Ammonification anaerobic fermentation equipment and method for production of straw biogas

An anaerobic fermentation and straw biology technology, applied in biochemical equipment and methods, gas production bioreactors, bioreactor/fermentation tank combinations, etc., can solve the problems of low efficiency of straw anaerobic fermentation, complex equipment structure, and production costs Advanced problems, to achieve the effect of improving cell transformation rate, improving economic benefits, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing. But the content of the present invention is not limited thereto.

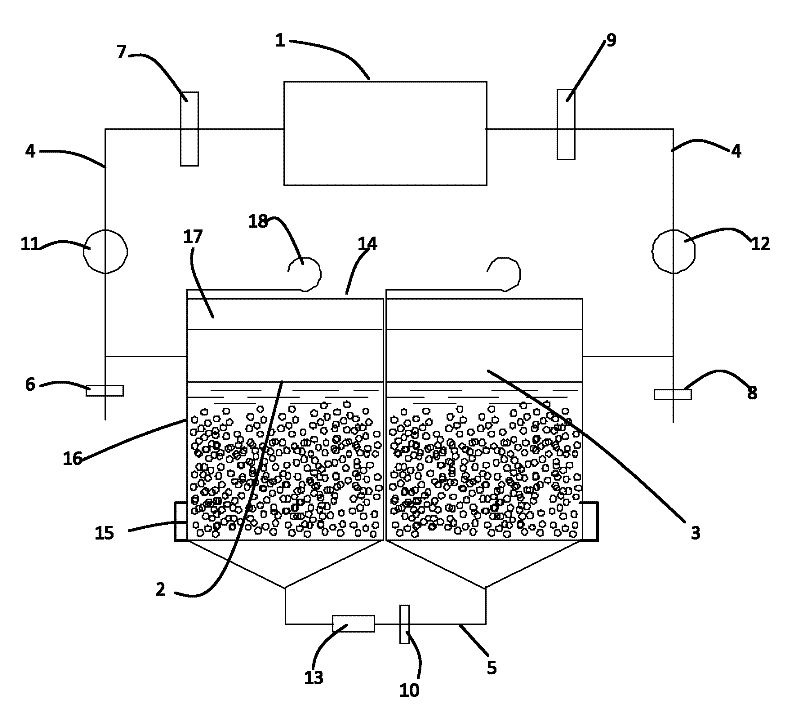

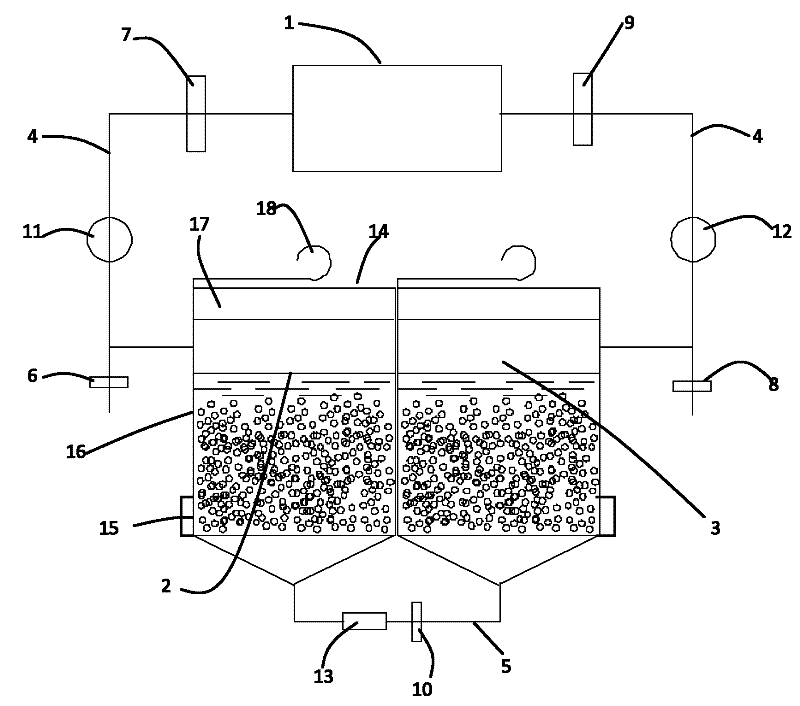

[0031] Please refer to figure 1 , an ammonification anaerobic fermentation equipment for producing straw biogas according to the present invention, which includes a gas storage tank 1, a first reaction chamber 2, a second reaction chamber 3, a gas pipeline 4, a fermentation liquid return pipe 5, First emptying valve 6 , first air outlet valve 7 , second emptying valve 8 , second air outlet valve 9 , stop valve 10 , first gas purification device 11 , second gas purification device 12 , and electrothermal compensation device 13 .

[0032] The first reaction chamber 2 and the second reaction chamber 3 are respectively connected to the gas storage tank 1 through gas pipelines 4 . The gas pipeline 4 connecting the first reaction chamber 2 and the gas storage tank 1 is provided with a first emptying valve 6 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com