Patents

Literature

72results about How to "Improve the efficiency of anaerobic fermentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

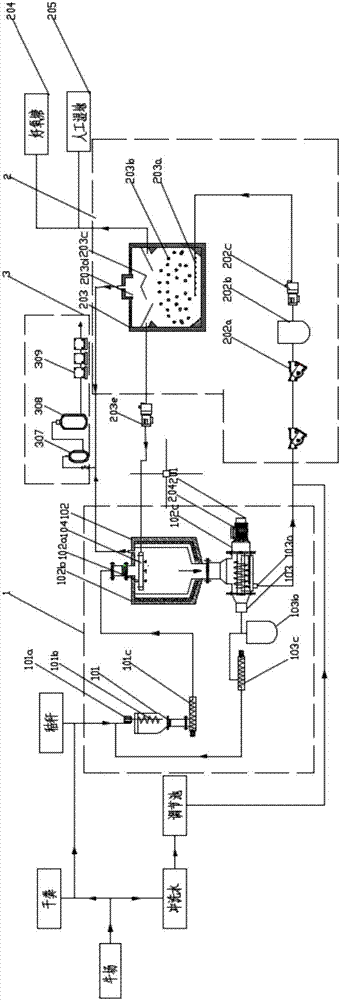

Comprehensive treating system for domestic wastes

InactiveCN102527701AIncrease productionImprove qualityBio-organic fraction processingWaste processingSludgeOrganic manure

