Efficient anaerobic fermentation device and method for livestock and poultry manure

An anaerobic fermentation and anaerobic fermentation tank technology, which is applied in the field of high-efficiency anaerobic fermentation equipment for livestock and poultry manure, can solve the problems of increased labor costs, insufficient pretreatment process, increased investment costs, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

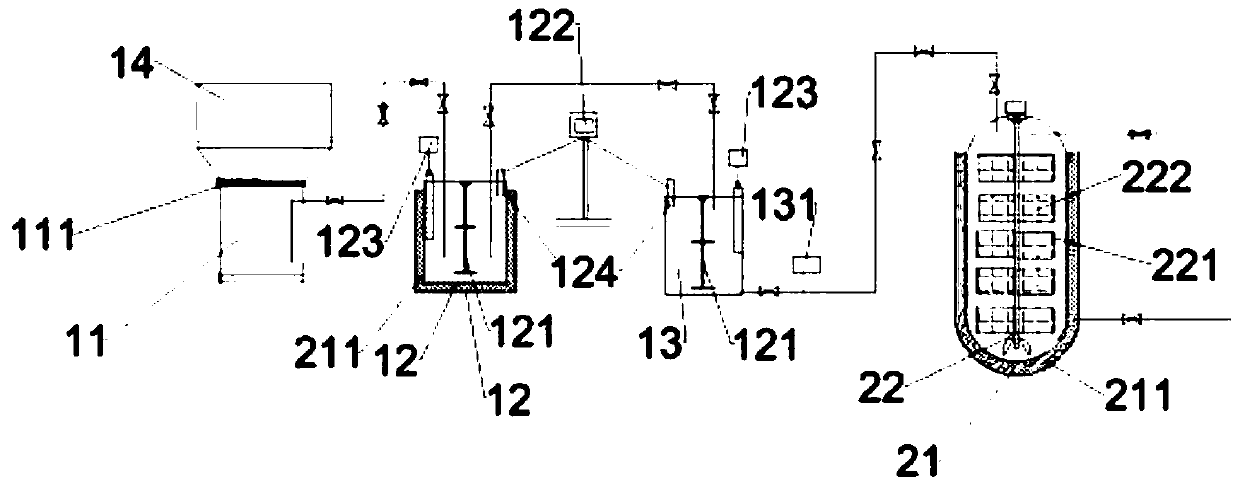

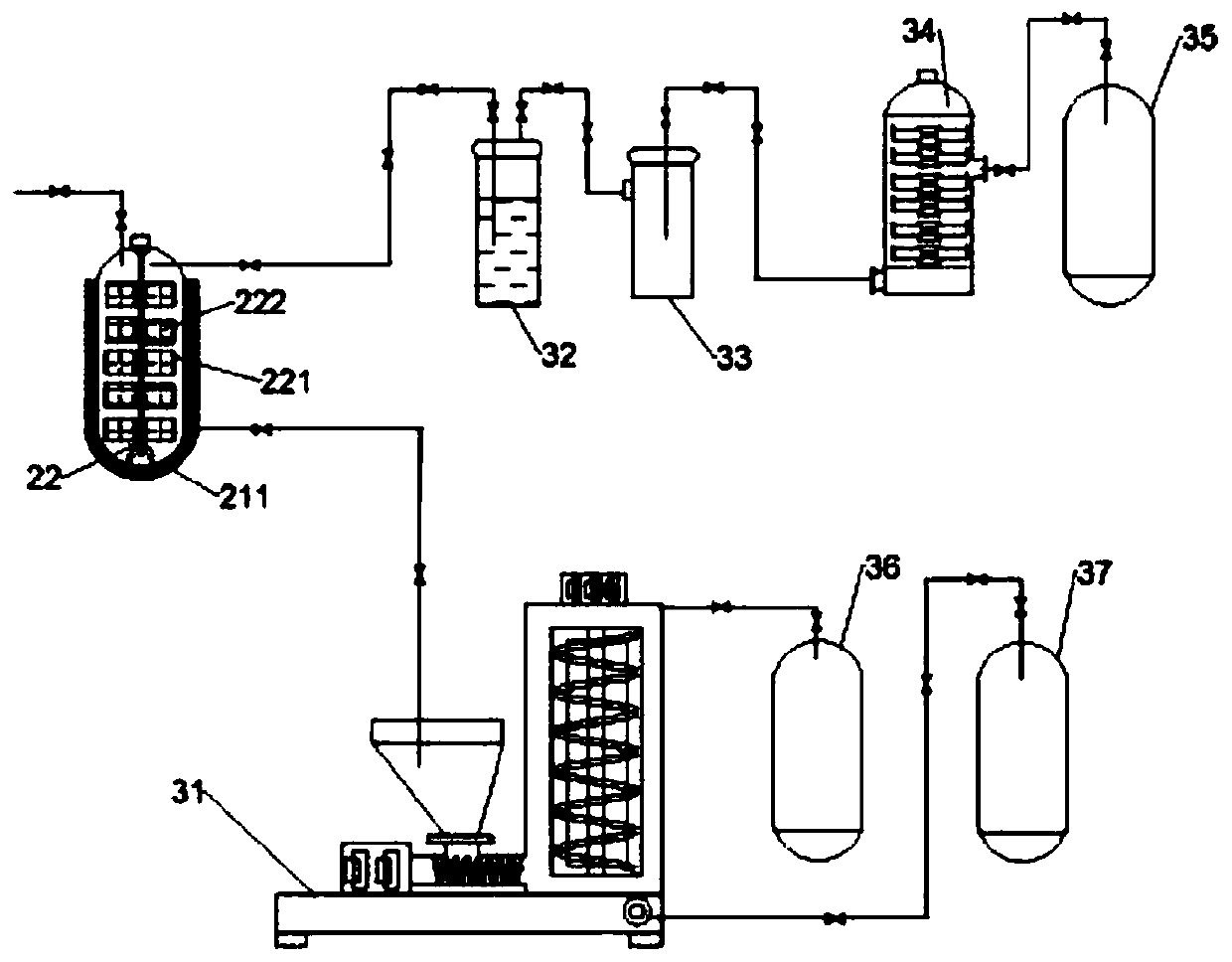

[0033] Such as figure 1 As shown, a high-efficiency anaerobic fermentation device for livestock and poultry manure includes a pretreatment system, an anaerobic fermentation system, and a collection system. The pretreatment system includes a grit tank 11, an acid hydrolysis tank 12, and a regulating metering tank connected in sequence 13. A stirrer 121 and a pH meter 123 electrically connected by a PLC controller 122 (purchased from Delta Electronics Enterprise Management (Shanghai) Co., Ltd.) are installed inside the acidification hydrolysis tank 12 and the adjustment metering tank 13 (Purchased from Hangzhou Liance Automation Technology Co., Ltd.) and a reagent