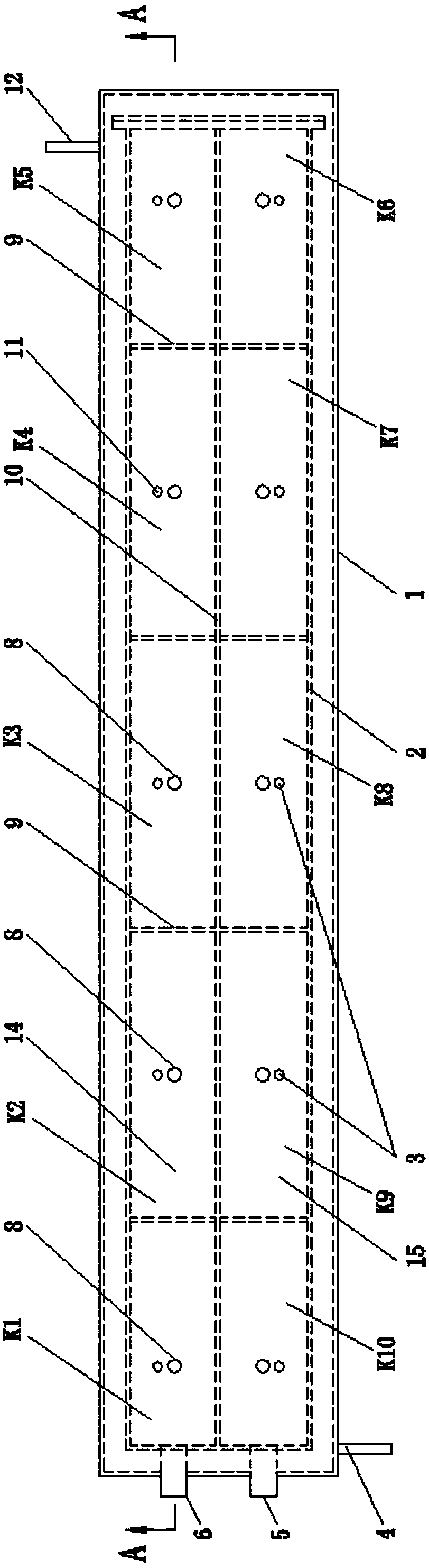

Plug-flow type reactor and controlling method of biogas produced by utilizing cow dung

PendingCN108017249AEnough time to staySpatial independenceWaste water treatment from animal husbandryGaseous fuelsFiberOrganic matter

The invention discloses a plug-flow type reactor and a controlling method of biogas produced by utilizing cow dung, belongs to the technical field of environmental protection and biomass energy, and aims to solve the technical problems of low energy recycling efficiency, a low utilization ratio of organic matters and a low methane recycling ratio in an existing fecal residue and waste water anaerobic fermentation technology, in particular to treatment on substrates with high fiber substance contents. The interior of a main body reactor of the plug-flow type reactor disclosed by the invention is divided into two reaction chambers by a partition plate in a long-side direction; the reaction chambers are divided into ten air chambers by partition plates in a short-side direction; an air outletpipe, a sampling pipe, a feeding hole and a discharging hole are also arranged on and formed in the main body reactor; a heat insulation device is arranged on the outer part of the main body reactor.The method disclosed by the invention comprises the following steps: 1, controlling of parameters; 2, starting; 3, stable operation. According to the plug-flow type reactor and the controlling methoddisclosed by the invention, the biogas produced by utilizing anaerobic digestion of fecal residue and waste water with a high solid ratio, fiber substances and sludge is realized, and the plug-flow type reactor has the advantages of no blocking, no maintenance, simple structure, low construction cost, high efficiency, stable operation and easiness for controlling.

Owner:HARBIN INST OF TECH

Biogas fermenting tank

ActiveCN104403930AImprove the efficiency of anaerobic fermentationCompact structureGas production bioreactorsWaste based fuelAtmospheric pressureExhaust pipe

The invention discloses a biogas fermenting tank. The biogas fermenting tank comprises a main tank body, a liquid seal pool, an exhaust pipe, an air pressure adjustment chamber, a liquid discharge pipe, a shell breaking awl and a shell breaking grating. The main tank body is respectively communicated with the liquid seal pool and the air pressure adjustment chamber. The liquid seal pool is arranged at the top of the main tank body. The main tank body is provided with a diversion opening and a material discharge outlet. The exhaust pipe is arranged at the joint of the liquid seal pool and the main tank body and is communicated with the main tank body. The air pressure adjustment chamber is provided with an overflow mouth. The liquid discharge pipe is arranged at the joint of the liquid seal pool and the main tank body and is communicated with the main tank body. The shell breaking awl sleeves the liquid discharge pipe and is located in the main tank body. The shell breaking grating is arranged in the main tank body. The biogas fermenting tank is provided with the main tank body, the liquid seal pool, the exhaust pipe, the air pressure adjustment chamber, the liquid discharge pipe, the shell breaking awl and the shell breaking grating, has a compact and simple structure and prevents crusting phenomenon. The biogas fermenting tank has high anaerobic fermentation efficiency and a high biogas yield.

Owner:韩翼

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com