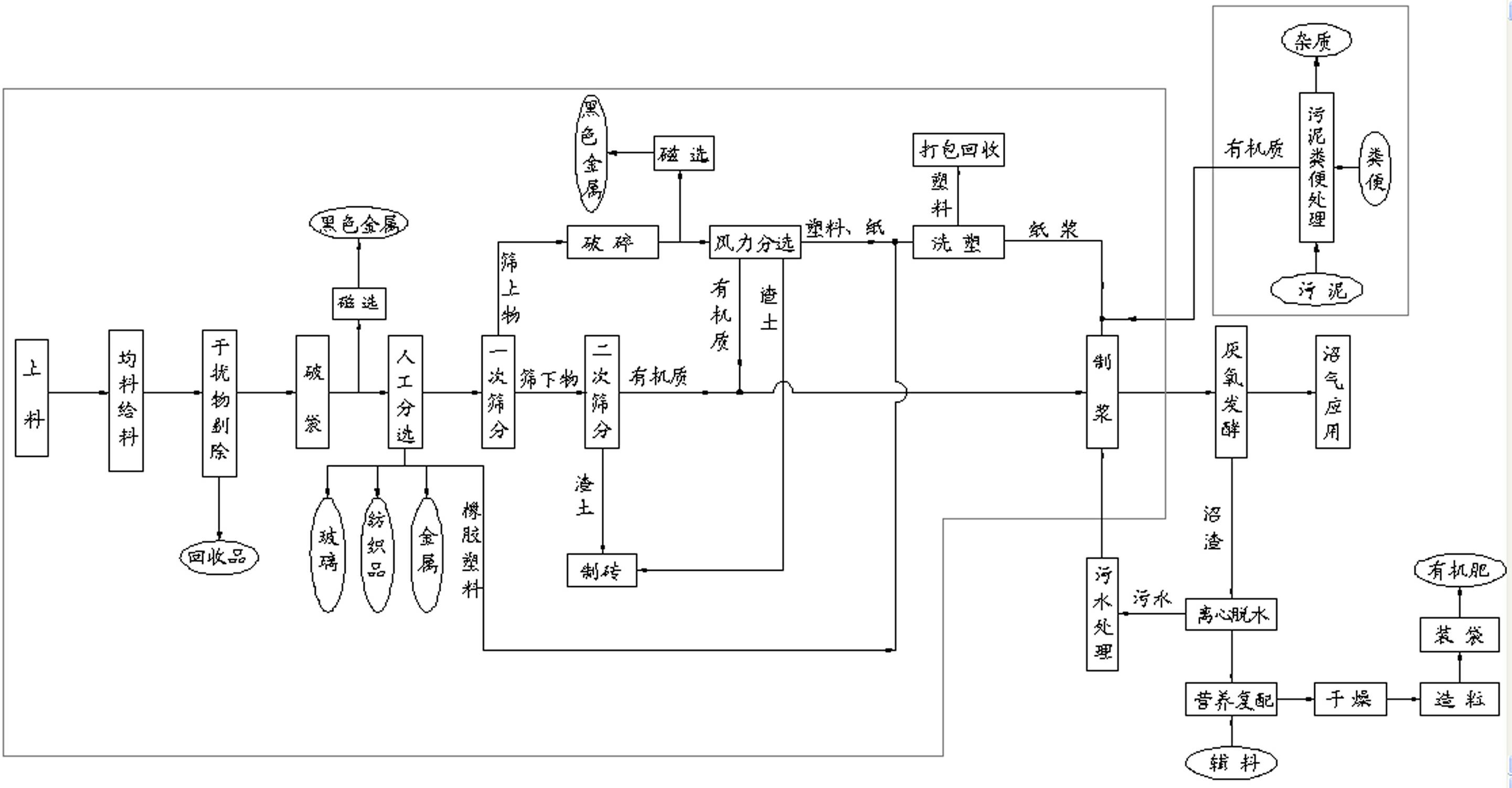

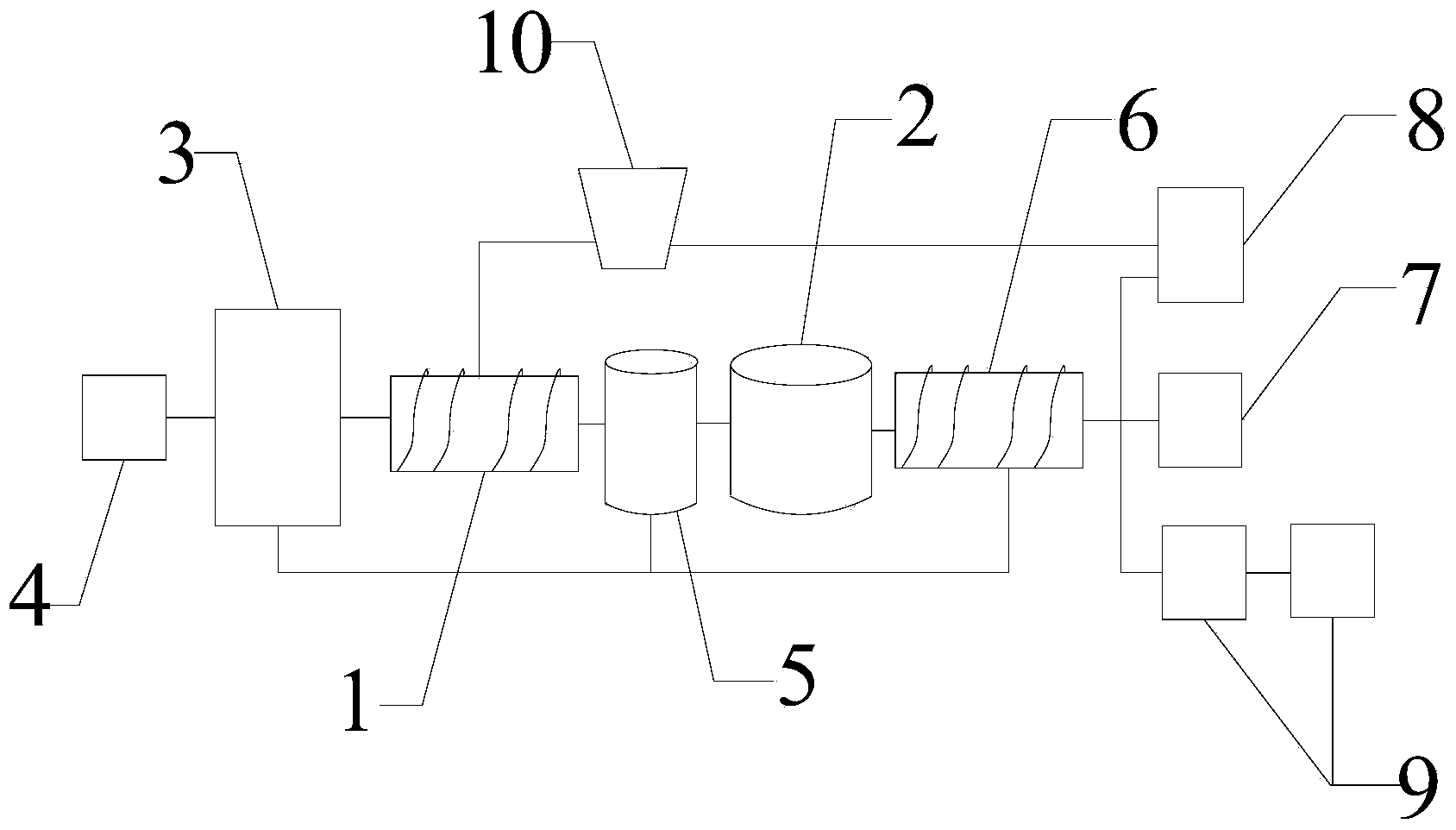

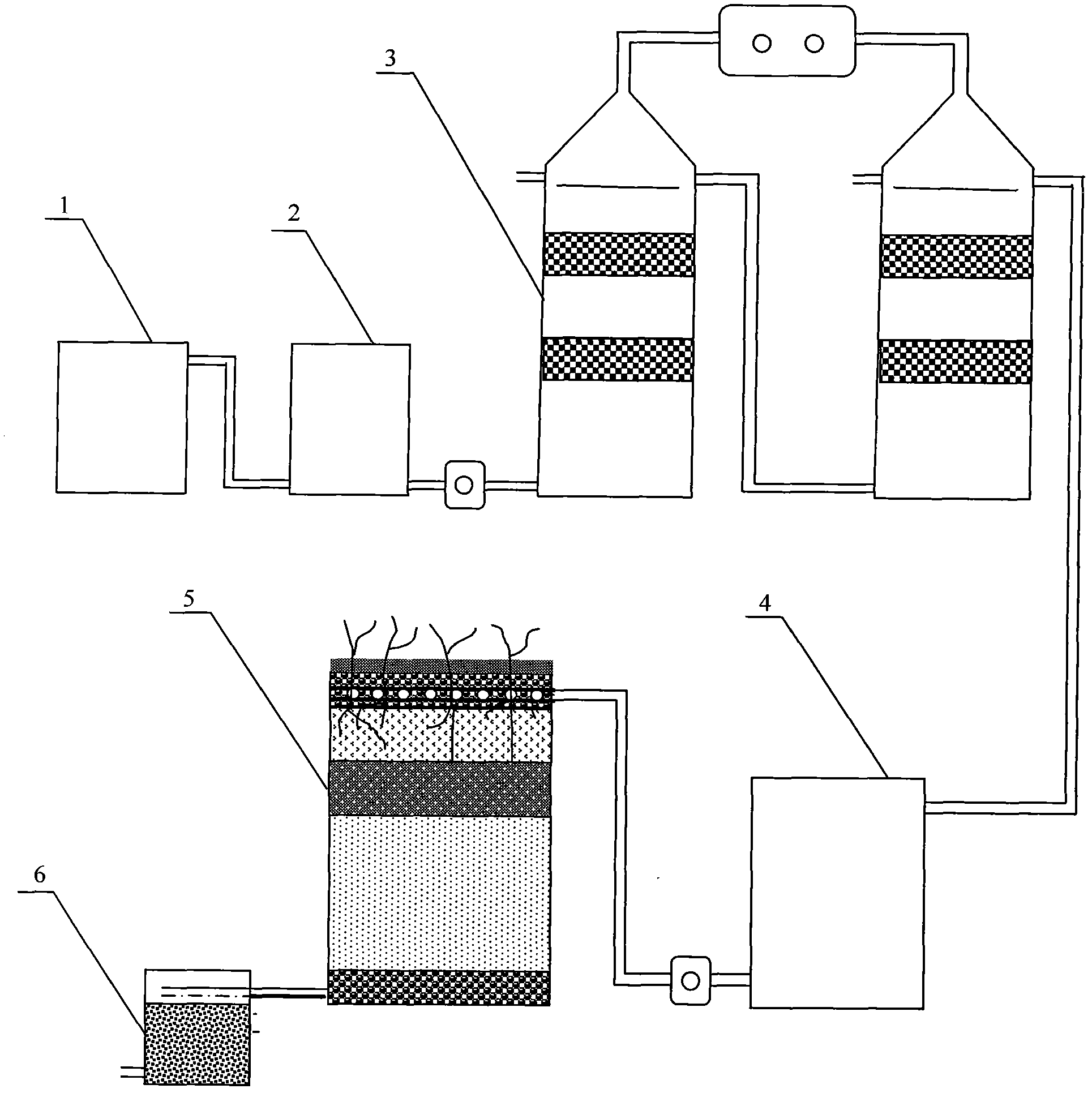

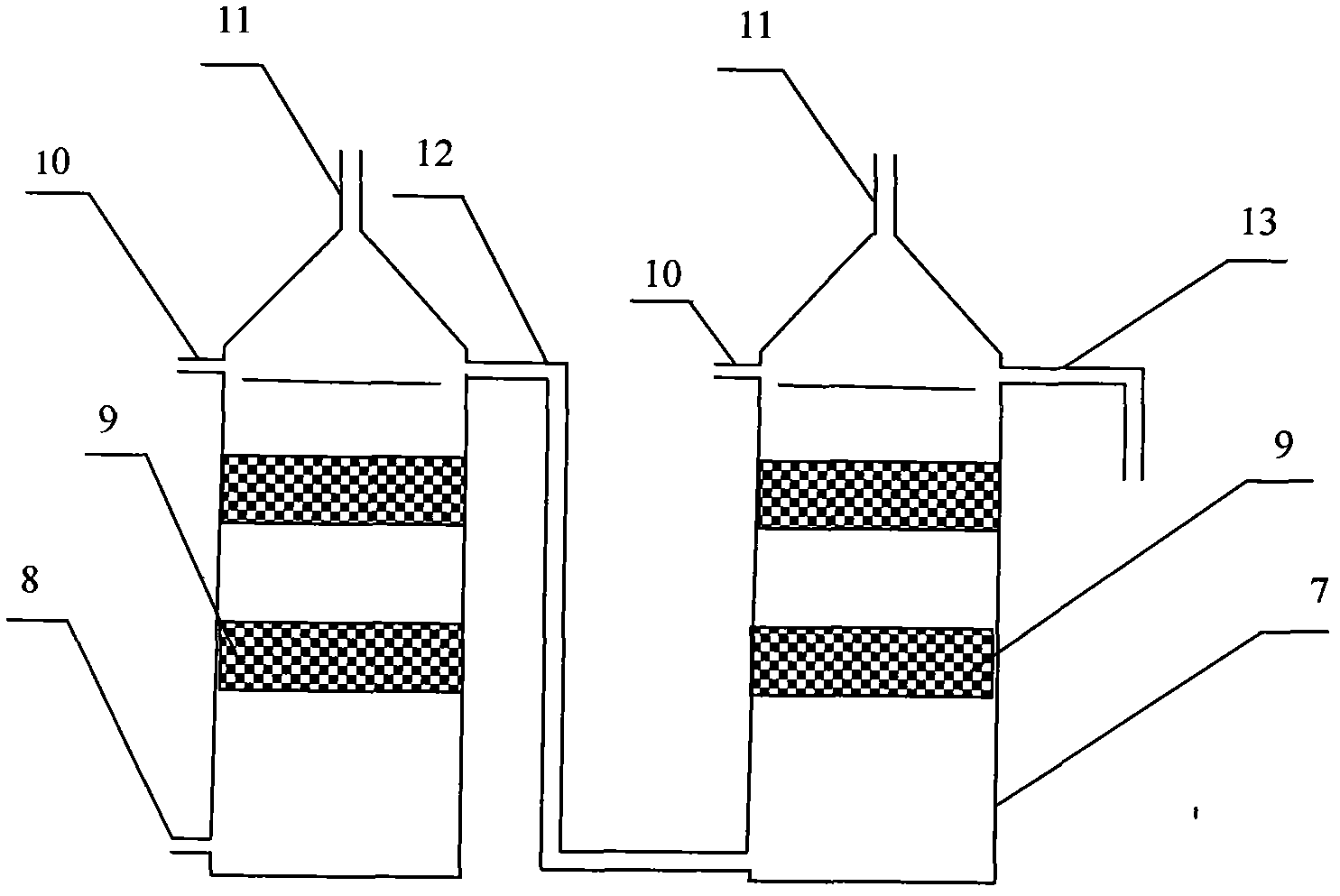

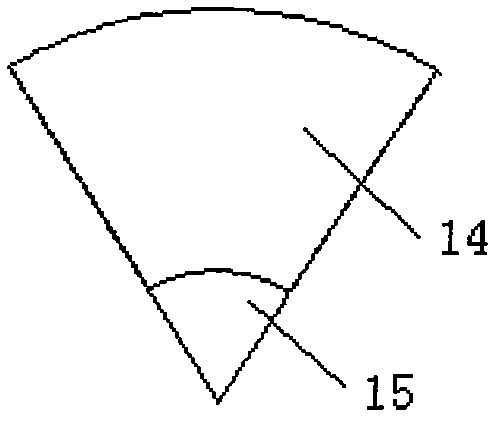

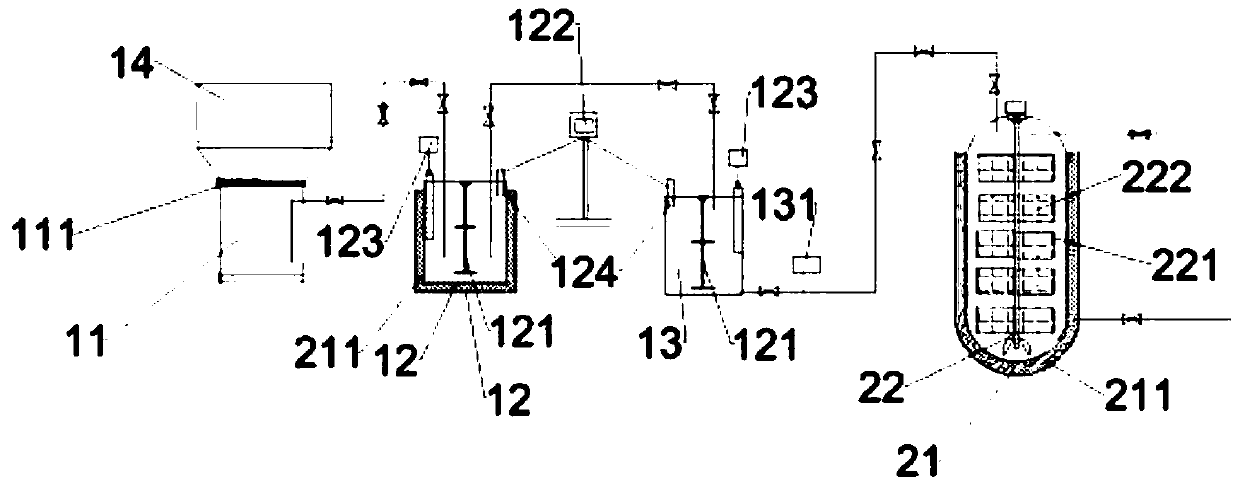

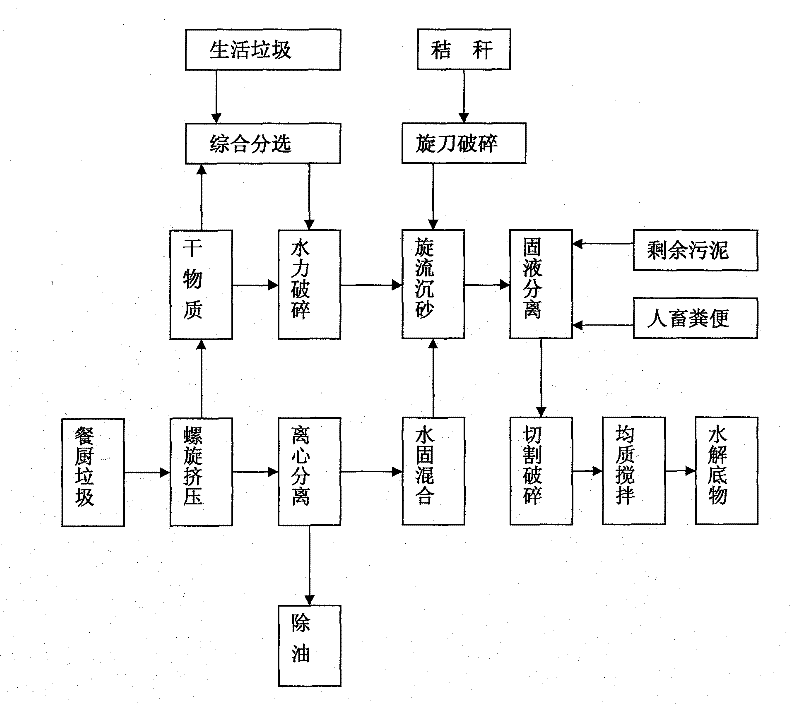

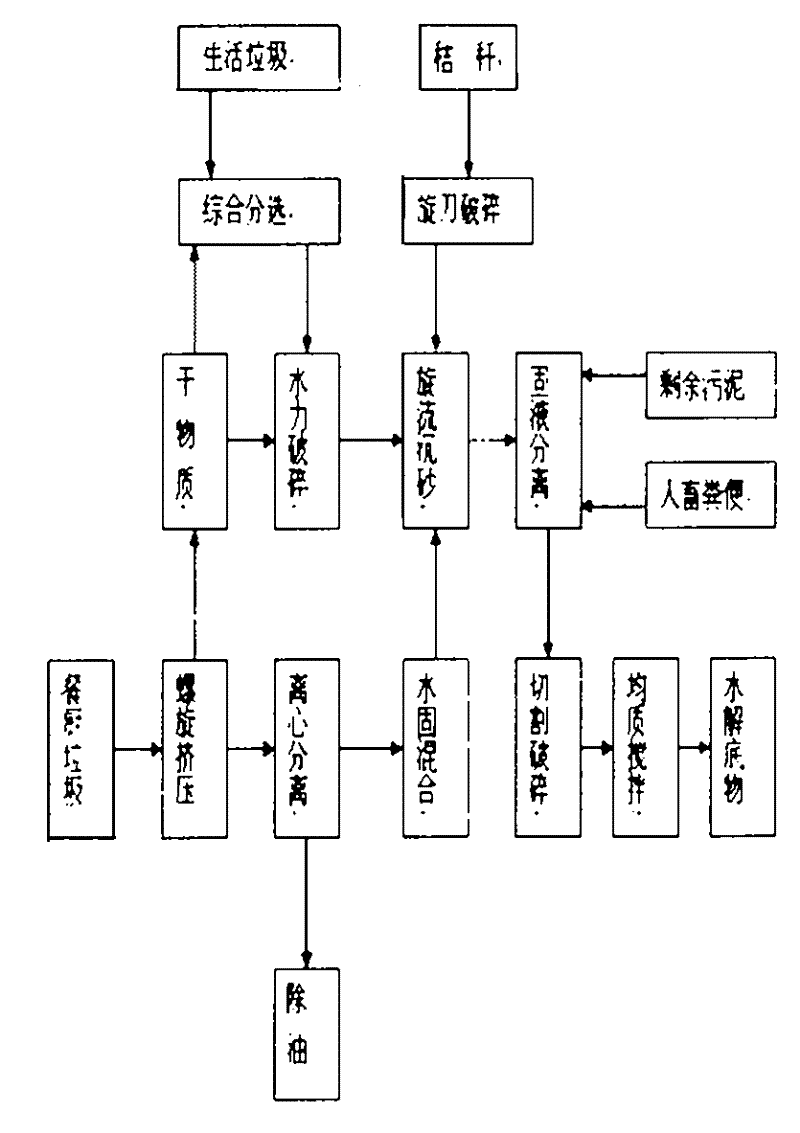

The invention discloses a comprehensive treating system for domestic wastes. Reutilizing comprehensive treatment for mixed wastes is realized by the system according to a comprehensive sorting technology and a combined anaerobic fermentation technology, wherein the advanced sorting techniques, such as, crushing, magnetic separating, sieving, air classifying, and the like, are adopted in the comprehensive sorting technology; reutilized products, such as metal, plastics, organic matters, and the like, are screened out; the screened organic matters are prepared into slurry together with sludge and excrements and are then subjected to the combined anaerobic fermentation; the reutilized products, such as methane, organic fertilizer, and the like, can be produced under the action of anaerobic fermentation; and after the methane is purified, the methane is used for generating power, domestic fuel or vehicle-mounted fuel. According to the technology, the intensified treatment for organic wastes, such as domestic wastes, sludge, excrements, kitchen wastes, and the like, can be realized. The comprehensive treating system is high in mechanical and automated degree. Compared with the prior art, the comprehensive treating system has the advantages of simplification, effectiveness, less labor power, and the like.

Owner:BEIJING HAOHAI TIANJI TECH +1

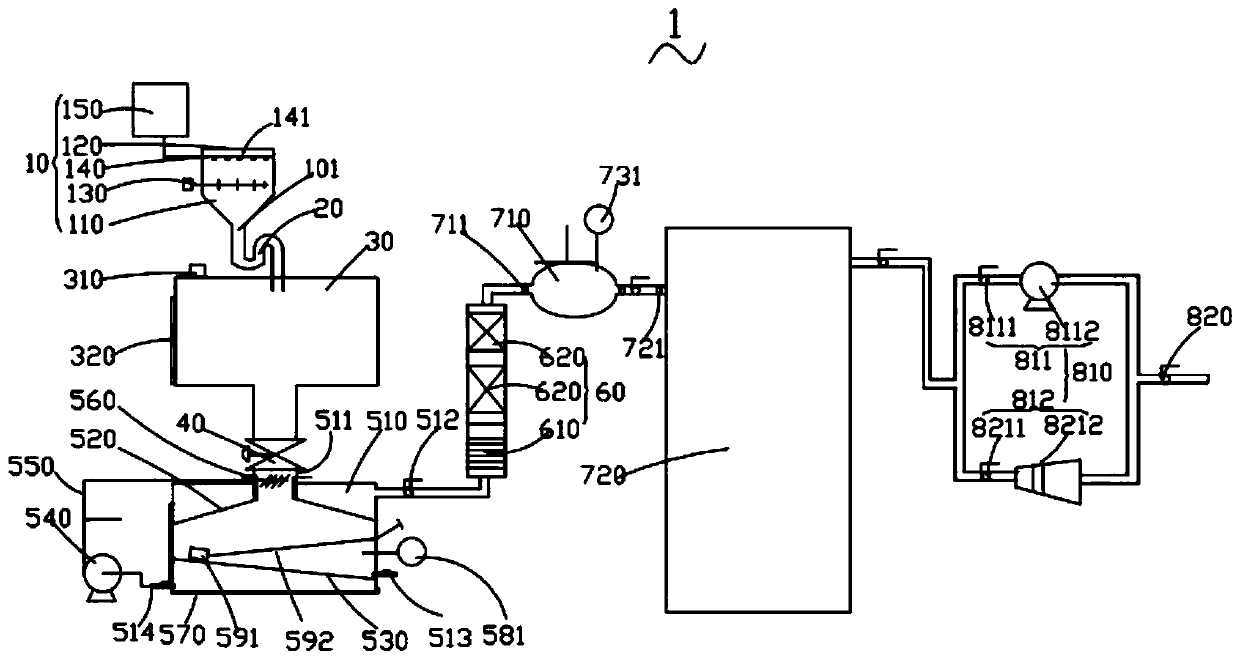

Kitchen waste and sludge collaborative treatment system and method

PendingCN110538861AIncrease profitSmall footprintBioreactor/fermenter combinationsBio-organic fraction processingOil and greaseBiodiesel

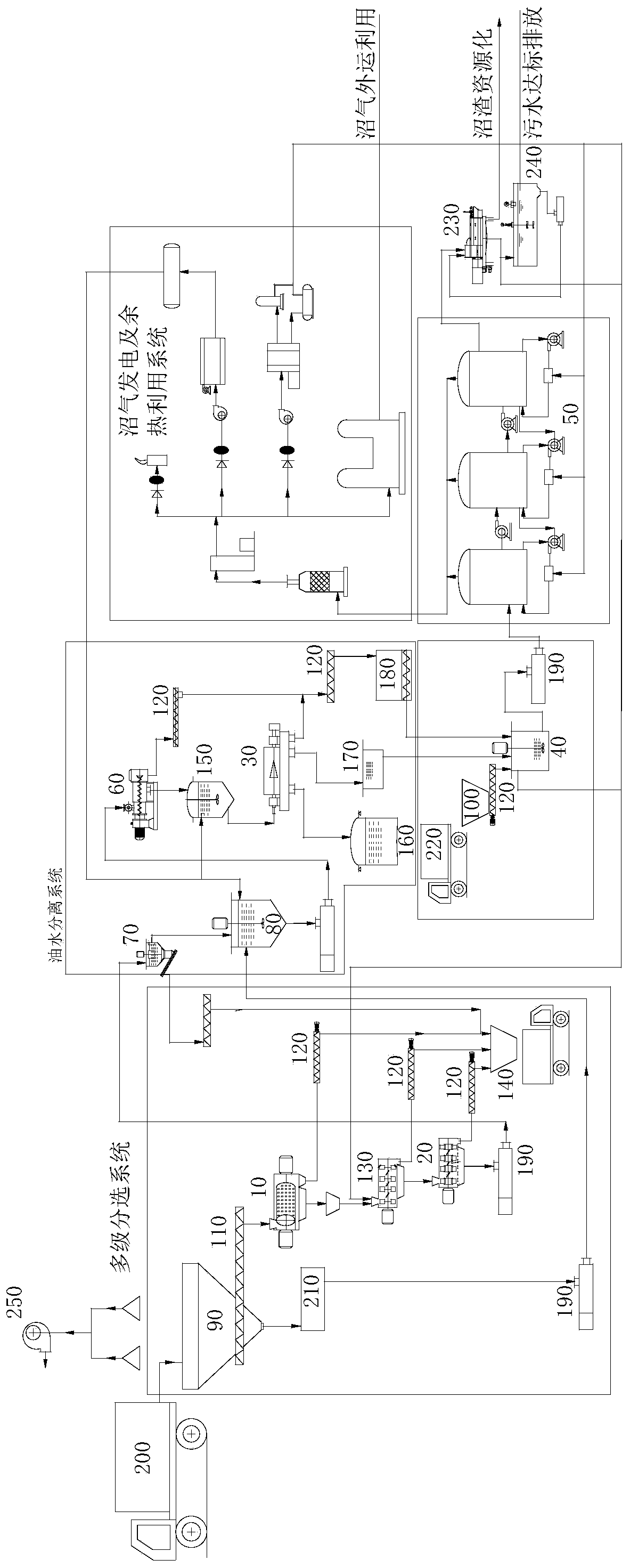

The invention discloses a kitchen waste and sludge collaborative treatment system and method. The system comprises screen type separation equipment for screening kitchen waste, crushing and separationequipment for crushing and separating the small kitchen materials obtained after screening, oil-water separation equipment for carrying out oil removal treatment on the kitchen slurry separated out by the crushing and separation equipment, collaborative pulping equipment for mixing the sludge and the kitchen slurry after oil removal treatment and anaerobic digestion equipment for carrying out anaerobic digestion on the mixed slurry prepared by the collaborative pulping equipment. After the kitchen waste is subjected to classification and separation and slag removal, the content of inorganic matter can be reduced, and the anaerobic fermentation efficiency is improved. Meanwhile, the internal abrasion of a tank body is reduced. On one hand, the oil removal treatment can collect the waste oil for reutilization (such as preparing of biodiesel), so that the project benefit is increased; and on the other hand, the grease content and the specific adhesion and isolation characteristics of grease in the slurry can be reduced, and the anaerobic reaction effect is increased after the grease is removed.

Owner:中铁环境科技工程有限公司

Kitchen waste hydrothermal treating method and device

ActiveCN103894393AReduce total dwell timeSave volumeSolid waste disposalOil and greaseReaction temperature

The invention discloses a kitchen waste hydrothermal treating method and device. The kitchen waste hydrothermal treating method comprises the following steps of rejecting impurities, separating grease, and extracting waste grease at the upper layer in kitchen wastes; performing first-order hydrothermal reaction, namely electrically heating the kitchen wastes after grease separating to realize sequential temperature rising, wherein the hydrothermal reaction temperature is 200-250 DEG C, the reaction time is 5-25 minutes, and a PH value is smaller than 7; performing heat exchange, namely cooling a reactant obtained after the first-order hydrothermal reaction to 130-180 DEG C by virtue of liquid; performing secondary-order hydrothermal reaction, namely carrying out the hydrothermal reaction on the reactant after heat exchange again, wherein the reaction temperature is 130-180 DEG C, and the reaction time is 40-80 minutes; and performing three-phase separation, namely cooling the reactant after the secondary-order hydrothermal reaction until room temperature, and separating solid, liquid and gas. With the adoption of the kitchen waste hydrothermal treating method, the reaction time is shortened, and the energy consumption is low; the process is flexible and accurate to control; the biodegradability of carbonizing liquid can be optimized, and the efficiency of the carbonizing liquid entering the anaerobic treatment process is improved.

Owner:SICHUAN UNIV

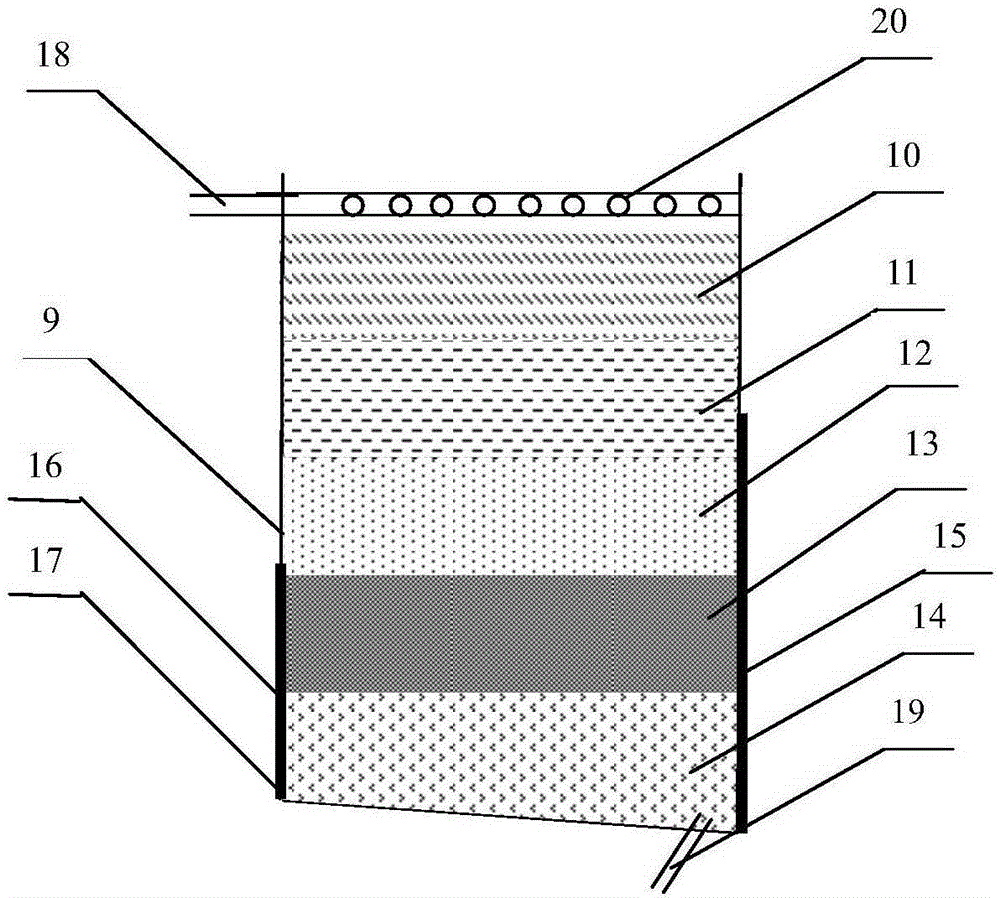

Coculture and method using coculture to ferment wheat straw to produce methane

ActiveCN107130001AEfficient degradation abilityFree from pollutionMicroorganism based processesWaste based fuelMicroorganismMicrobiology

The invention discloses anaerobic fungus-methanogens coculture and a method using the coculture to ferment wheat straw to produce methane. The coculture is naturally-coexisting PiromycesYak TZ+M. ruminantium separated from the rumen fluid of fully-grazing yak of the Gansu Tianzhu Nanniwan pasture of the Qinghai-Tibet Plateau, and the preservation number of the coculture in the China General Microbiological Culture Collection Center is CGMCC No. 12952. When the coculture is used to perform anaerobic fermentation on the wheat straw, a large amount of methane can be produced, the quantity of the methane produced after the coculture degrades the wheat straw for 7 days reaches 3.7mmol / g DM, fermentation time is short, the fermentation process is simple, and the coculture is promising in application prospect.

