Patents

Literature

56results about How to "Small and efficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

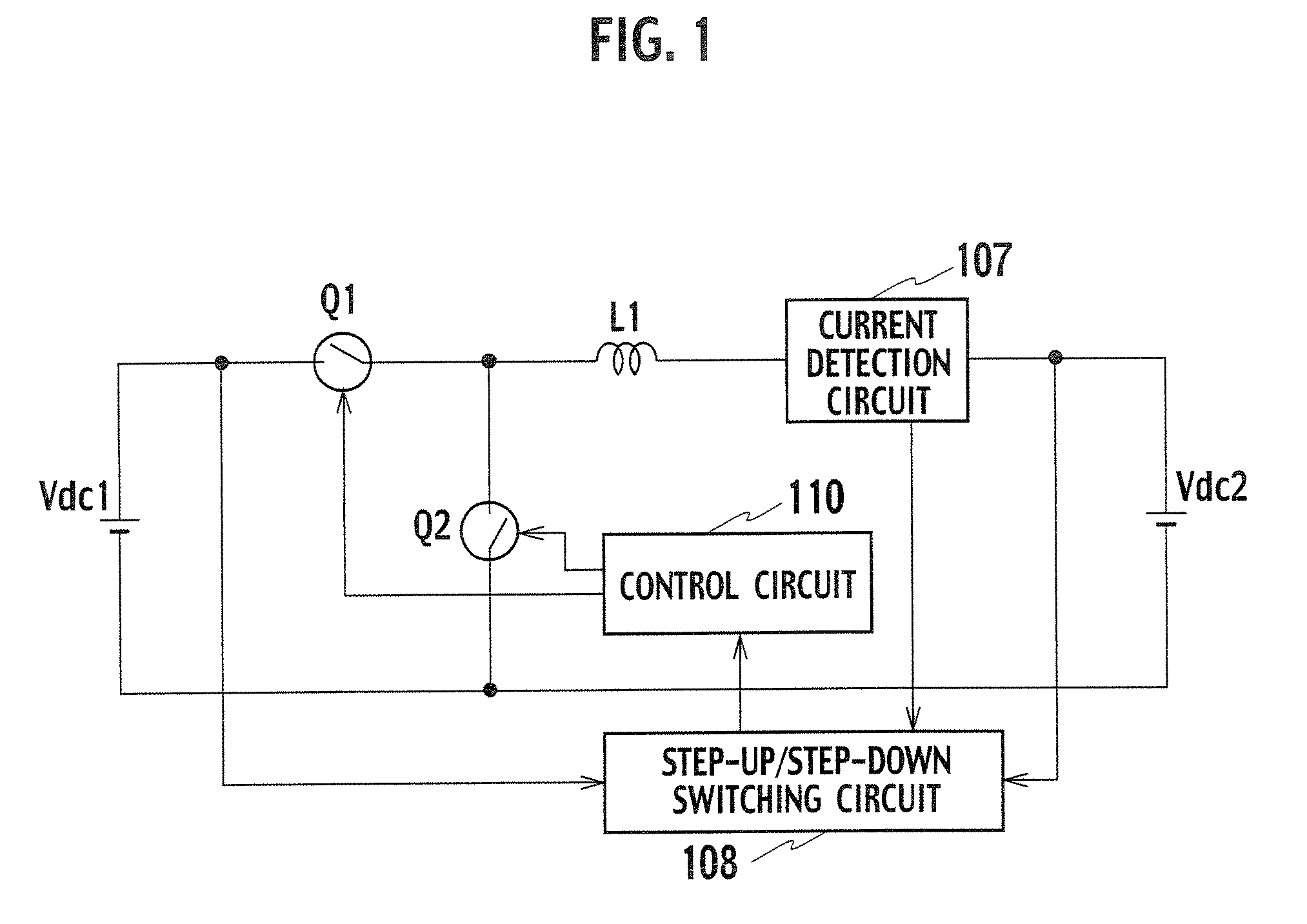

Dc-dc converter

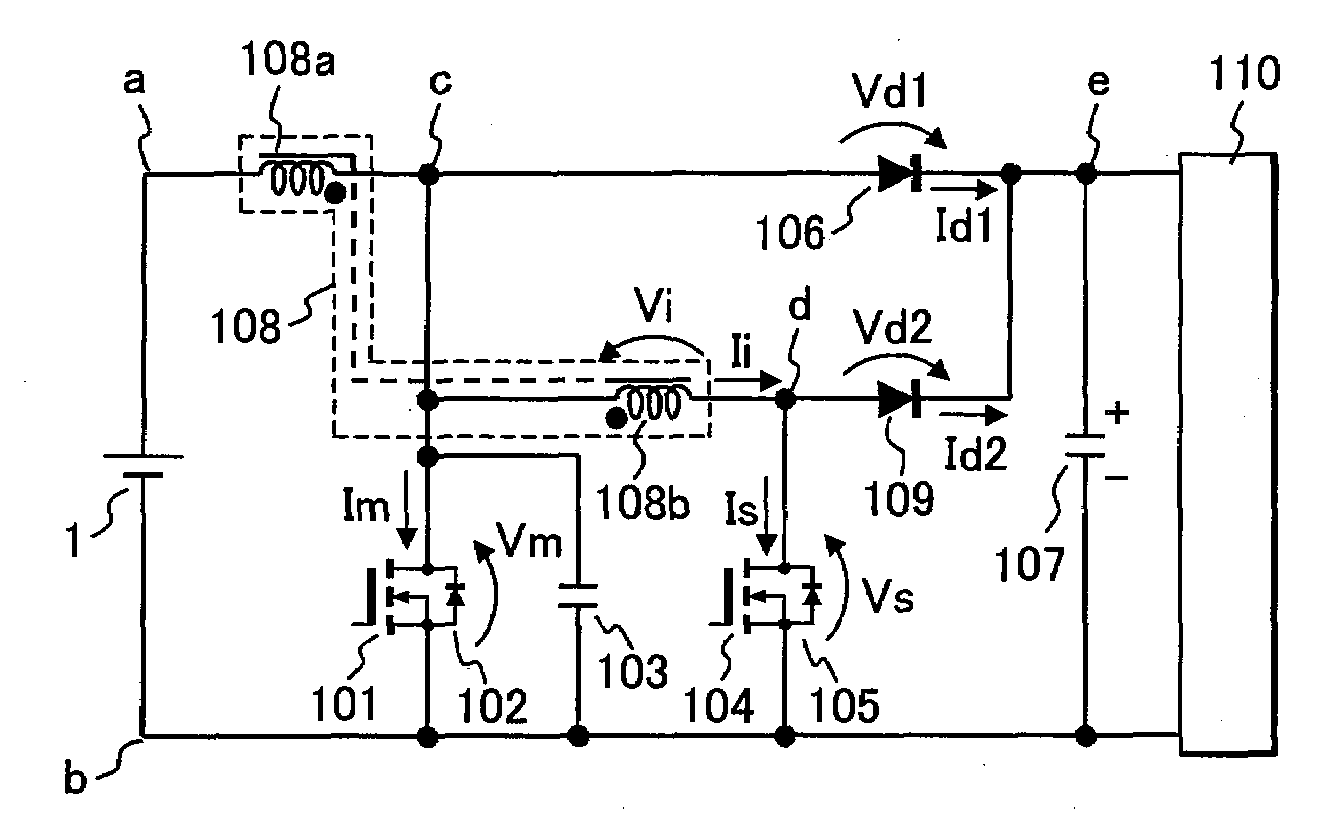

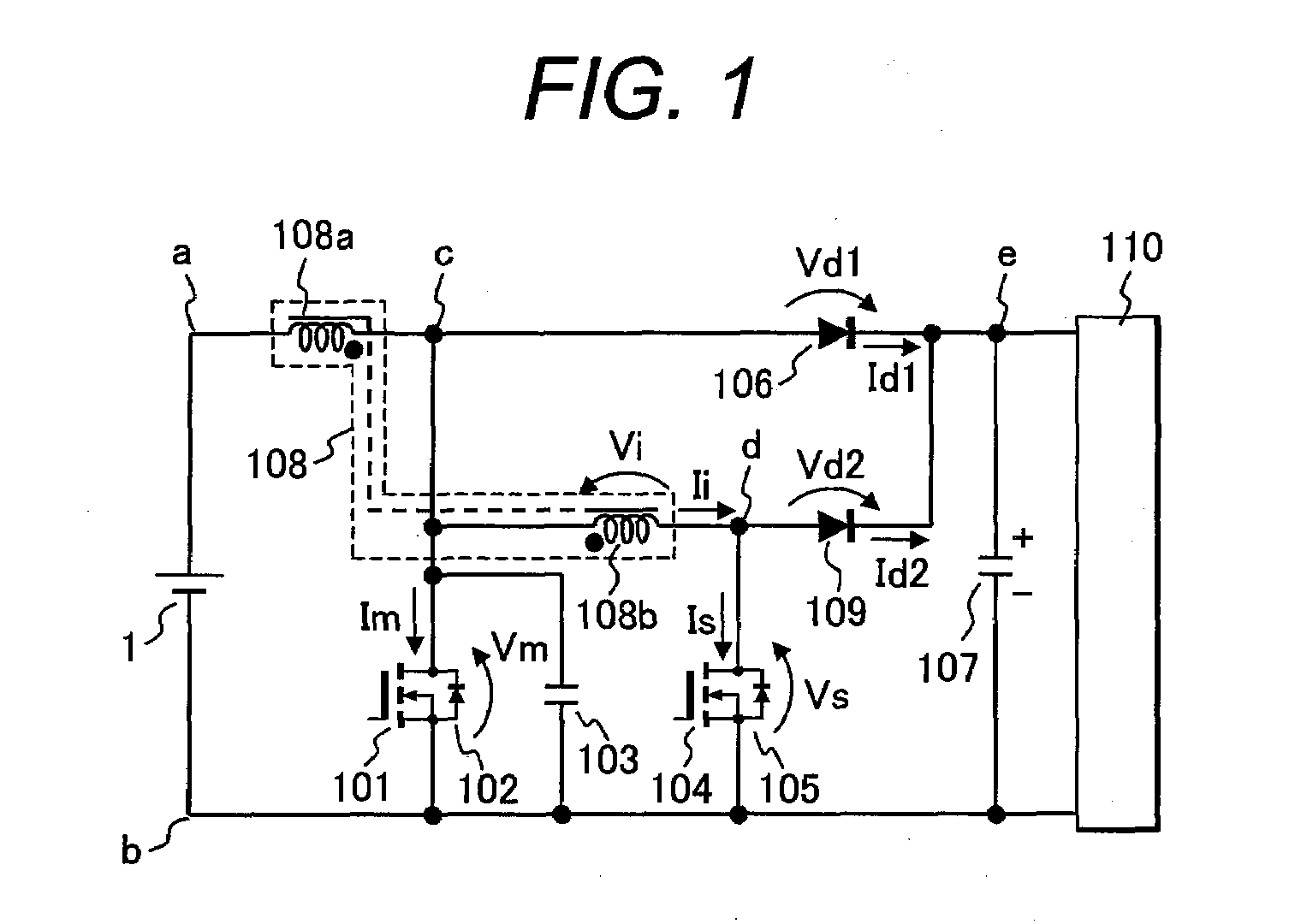

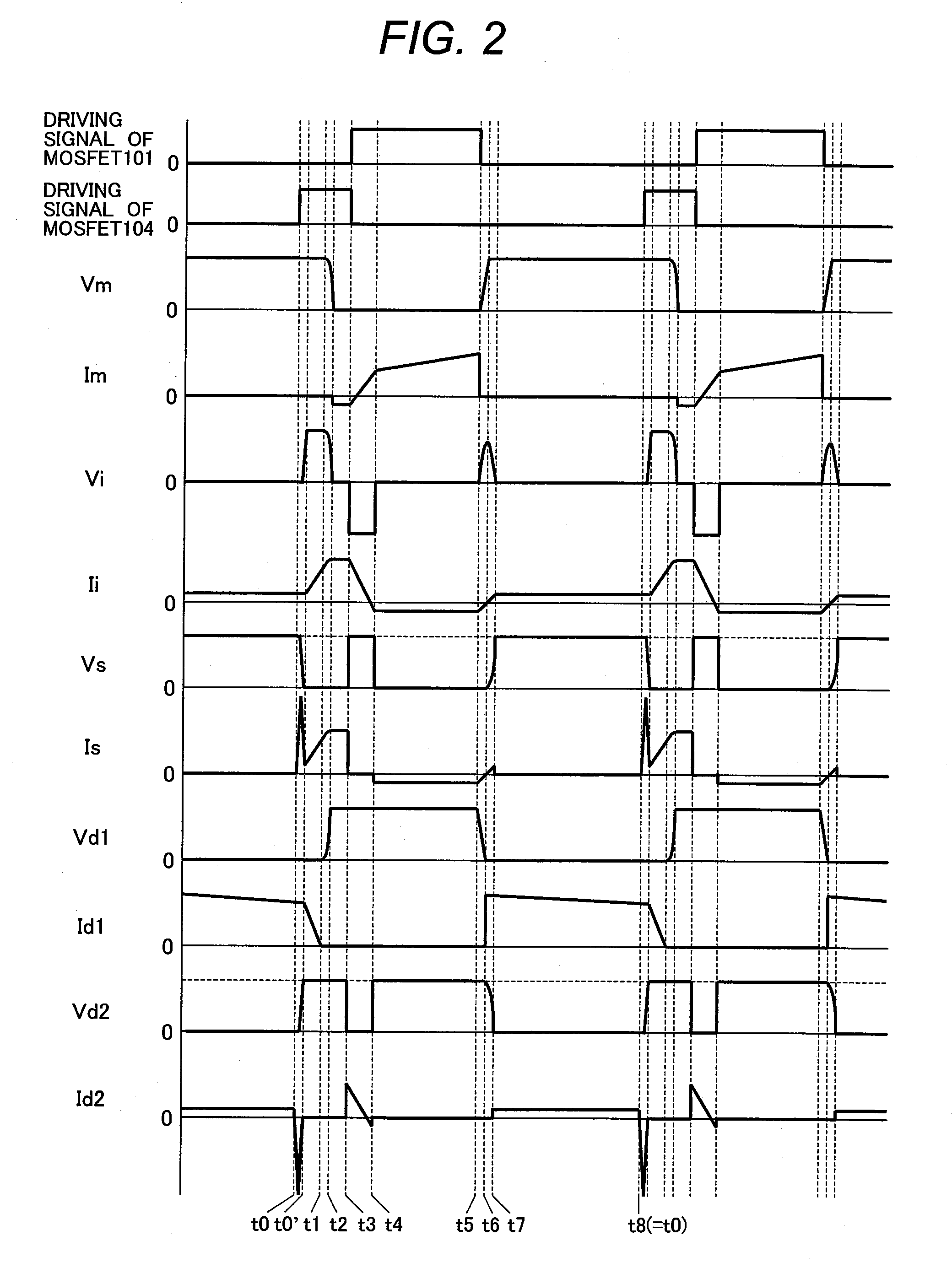

InactiveUS20100061122A1Small sizeReduce weightEfficient power electronics conversionDc-dc conversionCapacitanceSoft switching

