A kind of treatment method of terephthalic acid wastewater

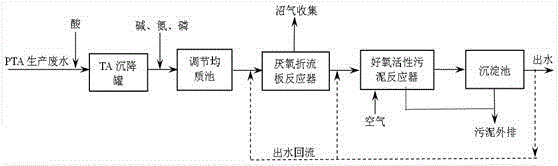

A technology of terephthalic acid and a treatment method, which is applied in the field of treatment of high-concentration terephthalic acid production wastewater, can solve the problem that the device occupies a large area, increases investment costs, fails to meet direct discharge requirements, and discharges excess sludge. problems, to achieve the effect of shortening residence time, shortening residence time, and small output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

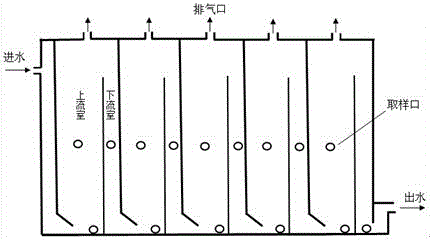

[0025] Purified terephthalic acid production wastewater (CODcr is 7870 mg / L, TA concentration is 2417mg / L) is adjusted to about 4.0 by adding acid, and pumped into TA settling tank for solid-liquid separation, and the settled TA is packaged Recycling to reduce the concentration of organic pollutants in wastewater; the wastewater after pH adjustment and solid-liquid separation (CODcr is 5100 mg / L, TA concentration is 1280mg / L) is pumped into the regulating homogeneous tank, and alkali is added to adjust When the pH is about 7.0, nitrogen and phosphorus nutrients are added according to the ratio of CODcr: N: P = 200: 5: 1; the wastewater regulated and treated by the homogeneous tank is pumped into the anaerobic baffle reactor, and the anaerobic baffle reactor Oxygen baffle reactor length × width × height = 2.23 × 0.54 × 1.26m, effective volume 1.05m 3 , the reactor is divided into five compartments by five baffles with a 45° angle at the bottom. There are five exhaust ports on t...

Embodiment 2

[0032] Processing method is as embodiment 1. .The specific operating indicators are:

[0033] The CODcr of purified terephthalic acid production wastewater is 9660mg / L, and the TA concentration is 3062mg / L.

[0034] The effluent after acid precipitation pretreatment is 6450mg / L, and the TA concentration is 1687mg / L.

[0035] Anaerobic baffle reactor effluent 620mg / L, TA concentration 34mg / L, organic volume load 3.80KgCOD / (m 3 ﹒ d).

[0036] The dissolved oxygen in the aerobic activated sludge reactor was 4mg / L, the temperature was 30°C, and the hydraulic retention time was 5h. The strains inoculated with high-efficiency degradation of terephthalic acid were YPC-TA2 and YPC-TA3.

[0037] After aerobic activated sludge treatment, the effluent of the supernatant of the sedimentation tank is 90 mg / L, the concentration of TA is 8mg / L, and the organic volume load is 1.39KgCOD / (m 3 ﹒ d).

Embodiment 3

[0039] Processing method is as embodiment 1. .The specific operating indicators are:

[0040] The CODcr of purified terephthalic acid production wastewater is 8015mg / L, and the TA concentration is 2755mg / L.

[0041] The effluent after acid precipitation pretreatment was 5575mg / L, and the TA concentration was 1428mg / L.

[0042] Anaerobic baffle reactor effluent 670mg / L, TA concentration 28mg / L, organic volume load 3.21KgCOD / (m 3 ﹒ d).

[0043] The dissolved oxygen in the aerobic activated sludge reactor is 4mg / L, the temperature is 30°C, and the hydraulic retention time is 4h. The inoculated terephthalic acid-degrading strain is YPC-TA4.

[0044] After aerobic activated sludge treatment, the effluent of the supernatant of the sedimentation tank is 75mg / L, the concentration of TA is 7mg / L, and the organic volume load is 1.44KgCOD / (m 3 ﹒ d).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com