Owner:GANSU ACAD OF SCI INST OF BIOLOGY

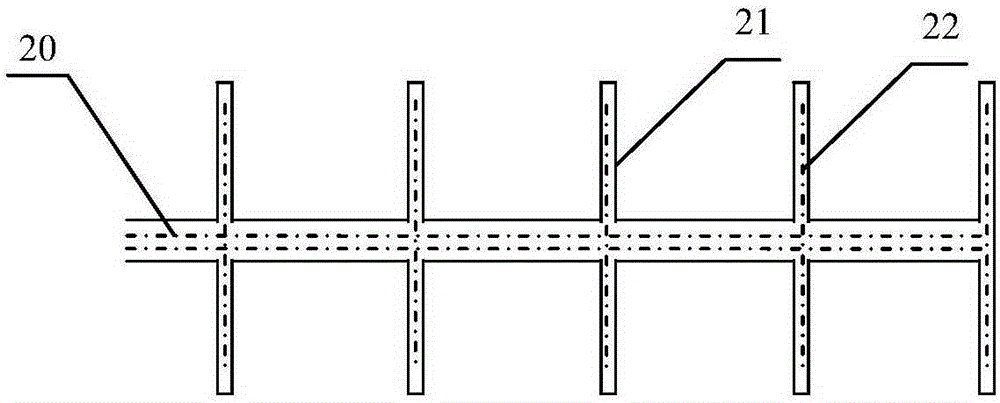

Wastewater treatment system suitable for small and medium size farms

ActiveCN105217898AImprove adsorption capacityImprove fertilizer efficiencyClimate change adaptationExcrement fertilisersAbsorption saturationWastewater

The invention relates to a wastewater treatment system suitable for small and medium size farms and a solid waste comprehensive treatment method. The system comprises a sedimentation basin, a regulating reservoir, an efficient filtering basin, a plant purifying pond and a composting field which are connected in sequence. The efficient filtering basin comprises a plurality of efficient filtering basin modules, wherein each efficient filtering basin module comprises a filtering basin cavity and filtering materials arranged in the filtering basin cavity. A water distributing system is arranged on the upper portion of the efficient filtering basin, a main water outlet pipe is arranged on the lower portion of the efficient filtering basin, and a discharging port is formed in the side face of the efficient filtering basin. The efficient filtering basin is filled with the efficient adsorption materials which serve as carriers, and the adsorption materials are porous materials and have very large surface area so that pollutants in wastewater can be easily adsorbed, and the anaerobic fermentation efficiency can be improved; by means of the design of the device, absorption saturated materials can be easily discharged and used, the materials obtained after absorption saturation can be used for producing organic fertilizer together with excrement of the farms, the fertilizer efficiency is improved, and waste is recycled.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Dry collection-based integrated manure treatment method for livestock farm and device

PendingCN107162321AReduce construction costsImprove hygieneSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesConstructed wetlandFeces

The invention discloses a dry collection-based integrated manure treatment method for a livestock farm and a device for the integrated manure treatment method. The method comprises the steps of firstly carrying out solid-liquid separation on livestock manure to treat solid manure and manure wastewater separately, wherein the step of treating the livestock manure comprises the steps of straw mixing, feeding, anaerobic dry fermentation and discharging in sequence; the step of treating the manure wastewater comprises the steps of water feeding, anaerobic fermentation, aerobic pond, constructed wetland and water discharging in sequence. Meanwhile, the invention discloses a device for achieving the manure treatment method. The device comprises a dry manure treatment system, a sewage treatment system and a biogas purification system. Continuous treatment of livestock manure is achieved by using continuous closed feeding and discharging; sewage is treated by using an efficient anaerobic system, so that the floor space required for a manure yard can be reduced, the biogas production efficiency and the system operation stability are improved, stable up-to-standard discharge of breeding sewage treatment is ensured, and meanwhile, the manure treatment cost can be reduced.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

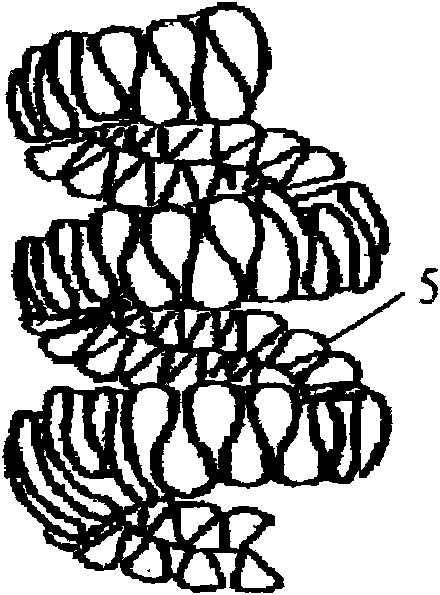

Methane generator for cattle farms

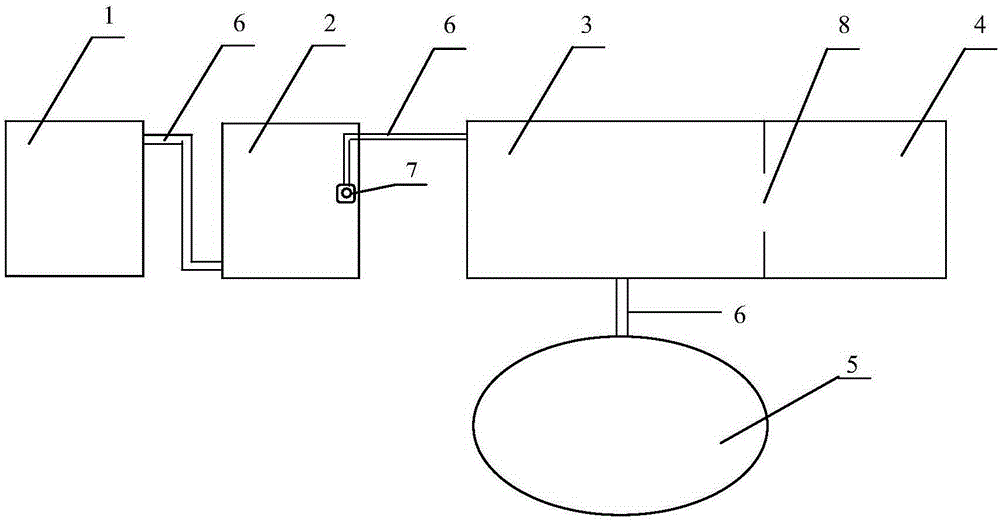

InactiveCN102676373AImprove the efficiency of anaerobic fermentationGas production bioreactorsWaste based fuelEngineeringFermentation

The invention discloses a methane generator for cattle farms. The methane generator for the cattle farms comprises a material inlet, a generation layer, a settling tank and a back-flushing layer, wherein the material inlet is arranged on the top side of the generator, the generation layer is arranged in the middle of the generator, the settling tank is arranged on the lower portion of the generation layer, the back-flushing layer is arranged on the lower portion of the settling tank, and spiral staggered materials are filled in the generation layer. Wastes in the cattle farms are subjected to anaerobic fermentation by the aid of the novel spiral staggered materials, and by the aid of the intrinsic structural property of the spiral staggered materials, anaerobic fermentation efficiency of the wastes of the cattle farms can be improved, and methane is generated, so that energy is effectively used, and environmental protection is achieved.

Owner:苏州富奇诺环保节能科技有限公司

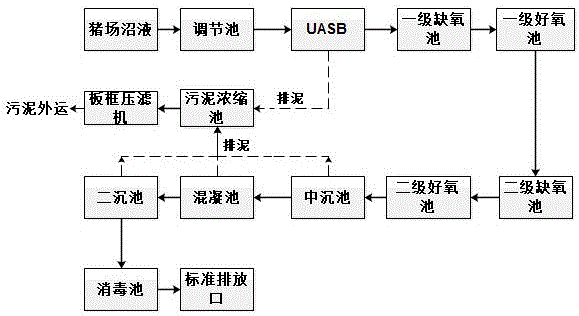

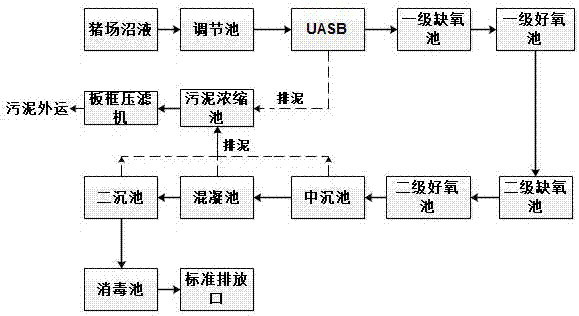

UASB-two-stage A/O-coagulation treatment piggery methane slurry system

InactiveCN106830542AIncrease ascent speedGuaranteed uptimeWater contaminantsWaste water treatment from animal husbandryLoad resistanceSludge

The invention discloses a UASB-two-stage A / O-coagulation treatment piggery methane slurry system. The system comprises a regulating reservoir, a UASB reactor, a primary anoxia tank, a primary aerobiotic tank, a secondary anoxia tank, a secondary aerobiotic tank, a mid-sedimentation tank, a coagulating tank, a secondary sedimentation tank, a disinfection tank and a standard discharge outlet which are connected in sequence. The UASB reactor, a sludge thickening tank and a plate-and-frame filter press are sequentially connected; the mid-sedimentation tank, the secondary sedimentation tank, the coagulating tank and the sludge thickening tank are connected, sot that sludge in the three tanks is discharged into the slurry thickening tank. The system is obvious in nitrogen and phosphorus removal effect, stable in treatment effect, high in impact load resistance, easy to operate and low in operating cost, and all indexes of outflow water obtained after piggery methane slurry is treated through the combination technology meet the requirement the discharge standard of pollutants for livestock and poultry breeding (GB 18596-2001).

Owner:NANCHANG UNIV

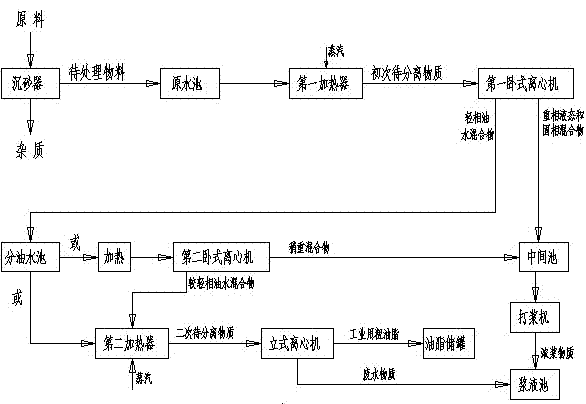

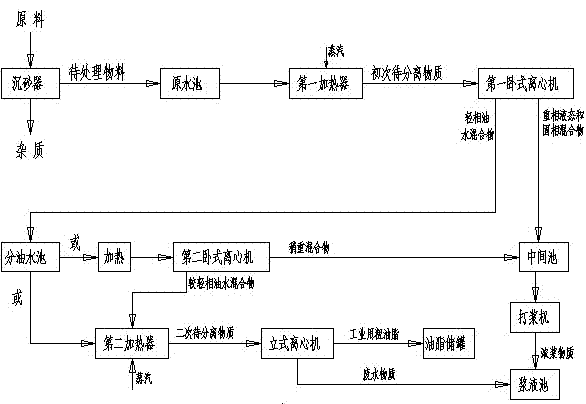

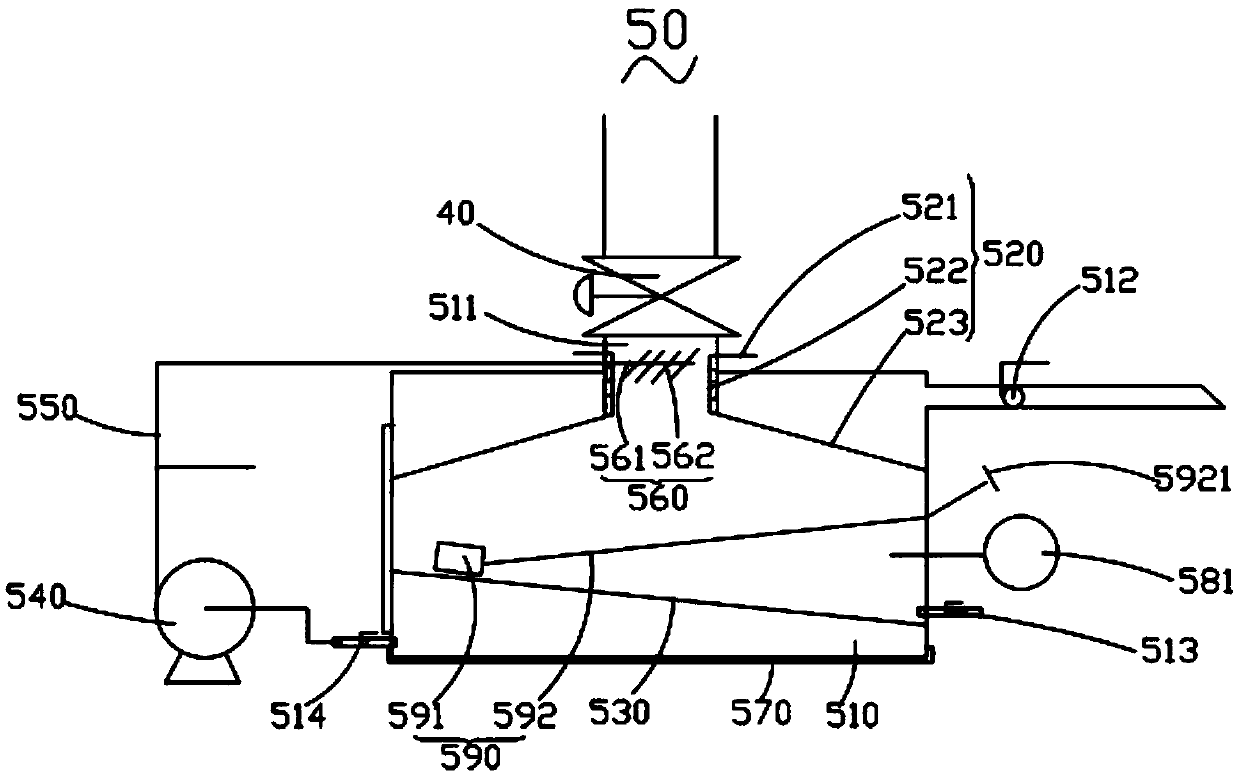

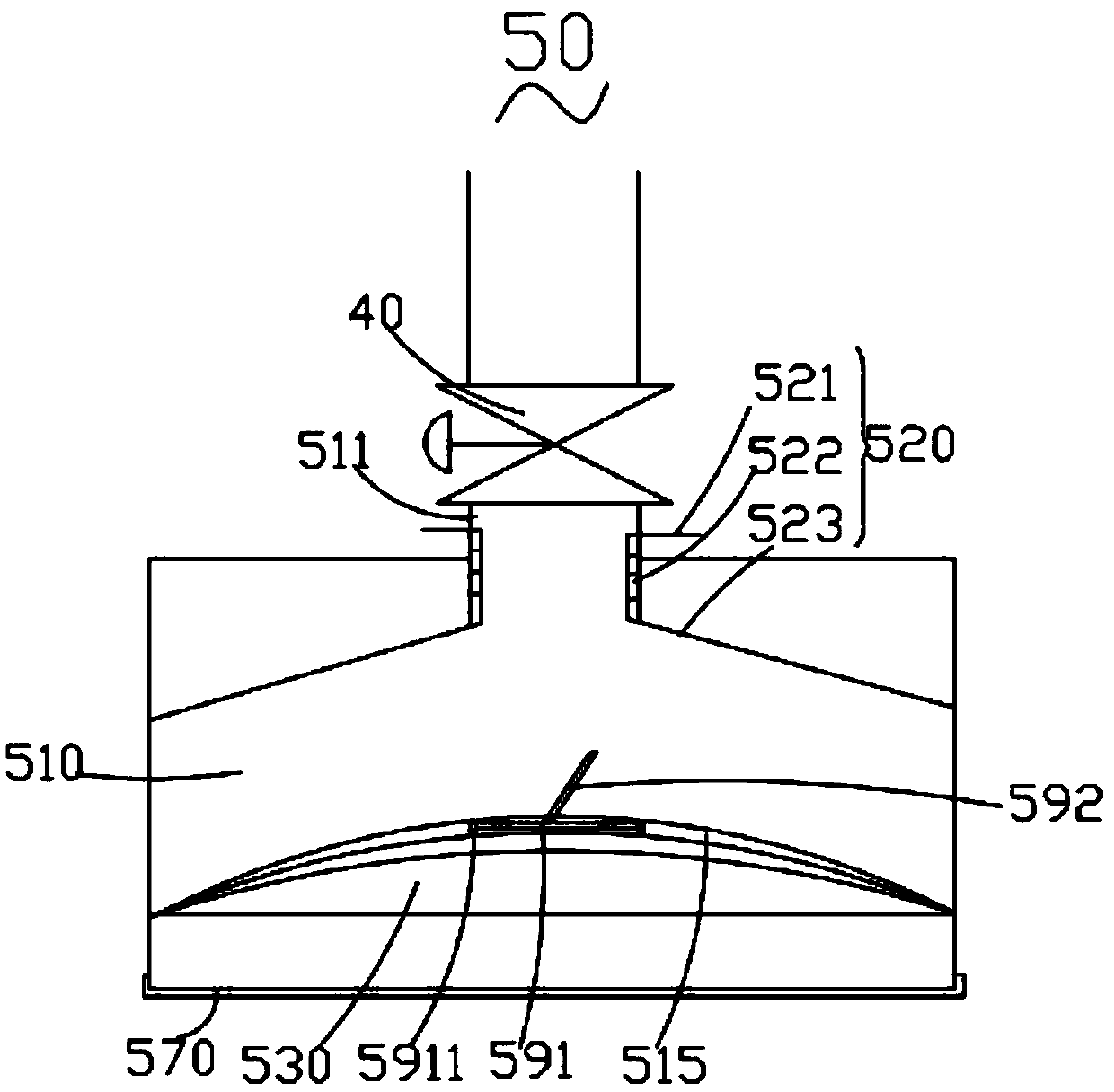

Oil-water separation process of pulpifying centrifugal treatment system

ActiveCN102583855AEasy to separateIncrease digestion rateEnergy based wastewater treatmentMultistage water/sewage treatmentOil and greaseWear resistant

The invention discloses an oil-water separation process of a pulpifying centrifugal treatment system. The pulpifying centrifugal treatment system comprises a pulp beater, a sand settling device, a horizontal centrifuge, a heater, a vertical centrifuge and a pulp tank. The oil-water separation process comprises the steps as follows: a preparation step, a primary heating step, a primary centrifugation step, a secondary heating step, a secondary centrifugation step and a hydration and pulp-beating step. Hydrated beaten pulp continuously and mutually collides with wear-resistant material in the equipment at a high speed and is ground into thickened pulp material, so that the digestion rate of a back-section anaerobic fermentation system and the biogas yield are increased; a secondary centrifugation step is added, so that the design flow of the oil-water separation process is reasonable, the next step vertical centrifugation effect is facilitated, and the outlet oil concentration and the operation efficiency are increased; a good centrifugal oil outlet effect is achieved, and the water content of obtained thick oil and the oil content of wastewater material are low; and the back-section anaerobic fermentation efficiency is improved, oil-water separation of the material is conducted more thoroughly and re-consumption of energy is avoided.

