Semi-fermented broken tea and preparation method thereof

A semi-fermented tea and semi-fermented technology, which is applied in food preparation, tea extraction, tea treatment before extraction, etc. It can solve the problems of affecting the aroma and taste of tea soup, increasing the cost of tea production, and affecting the appearance of finished tea. It is easy to reach the degree of fermentation Control, good quality, good separation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] In the process of researching and improving the preparation method of semi-fermented tea, the present inventor found that if the tea leaves are broken apart from the leaf edge, such as being broken into fragments by machinery and then fermented, since the tea leaves have been broken, their individual The tablet area is reduced and the broken edges are increased, so the fermentation speed can be accelerated and the degree of fermentation can be deepened. At the same time, because the surface area is enlarged, the dissolution of tea ingredients can also be improved during brewing.

[0050] Compared with the traditional production process, this crushed tea production process differs mainly in that additional processes such as rolling and crushing before fermentation are added in the production process.

[0051] The production process of traditional oolong tea is roughly as follows:

[0052] Tea green→withering→making green / shaking green (fermentation)→cooking→kneading→dryi...

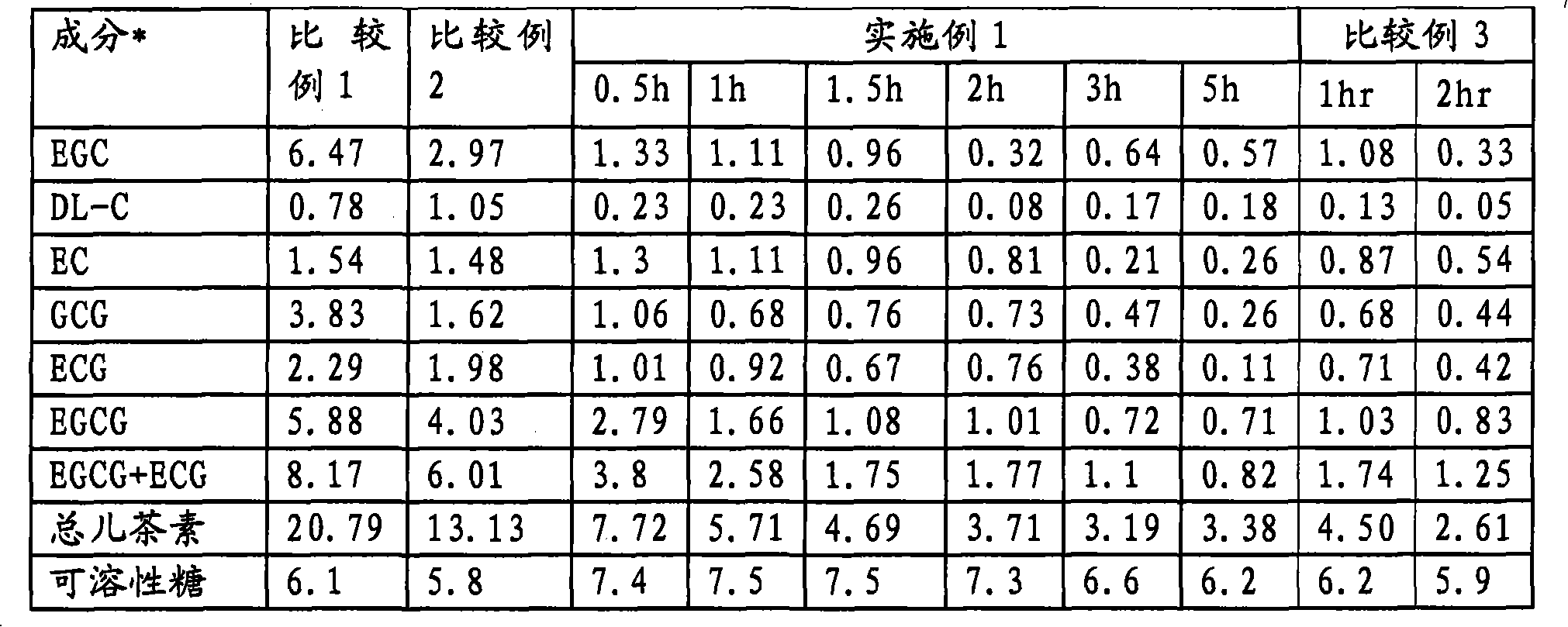

Embodiment 1

[0104] Processing technology: Tea green→withering (sun-green-cool green)→shaking green→broken (stem-leaf separation)→centrifugal sorting (removal of stems)→spreading (re-fermentation)→killing→kneading→drying→raw tea→baking→tea .

