Kitchen waste, straw and municipal sludge resourceful treatment system and method

A technology for kitchen waste and municipal sludge, applied in the field of solid waste resource utilization, can solve the problems of long hydrolysis process, low gas production efficiency, slow biogas hydrolysis rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

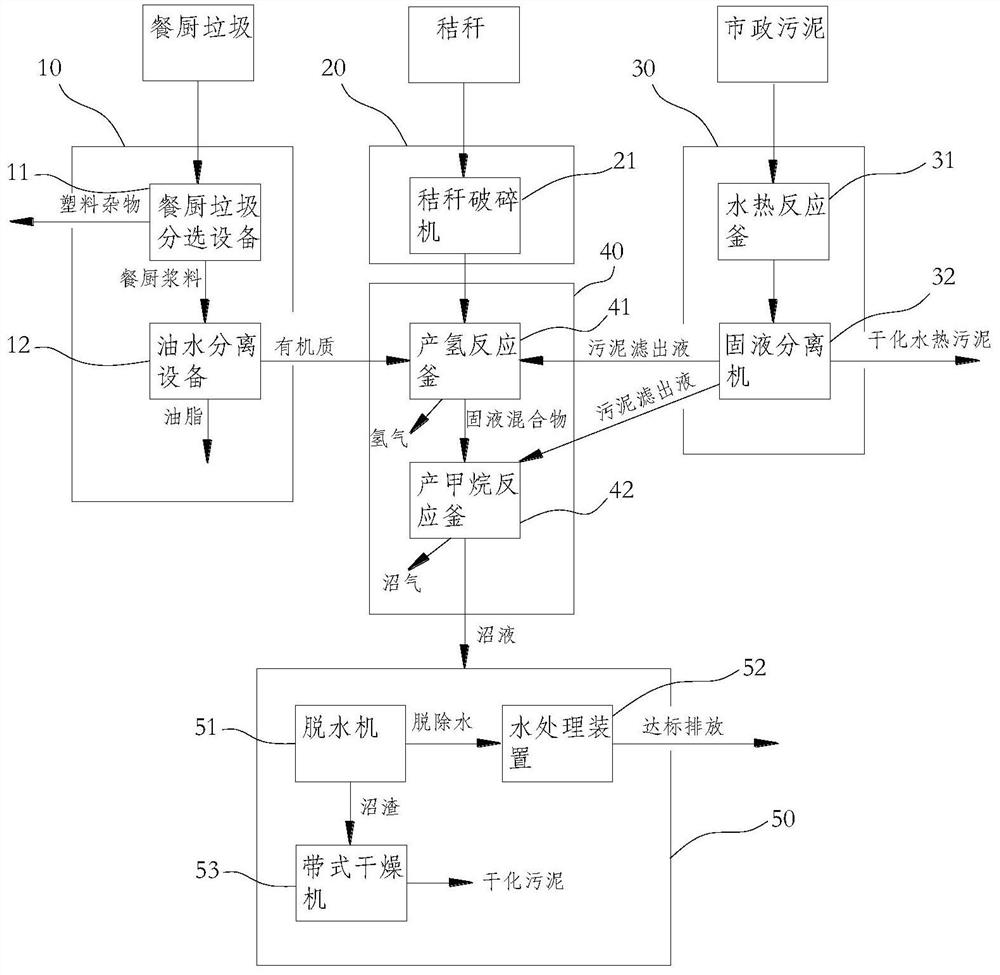

[0064] Refer to figure 1 , This embodiment provides a resource treatment system for kitchen waste, straw and municipal sludge, including kitchen waste pretreatment device 10, straw pretreatment device 20, municipal sludge pretreatment device 30, and anaerobic digestion reaction device 40 And the biogas slurry treatment device 50.

[0065] The food waste pretreatment device 10 includes a food waste sorting device 11 and an oil-water separation device 12.

[0066] The food waste sorting equipment 11 is an existing technology and has a food waste inlet, a plastic debris outlet, and a food slurry outlet. Kitchen waste is food processing leftovers and edible residues produced by restaurants, canteens, colleges and other catering industries. The composition is very complex. In addition to containing oil, water, vegetables, rice noodles, and fish, it also includes waste tableware, plastic, paper towels, and bones. Wait for solid waste. The kitchen waste sorting equipment 11 can effectiv...

