Sludge fermentation stirring device

A technology of stirring device and sludge, applied in fertilization device, sludge treatment, sewage/sludge fertilizer, etc., can solve the problems of fatigue fracture, low oxygenation rate, and large sludge consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

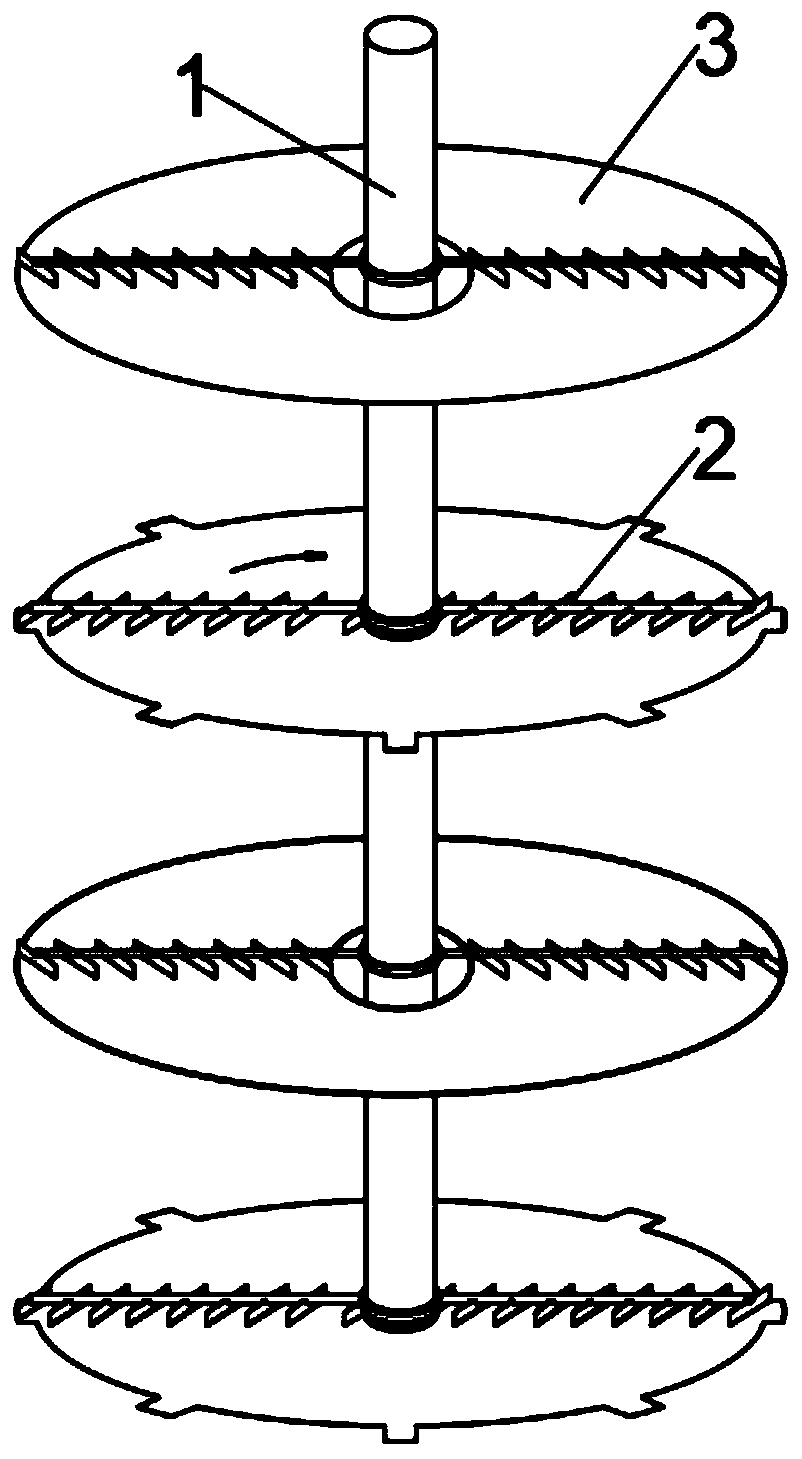

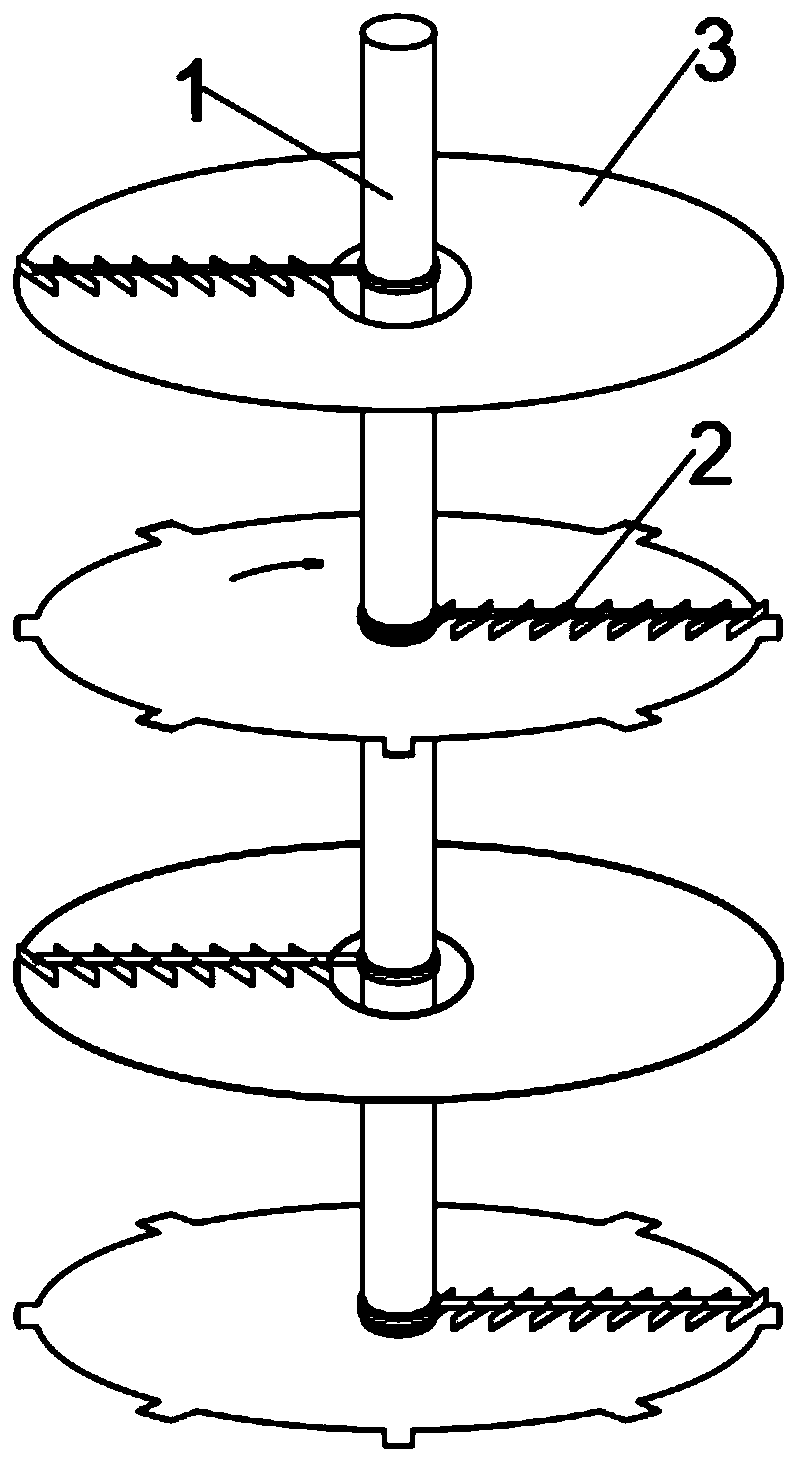

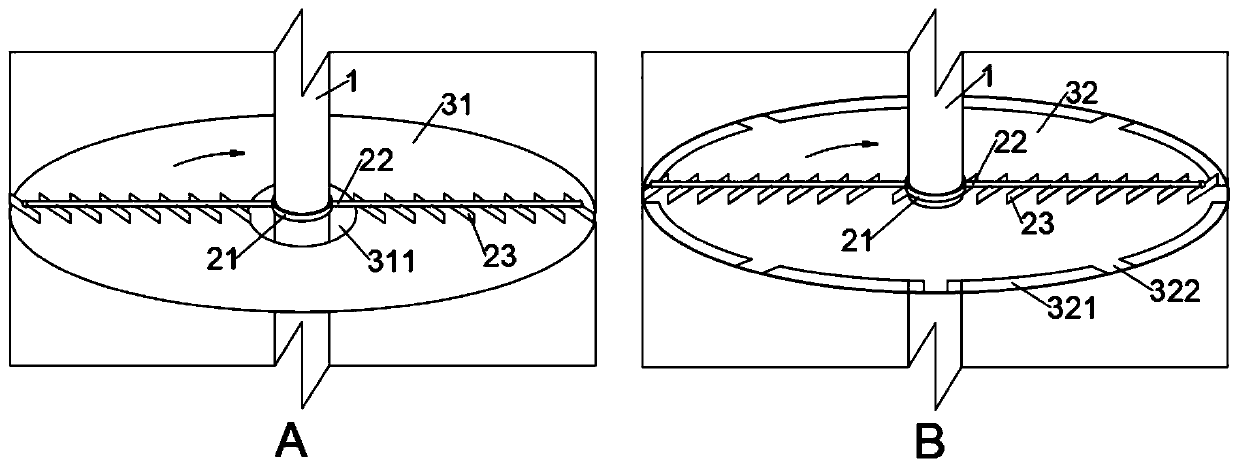

[0052] see figure 1 , providing a sludge fermentation stirring device, including a stirring main shaft 1 and a number of stirring units 2 fixed on the stirring main shaft 1; the stirring device is rotatably arranged in a sludge fermentation tower, and the sludge fermentation tower includes several Plate 3, said tray 3 includes A-type tray 31 and B-type tray 32, both of which are arranged alternately along the height direction in the tower