Owner:NINGBO KASEEN ECOLOGY TECHNOLOGY CO LTD

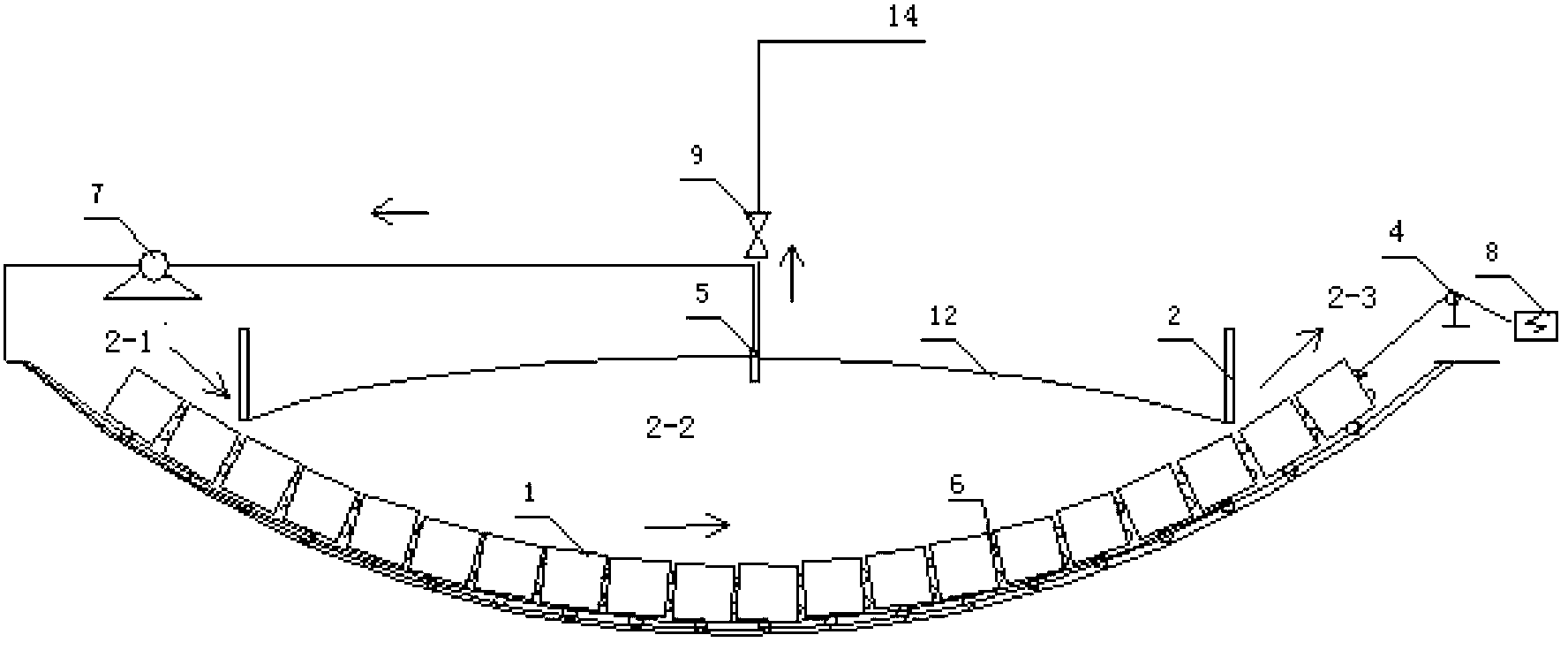

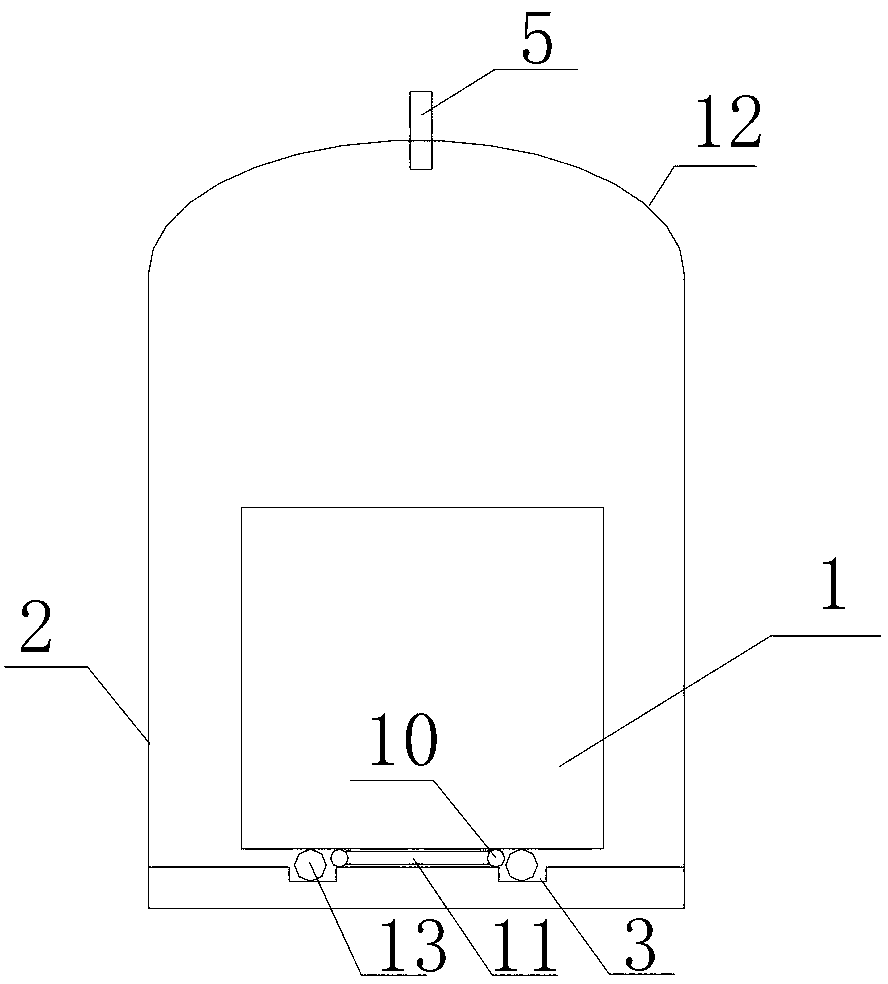

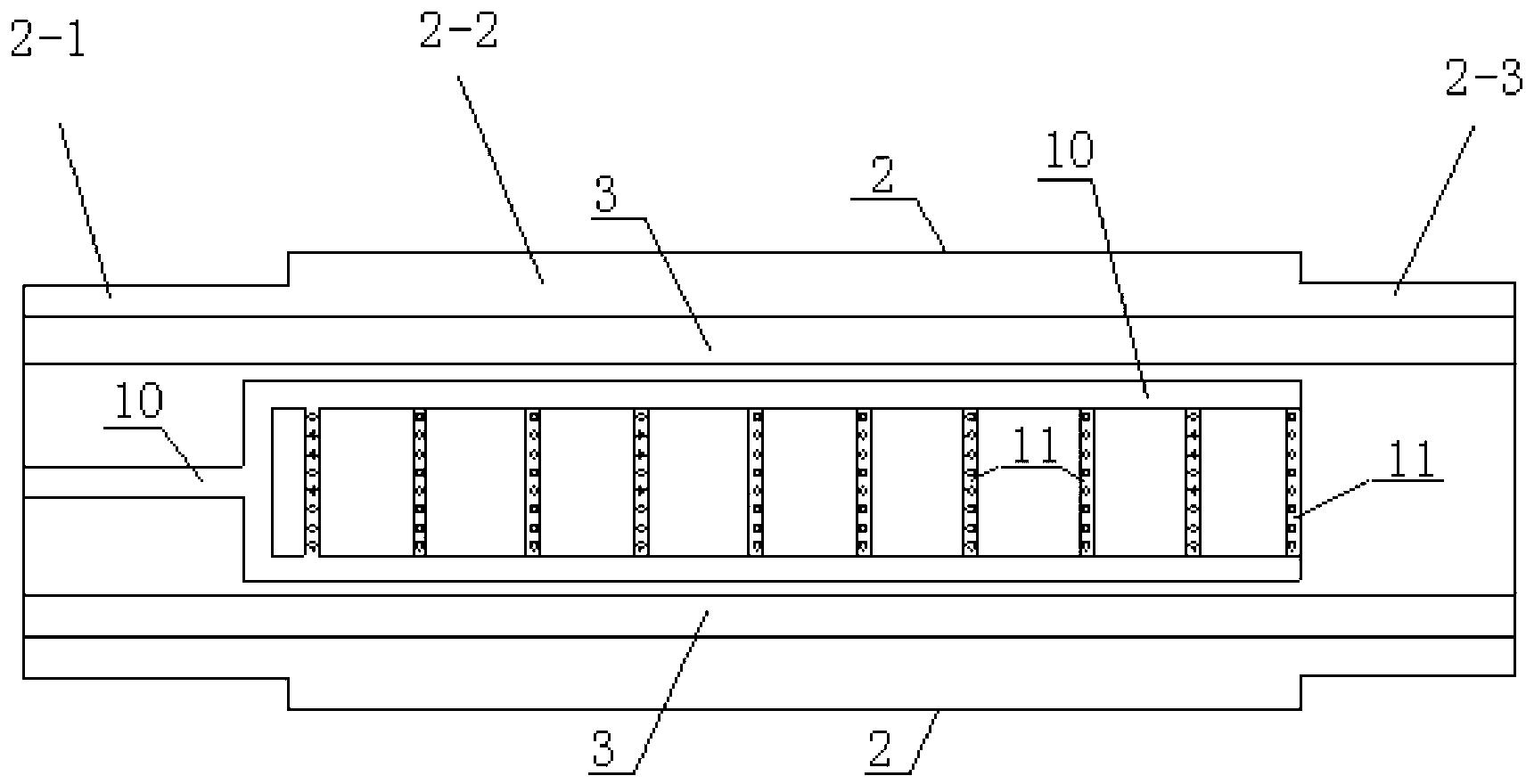

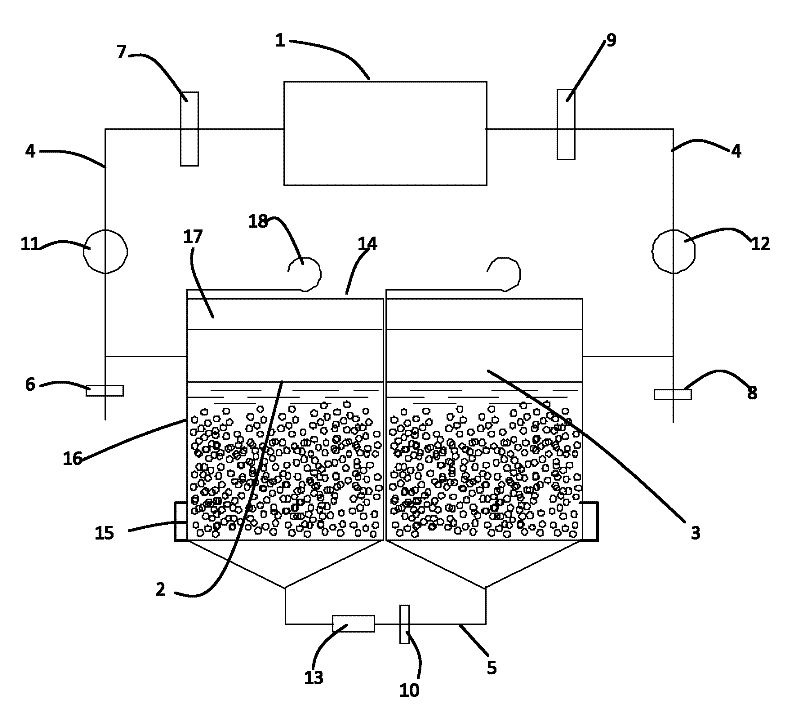

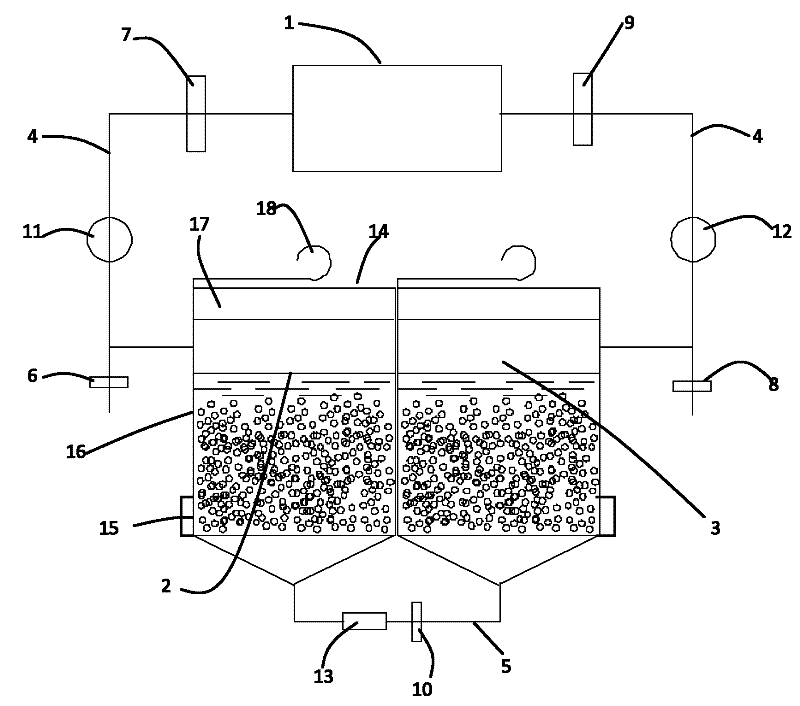

Organic waste treatment system and treatment method thereof

InactiveCN102796657AImprove processing efficiencyImprove efficiencyBio-organic fraction processingGas production bioreactorsBiogasWaste treatment

The invention relates to an organic waste treatment system, which comprises an arc treatment pool and material net cages. The arc treatment pool includes an inlet aerobic zone, an anaerobic zone and an outlet aerobic zone. The anaerobic zone is located at the bottom of the arc treatment pool. The inlet aerobic zone and the outlet aerobic zone that are communicated with the anaerobic zone are respectively and symmetrically arranged on both sides of the anaerobic zone. An arched top equipped with a gas guide tube is disposed at a position corresponding to the anaerobic zone at the top of the arc treatment pool. A track running through the inlet aerobic zone, the anaerobic zone and the outlet aerobic zone is disposed at the bottom of the arc treatment pool. According to the invention, a material is subjected to hydrolytic acidification in the inlet zone, and is then brought into the anaerobic zone for fermentation to obtain biogas. At the same time, in the anaerobic zone, the biogas is subjected to pressurization and refluxing stirring, so that fermentation blind zones can be reduced, the biogas generation rate is improved, the variety and characteristic of a fermentation raw material are no longer confined, and the operation and construction costs are reduced at the same time.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

