Kitchen waste hydrothermal treating method and device

A technology for kitchen waste and hydrothermal treatment, which is applied in the removal of solid waste and other directions, can solve the problems of high energy consumption, increased processing cost of hydrothermal reaction liquid, and high cost, and achieves low energy consumption, optimized biodegradability, and thermal energy. Low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

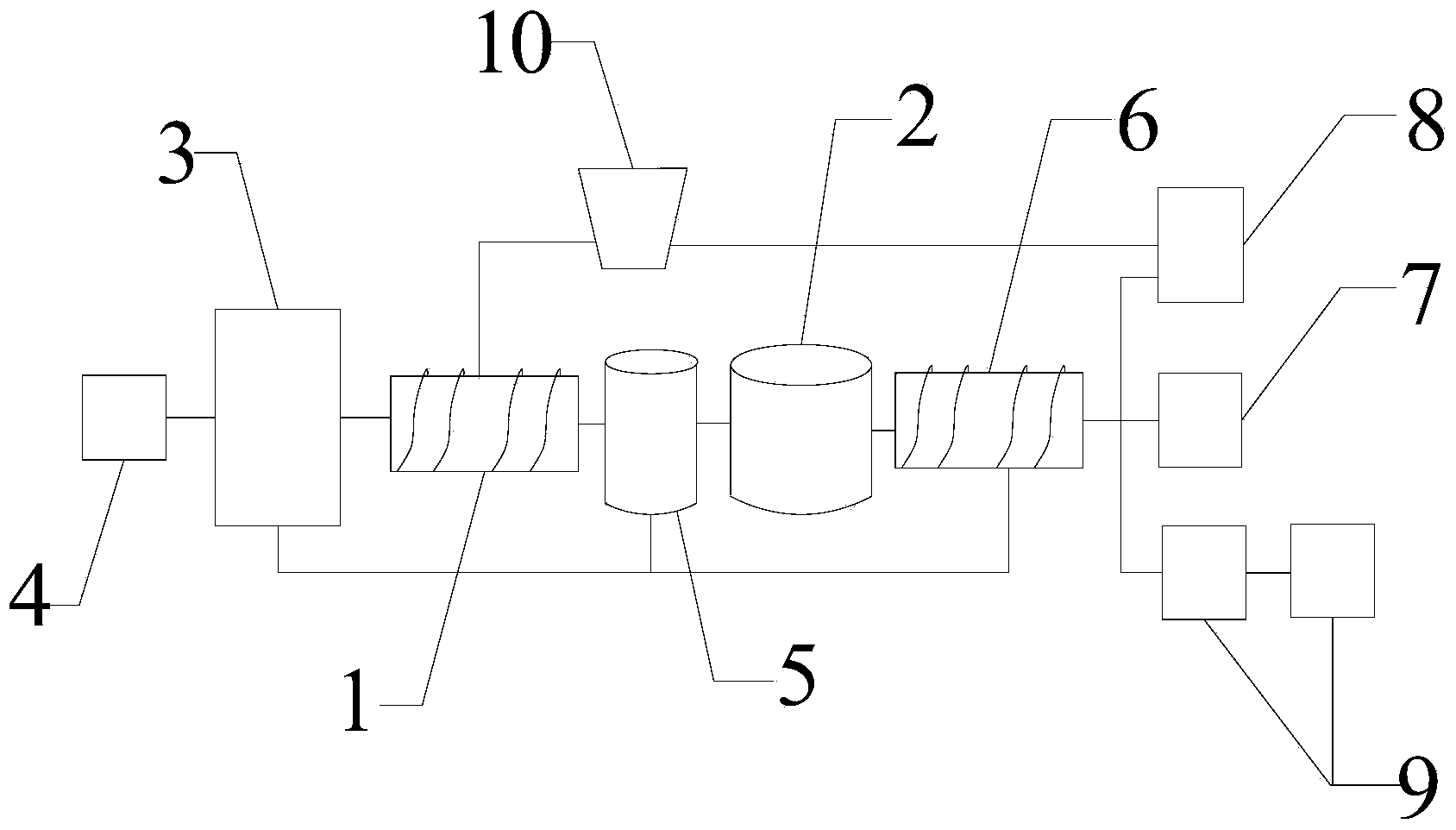

[0033] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0034] Such as figure 1 Shown, a kind of food waste hydrothermal treatment method comprises the following steps:

[0035] Removal of impurities: removal of large pieces of foreign matter in the kitchen waste;

[0036] Grease separation: preheat the food waste after removing impurities, and keep it standing still to extract the upper layer of waste oil in the food waste;

[0037] First-level hydrothermal reaction: The food waste separated from oil, that is, the reactant, is heated sequentially by electric heating. The hydrothermal reaction temperature is between 200°C and 250°C, and the reaction time is between 5 and 25 minutes. less than 7;

[0038] Heat exchange: The reactants after the primary hydrothermal reaction are cooled by liquid to reduce the temperature to between 130°C and 180°C;

[0039] Secondary h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com