Embodiment approach 2

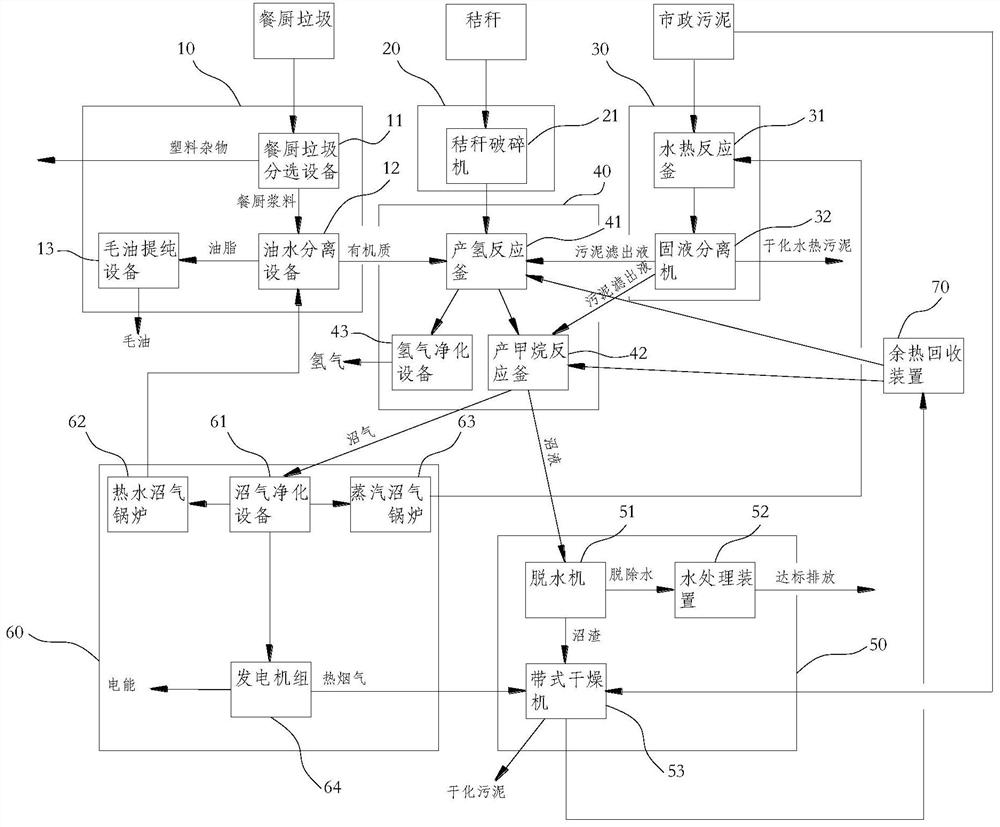

[0081] Refer to figure 2 This embodiment provides a resource treatment system for kitchen waste, straw and municipal sludge, which is an improvement made on the basis of Embodiment 1, except that it includes the same kitchen waste pretreatment device 10 as in Example 1. , In addition to the straw pretreatment device 20, the municipal sludge pretreatment device 30, the anaerobic digestion reaction device 40, and the biogas slurry treatment device 50, it also includes a biogas treatment device 60 and a waste heat recovery device 70.

[0082] The biogas treatment device 60 includes a biogas purification device 61, a hot water biogas boiler 62, a steam biogas boiler 63 and a generator set 64.

[0083] The biogas purification equipment 61 is an existing technology and has a biogas inlet and a clean biogas outlet. The biogas inlet is connected to the biogas outlet of the methane-producing reactor 42 and is used to purify the methane-producing reactor 42 to obtain biogas and remove sulfid...

Embodiment approach 3

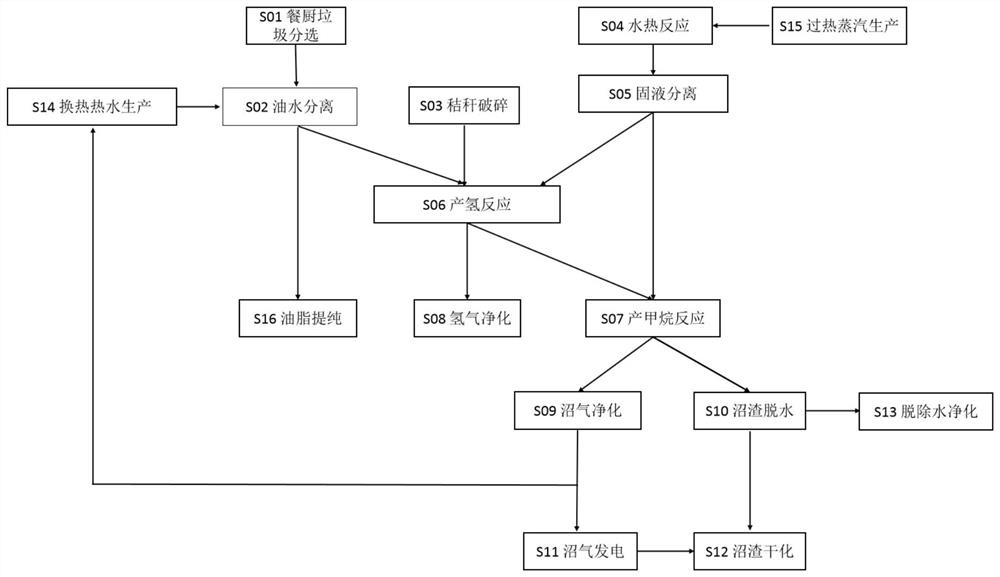

[0093] See image 3 , This embodiment provides a resource treatment method for kitchen waste, straw and municipal sludge, which includes the following steps:

[0094] S01: Food waste sorting

[0095] In this step, the food waste sorting equipment 11 is used to sort the food waste, so as to obtain the food slurry and plastic sundries. Kitchen waste is food processing leftovers and practical residues produced by restaurants, canteens, colleges and other catering industries. The composition is very complex. In addition to containing oil, water, vegetables, rice noodles, and fish, it also contains waste tableware, plastic, paper towels, and bones. Wait for solid waste. The sorting of food waste can effectively separate this part of plastic debris.

[0096] S02: Oil-water separation

[0097] In this step, the oil-water separation device 12 is used to separate the kitchen slurry from oil and water, so as to obtain grease and organic matter. The oil-water separation process mainly heats t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com