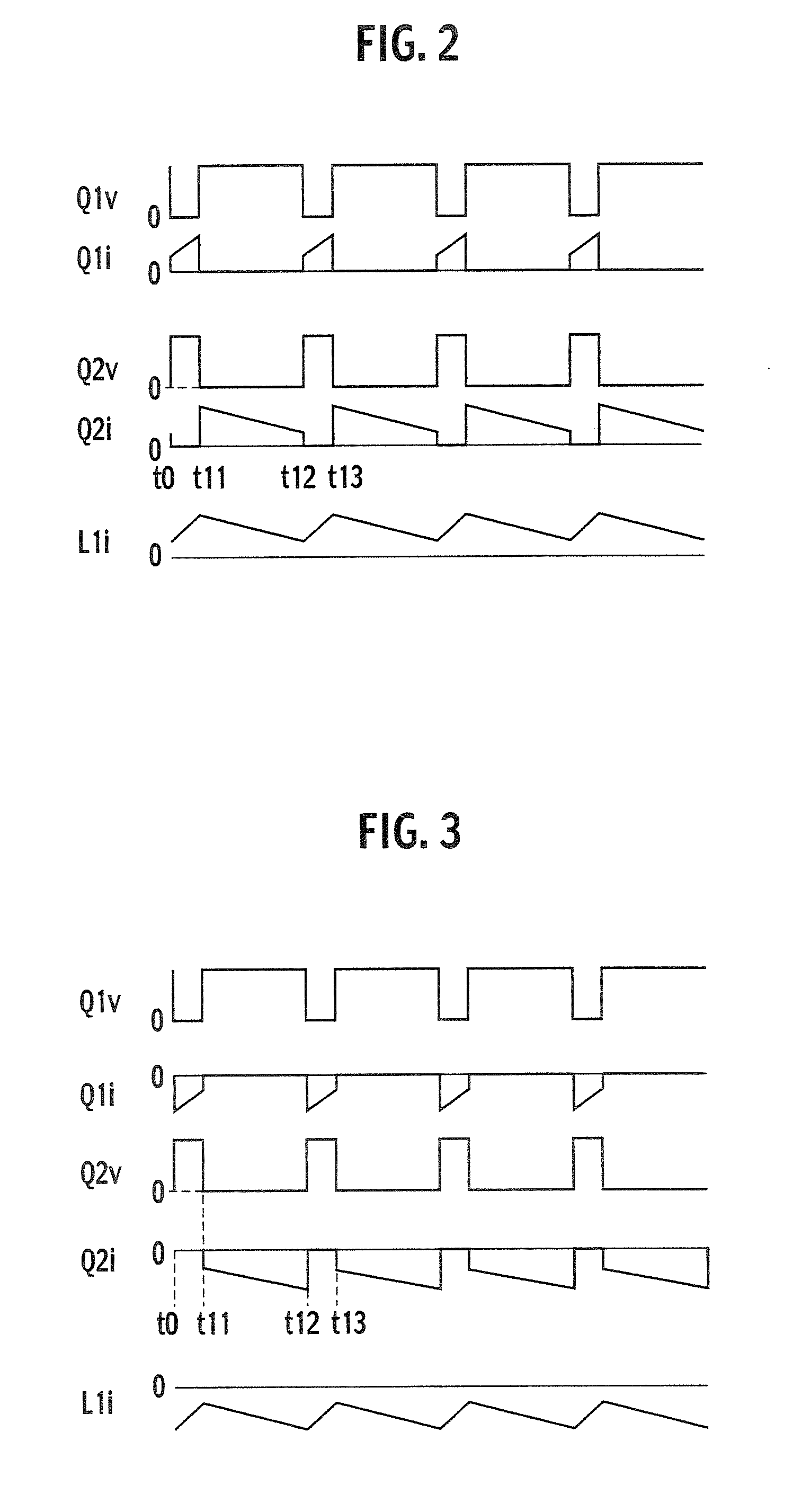

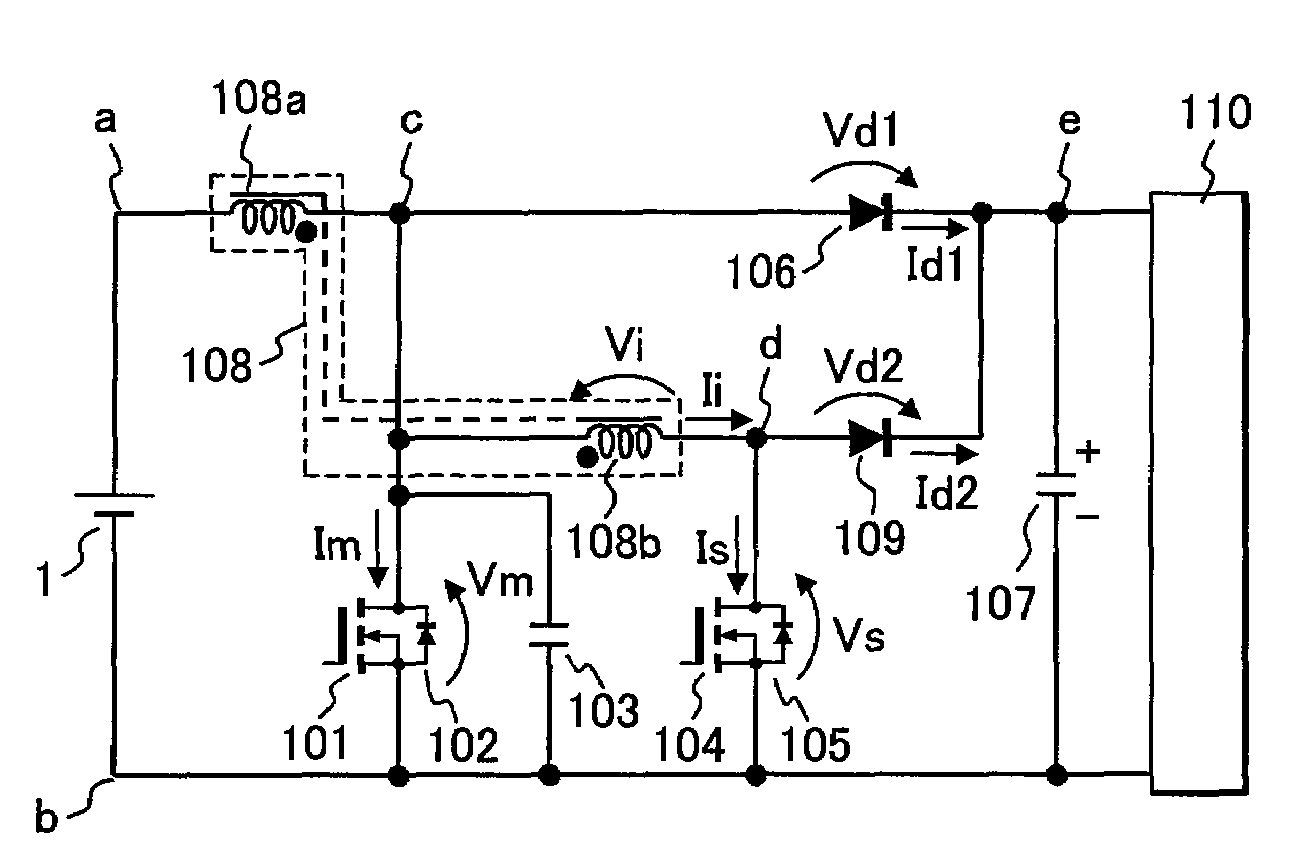

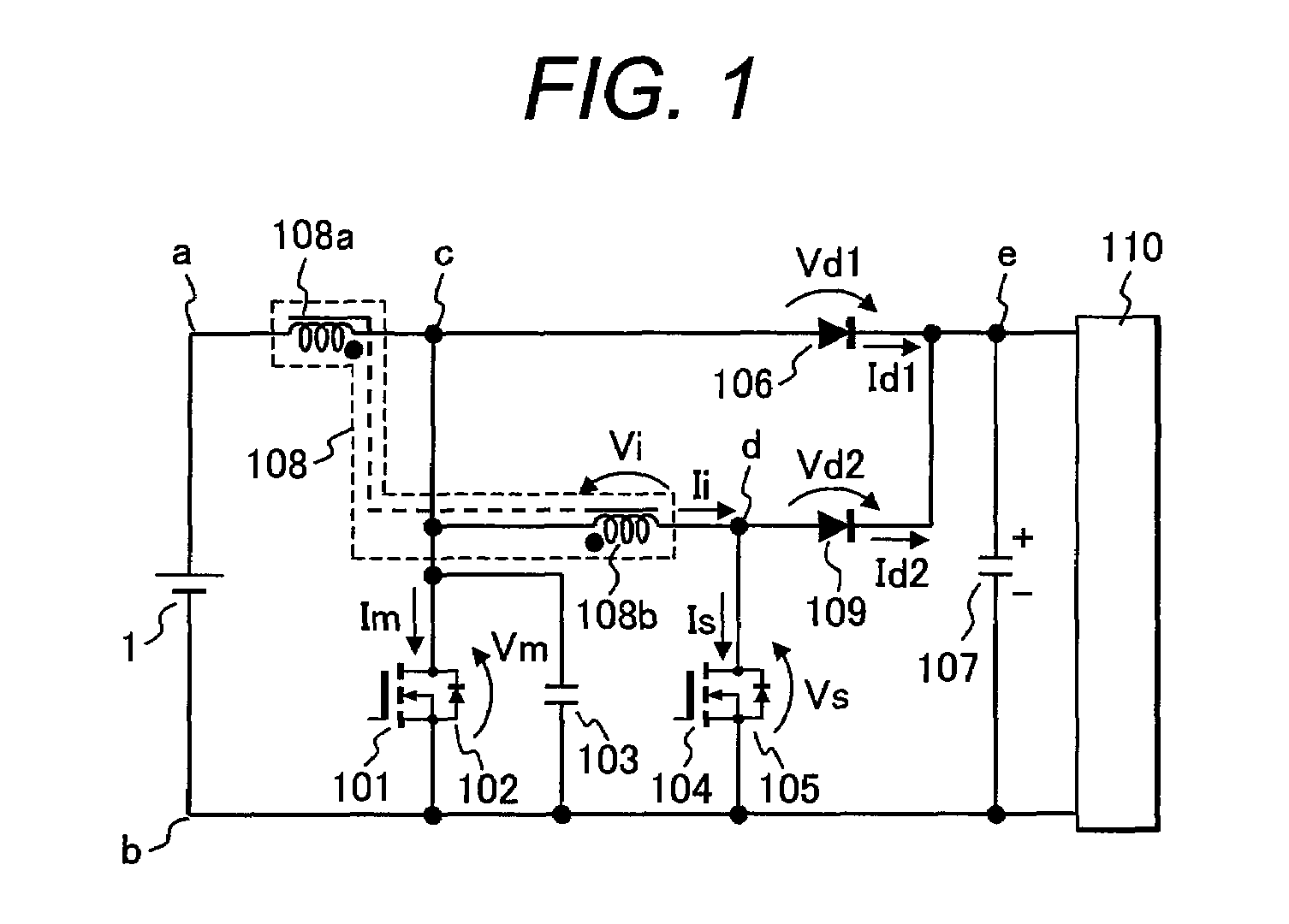

A small and efficient DC-DC converter is provided. In this DC-DC converter, passive elements such as an inductor and a capacitor can be reduced in size by reducing switching loss by a soft switching technology and increasing the drive frequency of a switching element. The DC-DC converter has a main switching element, a main diode and an auxiliary circuit that discharges the electric charges of the capacitance between the ends of the main switching element. The DC-DC converter includes an auxiliary inductor magnetically coupled with the main inductor, an auxiliary switching element that stores energy in the auxiliary inductor, and an auxiliary diode that discharges energy stored in the auxiliary inductor to the direct-current power source or the output side. The auxiliary inductor is coupled with the main inductor in the direction in which backward voltage is applied to the auxiliary diode when the main inductor discharges energy.