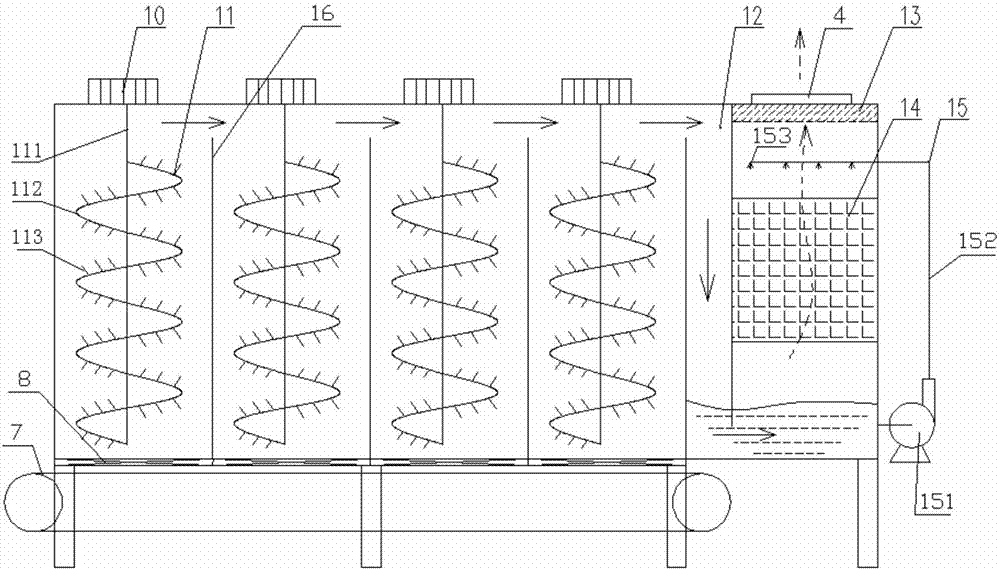

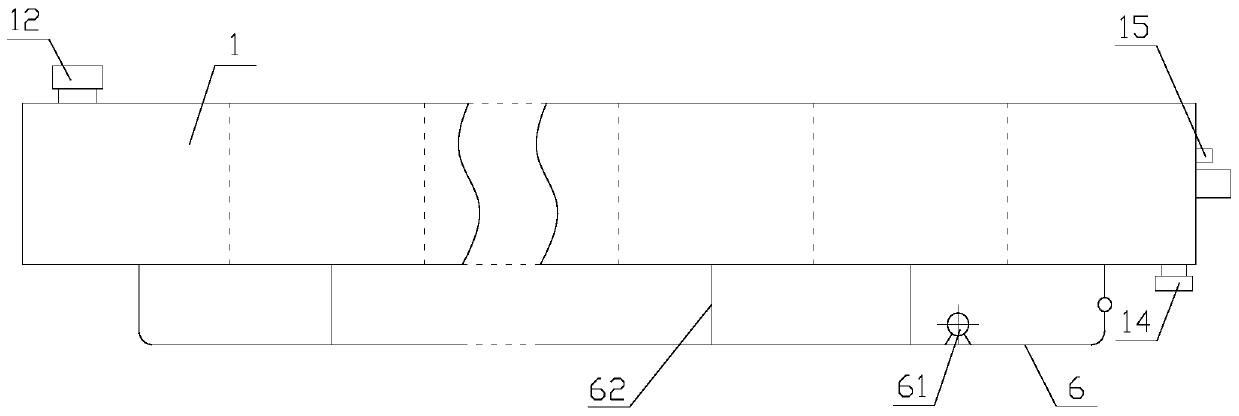

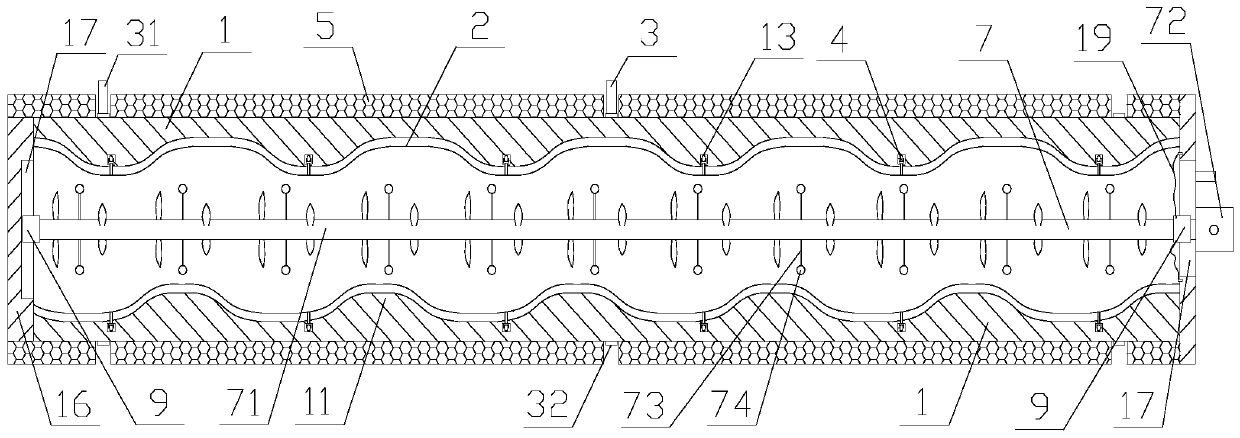

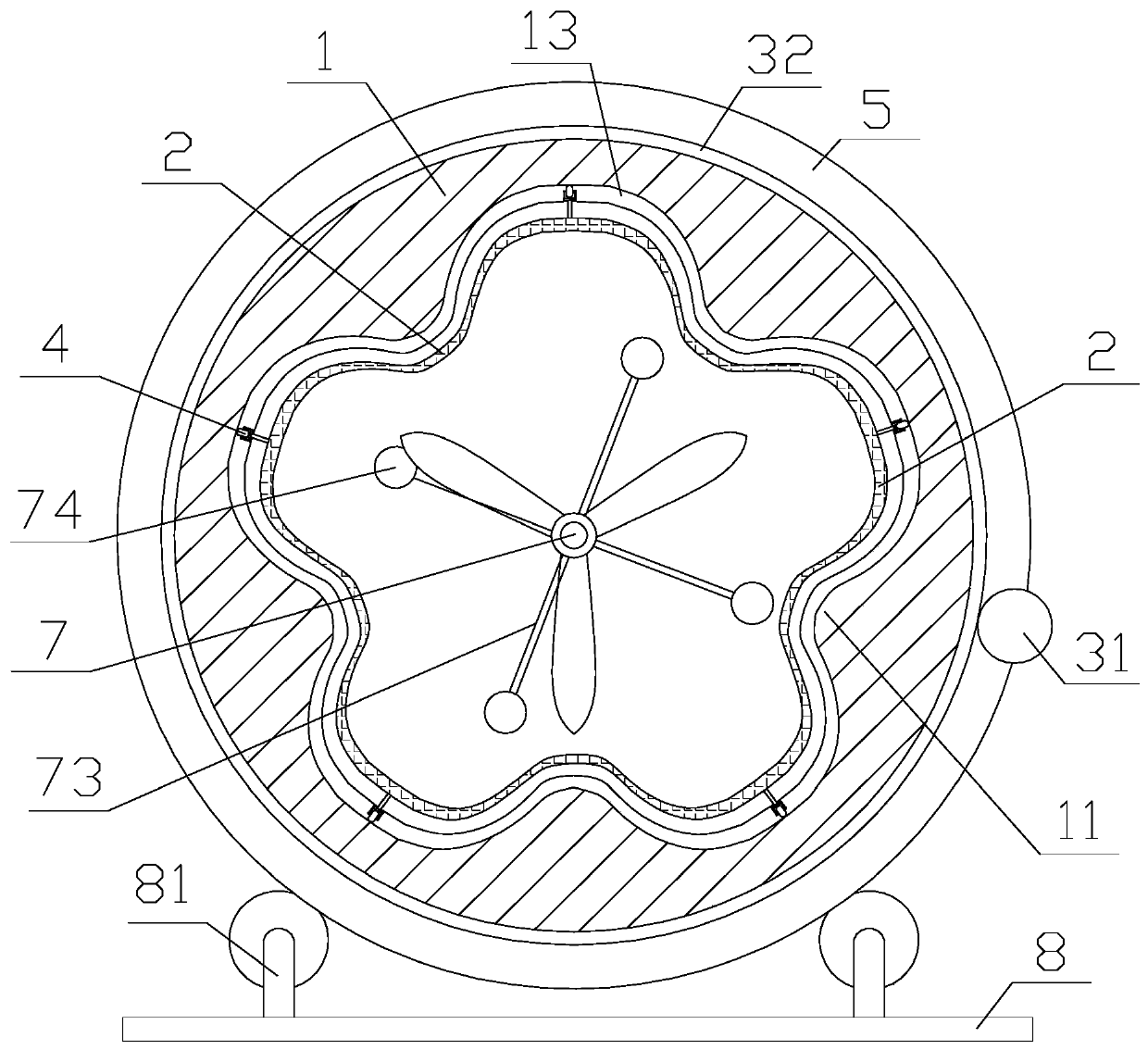

Mechanical and pneumatic combined dry anaerobic fermentation system and fermentation method

ActiveCN112812940AAnaerobic fermentation is efficientReduce energy consumption of mechanical stirringBioreactor/fermenter combinationsBiological substance pretreatmentsMethane productionProcess engineering

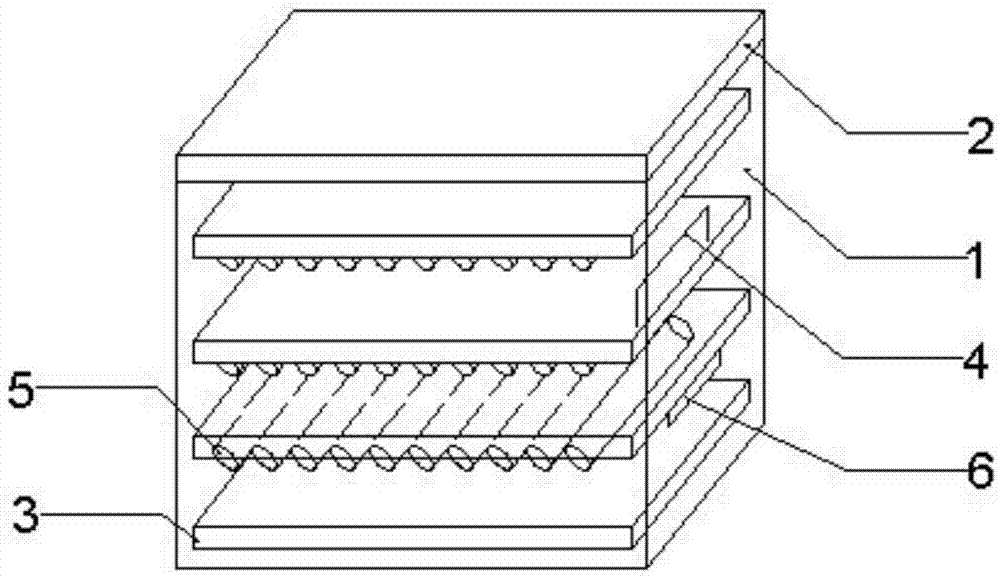

The invention discloses a mechanical and pneumatic combined dry anaerobic fermentation system. The system comprises a horizontal fermentation tank, a mechanical stirring assembly and a pneumatic stirring assembly, wherein the mechanical stirring assembly comprises a stirring shaft arranged in the axial direction of the horizontal fermentation tank and a plurality of blades arranged on the stirring shaft; the pneumatic stirring assembly comprises a first pneumatic pipe, a second pneumatic pipe and an air supply pipeline connected with the first pneumatic pipe and the second pneumatic pipe, and the first pneumatic pipe and the second pneumatic pipe are sequentially arranged in the axial direction of the horizontal fermentation tank. Through combination of the mechanical stirring assembly and the pneumatic stirring assembly, energy consumption of mechanical stirring is reduced, gas generated through fermentation is used for stirring, energy is saved, the first pneumatic pipe corresponds to the material acid production stage, the second pneumatic pipe corresponds to the material methane production stage, materials in the two stages are stirred in a differentiated mode, the stirring requirements of the materials in different stages are met, and efficient anaerobic fermentation of the fermented materials is facilitated.