body; said A-type tray 31 is circular, and its center is provided with The first circular opening, the diameter of the first circular opening is greater than the stirring main shaft 1, and forms an inner feeding opening 311 with the outer wall of the stirring main shaft 1; the B-type tray 32 is gear-shaped, and its center of circle is provided There is a second circular opening, and the diameter of the second circular opening is slightly larger than the stirring main shaft 1 so that the stirring main shaft 1 can realize rotary sealing with t...

Embodiment 2

[0055] see Image 6, the difference from Embodiment 1 is that, while maintaining the same shape and inclination angle of each scraper 23, the size of the scraper 23 arranged on the swing arm 22 is gradually reduced from the inside to the outside, so that from the inside to the outside The projected lengths of the arranged scrapers 23 on the swivel arm 22 gradually decrease, wherein the projected lengths of the scrapers 23 should satisfy that the areas of the circular paths formed by the scrapers 23 are the same, that is, S1'=S2' =S3'=S4'=S5'=S6'.

Embodiment 3

[0057] see Figure 7 , the difference from Embodiment 2 is that, under the condition that each scraper 23 has the same shape and size, the inclination angle of the scraper 23 arranged on the swivel arm 22 relative to the swivel arm 22 is gradually increased. , so that the projected lengths of the scrapers 23 arranged from the inside to the outside on the swing arm 22 gradually decrease, wherein the projected lengths of the scrapers 23 should satisfy that the areas of the circular paths formed by the scrapers 23 are the same, That is, S1'=S2'=S3'=S4'=S5'=S6'.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com