Owner:HITACHI LTD

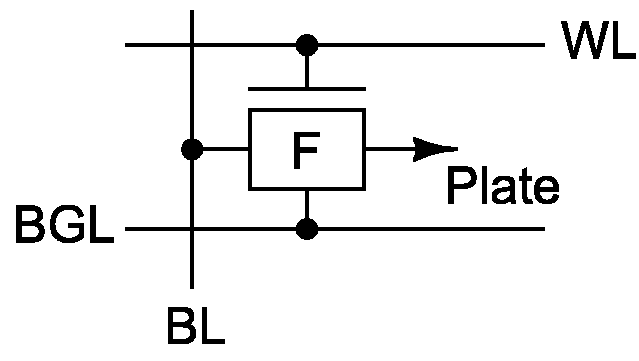

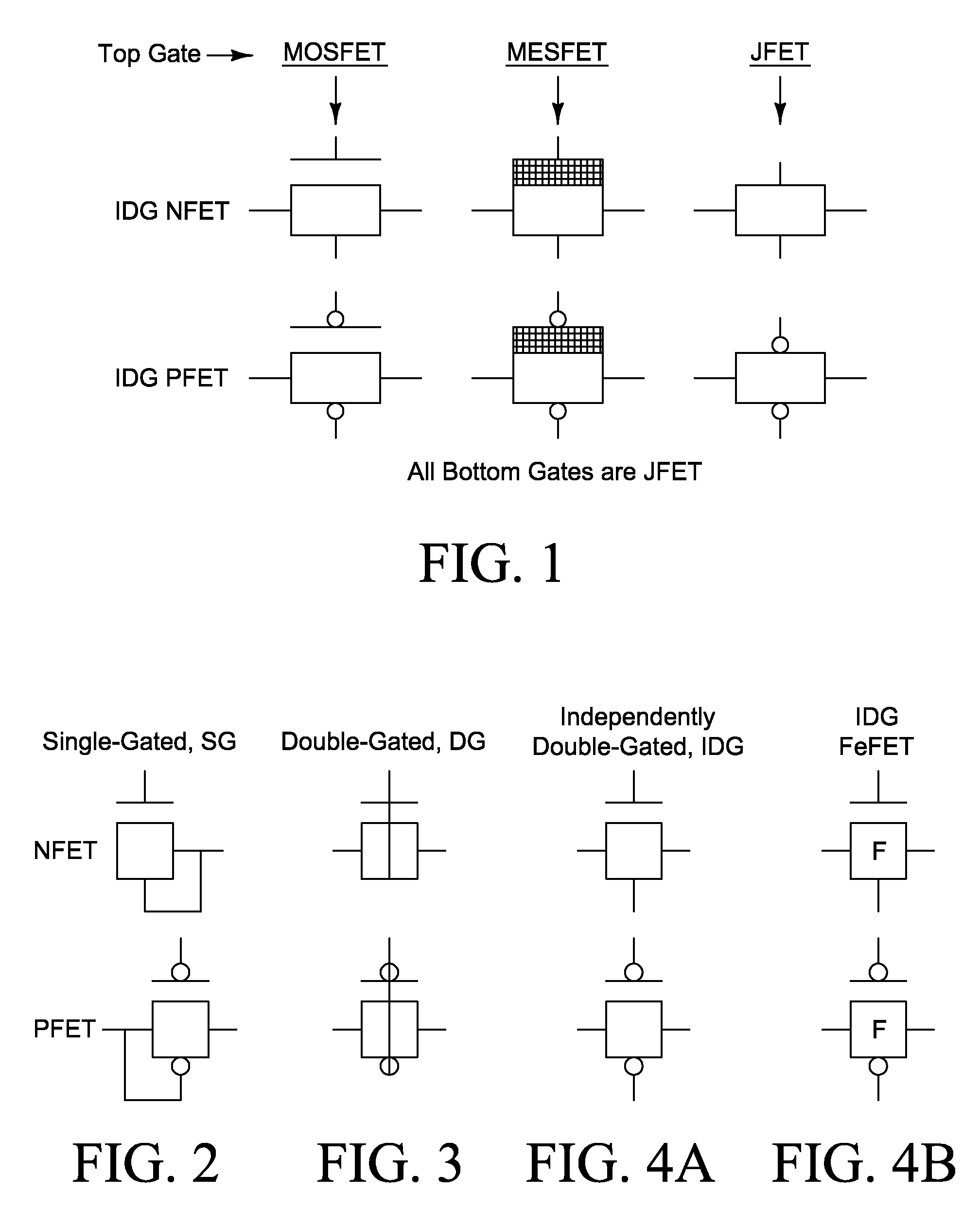

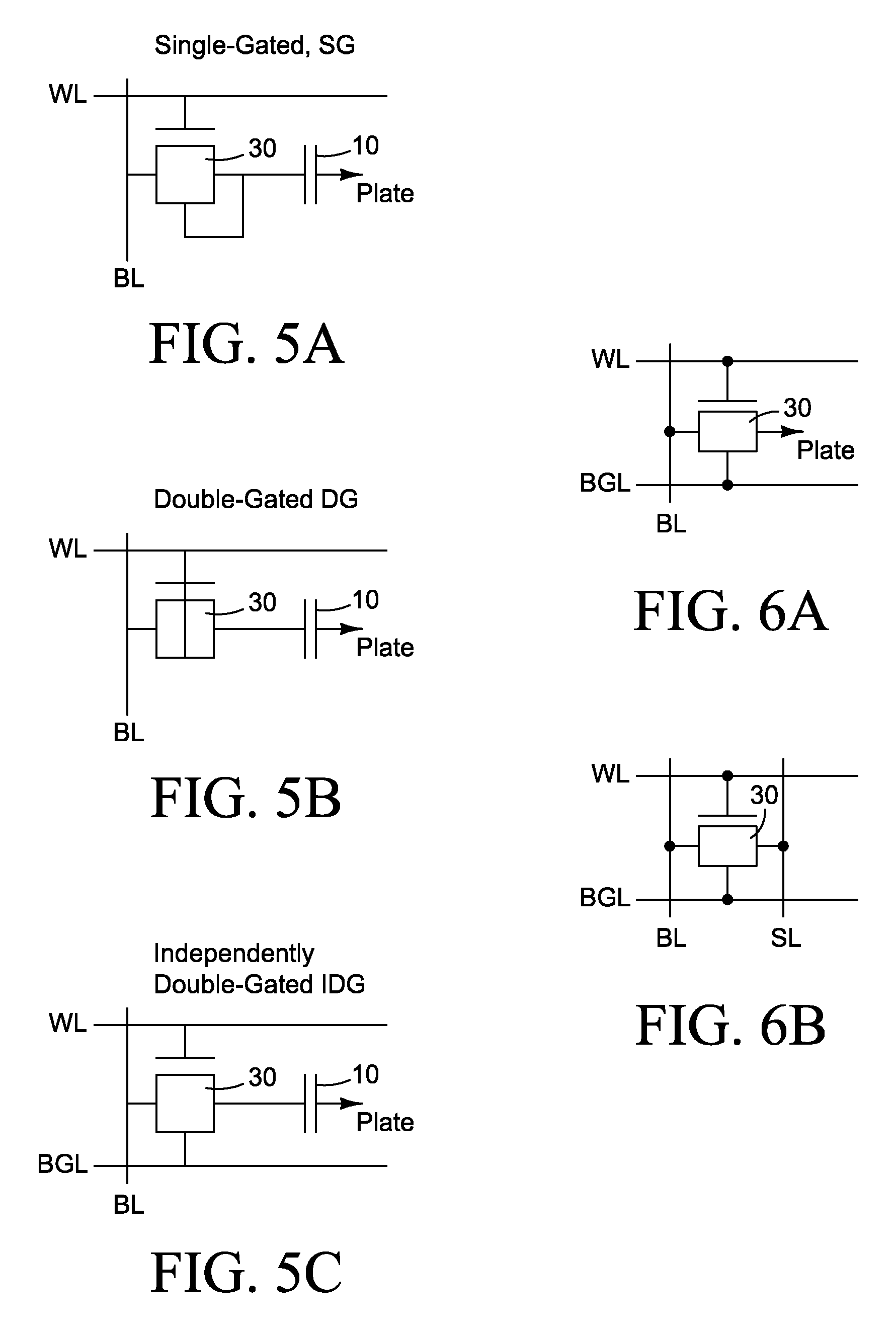

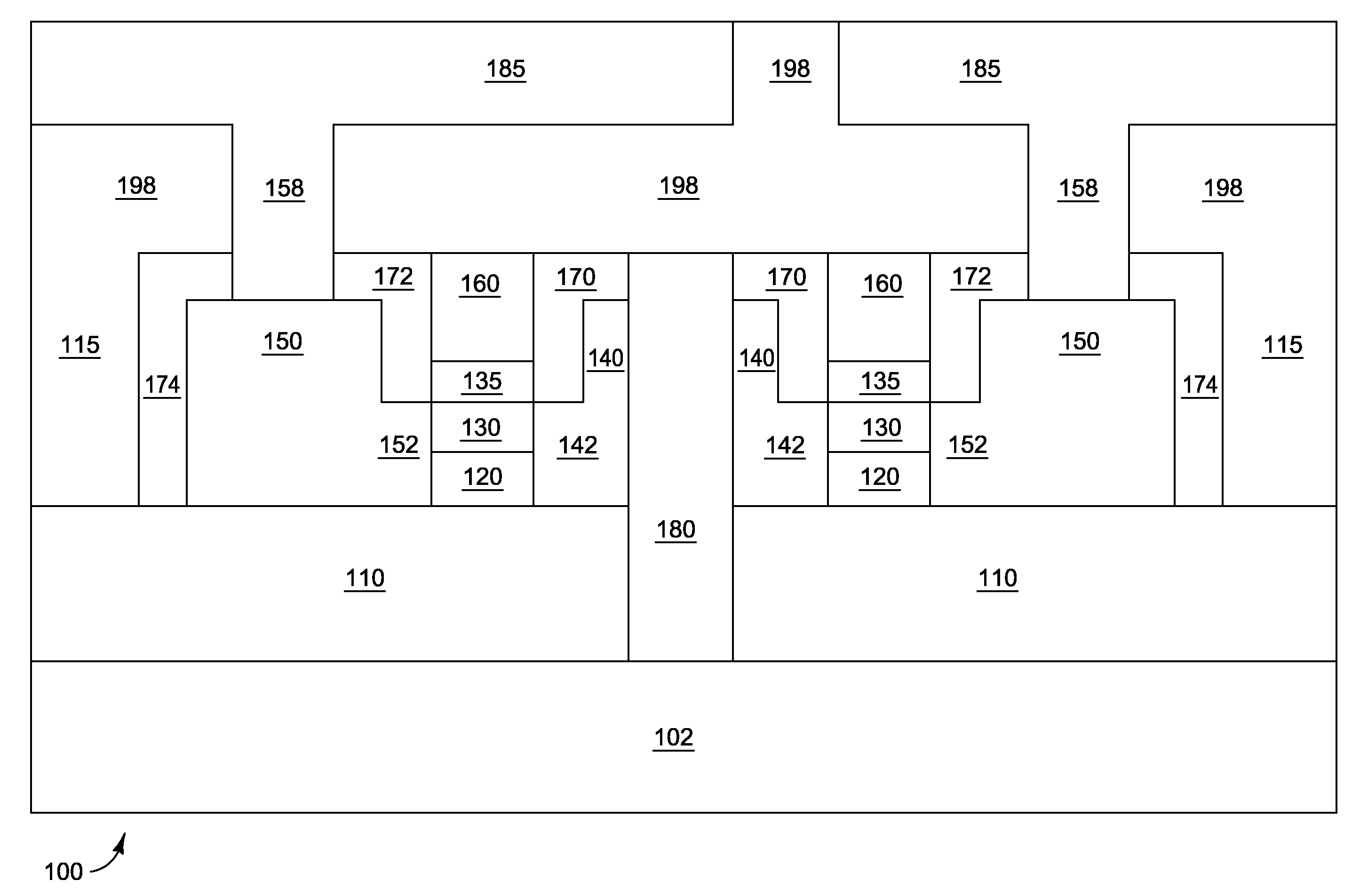

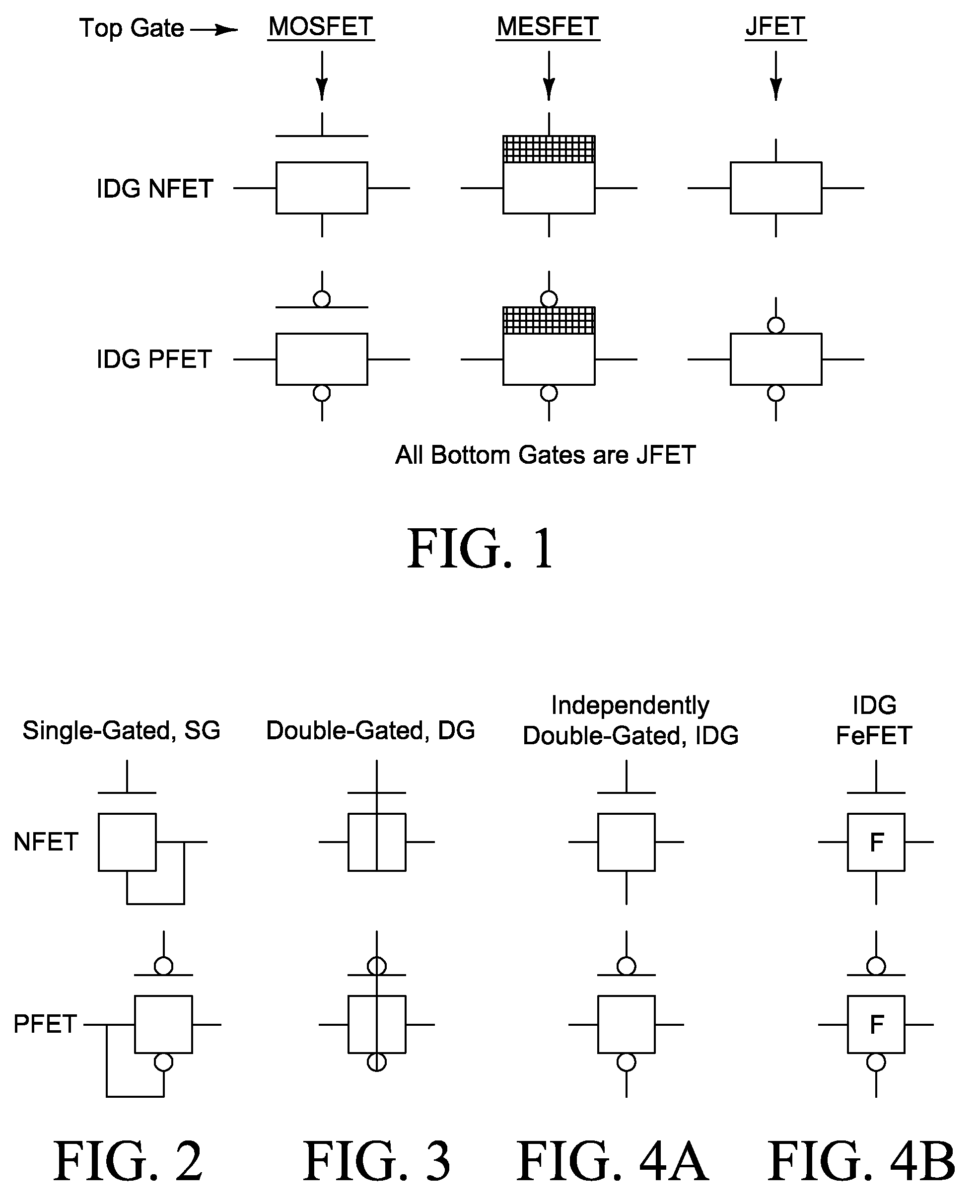

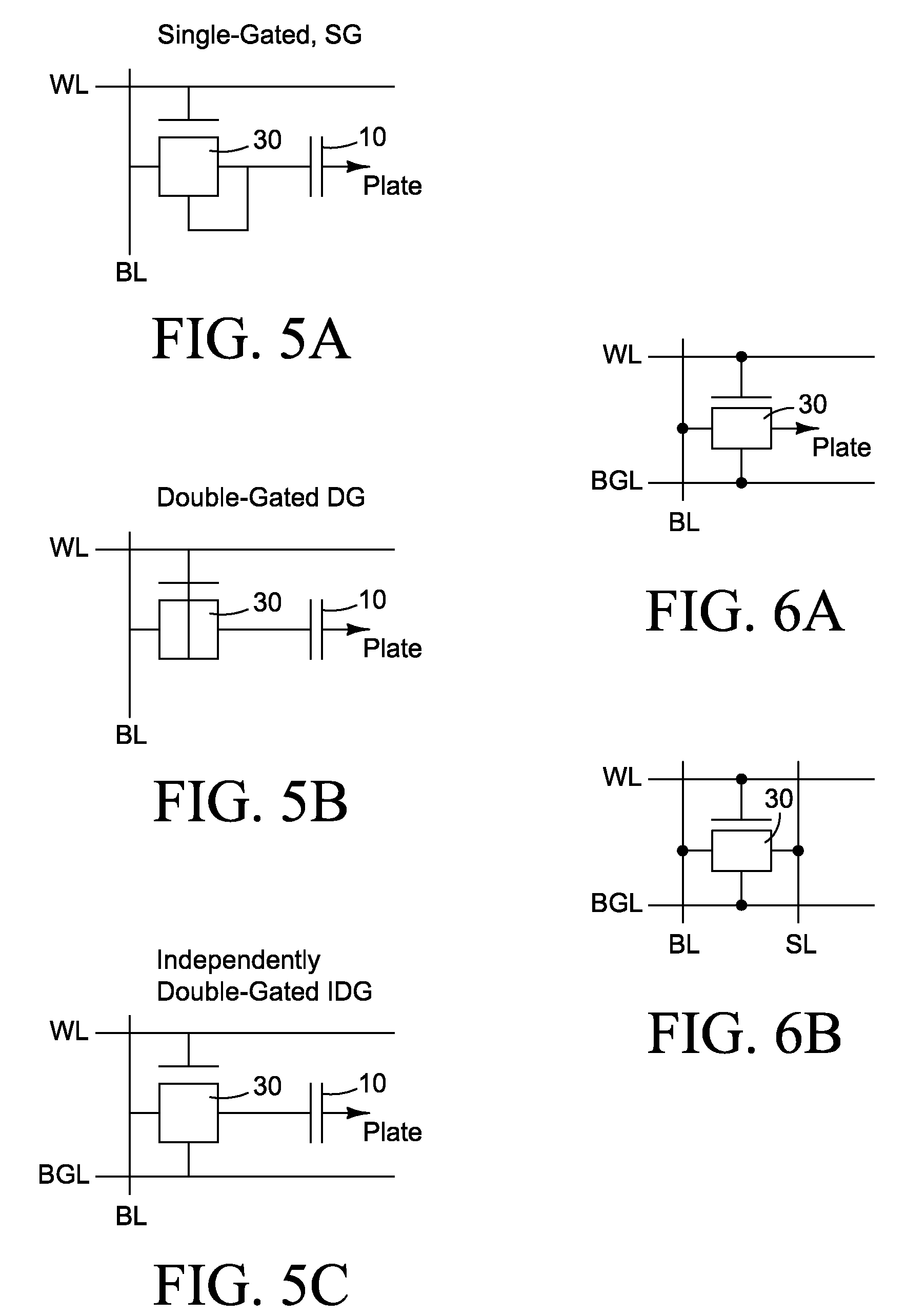

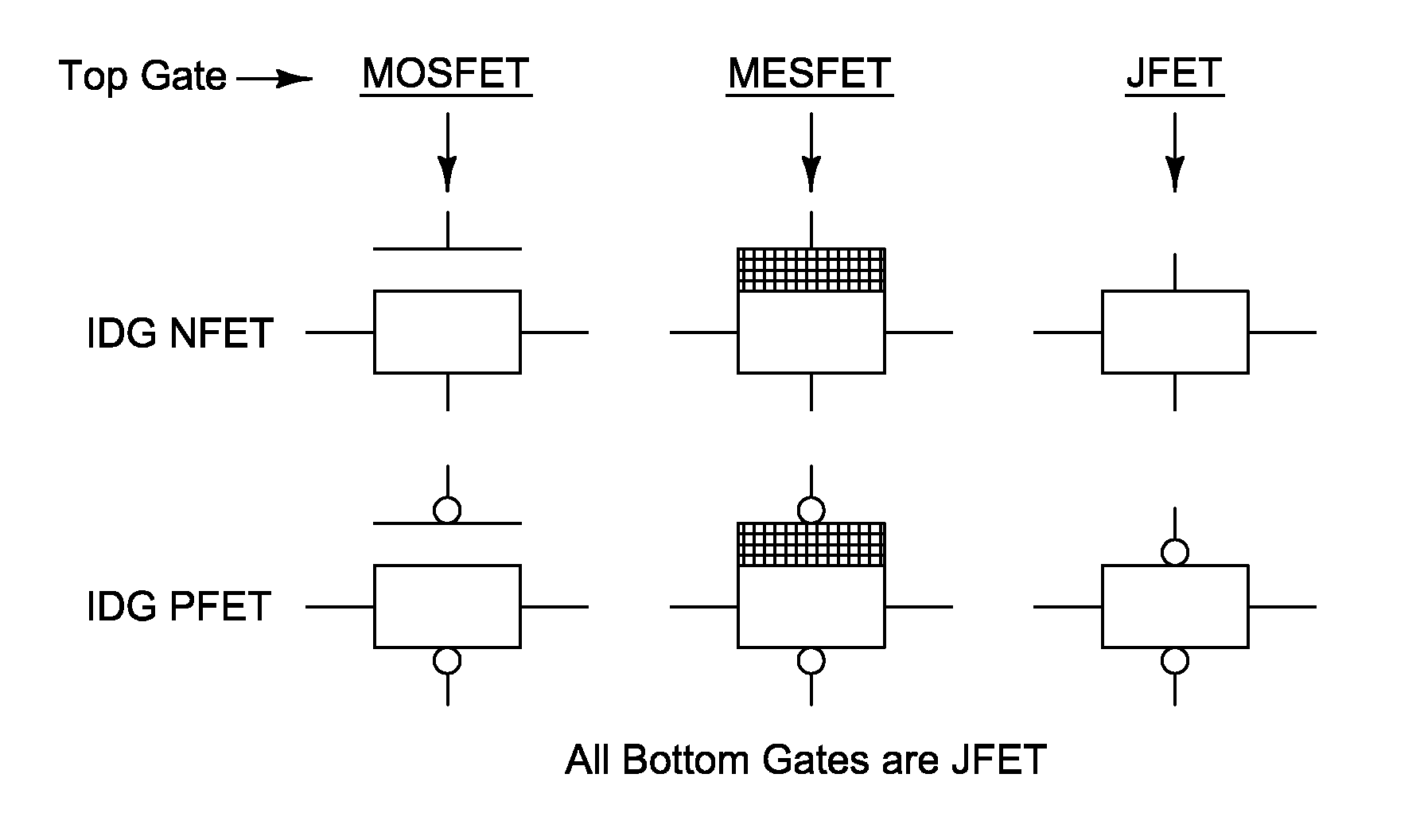

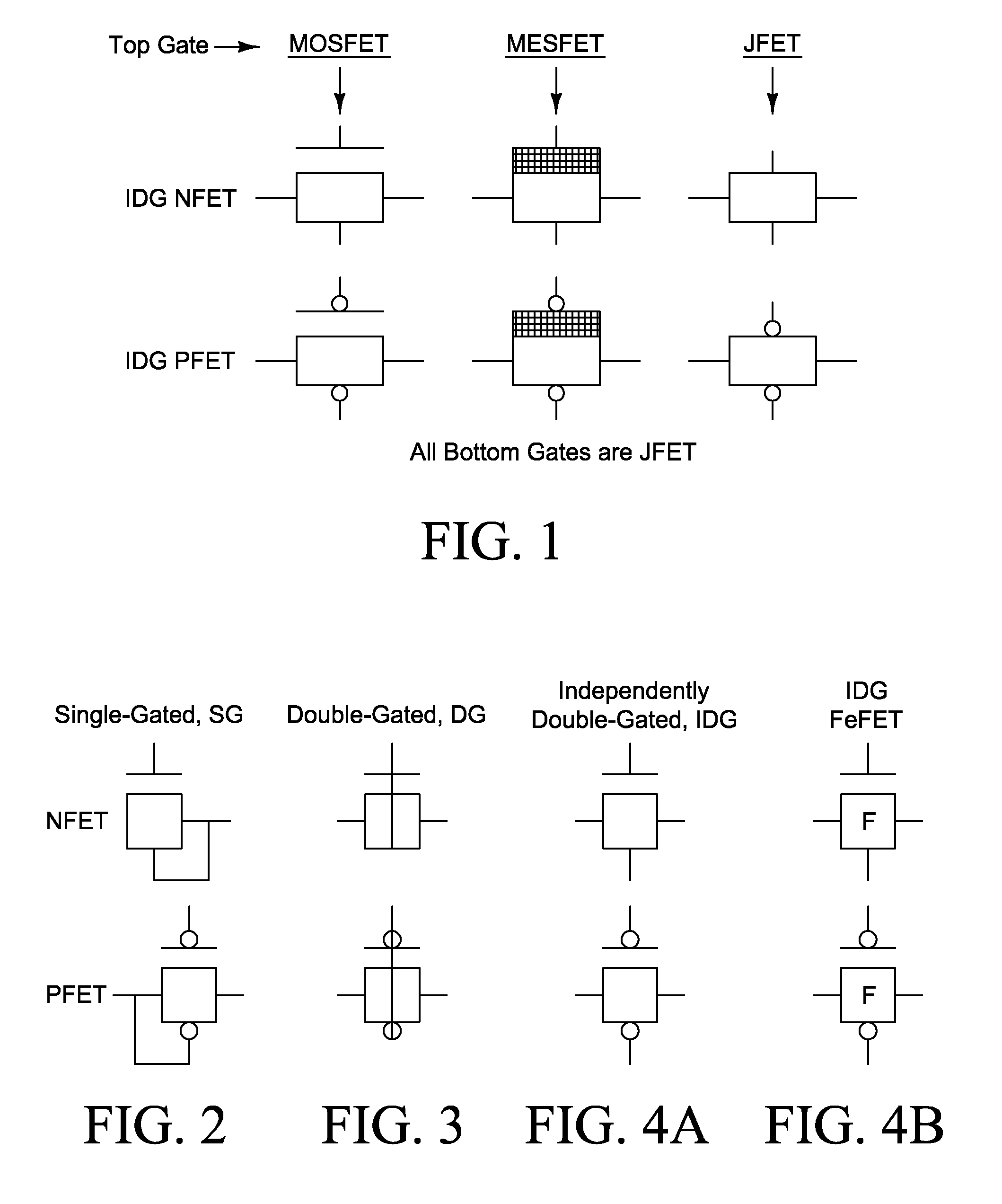

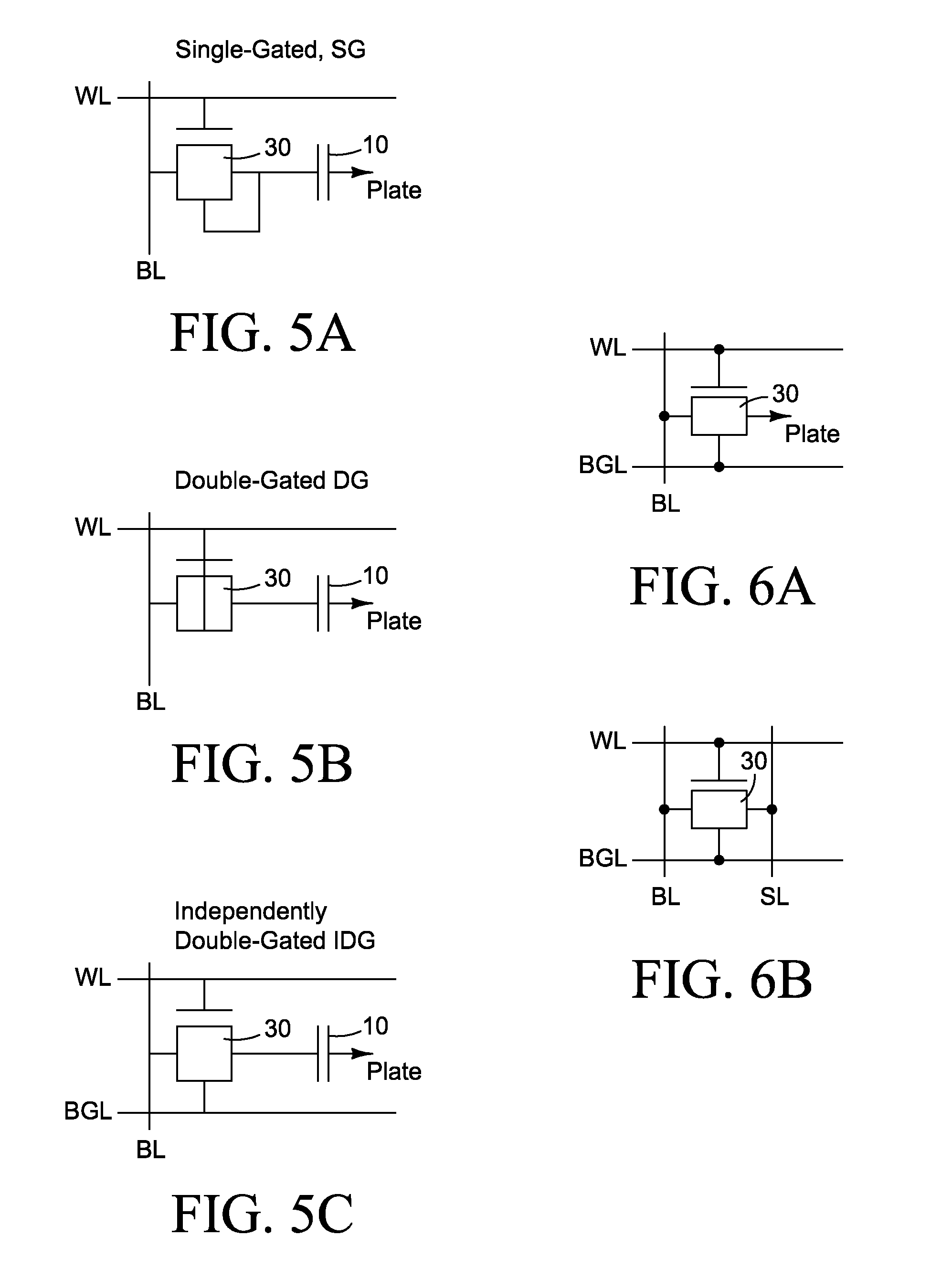

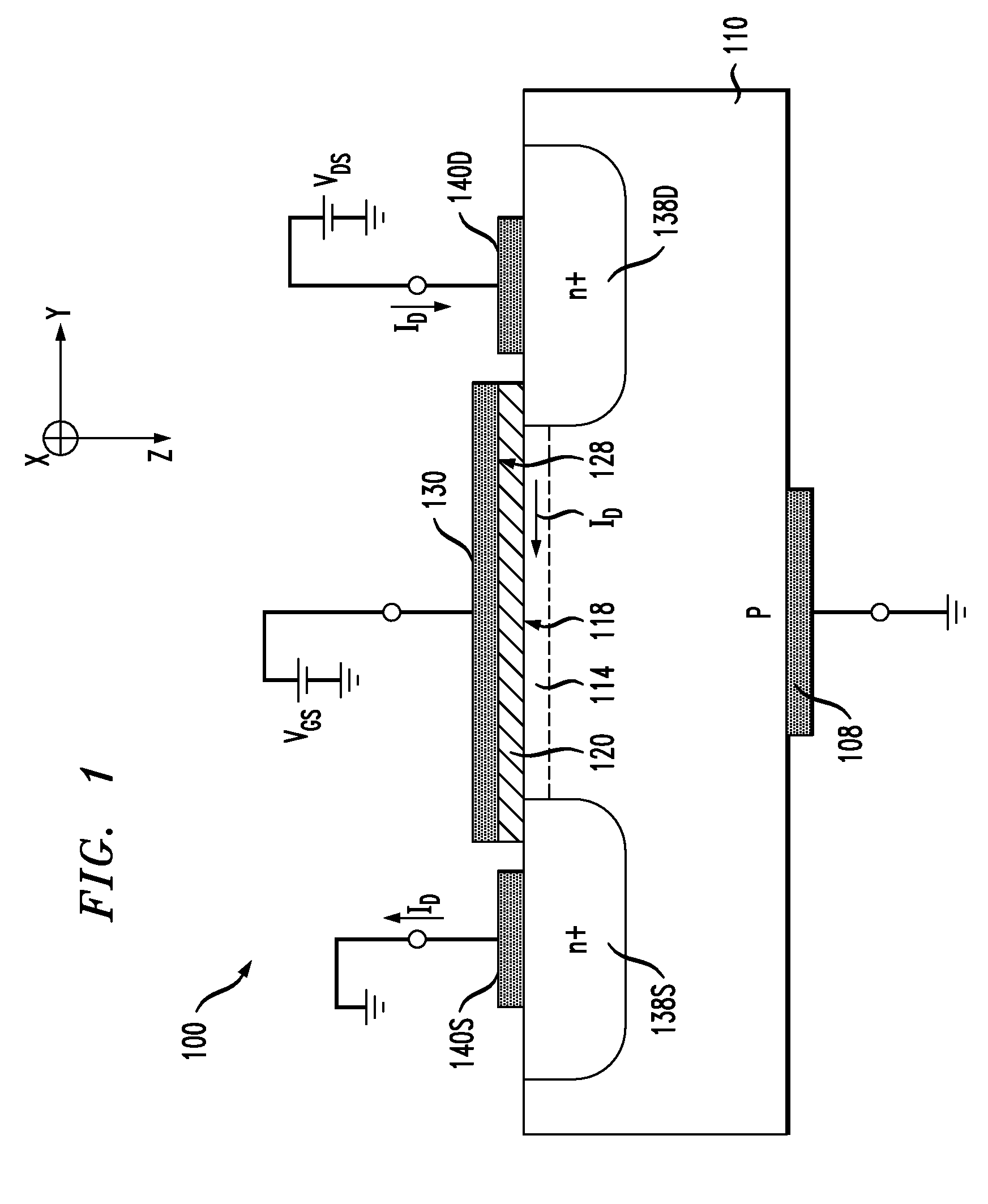

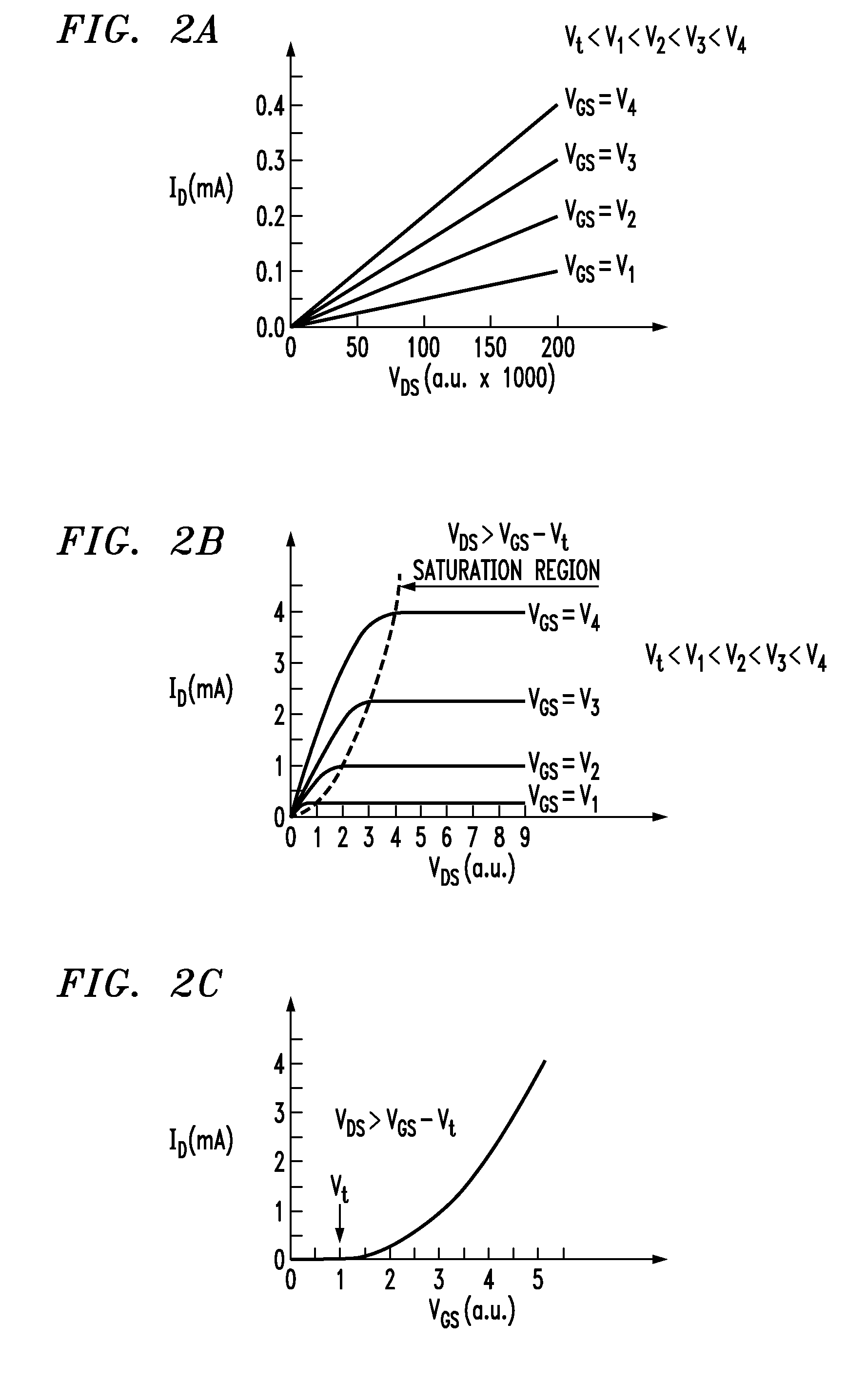

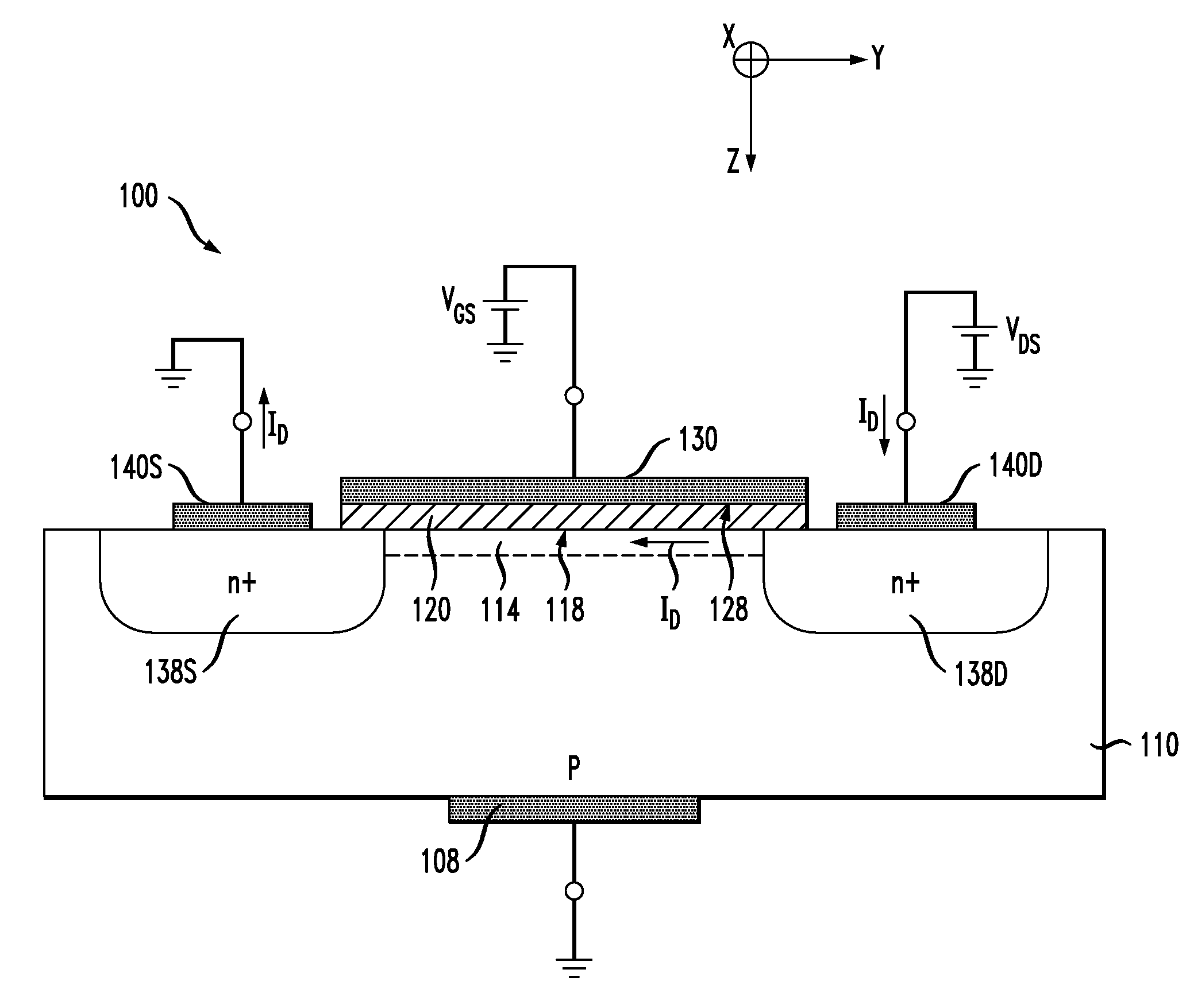

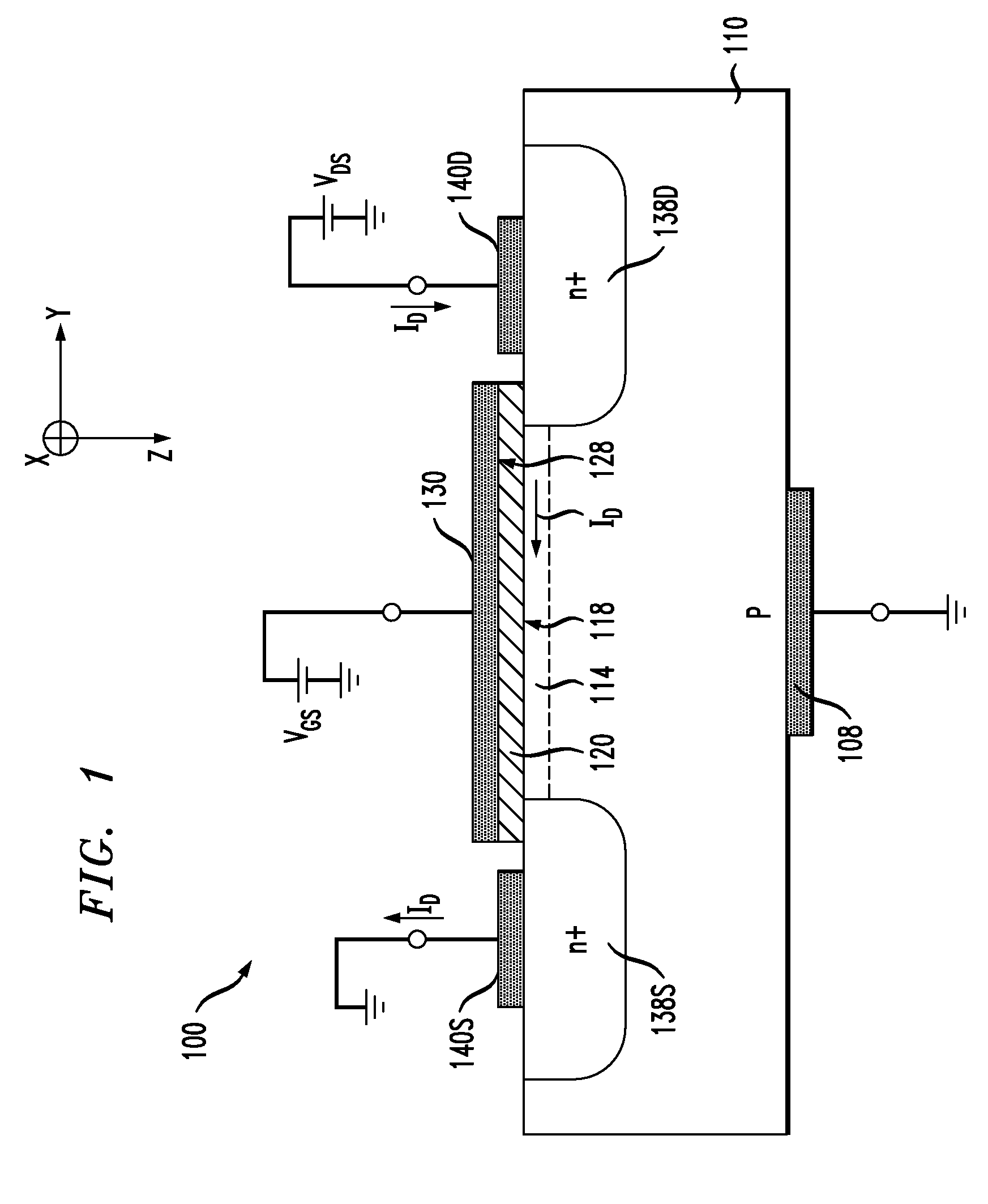

Independently-Double-Gated Transistor Memory (IDGM)

InactiveUS20080203443A1Function increaseSmall and efficientTransistorSolid-state devicesMemory retentionPower parameter

Memory cells are constructed from double-gated four terminal transistors having independent gate control. DRAM cells may use one, two or three transistors. Single transistor cells are constructed either with or without a bit storage capacitor, and both NAND- and NOR-type Non-Volatile NVRAM cells, as well as Ferroelectric FeRAM cells, are described. For all cells, top gates provide conventional access while independent bottom gates provide control to optimize memory retention for given speed and power parameters as well as to accommodate hardening against radiation. In a single transistor cell without a capacitor, use of the bottom gate allows packing to a density approaching 2 F2. Using a ferroelectric material as the gate insulator produces a single-transistor FeRAM cell that overcomes the industry-wide Write Disturb problem. The memory cells are compatible with SOI logic circuitry for use as embedded RAM in SOC applications.