Owner:上海环境保护有限公司

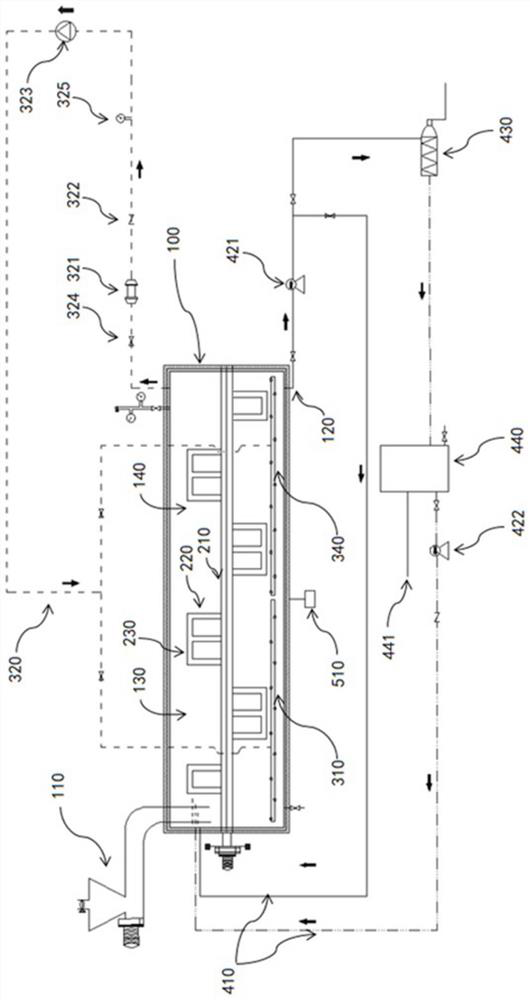

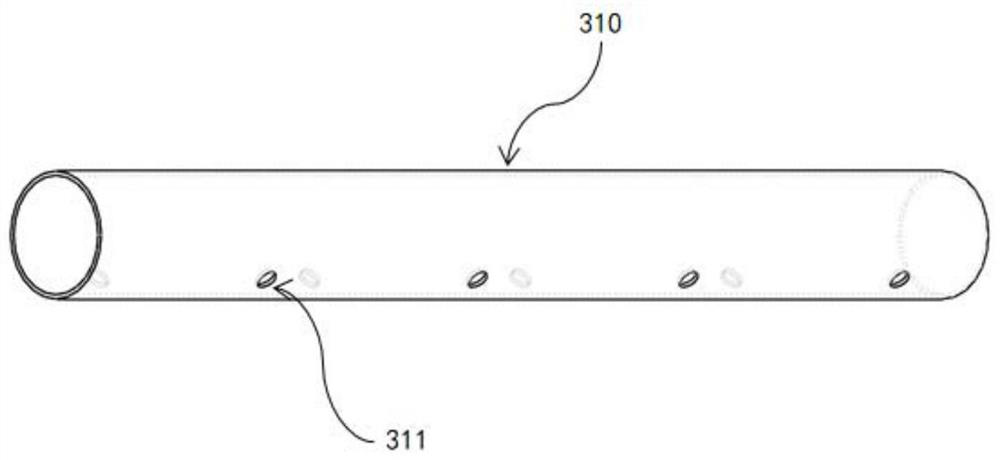

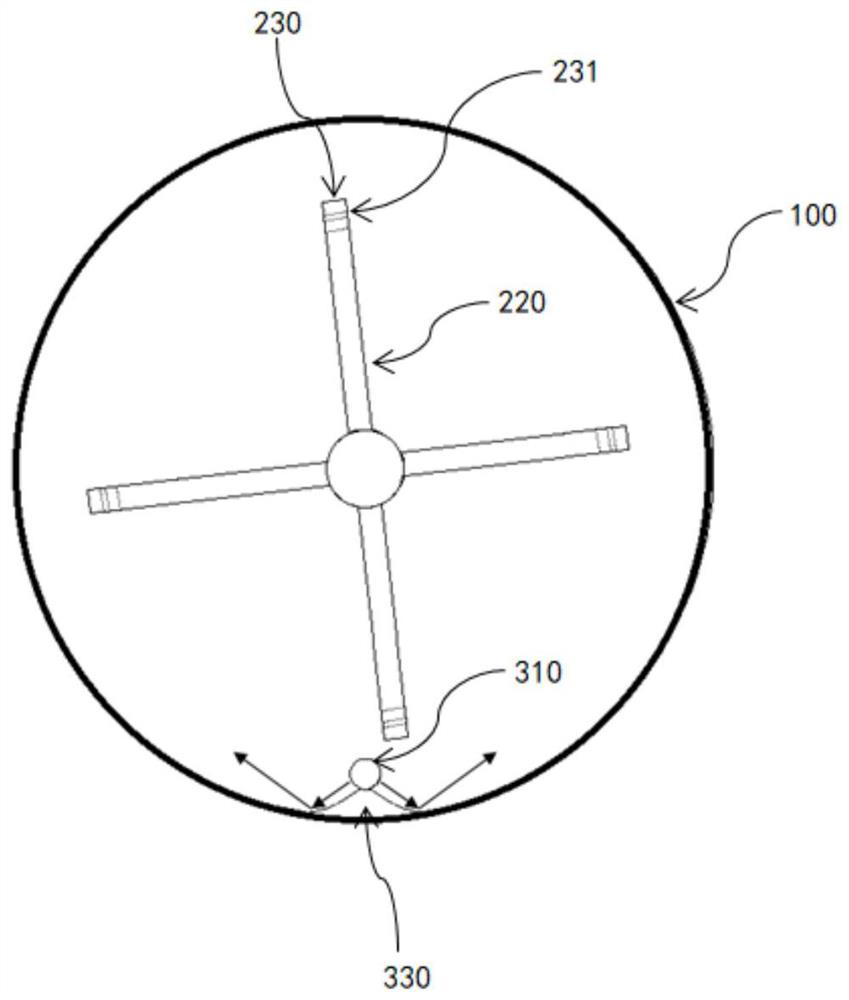

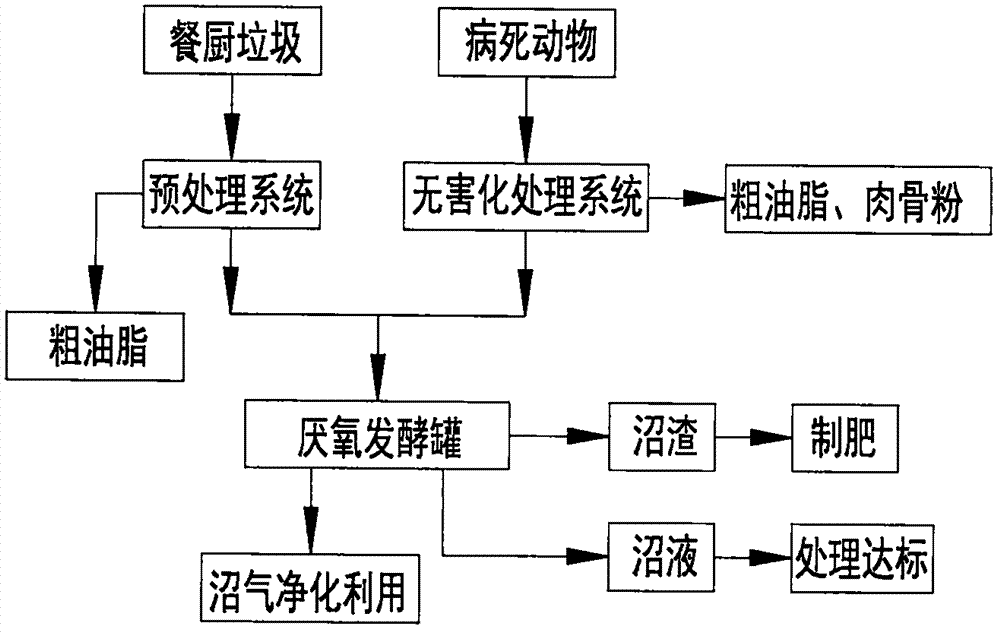

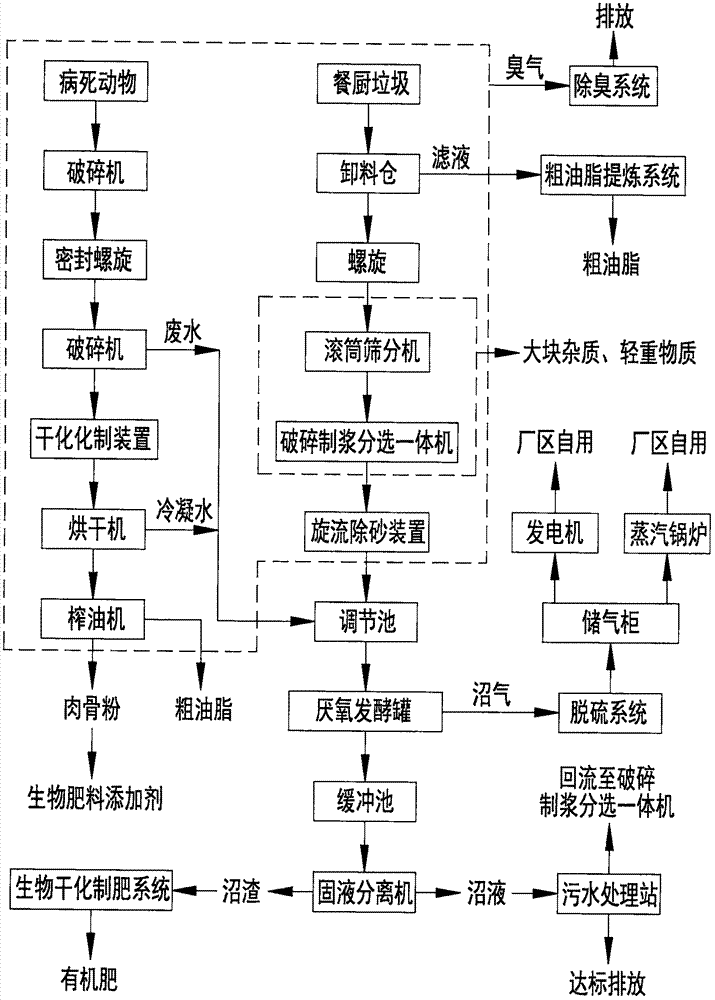

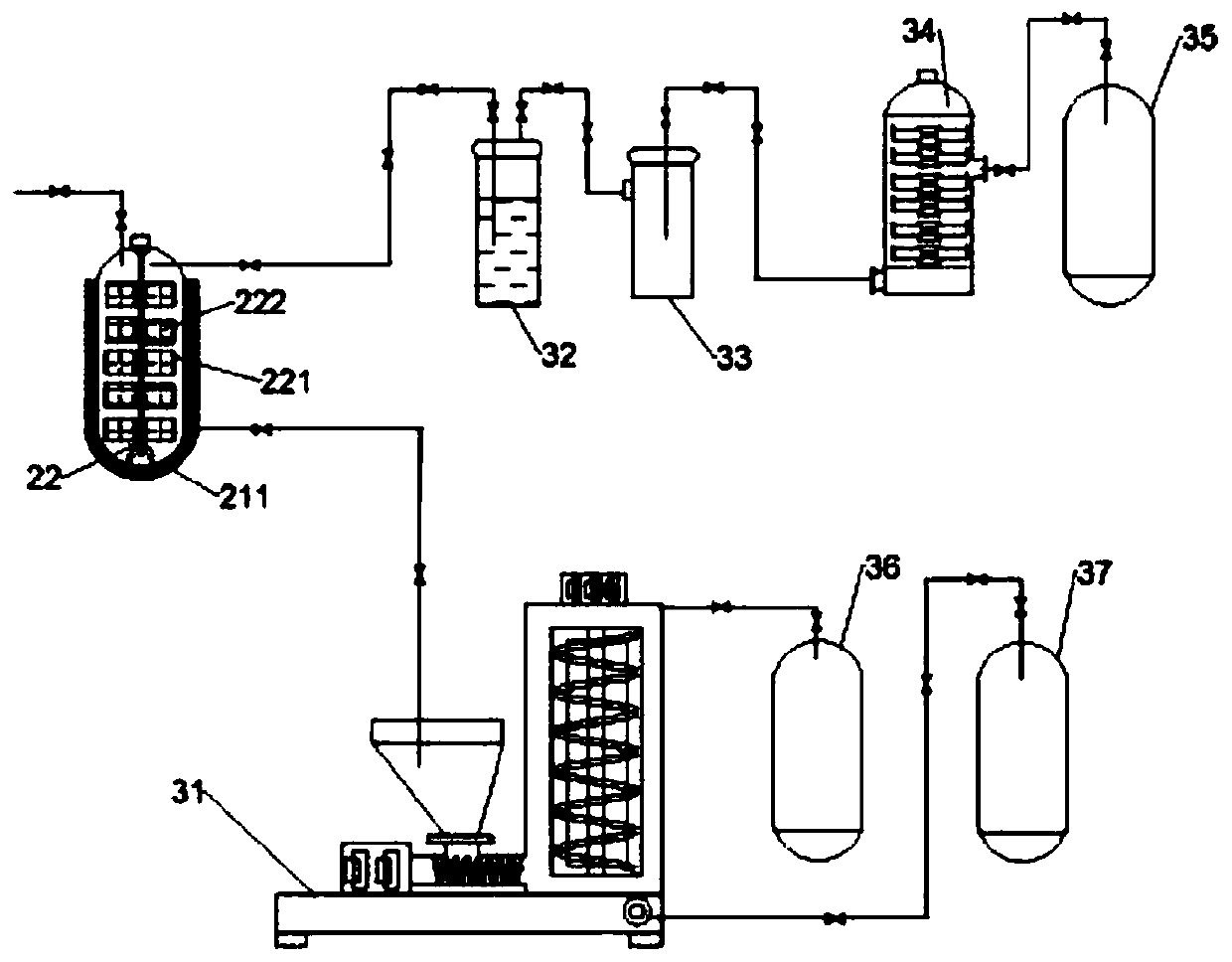

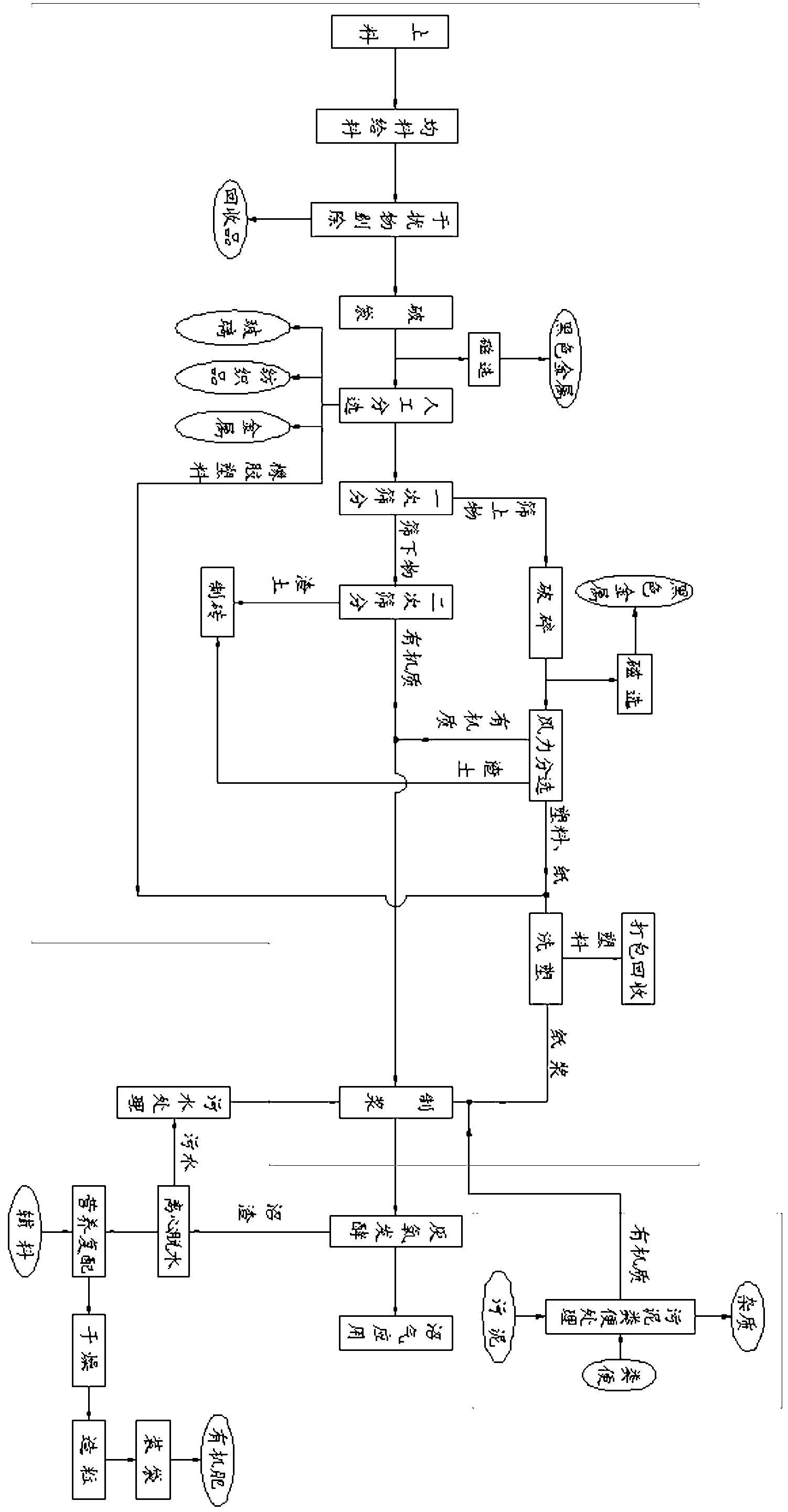

Kitchen waste and die-of-disease animal combined treatment technique system

InactiveCN107952779ASignificant economySignificant environmental benefitsWaste processingSolid waste disposalBiodieselClean energy

A kitchen waste and die-of-disease animal combined treatment technique system mainly comprises a kitchen waste pretreatment system, a die-of-disease animal harmless treatment system, a combined anaerobic fermentation system, a biogas purifying and utilization system, a biogas residue fertilizer making system, a biogas slurry treatment system and a deodorizing system. Organic materials in kitchen waste and wastewater and condensate wastewater in the die-of-disease animal harmless treatment process are subjected to combined anaerobic treatment; generated biogas is purified and then used for power generating and used for a steam boiler, biogas residues are made into compost, part of biogas slurry flows back, and the other part of the biogas slurry is discharged with the standard level; and crude grease extracted from the kitchen waste and die-of-disease animals is used for extracting biodiesel, meat and bone meal obtained after die-of-disease animal harmless treatment is used for bio-fertilizer addition agents, and odors generated in the combined treatment process are discharged with the standard level. According to the kitchen waste and die-of-disease animal combined treatment technique system, the kitchen waste and the die-of-disease animals are treated in a combined mode so as to generate clean energy sources, so that land occupation and investment are saved, the anaerobic fermentation efficiency is improved, significant economic and environmental benefits are brought for the society, and thus the kitchen waste and die-of-disease animal combined treatment technique system has popularization value.

Owner:BEIJING CSCE ENVIRONMENTAL ENG

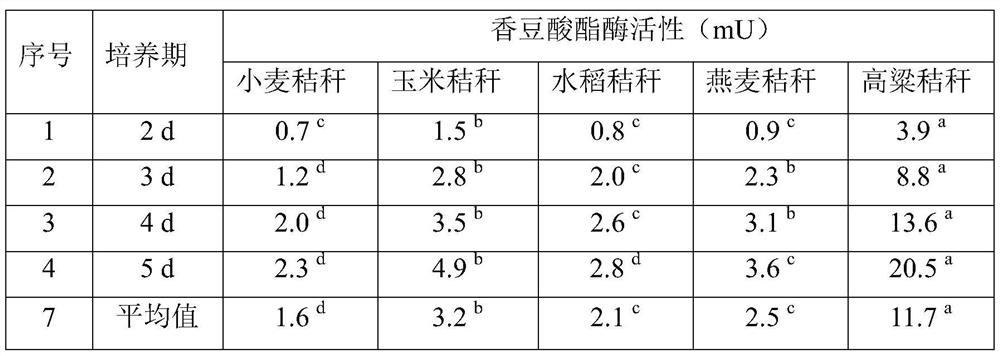

Mechanical grinding combined facultative anaerobic hydrolysis preprocessing method for anaerobic fermentation of straws

The invention discloses a mechanical grinding combined facultative anaerobic hydrolysis preprocessing method for anaerobic fermentation of straws, and belongs to the technical field of biogas production by straw anaerobic processing. The mechanical grinding combined facultative anaerobic hydrolysis preprocessing method comprises the following steps of: 1, straw preprocessing, i.e., grinding the straws, wherein the particle size of the ground straws is 1 to 2cm; 2, straw blending, i.e., adding biogas slurry and an inoculum into the straws obtained in the step 1 so as to obtain feed liquid, wherein solid content of the feed liquid is 8 to 10%; 3, straw hydrolysis, i.e., carrying out facultative anaerobic hydrolysis on the feed liquid obtained in the step 2 for 1 to 2 days at a hydrolysis temperature of 38 plus or minus 2 DEG C, and carrying out intermittent aeration according to an aeration gas-water ratio of 6:1 to 20:1 so as to obtain hydrolysate. According to the mechanical grinding combined facultative anaerobic hydrolysis preprocessing method disclosed by the invention, the problems of straw anaerobic fermentation crusting and difficulty in feeding and discharging are effectively solved, straw anaerobic fermentation efficiency is improved; fermentation time is shortened by 10 to 20 days; by biogas slurry reflux blending, water for blending can be saved by 7 to 9 tons per ton of straws, so that one-time investment of engineering is directly reduced by 1 to 1.5 millions, and operation cost is reduced by 10 to 15%.

Owner:QINGDAO TIANREN ENVIRONMENT

UASB-two stage A/O-coagulation process for treatment of pig farm biogas slurry

InactiveCN106946403AReduce concentrationReduce processing loadWaste water treatment from animal husbandryWaste based fuelPig farmsTreatment effect

A UASB-two stage A / O-coagulation process for treatment of pig farm biogas slurry. The pig farm biogas slurry successively passes through and is treated in a regulating tank, an upstream anaerobic sludge bed reactor (UASB), a primary anoxic / oxic tank (primary A / O), a second anoxic / oxic tank (secondary A / O), a mid-sedimentation tank, a coagulation tank, a second-sedimentation tank, and a disinfecting tank, and finally is discharged after reaching standard. The two A / O process stages are connected in-series front and back, wherein in the first A / O stage, an active sludge process is employed, so that phosphorous is removed through a sludge discharge method by reducing age and hydraulic retention time of the sludge; and in the second A / O stage, a bio-membrane process is employed and a combined pack is arranged in the tank, so that denitrification is enhanced since a bio-membrane enriches denitrifying bacteria. The combined process has significant nitrogen and phosphorus removal effect and stable treatment effects, is strong in shock load resistance, has simple operation and has low operation cost. After treatment through the combined process to the pig farm biogas slurry, indices of discharged water satisfy demands in Discharge Standard of Pollutants for Livestock and Poultry Breeding (GB 18596-2001).

Owner:NANCHANG UNIV

Method for producing acetic acid from corn straw through anaerobic fermentation

ActiveCN107326060AEfficient degradation abilityAvoid pollutionMicroorganism based processesFermentationAcetic acidMicroorganism

The invention discloses a method for producing acetic acid from corn straw through anaerobic fermentation. The fermentation bacterial agent adopted in the method is naturally coexisting anaerobic fungi and PiromycesYak Tz+M. ruminantium, which are separated from the rumen liquid of yaks which are fully grazed in the Nanniwan pasture located in Tianzhu, Gansu in the Qinghai-Tibet plateau. The coculture is deposited with the China General Microbiological Culture Collection Center and assigned the accession number CGMCC No. 12952. The coculture is taken as a bacterial agent for anaerobic fermentation of corn straw, acetic acid can be efficiently produced, and in 7 days of a culture period, the coculture can degrade corn straw to generate 49.0 mM of acetic acid. The method is short in fermentation time and simple in fermentation process, and has bright application development prospects.

Owner:GANSU ACAD OF SCI INST OF BIOLOGY

Method for producing xylanase by anaerobic fermentation of corn straws

ActiveCN106987572AEfficient degradation abilityImprove the efficiency of anaerobic fermentationHydrolasesMicroorganism based processesCorn stoverLaboratory culture

The invention discloses a method for producing xylanase by anaerobic fermentation of corn straws. A fermentation strain used in the method comprises natural coexisting Piromyces Yak TZ+M. ruminantium coculture separated from rumen fluid of yak fully grazed in a Tianzhu Nanniwan pasture on the Tibetan plateau, and the collection number of the coculture at the China General Microbiological Culture Collection Center is CGMCC No. 12952. The coculture serving as the strain is used for anaerobic fermentation of the corn straws, the xylanase can be efficiently produced, the enzymatic activity of the xylanase generated by degrading the corn straws through the coculture within the culture period of 7 days reaches up to 6905mU, and the method is short in fermentation time, simple and convenient in fermentation process and has a wide application and development prospect.

