A New Method and Special Device for Multi-mode Vacuum Air-Conditioned Compression Casting of Supercharger Impeller

A supercharger and impeller technology, which is applied in the field of "one-tube multi-mode" vacuum air-conditioned pressure casting of supercharger impellers, can solve the problems of low production efficiency and high production cost, and achieve the improvement of production efficiency, casting quality and elongation Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

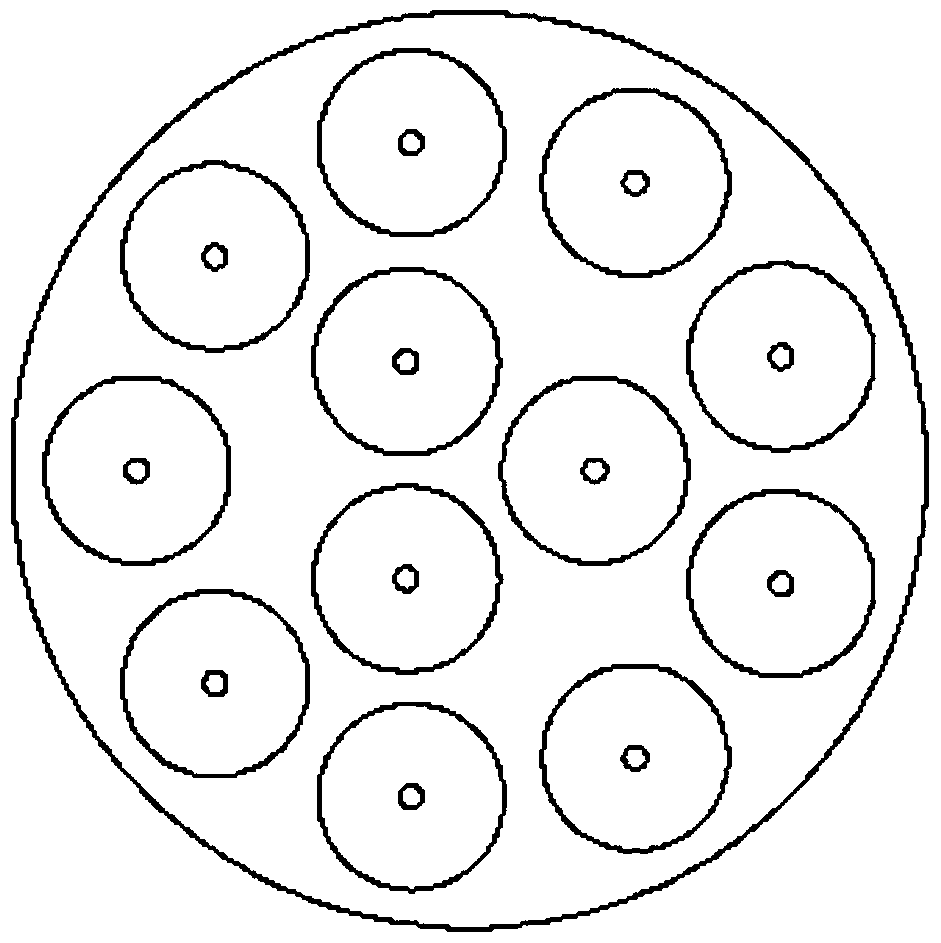

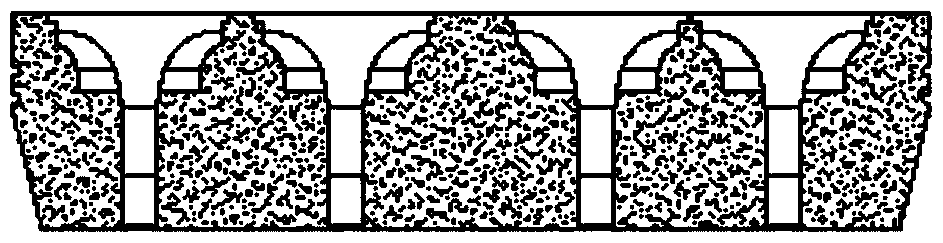

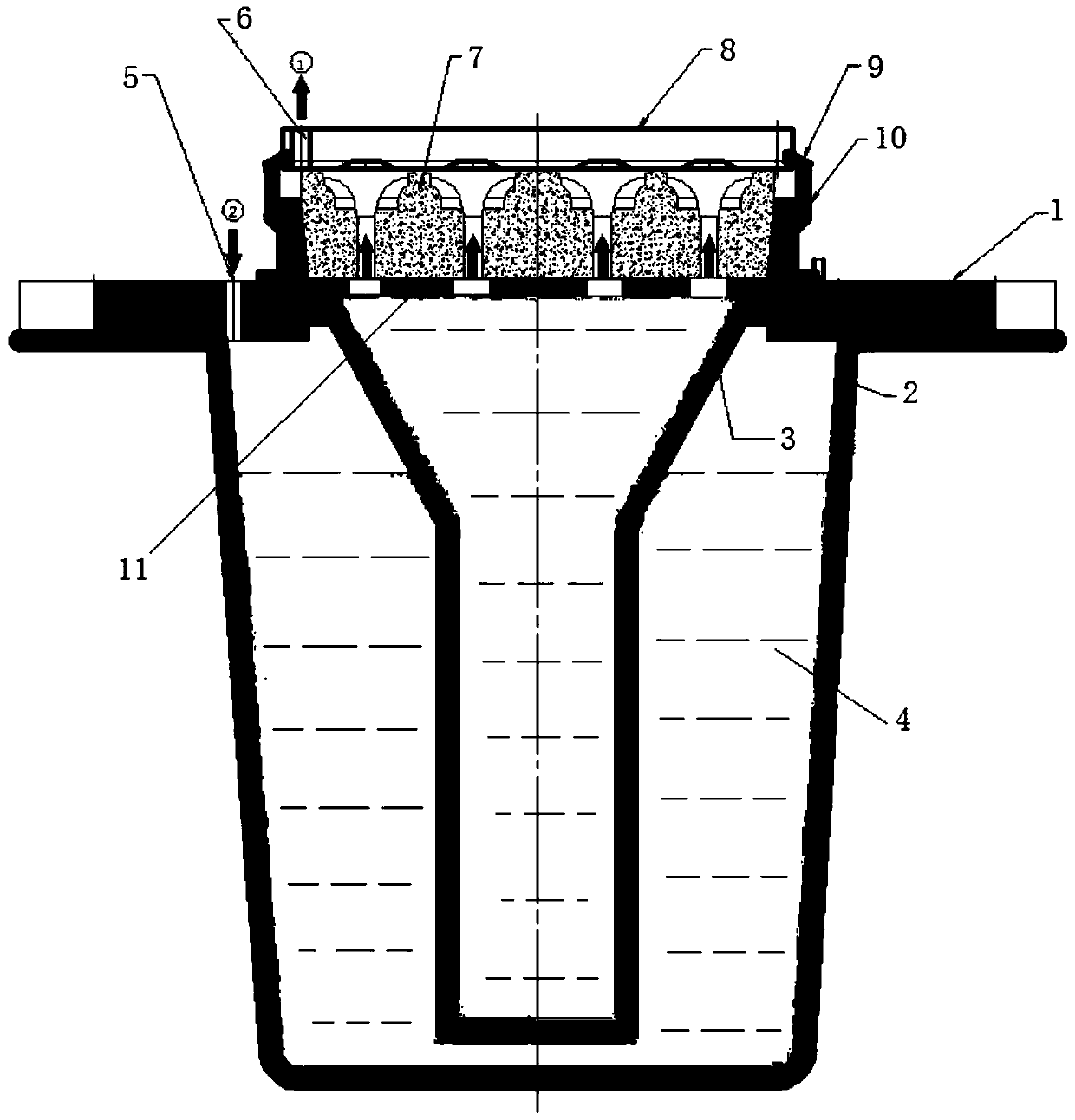

[0030] Such as Figure 1-Figure 4 As shown, the special device for "one tube multi-mode" vacuum pressure casting of the booster impeller of the present invention mainly includes: cover plate 1, crucible 2, riser tube 3, aluminum liquid 4, positive pressure gas circuit 5, vacuum pipeline 6 , gypsum shell 7, cold iron 8, sealing ring 9, protective cover 10, etc., the specific structure is as follows:

[0031] Such as image 3 As shown, the top of the crucible 2 is provided with a cover plate 1 , the lower end of the conical liquid riser 3 extends into the aluminum liquid 4 in the crucible 2 , and the upper end of the liquid riser 3 is arranged on the cover plate 1 . A partition with holes 11 and a gypsum shell 7 are arranged on the top of the liquid riser 3 , and the liquid riser 3 and the gypsum shell 7 communicate through the through holes on the partition with holes 11 . The outer side of the gypsum shell 7 is provided with a protective cover 10, and the top of the gypsum s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com