box 124, used to control the pH of the manure liquid, the acidification hydrolysis tank 12 and the anaerobic fermentation tank 21 are wound around the outside of the tank body and the tank body Heated resistance wire 211, the collection system is used to store biogas after desulfurization and dehydration and separate sto...

Embodiment 2

[0035] The second embodiment is the same as the first embodiment except for the following contents:

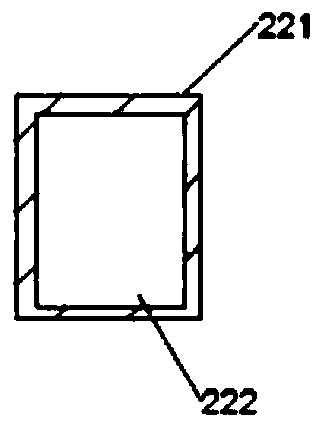

[0036] Such as Figure 3-b As shown, the surface area of the semi-permeable membrane 222 is slightly larger than the area of the stirring blade 221, and the semi-permeable membrane 222 is sleeved on the outer surface of the stirring blade 221.

Embodiment 3

[0038] The third embodiment is the same as the first embodiment except for the following contents:

[0039] Such as Figure 4-b As shown, the side of the stirring rod 22 is symmetrically screwed with two stirring blades 221 that can rotate about the stirring rod 22 as an axis. The length of the stirring blades 221 is slightly smaller than the height of the anaerobic fermentation tank 21.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com