Owner:AMERICAN SEMICON

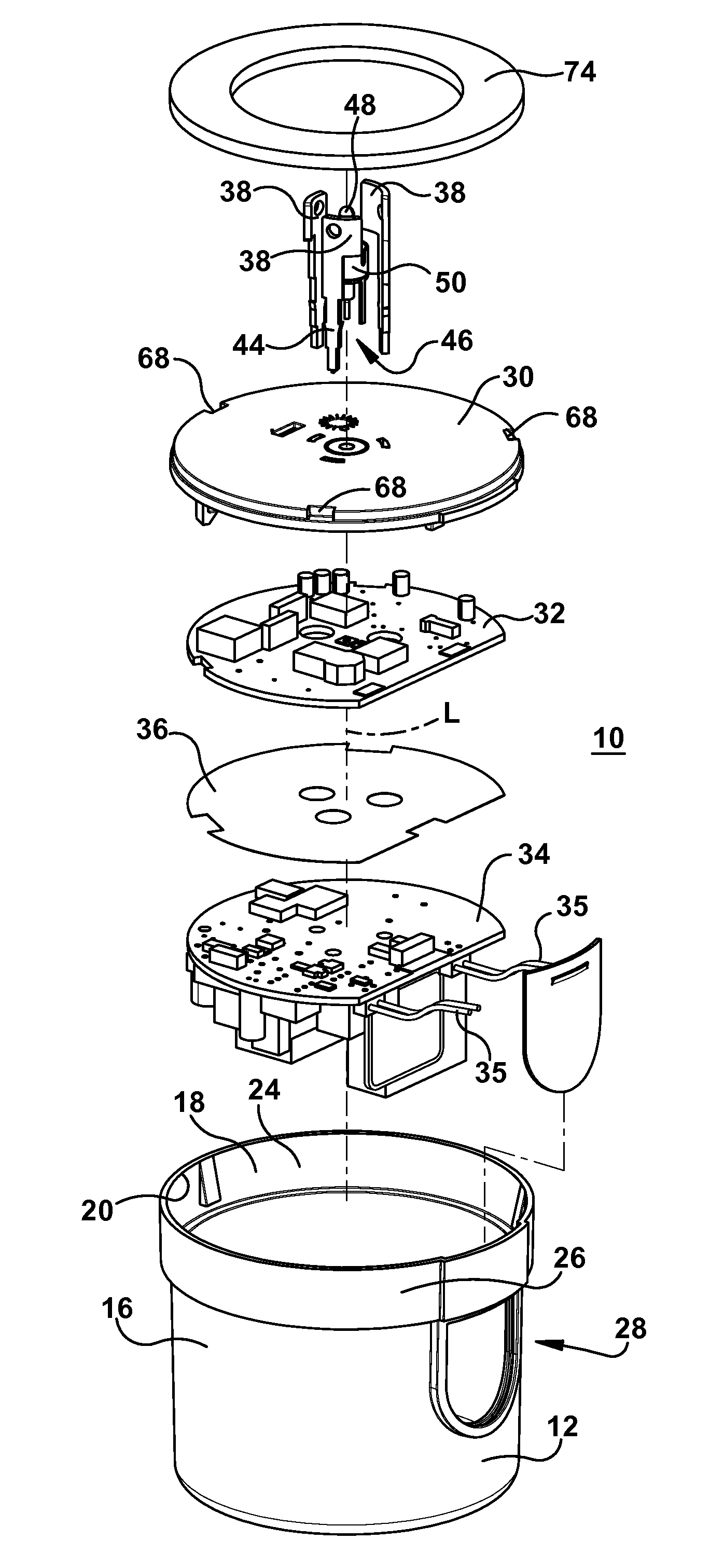

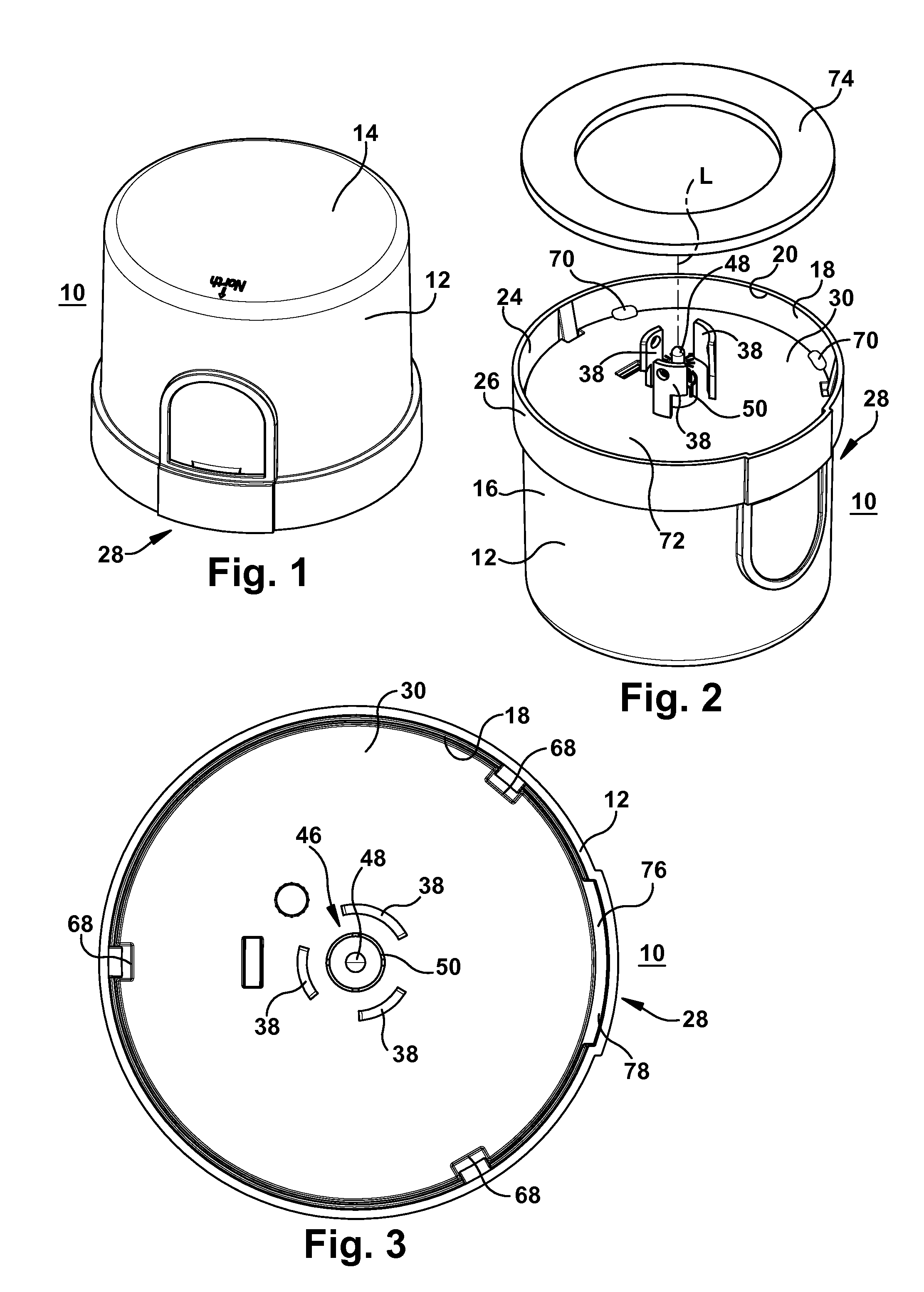

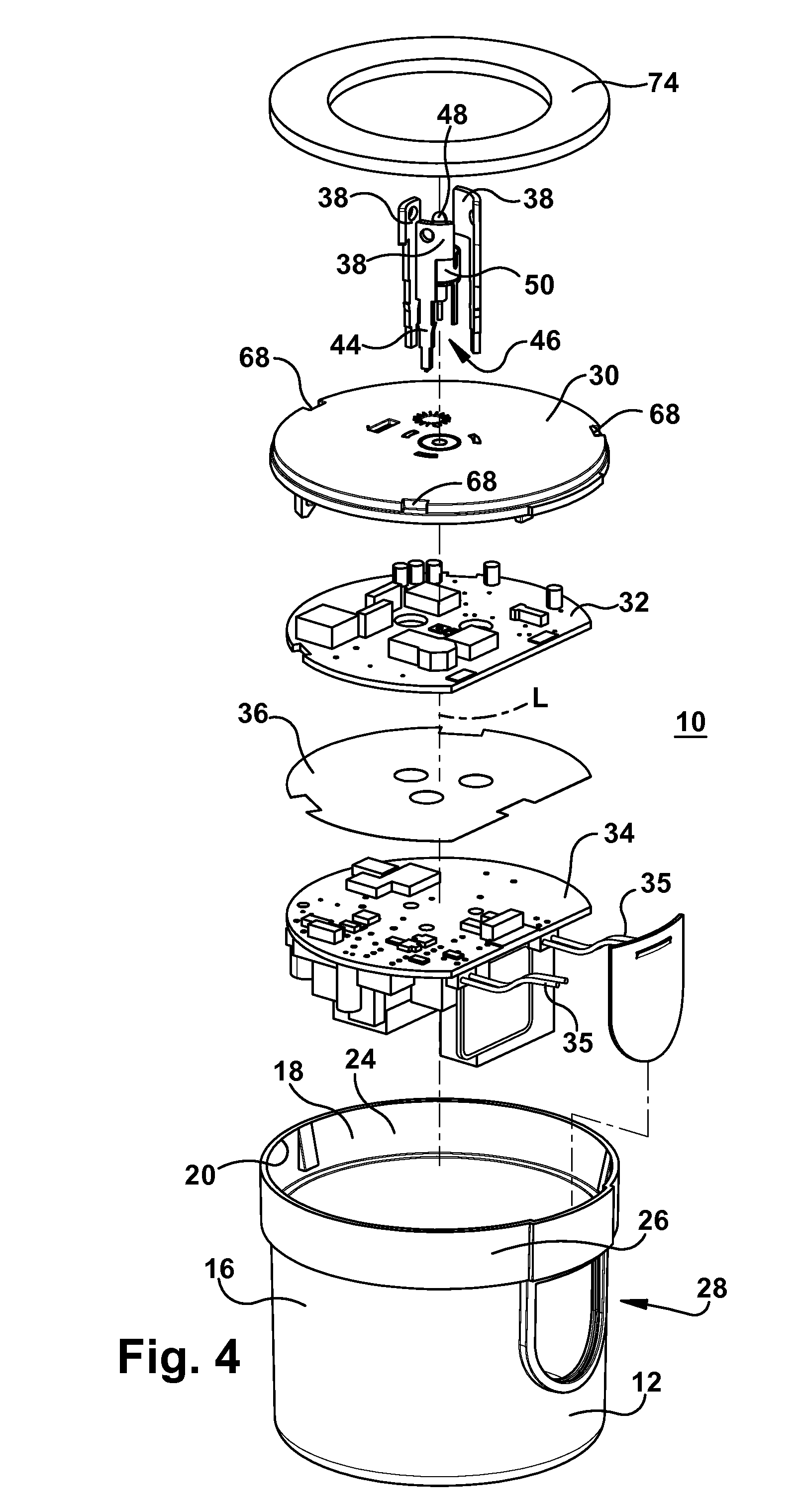

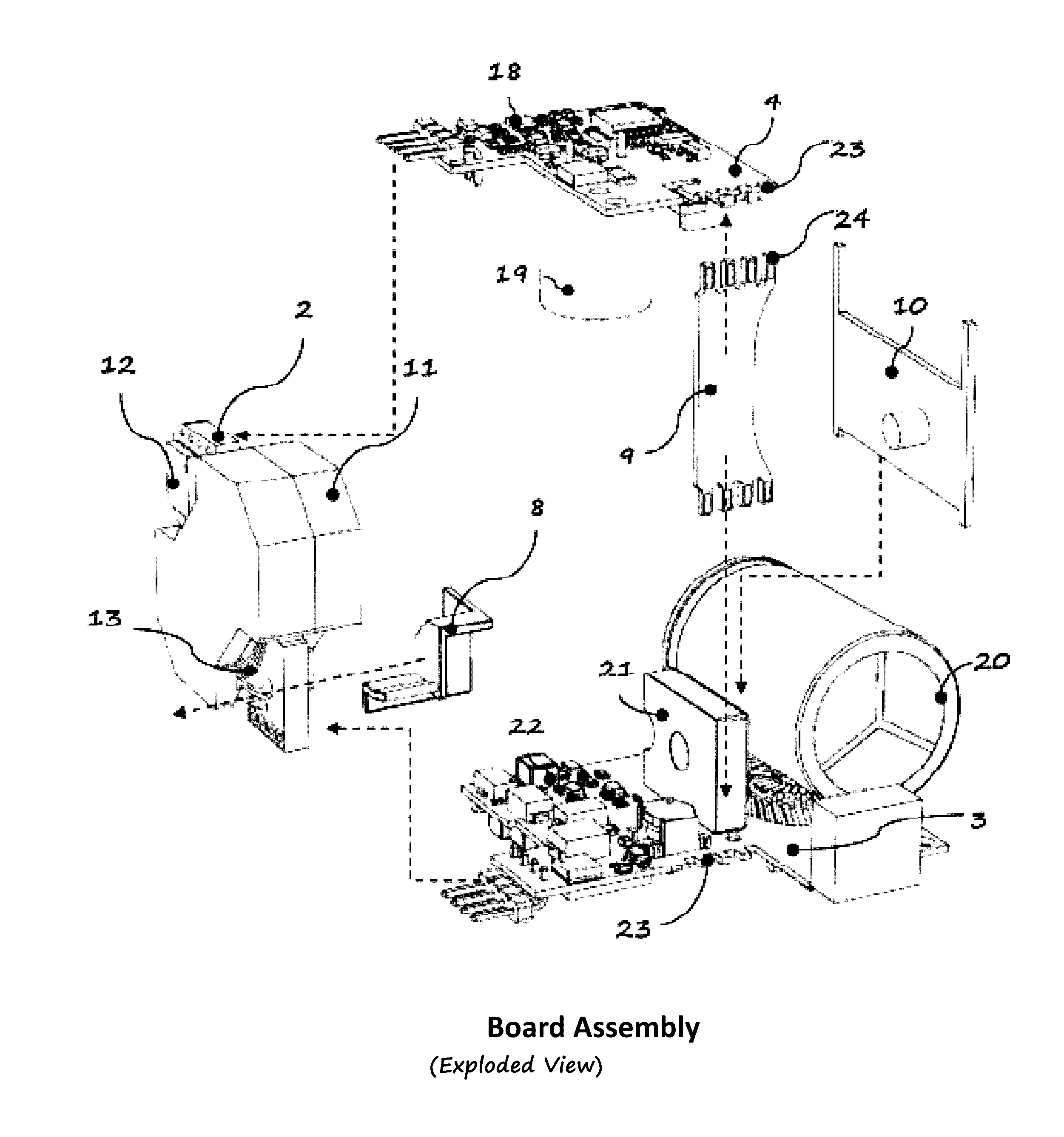

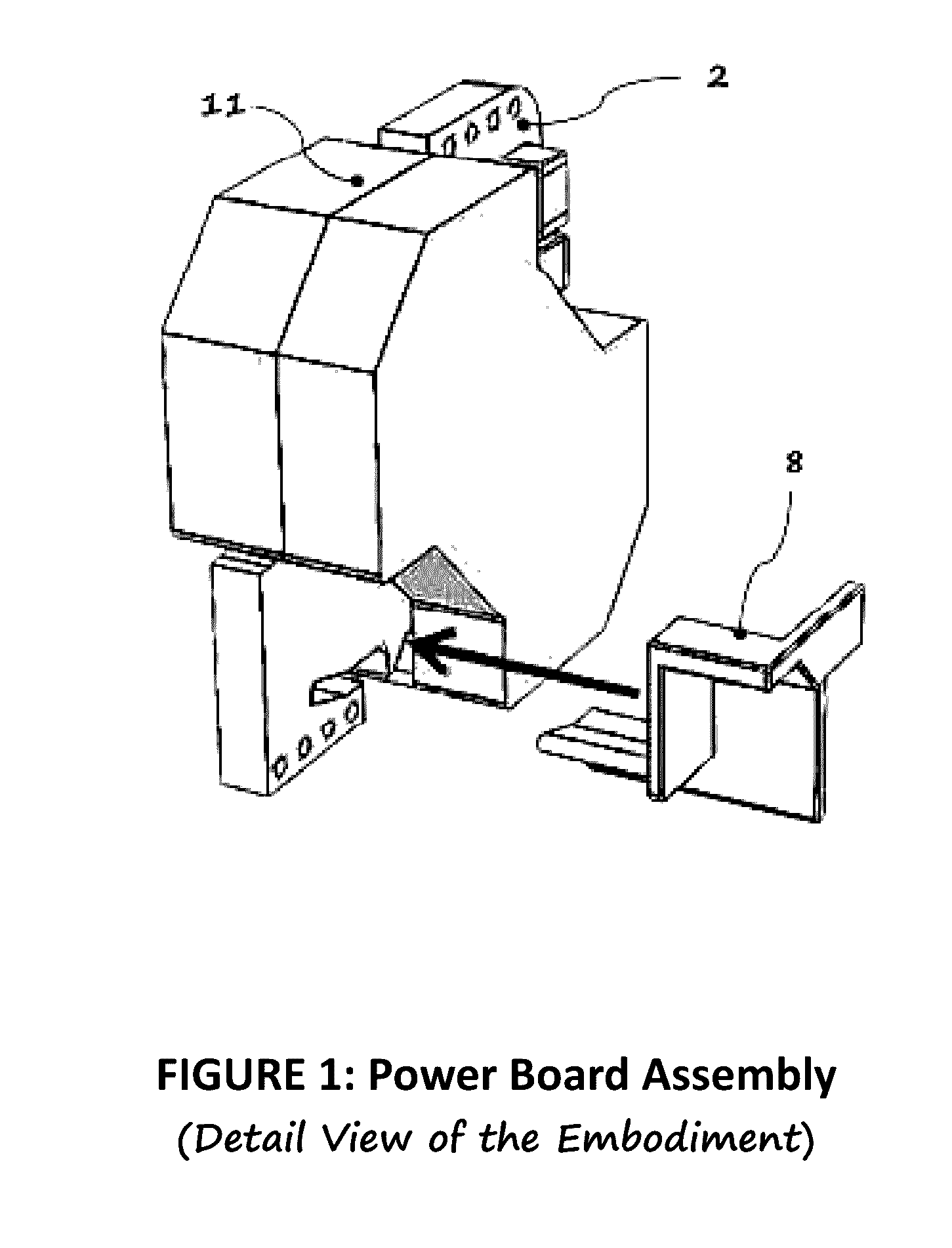

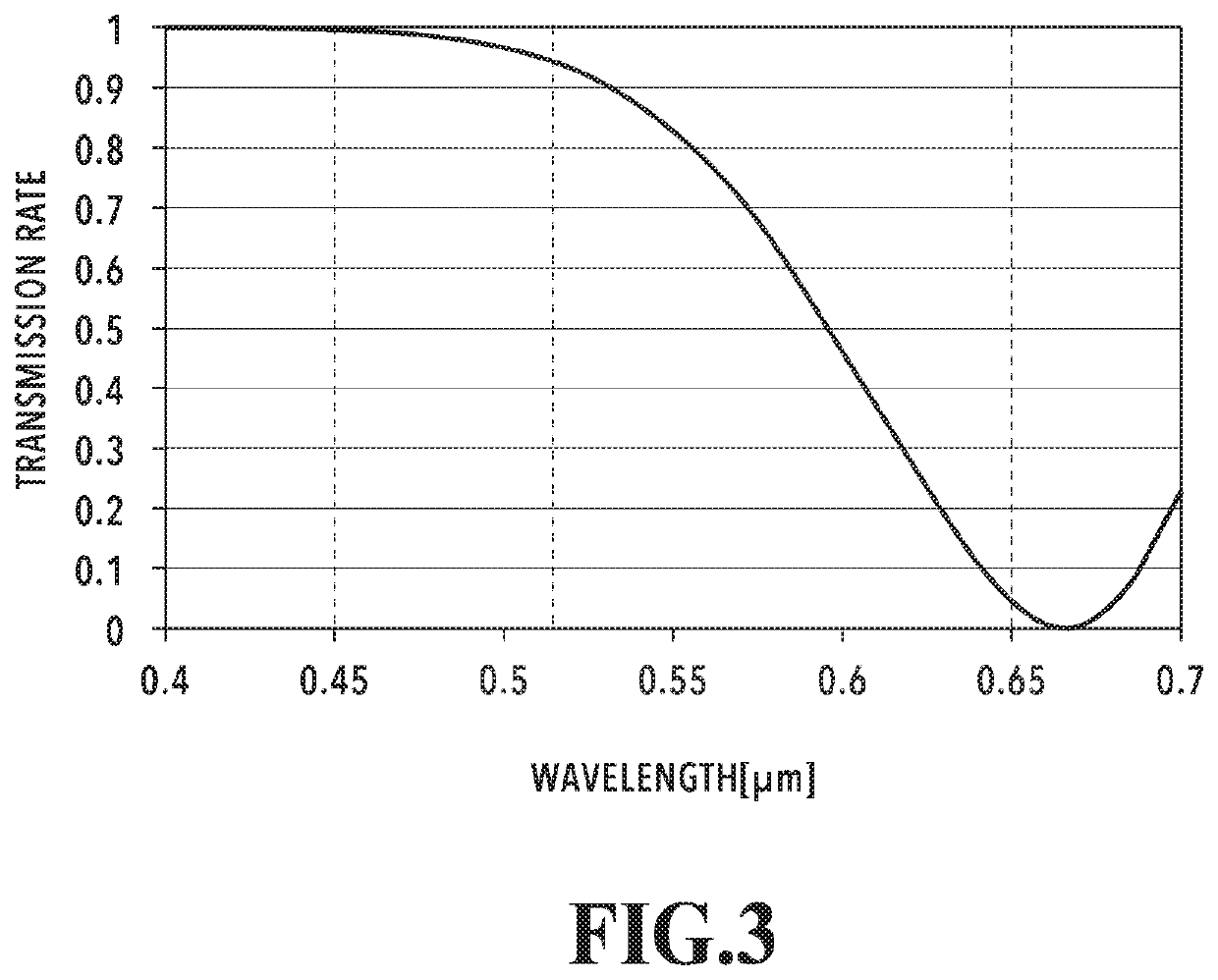

System assembly and design of photoelectric controller device

InactiveUS20130044444A1Small and efficientMechanical apparatusElectric circuit arrangementsElectro-optical sensorEngineering

A photoelectric controller device includes a housing. At least two printed circuit boards can be secured in an interior of the housing. The printed circuit boards include a photosensor and communication circuitry. Electrically conductive, main terminals are secured in electrical contact with one of the printed circuit boards. A communication terminal is also secured in electrical contact with the communication circuitry on one of the printed circuit boards. Also featured is a design of a base plate of the photoelectric controller device that secures at least one circuit board and a design of a window for the photosensor. The controller may include at least one printed circuit board comprising a sensor selected from the group consisting of the photosensor, an infrared sensor or a visible detector, and combinations thereof.

