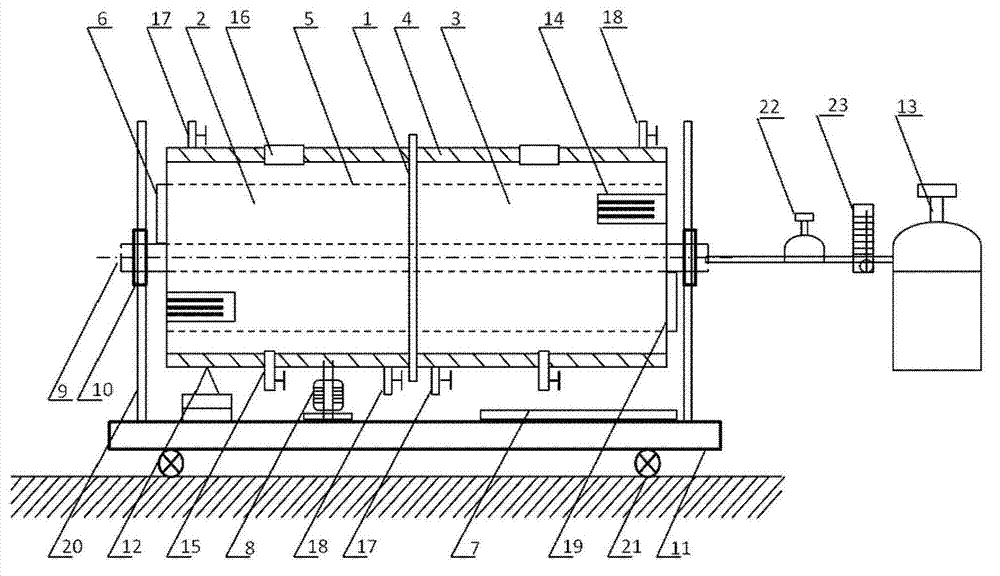

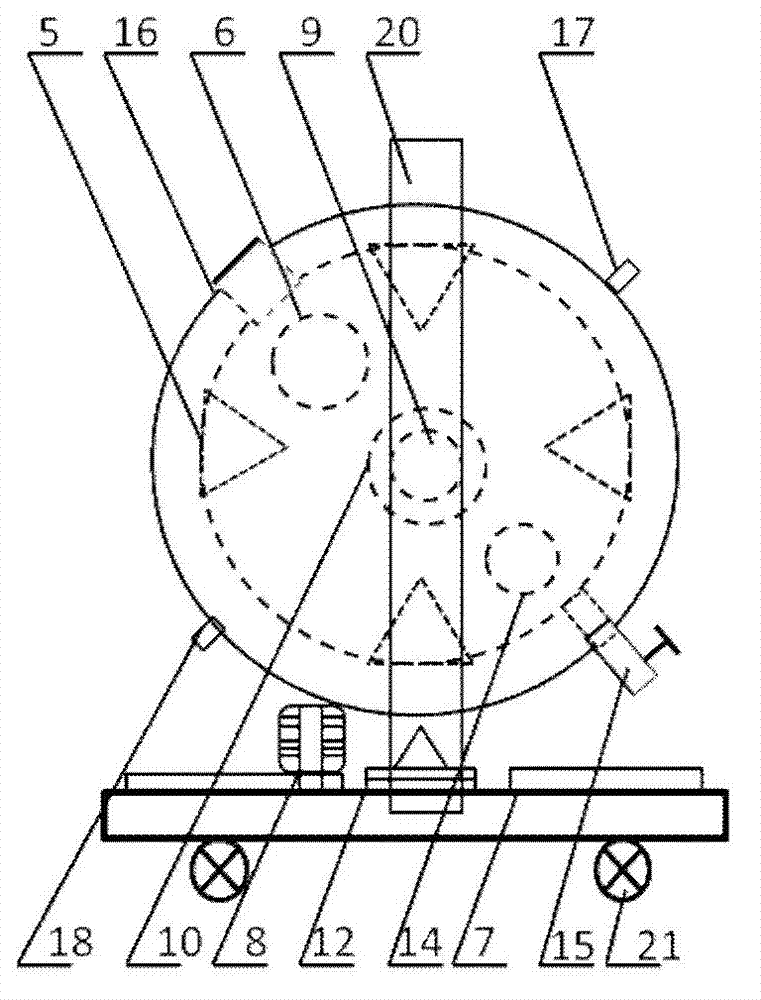

Device and method for temperature-controlled aerobic-anaerobic coupled biological hydrogen production

A hydrogen production device and biological hydrogen production technology, which are applied in biochemical equipment and methods, gas production bioreactors, biochemical instruments, etc., can solve the problems of high pretreatment requirements, large floor space, unstable operation, etc. Improve processing capacity, reduce floor space, and ensure the effect of microbial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0055] A specific example is as follows:

[0056] Good temperature control without power - the design parameters of the anaerobic coupled biological hydrogen production device are the tank height-to-diameter ratio of 2:1, the overall size of 2m×1m, and the total volume of 1.5m 3 , in which the effective volume of the pretreatment chamber is 0.5m 3 , the effective volume of the anaerobic hydrogen production chamber is 1.0m 3 . The straw and pig manure are mixed and crushed according to the mass ratio of 5:1, and then packed into an aerobic chamber for aerobic decomposition pretreatment, and the filling amount is 50% of the effective volume. After 10 days of decomposition, the material is transferred to the anaerobic hydrogen production room through the one-way openable valve, and the high-efficiency hydrogen production bacteria are added through the sampling port to strengthen the hydrogen production. At the same time, the unpowered temperature control system is started to ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com