[0105] Pick 100 kilograms of tea greens of one bud (big open face) three-leaf or one bud (big open face) four-leaf variety hairy crab. After drying the green leaves for 30 minutes, take back the sun-dried green leaves and spread them out on an indoor drying rack. Wither for 2 hours, then start to shake green. Shaking blue and green plants is controlled by a comprehensive green machine program, shaking green and green three times, followed by 10 minutes, 15 minutes, and 20 minutes, and the intervals between shaking green and green three times are 80 minutes and 100 minutes respectively. Let it stand for 120 minutes after the last shaking, and then start to break. The crusher is a self-made double-shaft counter-rotating biting cutter, and the leave...

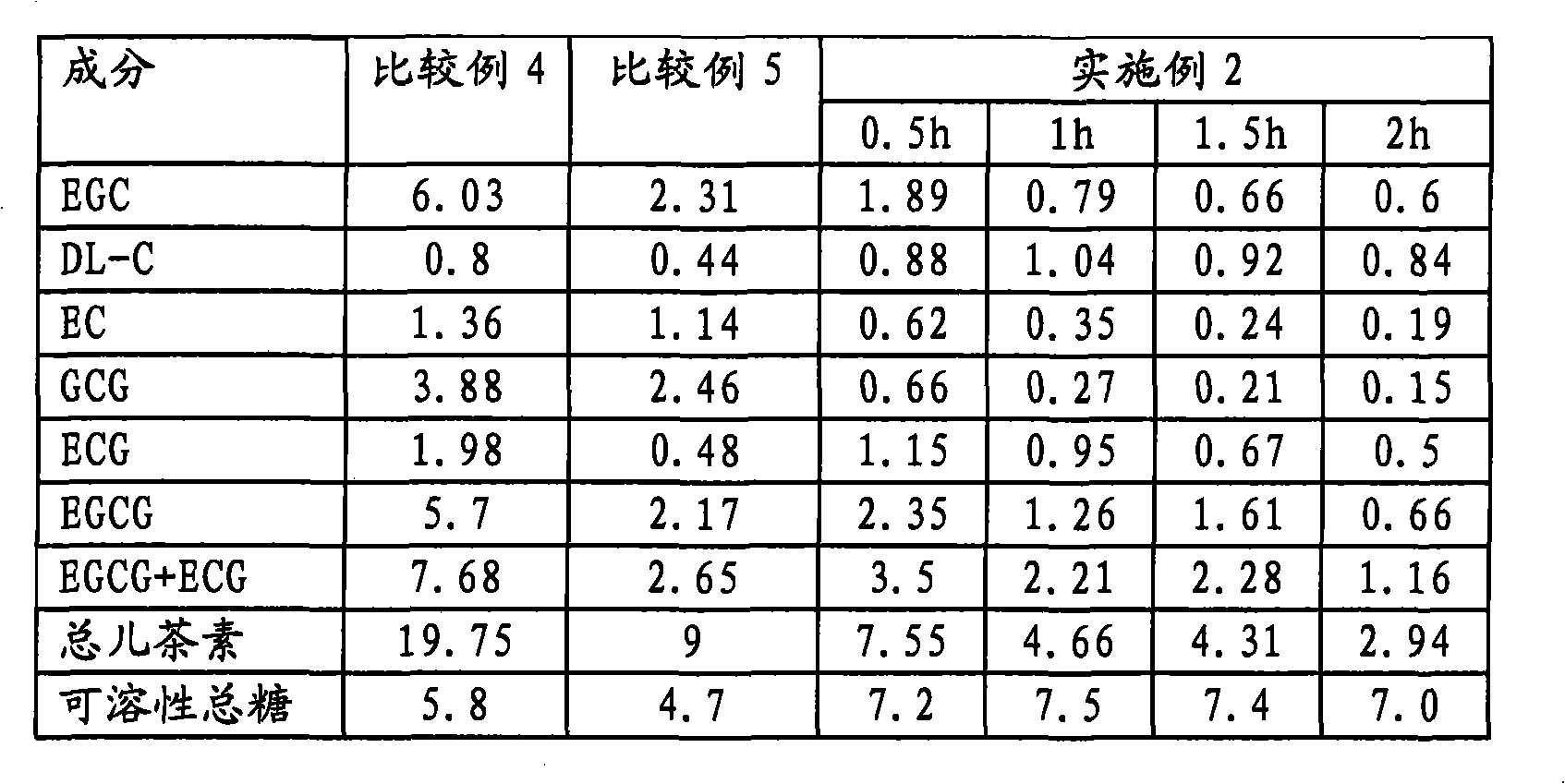

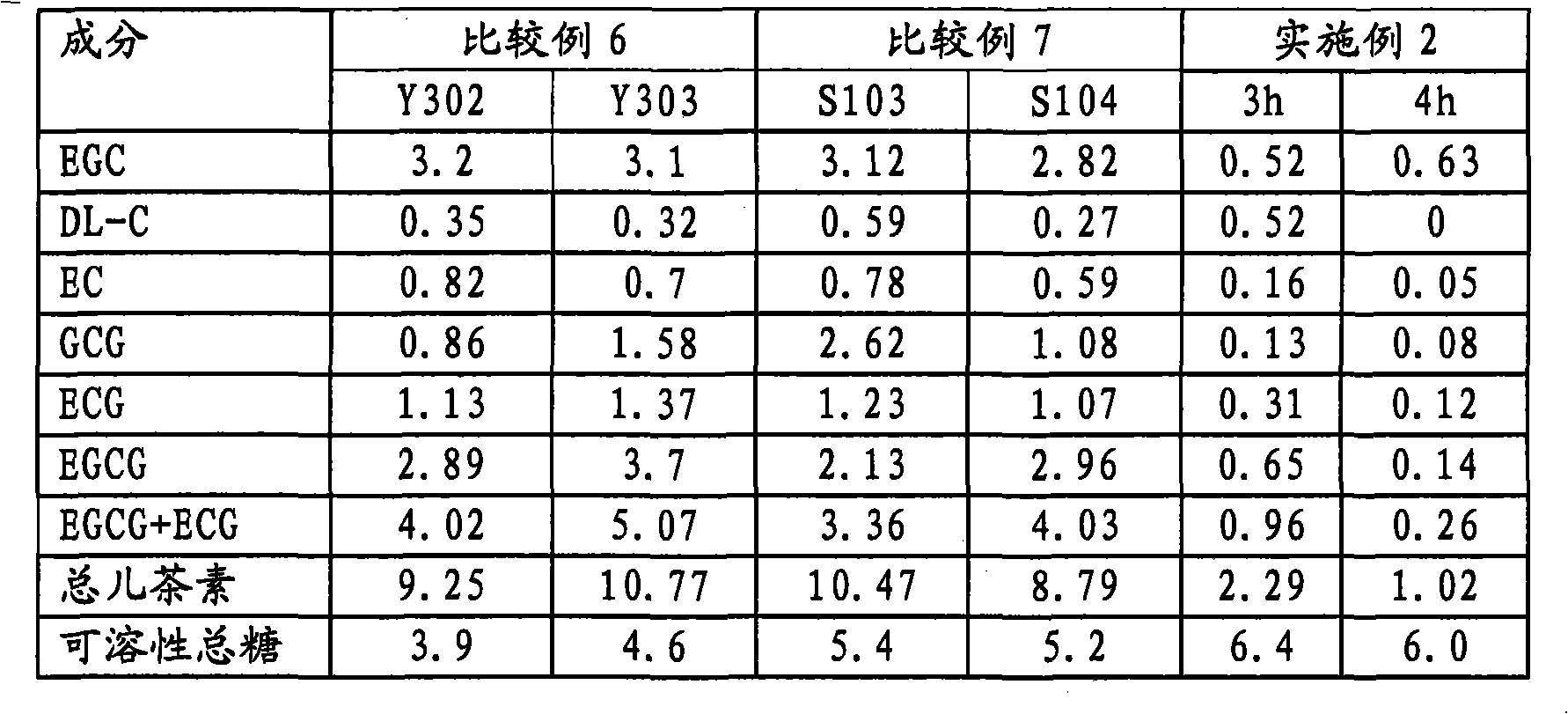

Embodiment 2

[0125] Processing technology: Green tea → withering → crushing (detachment of stalk leaves) → placing (fermentation) → finishing → drying → raw tea → destemming by specific gravity difference method → roasting → tea.

[0126] Pick one bud (big open face) three leaves and one bud (big open face) four-leaf Fuyun No. 6 tea green 50 kg, after drying and withering according to the usual method, use a self-made double-axis counter-rotating biting machine to crush, and the tea green Be broken into the broken leaf of 4 * 4mm (square) specification, the tea stalk at this moment is natural diameter * length (below about 4.8mm). Then leave it for fermentation. When the fermentation time is 0.5h, 1h, 1.5h, 2h, 3h, 4h, the greening is completed, the fermentation is stopped, and then dried into raw tea according to the usual method. Put the broken stalk leaves mixed with raw tea into the specific gravity difference sorting machine combined with wind and vibration. Since the tea stalks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com