Owner:GENERAL ELECTRIC CO

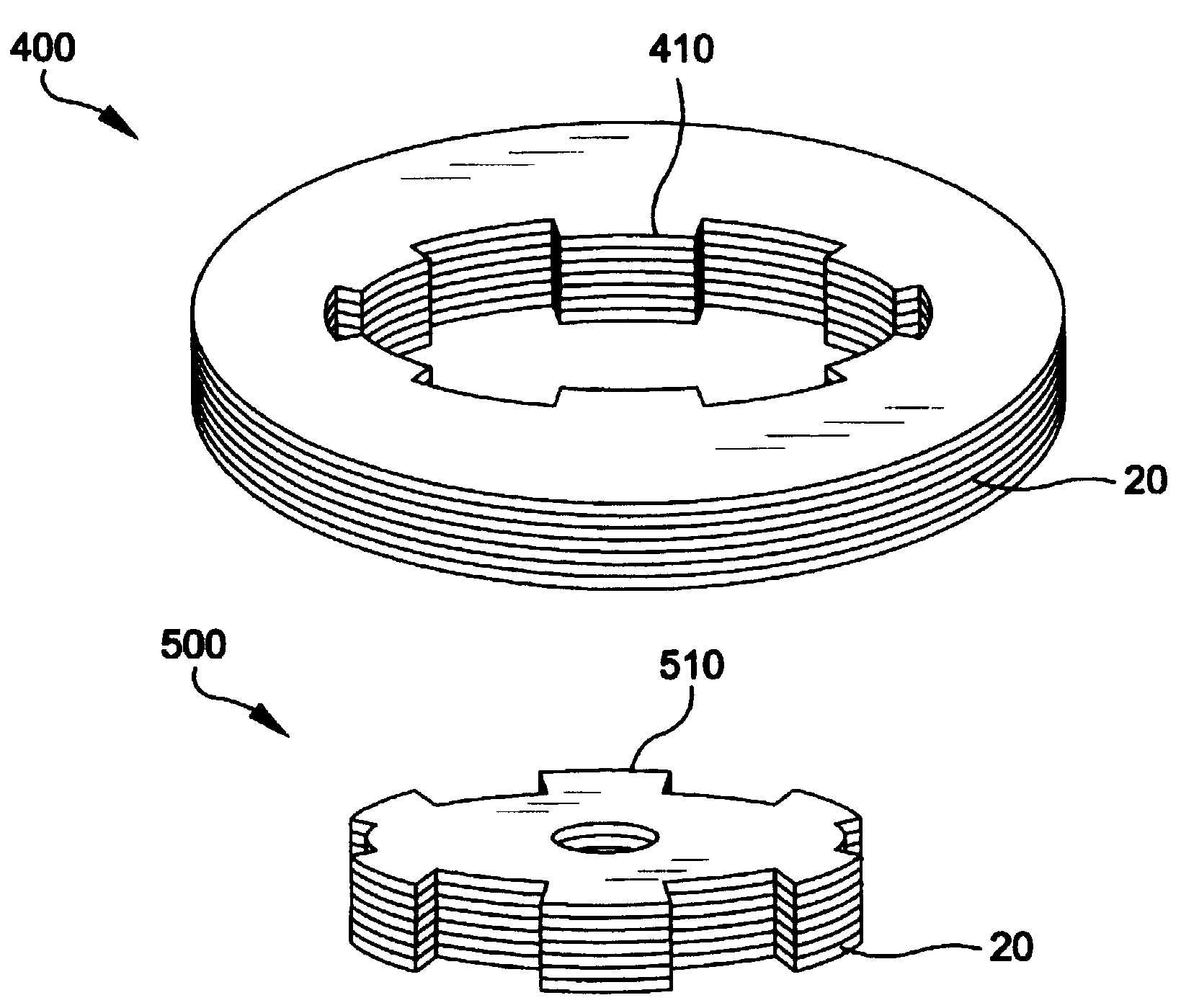

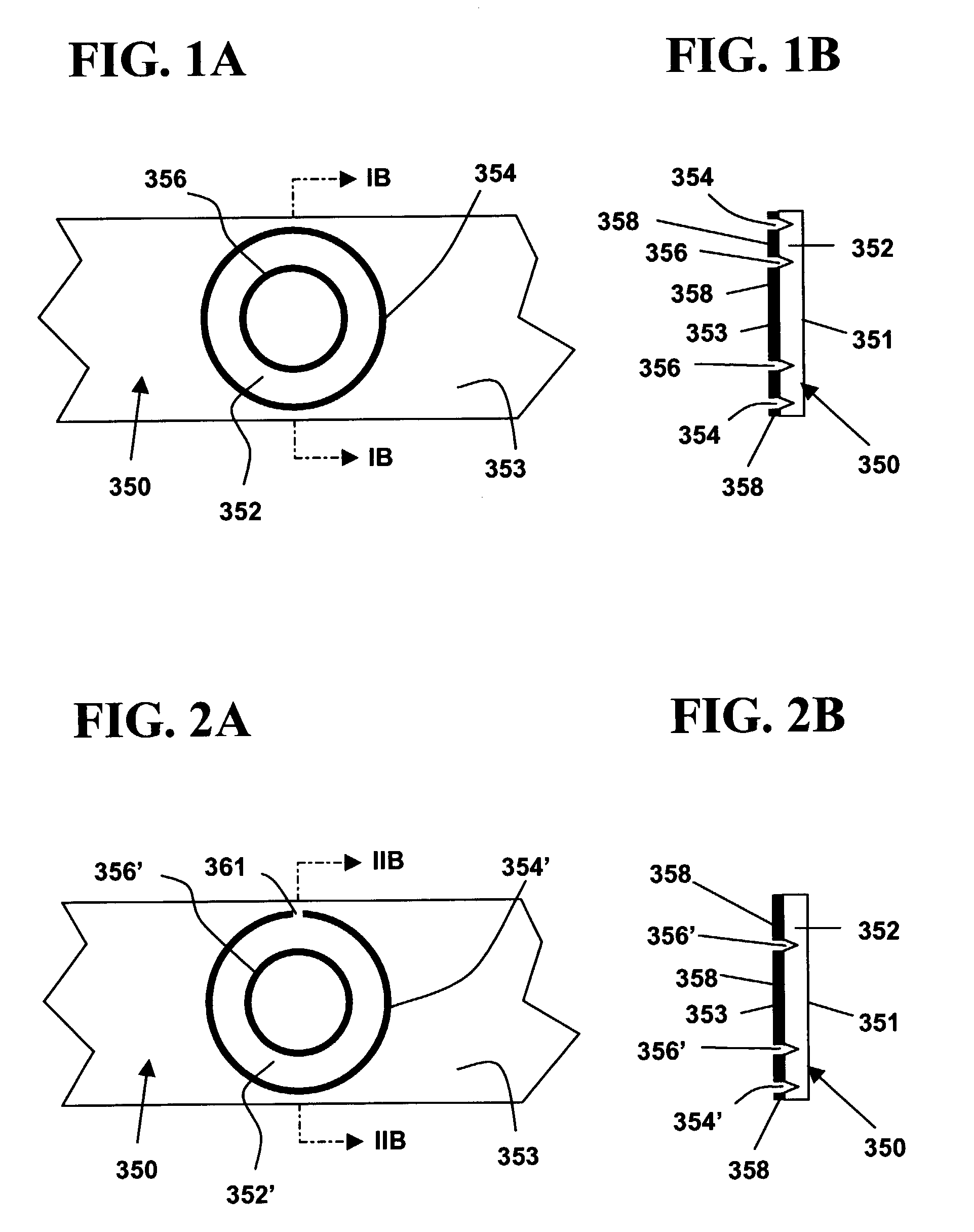

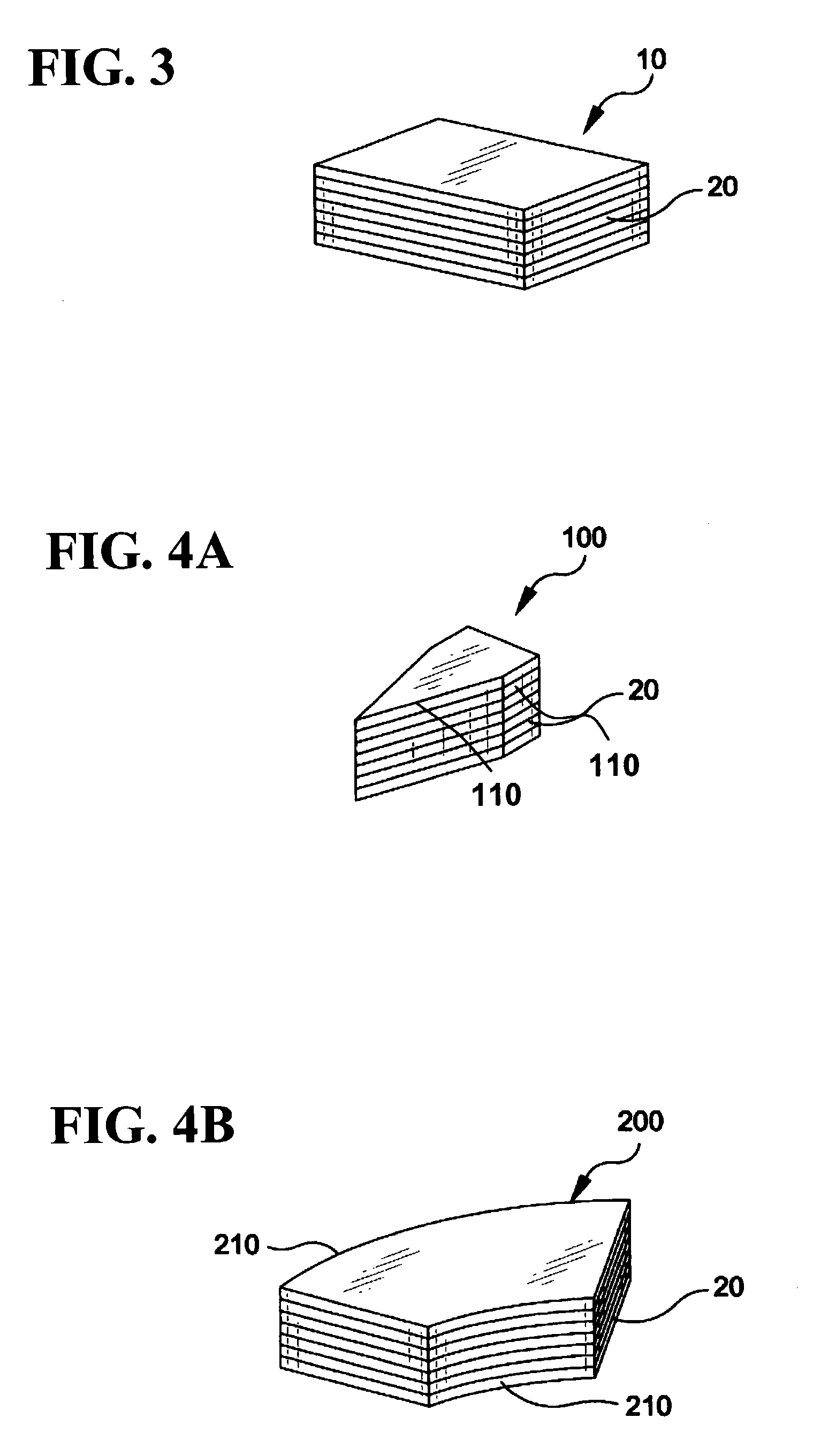

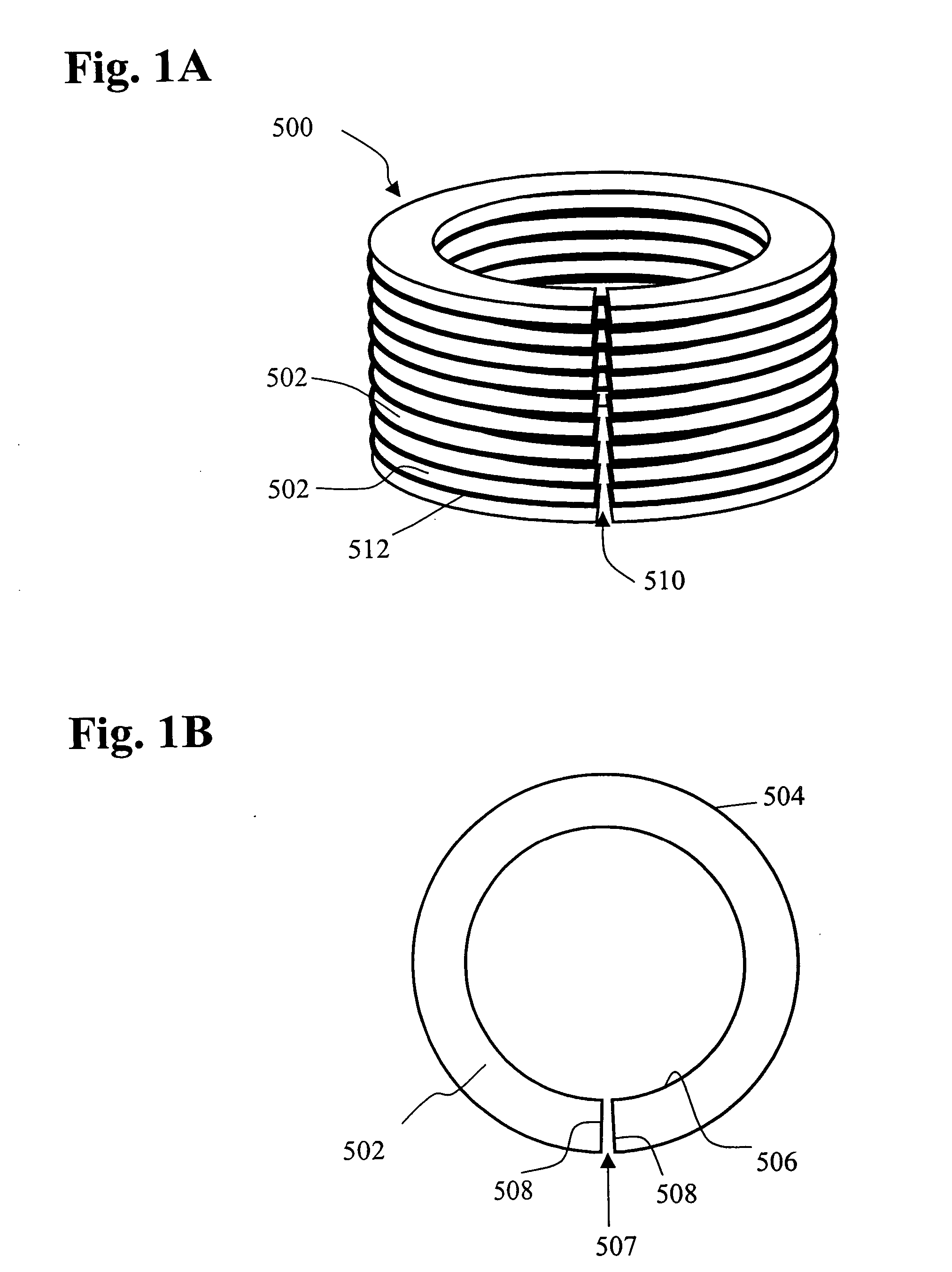

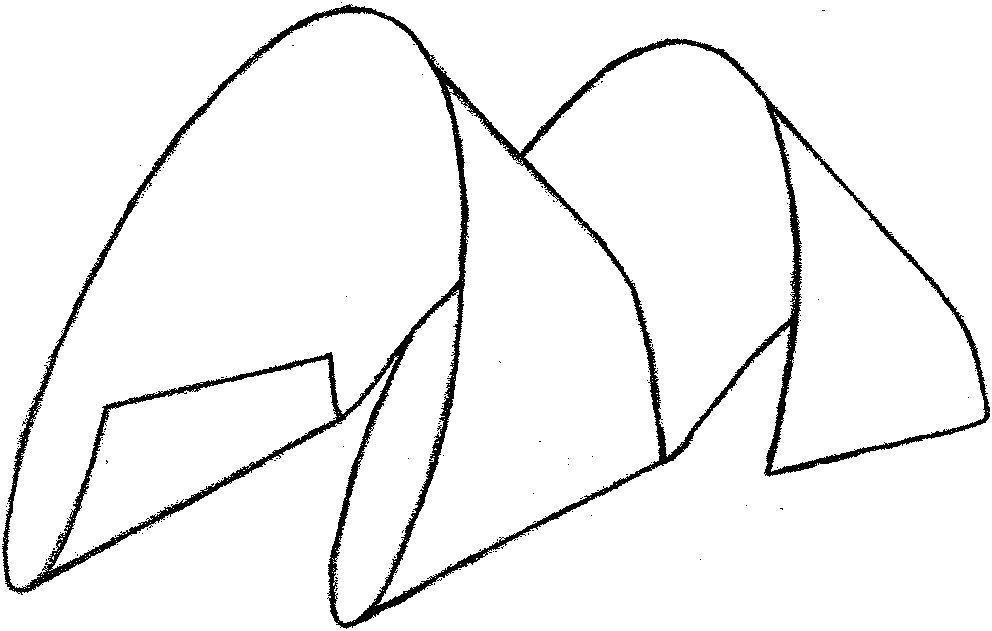

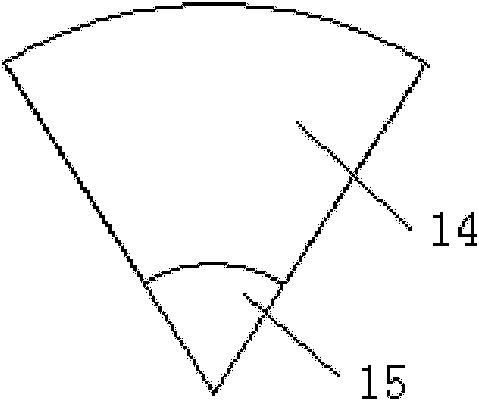

Selective etching process for cutting amorphous metal shapes and components made thereof

InactiveUS7235910B2More size and shapeEasily accommodatedMaterial nanotechnologyInorganic material magnetismMagnetic corePeak value

A selective etching process cuts shapes from amorphous metal strip feedstock. The etching process comprises depositing a chemically resistant material to one side of the strip in a pattern that defines the requisite shape, mating the metal strip with a carrier strip, exposing at least one side of the metal strip to an etching agent to selectively etch the desired shape, and separating the shape from the strip feedstock. A plurality of layers of the shapes is assembled by adhesive lamination to form a generally polyhedrally shaped bulk amorphous metal magnetic component useful in high efficiency electric motors and inductive devices. The bulk amorphous metal magnetic component may include an arcuate surface, and preferably includes two arcuate surfaces that are disposed opposite to each other. The magnetic component is operable at frequencies ranging from about 50 Hz to about 20,000 Hz. When the component is operated at an excitation frequency “f” to a peak induction level Bmax, the component exhibits a core-loss less than about “L” wherein L is given by the formula L=0.005 f(Bmax)1.5+0.000012 