A kind of compound metal polluted alfalfa reutilization method

A compound metal and alfalfa technology, which is applied in the field of compound metal contaminated alfalfa reuse, can solve the problems of insufficient research on alfalfa reuse, inhibition, toxicity, etc., and achieve the effect of improving the utilization rate of biomass resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In this example, the fermentation raw materials of the anaerobic fermentation experiment were selected from the alfalfa straw and cow dung polluted by the composite metal, and the part above the root of the alfalfa was selected. Alfalfa grass and cow dung were taken from Xuanhua District, Zhangjiakou. The concentration of each metal in alfalfa grass is: magnesium 4300mg / kg, calcium 11000mg / kg, zinc 42mg / kg, iron 2000mg / kg, nickel 1.19mg / kg, copper 100mg / kg, chromium 4.03mg / kg.

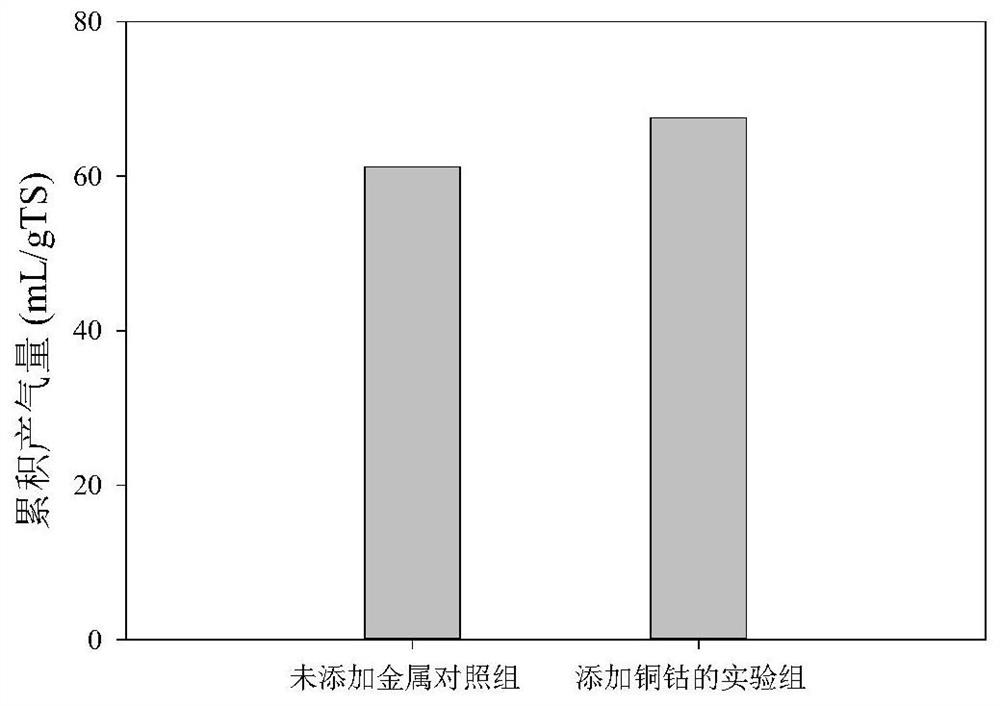

[0044] The air-dried alfalfa straw was ground with a pulverizer and passed through a 0.5mm standard soil sieve. The dry matter ratio of alfalfa straw and cow dung is 1:2. The total volume of the anaerobic fermentation device tank is 500mL, the working volume is 300mL, and the total solid concentration is 8%. The fermentation raw materials and deionized water were added according to the above proportions, and then 10.0 mg / L of copper and 1.0 mg / L of cobalt were added to the fermentation tank, a...

Embodiment 2

[0046] In this example, the fermentation raw materials of the anaerobic fermentation experiment were selected from the alfalfa straw and cow dung polluted by the composite metal, and the part above the root of the alfalfa was selected. The air-dried alfalfa straw was ground with a pulverizer and passed through a 0.5mm standard soil sieve. The concentration of each metal in alfalfa grass is: magnesium 4000mg / kg, calcium 11000mg / kg, zinc 36mg / kg, iron 1500mg / kg, nickel 7.81mg / kg, copper 300mg / kg, chromium 3.89mg / kg. Alfalfa grass and cow dung were taken from Xuanhua District, Zhangjiakou. The dry matter ratio of alfalfa straw and cow dung is 1:1.5. The total volume of the anaerobic fermentation device tank is 500mL, the working volume is 300mL, and the total solid concentration is 10%. The fermentation raw materials and deionized water were added according to the above proportions, and then 8.0 mg / L of copper and 0.5 mg / L of cobalt were added to the fermentation tank, and then...

Embodiment 3

[0048] In this example, the fermentation raw materials of the anaerobic fermentation experiment were selected from the alfalfa straw and cow dung polluted by the composite metal, and the part above the root of the alfalfa was selected. The air-dried alfalfa straw was ground with a pulverizer and passed through a 0.5mm standard soil sieve. The concentration of each metal in alfalfa grass is: magnesium 4000mg / kg, calcium 7900mg / kg, zinc 20mg / kg, iron 1500mg / kg, nickel 0.81mg / kg, copper 200mg / kg, chromium 4.03mg / kg. Alfalfa grass and cow dung were taken from Xuanhua District, Zhangjiakou. The dry matter ratio of alfalfa straw and cow dung is 1:1. The total volume of the anaerobic fermentation device tank is 500mL, the working volume is 300mL, and the total solid concentration is 12%. The fermentation raw materials and deionized water were added according to the above proportions, and then 15.0 mg / L of copper and 2.0 mg / L of cobalt were added to the fermenter, and then stirred f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com