Preparation method for papaya wine

A kind of papaya wine and papaya technology, applied in the field of food processing, can solve the problem that sulfur dioxide is not easy to drink for a long time, and achieve the effects of removing fat, improving sleep and promoting metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

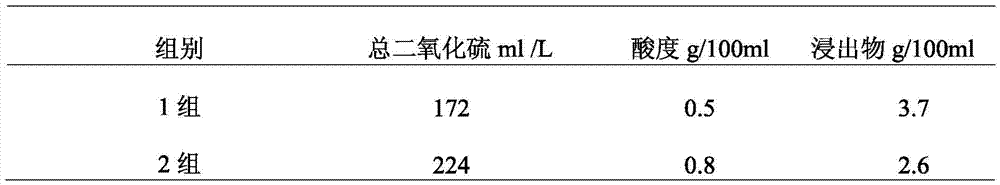

Examples

Embodiment 1

[0037] S1: Remove the peel and seeds from the fresh papaya, take 60 parts by weight of the peeled papaya and 10 parts by weight of grapes, mash it together, heat it in a water bath at 40°C for 10 minutes, and then add 150 parts by weight to cook Of corn flour, 20 parts by weight of purified water and 0.5 parts by weight of koji, and then fermented at 30° C. for 18 hours to obtain a fermented product.

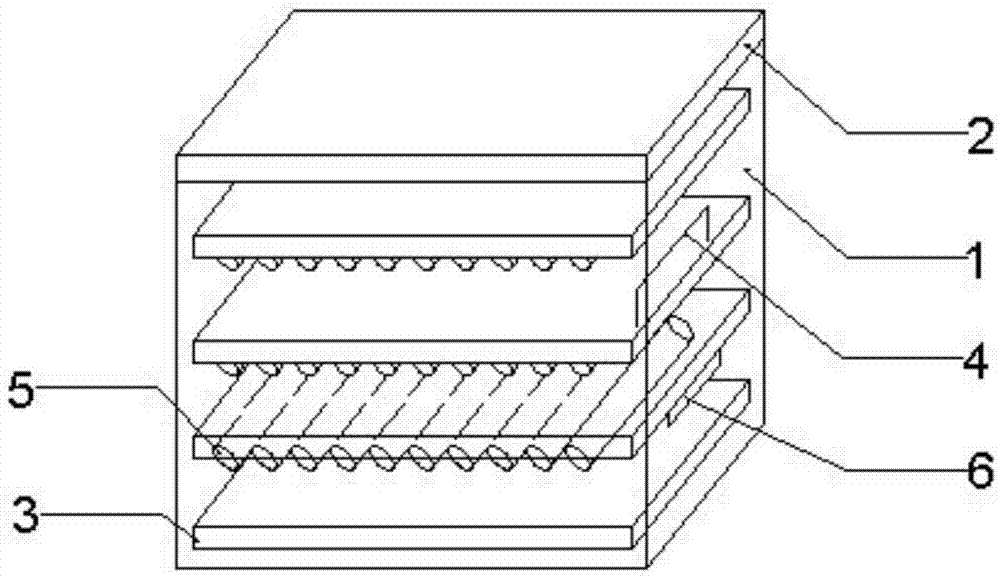

[0038] S2: After adjusting the pH of the primary fermentation product to 3.5 with citric acid, the primary fermentation product is equally divided into three equal parts and placed in a fermentation tank. The present invention provides a schematic structural diagram of a fermentation tank, such as figure 1 As shown, the fermentation tank includes:

[0039] The tank body 1 is a hollow rectangular parallelepiped. The inside of the tank body 1 includes a rectangular bottom surface, two opposite first side surfaces and two opposite second side surfaces, the area of the first side surfa...

Embodiment 2

[0050] S1: Remove the peel and seeds from the fresh papaya, and take 100 parts by weight of the peeled papaya and 30 parts by weight of grapes to mash together, heat it in a water bath at 50°C for 15 minutes, and then add 300 parts by weight to cook Of corn flour, 30 parts by weight of purified water and 1 part by weight of koji, and then fermented at 35°C for 24 hours to obtain a fermented product.

[0051] S2: After adjusting the pH of the primary fermentation product to 5 with citric acid, the primary fermentation product is equally divided into three equal parts and placed in a fermentation tank, the fermentation tank includes:

[0052] A trough body, which is a hollow cuboid, the interior of the trough body includes a rectangular bottom surface, two opposite first side surfaces, and two opposite second side surfaces, the area of the first side surface is larger than the second side surface;

[0053] A sealing cover, which can open and close the tank body;

[0054] The inside of...

Embodiment 3

[0063] S1: Remove the peel and seeds from the fresh papaya, take 80 parts by weight of the peeled papaya and 20 parts by weight of grapes, mash together, heat it in a water bath at 45°C for 12 minutes, and then add 200 parts by weight to cook Of corn flour, 25 parts by weight of purified water and 0.8 parts by weight of koji, and then fermented at 32° C. for 20 hours to obtain a fermented product.

[0064] S2: After adjusting the pH of the primary fermentation product to 4 with citric acid, the primary fermentation product is divided into three equal parts and placed in a fermentation tank, the fermentation tank includes:

[0065] A trough body, which is a hollow cuboid, the interior of the trough body includes a rectangular bottom surface, two opposite first side surfaces, and two opposite second side surfaces, the area of the first side surface is larger than the second side surface;

[0066] A sealing cover, which can open and close the tank body;

[0067] The inside of the tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com