Wastewater treatment system suitable for small and medium size farms

A technology for wastewater treatment systems and farms, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, applications, etc., can solve the problems of complex process control, increased processing difficulty, high operating costs, etc. Oxygen fermentation efficiency, low construction and operating costs, and the effect of improving fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

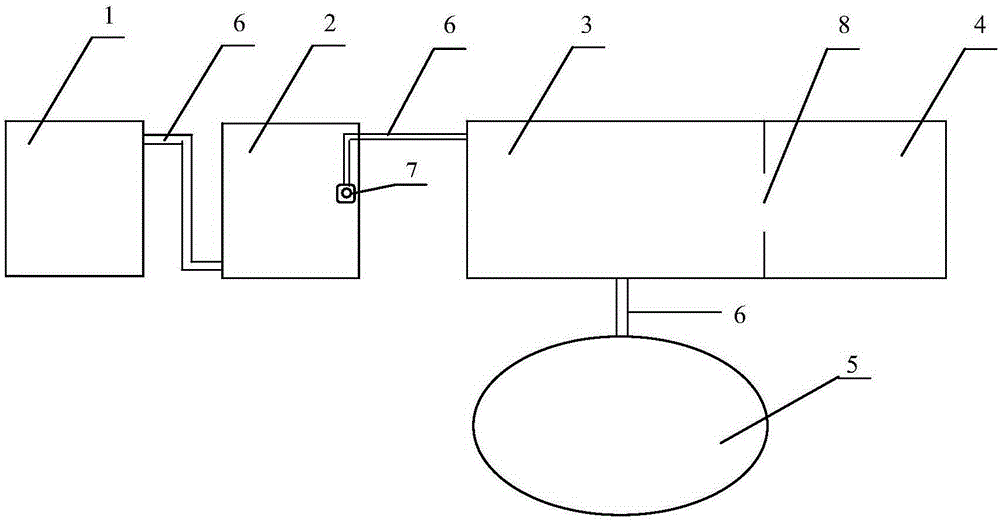

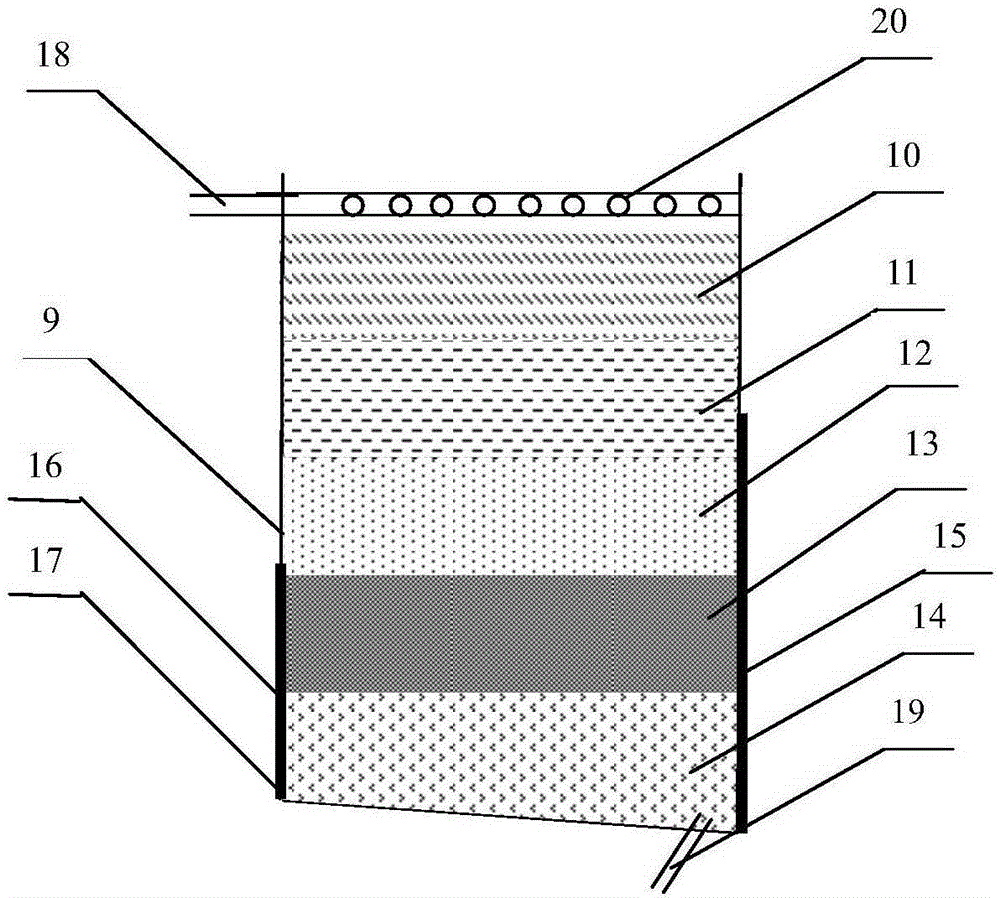

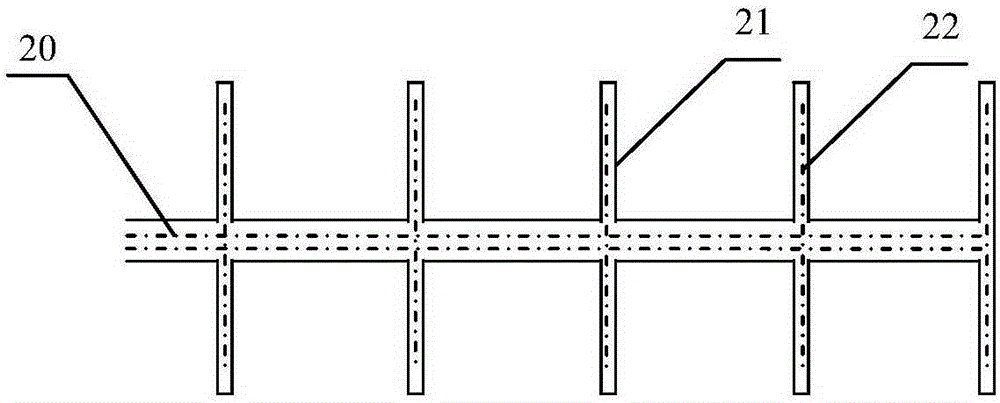

[0060] A wastewater treatment system suitable for small and medium-sized farms, the structure is as follows figure 1 As shown, it includes a sedimentation tank 1, a regulating tank 2, a high-efficiency filter tank 3, a plant purification tank 5 and a composting field 4 connected in sequence. The sedimentation tank 1 is communicated with the regulating tank 2 through a connecting pipe 6, and an inlet pump 7 is arranged in the regulating tank. The water inlet pump 7 communicates with the high efficiency filter pool 3 through the communication pipe 6 . The high-efficiency filter pool 3 includes two high-efficiency filter pool modules, the high-efficiency filter pool module includes a filter pool cavity and filter material arranged inside the filter pool cavity, two high-efficiency filter pool modules arranged in parallel, and the adjacent high-efficiency filter pool modules Separated by partitions, the partitions are movably inserted on the high-efficiency filter pool, and the hi...

Embodiment 2

[0067] Utilize the system of embodiment 1 to carry out the method for farm waste water treatment, comprise steps as follows:

[0068] The standard discharge treatment system suitable for small and medium-sized farm wastewater The relevant design parameters for the wastewater treatment of 1500 pig farms are as follows:

[0069] A farm of 1,500 pigs produces 20m of wastewater per day 3 , the system design is as follows:

[0070] (1) Sedimentation tank 1 is made of brick concrete with a volume of 6m 3 , the size is length × width × height = 6.0m × 1.0m × 1.0m;

[0071] (2) The adjustment pool 2 is made of brick concrete with a volume of 12m 3 , the size is length × width × height = 6.0m × 1.0m × 2.0m;

[0072] (3) The high-efficiency filter tank 3 system is a glass fiber reinforced plastic structure, and the design hydraulic load is 2.0m 3 / ㎡·d, the total design volume of each module is 5.0m 3 , the size is length × width × height = 5.0m × 2.0m × 0.5m. The height of the in...

Embodiment 3

[0087] Wastewater treatment of 3,000 pig farms:

[0088] The method for farm waste water treatment as described in embodiment 2, difference is:

[0089] A farm with 3,000 pigs in stock produces 40m of wastewater per day 3 , the system design is as follows:

[0090] (1) Sedimentation tank 1 is made of brick concrete with a volume of 10m 3 , the size is length × width × height = 5.0m × 2.0m × 1.0m;

[0091] (2) The adjustment pool 2 is made of brick concrete with a volume of 20m 3 , the size is length × width × height = 5.0m × 2.0m × 2.0m;

[0092] (3) The high-efficiency filter tank 3 system is a glass fiber reinforced plastic structure, and the design hydraulic load is 2.0m 3 / ㎡·d, design 4 modules, each module design total volume is 5.0m 3 , the size is length × width × height = 5.0m × 2.0m × 0.5m. The internal filler is designed to have a height of 20cm for ceramsite, a particle size of 3cm, a height of 15cm for humic acid, a particle size of 1.5mm, a height of 15cm f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com