Oil-water separation process of pulpifying centrifugal treatment system

A technology of centrifugal treatment and oil-water separation, which is used in energy and wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can improve the oil concentration, reduce the production of biogas residue, and avoid re-consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

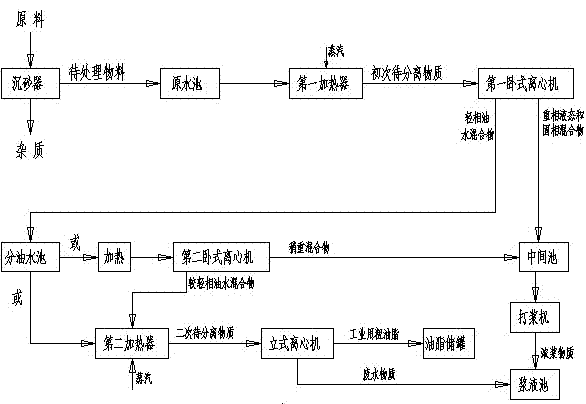

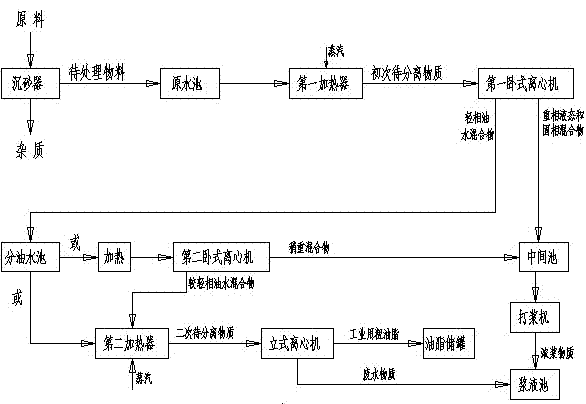

[0024] Such as figure 1 As shown, the embodiment of the present invention is an oil-water separation process of a slurry centrifugal treatment system. The slurry centrifugal treatment system includes a beater, a sand settler, a horizontal centrifuge, a heater, a vertical centrifuge and a slurry tank , the oil-water separation process includes the following steps:

[0025] Preparation steps: prepare a raw material containing oil and fat, and the raw material has been crushed and screened in advance;

[0026] Sand settling and impurity removal step: Put the raw materials into the sand settler one after another. There are partition chambers arranged side by side in a straight line in the middle of the sand chamber; the raw materials are divided into two parts after being filtered by the partition chamber: one part is impurities, and the other pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com