Method for improving gas yield of biogas fermentation

A biogas fermentation and gas production technology, applied in the direction of fermentation, waste fuel, etc., can solve the problems of human and financial loss, waste of fermentation resources, large biogas production, etc., and achieve the effects of short fermentation cycle, promotion of decomposition, and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

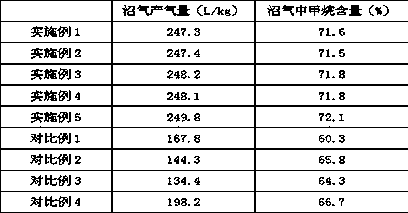

Examples

Embodiment 1

[0032] A method for improving the gas yield of biogas fermentation, comprising the following steps:

[0033] (1) Cut and pulverize the dry straw to make straw powder, add water to mix, then transfer to an ultrasonic crusher, and perform intermittent crushing to obtain straw slag;

[0034] (2) Mix the straw residue and 0.02 times the weight of calcium peroxide evenly and transfer it to the reactor, then add water 8 times the weight of the straw residue, stir well, seal the reactor, and treat it at 40kPa and 130°C for 20 minutes. Cool naturally to room temperature to obtain the hydrothermally pretreated straw slurry for subsequent use;

[0035] (3) Preparation of inoculum: Mix activated sludge and human and animal manure evenly according to the mass ratio of 1:0.3, cover with plastic film, stack for 2 days, and then use 60 Co gamma-ray irradiation to obtain the inoculum;

[0036] (4) Add the inoculum obtained in step (4) to the straw slurry obtained in step (2), then add magne...

Embodiment 2

[0044] A method for improving the gas yield of biogas fermentation, comprising the following steps:

[0045] (1) Cut and pulverize the dry straw to make straw powder, add water to mix, then transfer to an ultrasonic crusher, and perform intermittent crushing to obtain straw slag;

[0046] (2) Mix the straw residue with 0.03 times the weight of calcium peroxide evenly and transfer it to the reactor, then add water 10 times the weight of the straw residue, stir well, seal the reactor, and treat it at 60kPa and 150°C for 30 minutes. Cool naturally to room temperature to obtain the hydrothermally pretreated straw slurry for subsequent use;

[0047] (3) Preparation of inoculum: Mix activated sludge with human and animal manure at a mass ratio of 1: 0.4, cover with plastic film, stack for 3 days, and then use 60 Co gamma-ray irradiation to obtain the inoculum;

[0048] (4) Add the inoculum obtained in step (4) to the straw slurry obtained in step (2), then add magnesium-based oliv...

Embodiment 3

[0056] A method for improving the gas yield of biogas fermentation, comprising the following steps:

[0057] (1) Cut and pulverize the dry straw to make straw powder, add water to mix, then transfer to an ultrasonic crusher, and perform intermittent crushing to obtain straw slag;

[0058] (2) Mix the straw residue with 0.02 times the weight of calcium peroxide evenly and transfer it to the reactor, then add water 10 times the weight of the straw residue, stir well, seal the reactor, and treat it at 40kPa and 150°C for 20 minutes. Cool naturally to room temperature to obtain the hydrothermally pretreated straw slurry for subsequent use;

[0059] (3) Preparation of inoculum: Mix activated sludge with human and animal manure according to the mass ratio of 1: 0.4, cover with plastic film, stack retting for 2 days, and then use 60 Co gamma-ray irradiation to obtain the inoculum;

[0060] (4) Add the inoculum obtained in step (4) to the straw slurry obtained in step (2), then add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com