Owner:BAIYIN SINO BIOTECH

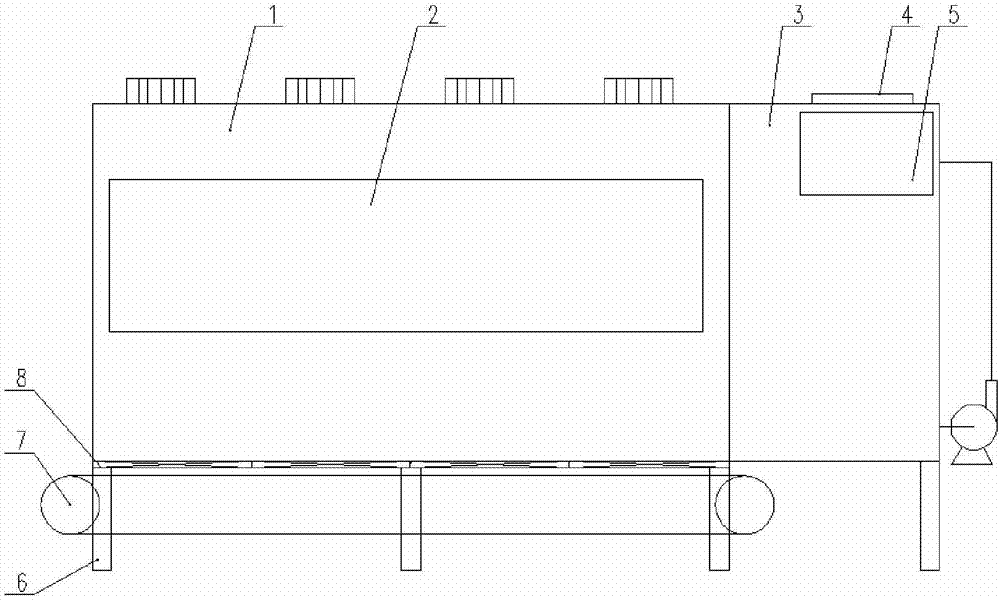

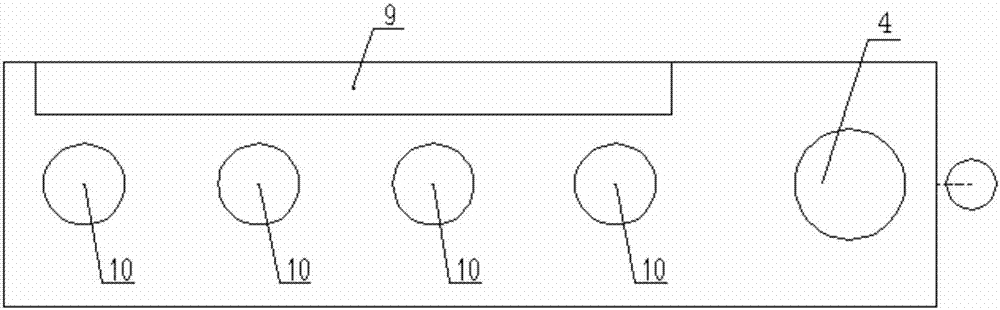

Device for marsh gas resource utilization of kitchen waste

ActiveCN106854617AEvenly heatedFlexible and controllable temperatureBioreactor/fermenter combinationsBiological substance pretreatmentsResource utilizationButt joint

The invention discloses a device for marsh gas resource utilization of kitchen waste. The device includes an anaerobic fermentation system and a marsh gas purification system. The anaerobic fermentation system is internally equipped with a crushing component for crushing kitchen waste and a heating component for providing constant anaerobic fermentation temperature. The marsh gas purification system is internally provided with a dedusting component and a biological purification component, the dedusting component is in butt joint with a gas channel, the marsh gas produced by the anaerobic fermentation system is subjected to dedusting purification, and the biological purification component and the dedusting component are in series connection to output dedusted marsh gas after biological desulfurization. According to the invention, kitchen waste is subjected to anaerobic fermentation to produce marsh gas, and the marsh gas is purified to realize resource utilization of marsh gas, the device provided by the invention is convenient and efficient for use, and effectively solves the treatment problem of kitchen waste and achieves effective use of marsh gas resources.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

Method for improving gas yield of biogas fermentation

ActiveCN107663527AImprove fermentation gas productionShort fermentation cycleWaste based fuelFermentationMicroorganismSludge

The invention provides a method for improving the gas yield of biogas fermentation. The method comprises the following steps: mixing straw pulp with an inoculant, magnesium-based olivine powder and mullite powder, and carrying out anaerobic fermentation to generate biogas, wherein a fermentation period is short and the gas yield of the biogas fermentation can be effectively improved. The straw pulp is obtained through ultrasonic crushing and hydrothermal treatment; the contact area between straw components and microorganisms is enlarged and the anaerobic fermentation efficiency is improved; the inoculant is obtained by heaping and retting active sludge and animal and human excrement and then irradiating through 60Co gamma-rays, and is used for promoting the degradation of organic matters;the magnesium-based olivine powder and the mullite powder contain rich metal elements including magnesium, aluminum and the like and can realize a catalytic action; the improvement of the fermentationefficiency is facilitated and the fermentation period is shortened.

Owner:JIANGSU ZHONGKE HEAVY IND CO LTD

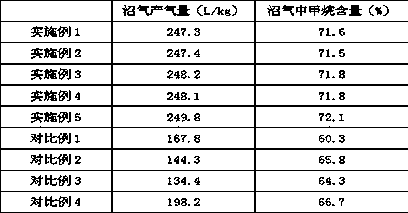

Naturally symbiotic mixed culture and method for producing coumaric acid esterase by degrading straws by using naturally symbiotic mixed culture

The invention relates to the field of renewable energy sources of biotechnology, in particular to a naturally symbiotic mixed culture YakQH5 composed of anaerobic fungi (Neocallimastix frontalis) andmethane bacteria (Methanobrevibacter gottschalkii). The mixed culture is preserved in china general microbiological culture collection center on 09 March 2020, the preservation number is CGMCC No.19299, and the mixed culture YakQH5 can be used for fermenting straws to produce coumaric acid esterase. The invention specifically discloses a fermentation method by using the mixed culture. According tothe mixed culture and the method, the activity of coumaric acid esterase generated by degrading sorghum straws can reach 20.5 mU, and composite antibiotics are added in a fermentation process, so that a mixed culture system can be prevented from being polluted by bacteria, the anaerobic fermentation efficiency is improved, and the important industrial application value is achieved.

Owner:GANSU ACAD OF SCI INST OF BIOLOGY

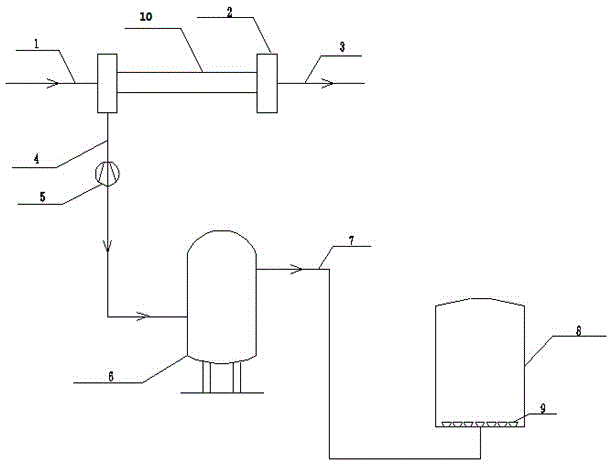

Small-scale kitchen waste garbage methane system

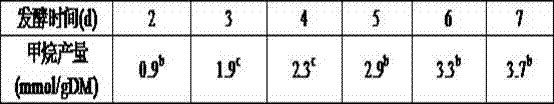

InactiveCN109609351APrevent floatingRealize resourcesBioreactor/fermenter combinationsBiological substance pretreatmentsCharge controlEngineering

The invention provides a small-scale kitchen waste garbage methane system, and belongs to the technical field of biological fermentation. The small-scale kitchen waste garbage methane system comprisesa charging pretreatment device, an S-shaped water sealing pipe, a raw material storing device, a charging control valve, a methane generation device, a methane purifying device and a methane storingdevice which are sequentially connected. From collection of kitchen waste garbage subjected to anaerobic fermentation to produce methane, to methane purification and storage and to final conveyance tousers, whole-course closed loop operation is realized, and resourceful and innocent treatment of the kitchen garbage can be effectively realized. According to the small-scale kitchen waste garbage methane system, automation control is realized in the whole course, man-made excessive intervention is not needed, and the small-scale kitchen waste garbage methane system is safe and reliable and highin applicability.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

Ammonification anaerobic fermentation equipment and method for production of straw biogas

InactiveCN102220230ASolve efficiency problemsSolve the costBioreactor/fermenter combinationsGas production bioreactorsContinuous fermentationEconomic benefits

Owner:SHAANXI UNIV OF SCI & TECH

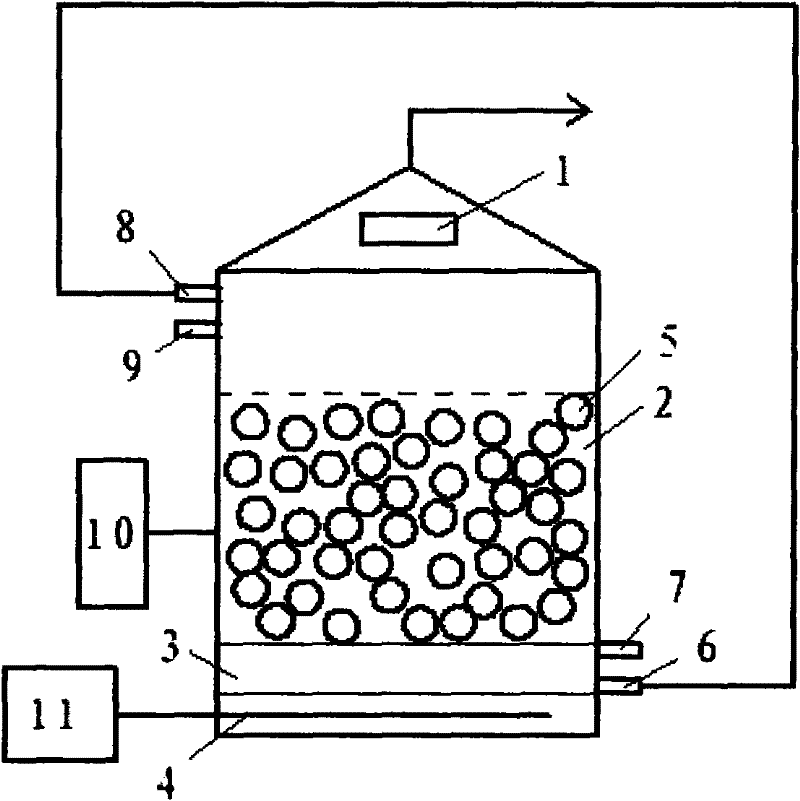

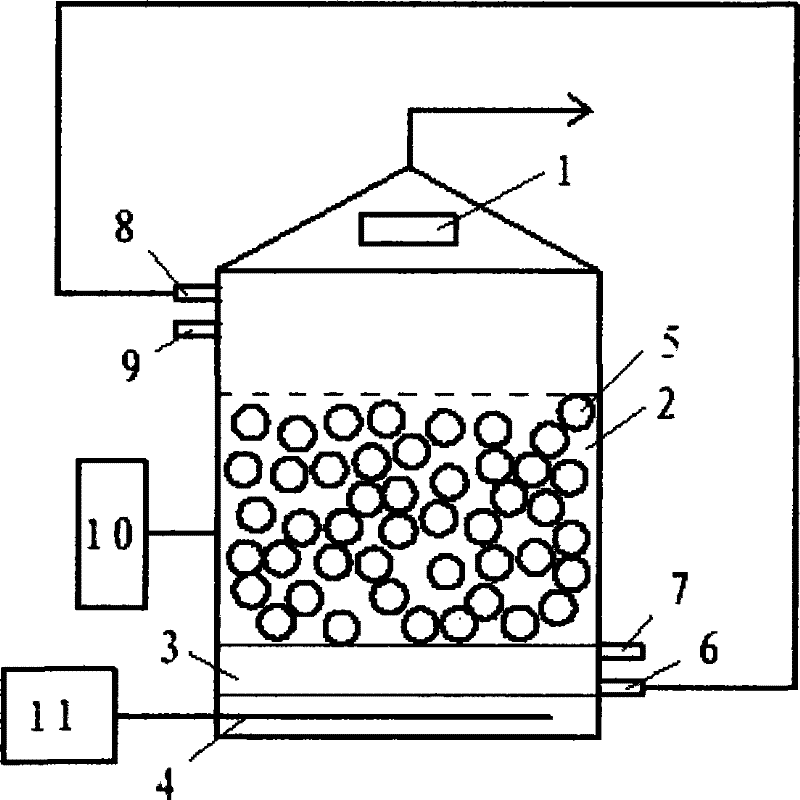

High-efficiency waste water treatment system for nursery

ActiveCN101955299ASmall and efficientIncrease microbial biomassWaste water treatment from animal husbandryTreatment with anaerobic digestion processesWater treatment systemSmall footprint

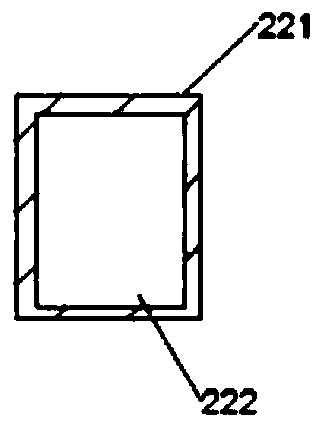

The invention relates to a high-efficiency waste water treatment system for a nursery, belonging to the technical field of waste water treatment. A waste water treatment system for a livestock and poultry nursery comprises a settling tank, a conditioning tank, an anaerobic reactor, an outlet water collecting tank, a sand type outlet water treating tank and a post-treating tank which are connected in order, wherein the anaerobic reactor is composed of a secondary biological nest anaerobic reactor, the biological nest anaerobic reactor comprises an anaerobic fermenter main body and a biological nest device, the biological nest device is arranged in the anaerobic fermenter main body, the lower part of the side wall of the anaerobic fermenter main body is provided with a water inlet, the upper part of the side wall of the anaerobic fermenter main body is provided with a water outlet and a sample connection, and the top of the anaerobic fermenter main body is provided with a gas outlet; and the biological nest device is of a hollow cylindrical structure, the upper wall and the lower wall of the biological nest device are provided with holes, and biological nest materials are filled in the biological nest device. The invention has the characteristics of high treating efficiency, small occupied area, low construction cost, convenient maintenance and operation and the like.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

Method of producing biogas by recycling orange peel residue and dehydrated sludge through fermentation

InactiveCN105130149AOvercome secondary pollutionSolve difficult environmental problemsGaseous fuelsWaste based fuelMicroorganismContinuous fermentation

The invention aims to the problem of difficult treatment on orange peel residues and municipal sludge and low recycling utilization rate and discloses a method of producing biogas by recycling orange peel and dehydrated sludge through fermentation. In the method, the orange peel residue and the dehydrated sludge are employed as raw materials to perform anaerobic fermentation, wherein the fermentation pH is regulated through a quick lime supernatant. The method allows continuous fermentation and batch fermentation. In the method, the characters that the orange peel residue is high in organic substance content and the dehydrated sludge is high in nitrogen and phosphorus contents and is abundant in microorganism colonies are fully utilized, thereby not only effectively solves the problems of recycling the orange peel residue and the municipal sludge, but also increasing common fermentation efficiency of the orange peel residue and increasing the utilizability of biogas residue and biogas liquid as fertilizers after common fermentation of the orange peel residue. The method is excellent in economic and environmental benefit.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Preparation method of biomass energy block capable of generating biogas

InactiveCN103088071AReasonable carbon and nitrogen ratioImprove the efficiency of anaerobic fermentationWaste based fuelFermentationHydrogenMixed materials

The invention provides a preparation method of a biomass energy block capable of generating biogas. The preparation method comprises the following steps of: firstly, mixing plant straw sections, excrements, cellulose, an aminating agent, anaerobic sludge and a pH (Potential Of Hydrogen) stabilizing agent to prepare a mixed material; then adjusting moisture content of the mixed material by using water, then pressing the mixed material into blocky mixed material, then packaging the blocky mixed material in a vacuum manner by using a plastic film to seal the blocky mixed material inside the plastic film, and carrying out the ammoniation and fermentation treatment at 15-30 DEG C; and then forming holes in the plastic film to evaporate moisture in the blocky mixed material after the ammoniation and fermentation treatment so as to obtain the biomass energy block. The preparation method of the biomass energy block capable of generating the biogas is low in cost and high in gas generation efficiency; and the prepared biomass energy block is convenient to use.

Owner:SHAANXI UNIV OF SCI & TECH

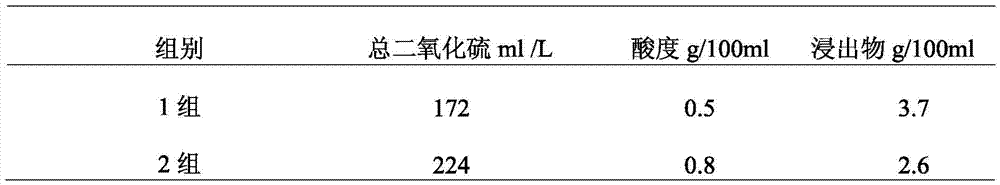

Preparation method for papaya wine

ActiveCN105441255ARich in nutrientsTo promote metabolismAlcoholic beverage preparationWater bathsVitis vinifera

The invention discloses a preparation method for papaya wine. The preparation method includes the steps: S1, taking papaya and grape, triturating the papaya and the grape together, heating in water bath, then adding cooked corn flour, purified water and distiller's yeast, and then fermenting for 18-24 h at the temperature of 30-35 DEG C, to obtain a primary fermentation product; S2, according to an order of laying one equal part of the primary fermentation product and then laying a sugarcane row, putting all the primary fermentation product in a fermentation tank, carrying out sealed fermentation for 5-10 days at the temperature of 28-32 DEG C, to obtain a secondary fermentation product; and S3, taking out the secondary fermentation product, filtering to obtain a fermentation liquid, carrying out sealed fermentation of the fermentation liquid for 15-25 days at the temperature of 20-27 DEG C, filtering to obtain a filtrate, adding papain to the filtrate, then carrying out sealed fermentation for 20-30 days at the temperature of 15-19 DEG C, and filtering to obtain the papaya wine. The preparation method reduces the content of total sulfur dioxide residual in the papaya wine; and the papaya wine has the efficacies of maintaining beauty, keeping young, improving sleeping and delaying senescence.

