Ensiling method for improving yield of methane produced through anaerobic fermentation of straw

A technology for anaerobic fermentation and biogas production, applied in fermentation, waste fuel and other directions, can solve the problems of destroying the lignocellulose structure of straw, loss of excessive organic components, etc., to improve biogas production, reduce losses, and avoid lignin the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

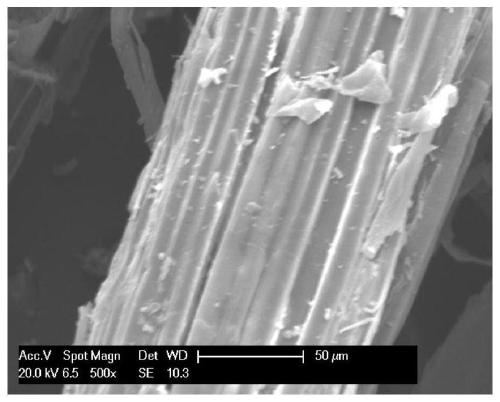

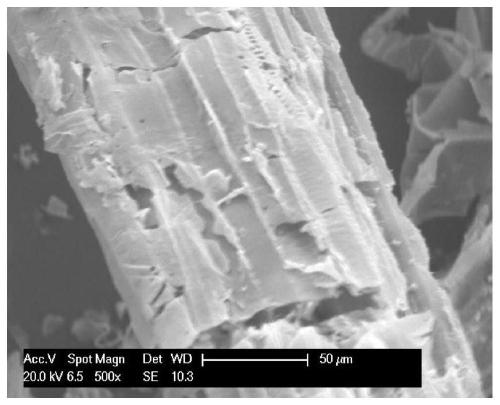

Image

Examples

Embodiment 1

[0025] The present invention proposes a silage method for improving straw biogas fermentation yield, and the present invention can be implemented by the following methods:

[0026] Preparation of silage stalks: crush the newly harvested corn stalks at the wax ripening stage to a length of 0.5-3 cm, and then spray a calcium peroxide solution with a concentration of 8 wt% in the crushed corn stalks, and the calcium peroxide solution is added in an amount of 40 mL / kg fresh Straw, stir evenly to obtain silage preparation;

[0027] Then prepare the silage and load it into a cellar: the depth of the silage cellar is 2.5 meters, each filling is 40 cm thick, tamp it with a stone pestle, and evenly spray an ammonia solution with a concentration of 15wt% on the upper surface of the silage once, and the amount of ammonia solution added is 80mL / kg silage Prepare the material, and then continue to repeat the filling of a new layer in the order of "filling-tamping-spraying" until the compac...

Embodiment 2

[0030] Preparation of silage stalks: crush the newly harvested corn stalks at the milk maturity stage to a length of 0.5-3 cm, and then spray a calcium peroxide solution with a concentration of 7 wt% in the crushed corn stalks, and the amount of calcium peroxide solution added is 30 mL / kg fresh Straw, stir evenly to obtain silage preparation;

[0031] Then prepare the silage and load it into a cellar: the depth of the silage cellar is 2.7 meters, each filling is 50 cm thick, tamp it with a stone pestle, and evenly spray an ammonia solution with a concentration of 18wt% on the upper surface of the silage, and the amount of ammonia solution added is 60mL / kg silage Prepare the material, and then continue to repeat the filling of a new layer in the order of "filling-tamping-spraying" until the compacted straw exceeds 40cm from the pit mouth. Cover it with 30 cm thick soil to seal it, and store it at natural temperature (5-25° C.) for 40 days to obtain silage straw.

[0032] Appli...

Embodiment 3

[0034] Preparation of silage stalks: crush the newly harvested mature corn stalks to a length of 0.5-3 cm, and then spray the crushed corn stalks with a concentration of 4wt% calcium peroxide solution, and the amount of calcium peroxide solution added is 50mL / kg of fresh stalks , to obtain silage stock preparation after stirring evenly;

[0035] Then prepare the silage and load it into a cellar: the depth of the silage cellar is 2.5 meters, each filling is 30 cm thick, tamp it with a stone pestle, and evenly spray an ammonia solution with a mass percentage concentration of 10wt% on the upper surface of the silage material once, and the amount of ammonia solution added is 130mL / kg silage preparation, and then continue to repeat the filling of a new layer in the order of "filling-tamping-spraying" until the compacted straw exceeds 50cm from the pit mouth, and the pit mouth is covered with plastic cloth. The plastic cloth is covered with 30 cm thick soil for sealing, and stored ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com