Kitchen waste and sludge collaborative treatment system and method

A technology of kitchen waste and co-processing, applied in biological sludge treatment, biomass post-treatment, biomass pre-treatment, etc., can solve problems such as poor treatment effect, secondary pollution, complicated management, etc., to improve energy utilization efficiency, saving floor space, and simplifying management procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

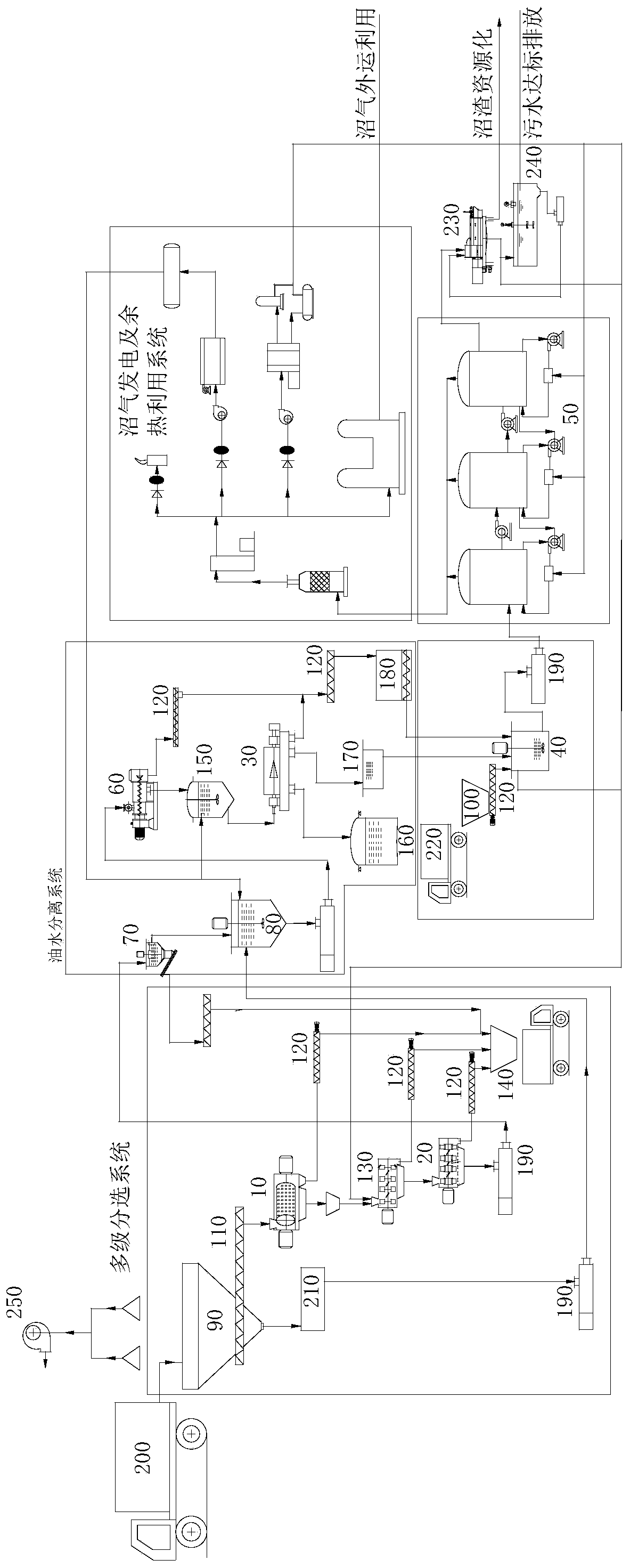

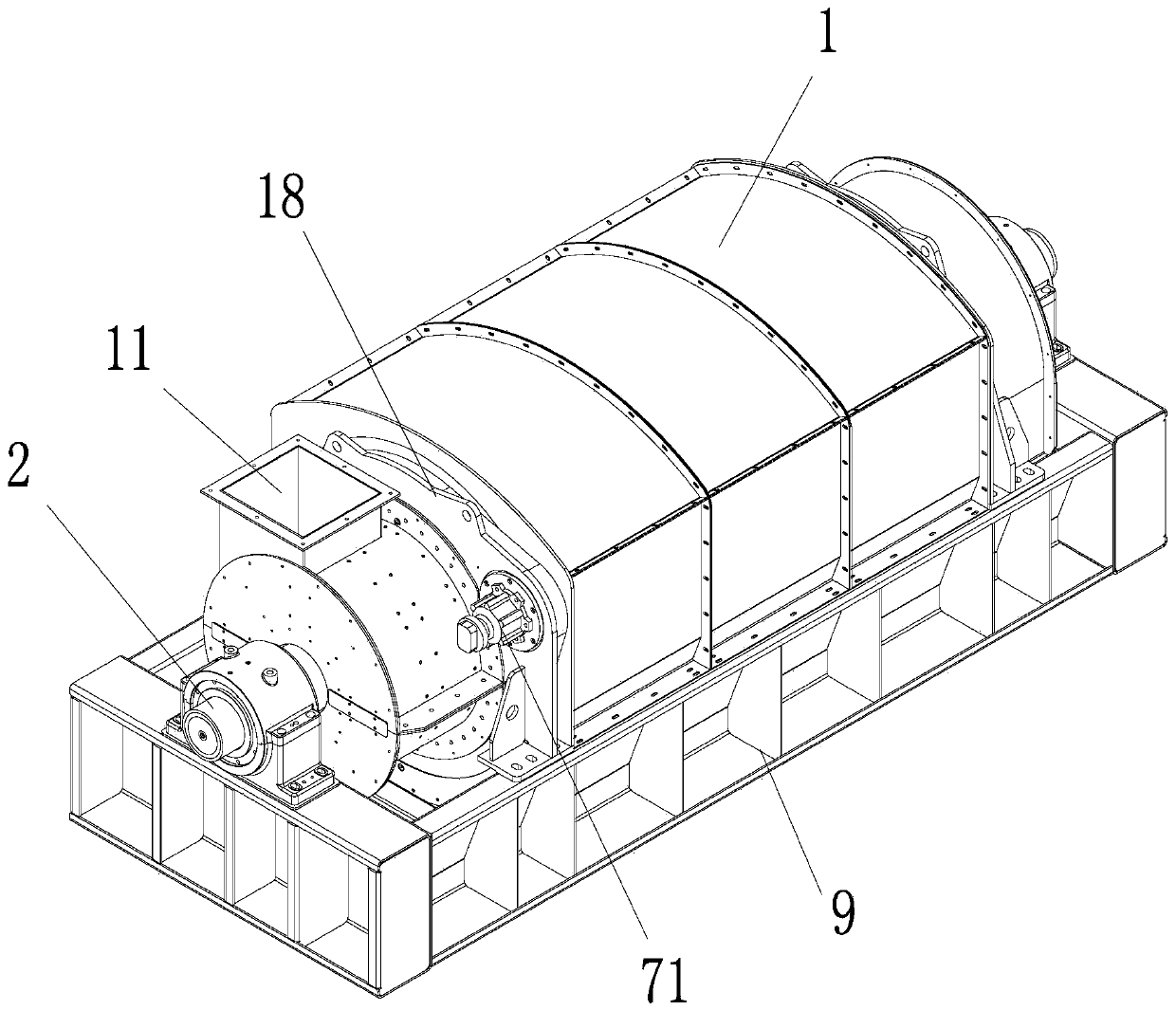