Owner:防城港市百穗酒业有限公司

Bionic dry-type anaerobic fermentation device

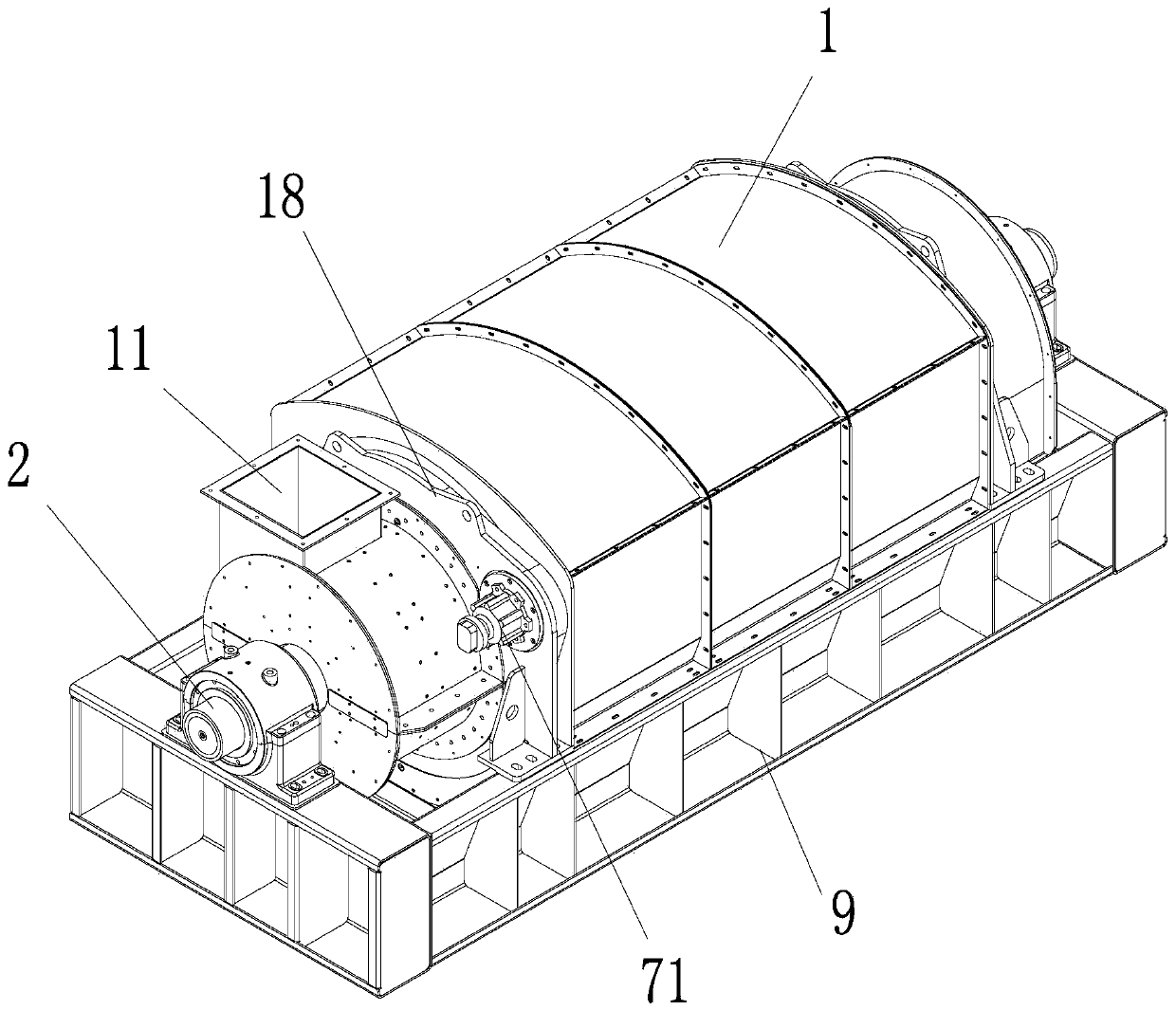

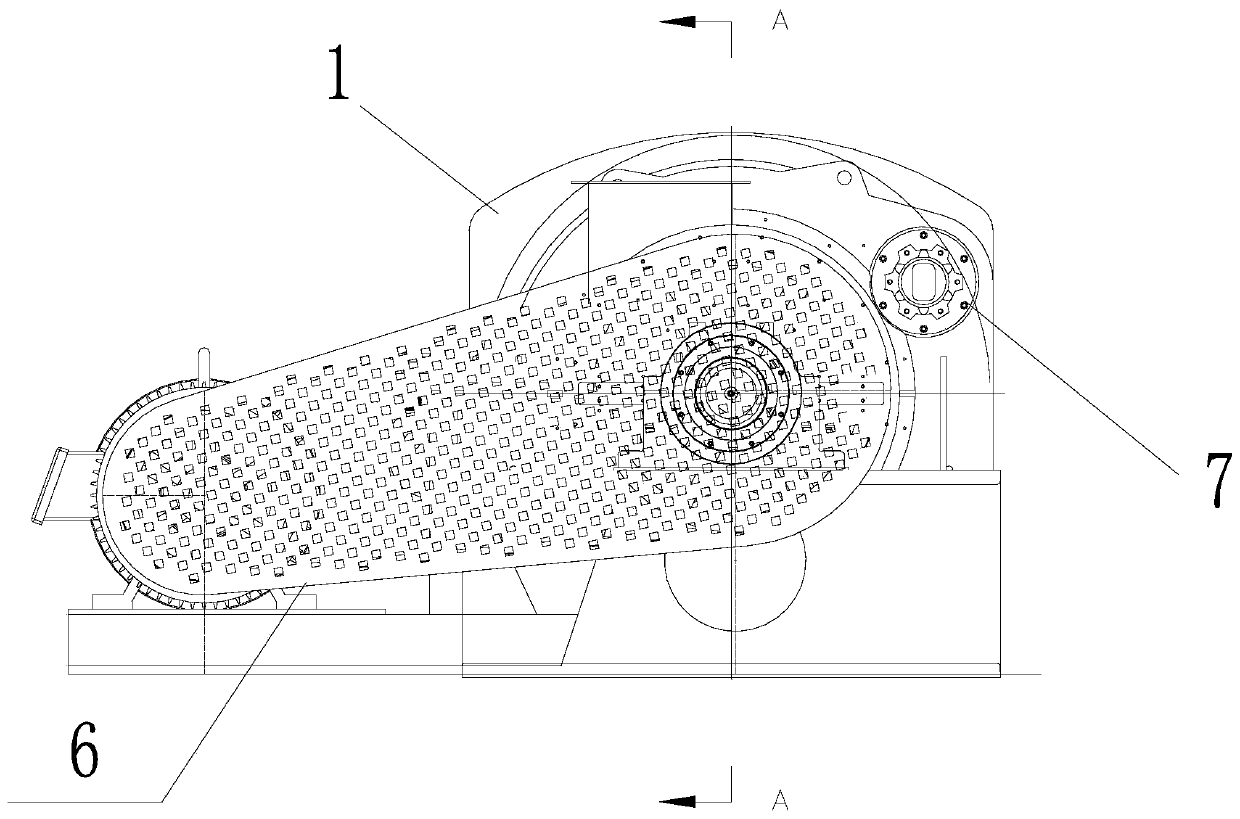

ActiveCN110484436AImprove the efficiency of dry anaerobic fermentationStirring effect is sufficientBioreactor/fermenter combinationsBio-organic fraction processingEngineeringFermentation

The invention discloses a bionic dry-type anaerobic fermentation device. The device comprises a horizontal fermentation bin, the fermentation bin comprises a rotation drum, a screen cloth and a driving mechanism, the outer wall of the rotation drum is cylindrical, and the inner wall of the rotation drum is provided with multiple protrusions; the screening cloth is cylindrical and is connected to the inner side of the inner wall of the rotation drum, a feeding pipe is connected to the rotation drum, and the driving mechanism is arranged on the outer wall of the rotation drum and drives the rotation drum to rotate around its axis. According to the device, the dry-type anaerobic fermentation efficiency of organic waste can be obviously improved, so that fermentation is more balanced and complete.

Owner:四川火尔赤清洁能源有限公司

Efficient anaerobic fermentation device and method for livestock and poultry manure

InactiveCN111170602AFirmly connectedHelp replaceWater treatment parameter controlWaste water treatment from animal husbandryBiotechnologyCollection system

The invention relates to the technical field of fermentation treatment of agricultural waste, and discloses an efficient anaerobic fermentation device and method for livestock and poultry manure. Thedevice comprises a pretreatment system, an anaerobic fermentation system and a collection system, wherein the pretreatment system comprises a grit chamber, an acidification hydrolysis tank and an adjustment metering tank; and a stirring rod of an anaerobic fermentation tank is provided with a semipermeable membrane which wraps anaerobic fermentation bacteria therein. According to the invention, the acidification hydrolysis tank with a controllable pH value and the adjustment metering tank are arranged, so excrement is efficiently pretreated before entering the fermentation tank; the stirring rod in the anaerobic fermentation tank is connected with the semipermeable membrane which is easy to replace and is internally provided with the anaerobic fermentation bacteria; and meanwhile, the controllability and the automation characteristic of the device are improved due to the arrangement of a PLC, so the anaerobic fermentation efficiency of the excrement is effectively improved, and the controllability of instrument operation is high.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

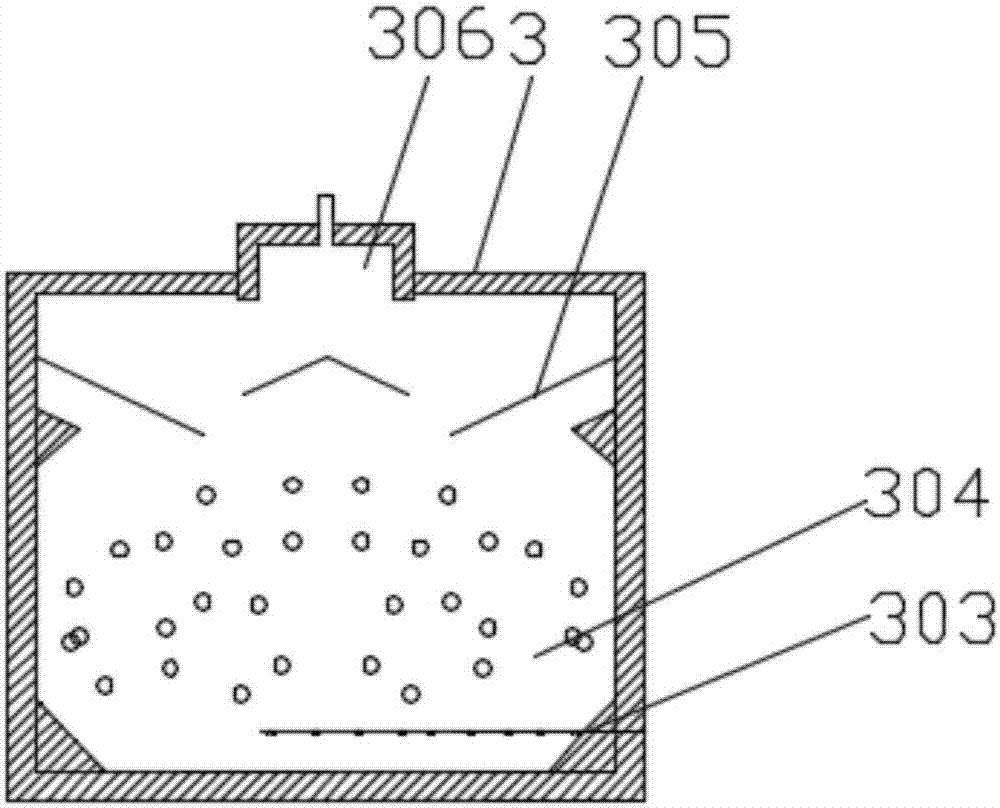

Pneumatic agitating system of biomass anaerobic fermentation tank

InactiveCN106467889AImprove the efficiency of anaerobic fermentationEasy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasExhaust gas

The invention discloses a pneumatic agitating system of a biomass anaerobic fermentation tank, and belongs to the technical field of biomass anaerobic fermentation. Biogas, generated from the anaerobic fermentation, is supplied into membrane decarburization equipment after being processed by virtue of dehydrating equipment and desulfurization and purification equipment, so that purified methane is obtained in one aspect and tail gas carbon dioxide, which serves as a pneumatic agitating power source of the system provided by the invention, is obtained in the other aspect; after the biogas is decarburized, the tail gas carbon dioxide, which is compressed by virtue of a compressor, is supplied into a carbon dioxide high-pressure storage tank; the compressed high-pressure carbon dioxide gas is supplied into the anaerobic fermentation tank by virtue of an agitating ventilation pipe, so that high-concentration anaerobic fermentation slurry is agitated. The pneumatic agitating system provided by the invention, which conducts agitating by virtue of high-pressure carbon dioxide gas, is high in anaerobic fermentation efficiency and the pneumatic agitating system has the characteristics of being high in agitating efficiency, simple to operate, safe and environment-friendly.

Owner:BEIJING SANTAI ENVIRONMENTAL TECH

Organic solid waste combined anaerobic fermentation method

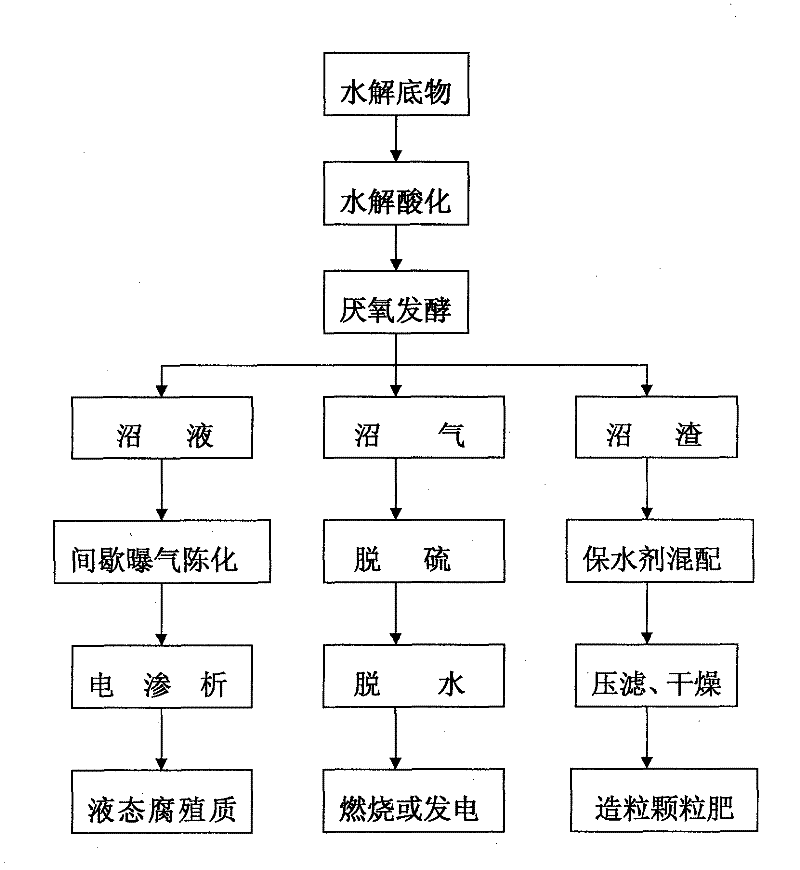

InactiveCN101337838BReduce consumptionImprove mass transfer efficiencyBio-organic fraction processingClimate change adaptationSludgeCombined method

The invention discloses a combined anaerobic fermentation method of organic solid wastes. The organic solid wastes used for the combined anaerobic fermentation include domestic wastes, excess sludge, feces, kitchen waste, straws, etc. The method comprises the following steps: carrying out different pre-processing processes to obtain organic materials with a granularity less than 5 mm; passing through a cutting pump, adjusting the C / N ratio, adjusting the water content, etc. to obtain a homogeneous fermentation substrate with a solid holdup of 2 to 10%; hydrolyzing and acidifying the fermentation substrate in the presence of a hydrolase; fermenting for a period of 15 to 25 days under the condition of stirring at a middle temperature of 32-38 DEG C to obtain biogas, which can be used for energy supply or output of a system; aging and desalting the biogas liquid to obtain a liquid humic acid fertilizer; and processing the biogas residues to a granular humic acid fertilizer. The fermentation substrate has proper C / N ratio to obviate feedback suppression of the substrate during the fermentation of a single material and simultaneously can enhance the hydrolysis effects of celluloses, lignin, hemicelluloses, etc. The method has the advantages of easy flow pattern control, low energy consumption, and no generation of sewages, and can obtain the high-quality biogas fluid and the high-quality granular humic acid fertilizer.

Owner:鄂尔多斯市城市矿产研究开发有限责任公司

Comprehensive treating system for domestic wastes

InactiveCN102527701BIncrease productionImprove qualityBio-organic fraction processingWaste processingSludgeOrganic manure

The invention discloses a comprehensive treating system for domestic wastes. Reutilizing comprehensive treatment for mixed wastes is realized by the system according to a comprehensive sorting technology and a combined anaerobic fermentation technology, wherein the advanced sorting techniques, such as, crushing, magnetic separating, sieving, air classifying, and the like, are adopted in the comprehensive sorting technology; reutilized products, such as metal, plastics, organic matters, and the like, are screened out; the screened organic matters are prepared into slurry together with sludge and excrements and are then subjected to the combined anaerobic fermentation; the reutilized products, such as methane, organic fertilizer, and the like, can be produced under the action of anaerobic fermentation; and after the methane is purified, the methane is used for generating power, domestic fuel or vehicle-mounted fuel. According to the technology, the intensified treatment for organic wastes, such as domestic wastes, sludge, excrements, kitchen wastes, and the like, can be realized. The comprehensive treating system is high in mechanical and automated degree. Compared with the prior art, the comprehensive treating system has the advantages of simplification, effectiveness, less labor power, and the like.

Owner:BEIJING HAOHAI TIANJI TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com