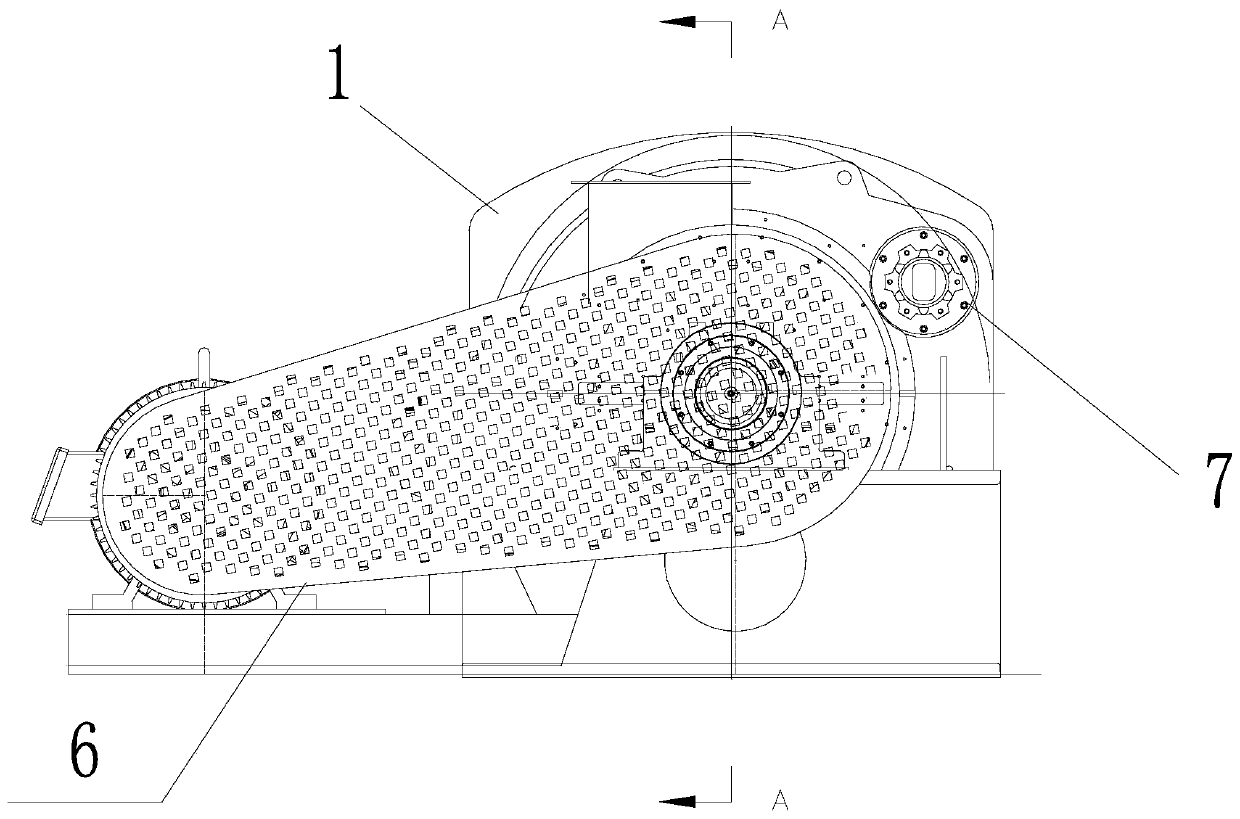

[0053] Such as figure 1 As shown, the food waste and sludge co-processing system of this embodiment includes a food waste receiving bucket 90, a sieve sorting device 10, a mixer 130, a crushing and sorting device 20, a waste residue collecting bucket 140, a sand removal Equipment 70, slurry storage equipment 80, centrifugal dehydration equipment 60, online heater 150, oil-water separation equipment 30, grease storage tank 160, liquid storage tank 170, slag storage tank 180, sludge receiving bucket 100, collaborative pulping equipment 40, Anaerobic digestion equipment 50.

[0054] Among them, the screening sorting equipment 10, the pulper 130, the pulverizing and sorting equipment 20, the desanding equipment 70, the slurry storage equipment 80, and the waste residue collecting hopper 140 form a multi-stage rapid sorting system. Centrifugal dehydration equipment 60, online heater 150, oil-water separation equipment 30, grease storage tank 160, liquid storage tank 170 and slag s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com