f1.5(Bmax)1.6, said core loss, said excitation frequency and said peak induction level being measured in watts per kilogram, hertz, and teslas, respectively. Performance characteristics of the bulk amorphous metal magnetic component of the present invention are significantly better than those of silicon-steel components operated over the same frequency range.

Owner:METGLAS INC

Independently-double-gated transistor memory (IDGM)

InactiveUS7898009B2Small and efficientMade small and moreTransistorSolid-state devicesMemory retentionPower parameter

Memory cells are constructed from double-gated four terminal transistors having independent gate control. DRAM cells may use one, two or three transistors. Single transistor cells are constructed either with or without a bit storage capacitor, and both NAND- and NOR-type Non-Volatile NVRAM cells, as well as Ferroelectric FeRAM cells, are described. For all cells, top gates provide conventional access while independent bottom gates provide control to optimize memory retention for given speed and power parameters as well as to accommodate hardening against radiation. In a single transistor cell without a capacitor, use of the bottom gate allows packing to a density approaching 2 F2. Using a ferroelectric material as the gate insulator produces a single-transistor FeRAM cell that overcomes the industry-wide Write Disturb problem. The memory cells are compatible with SOI logic circuitry for use as embedded RAM in SOC applications.

Owner:AMERICAN SEMICON

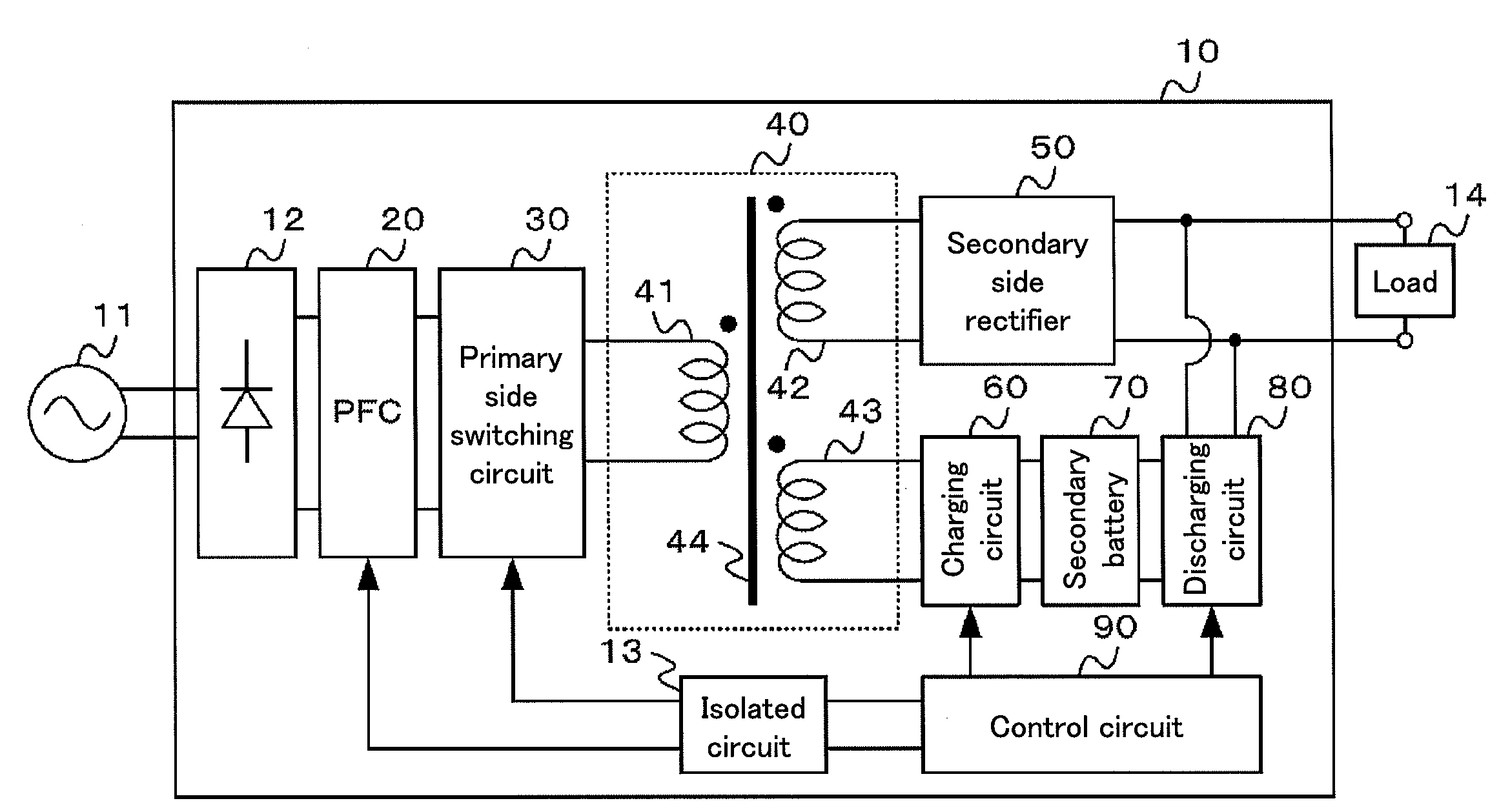

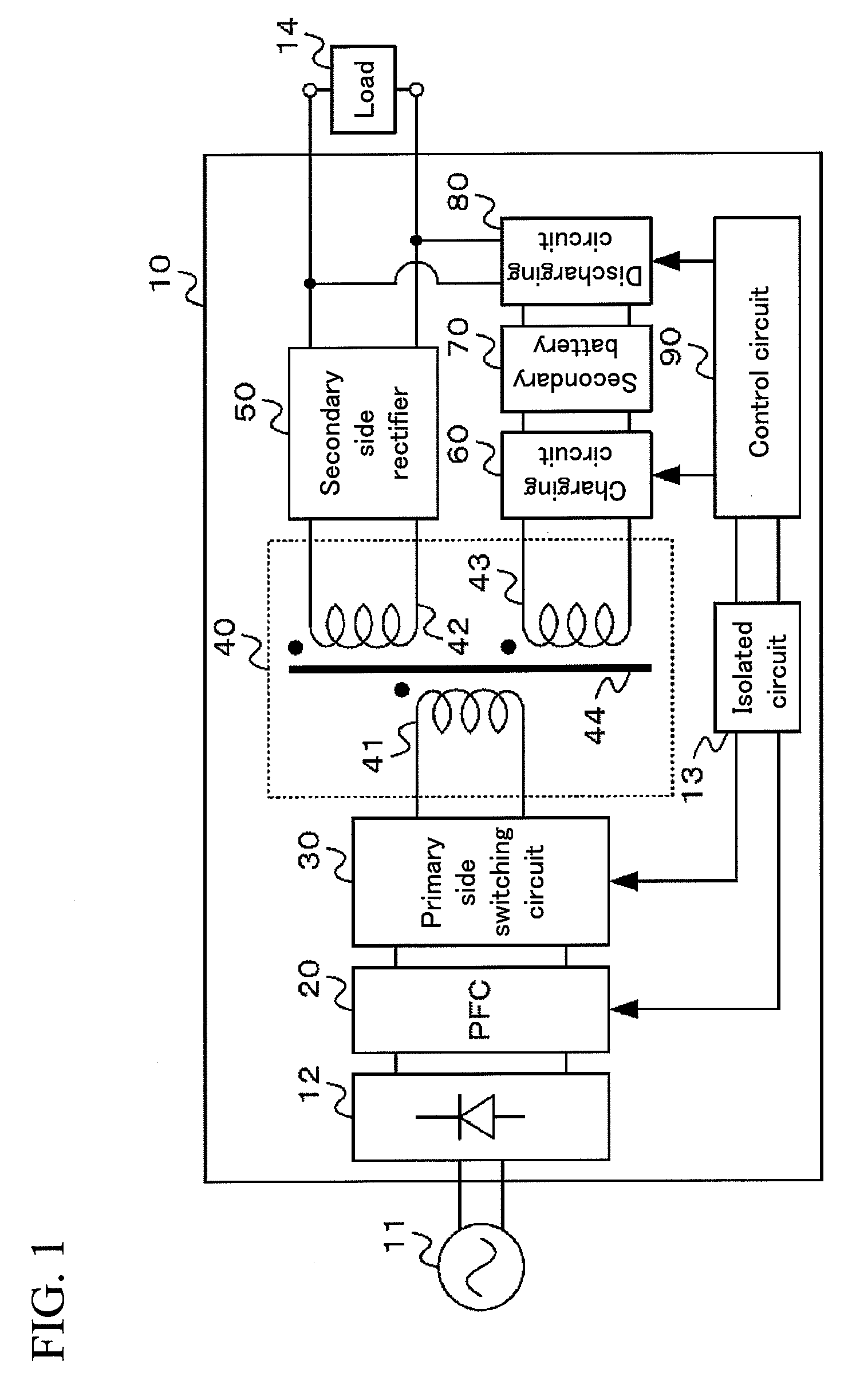

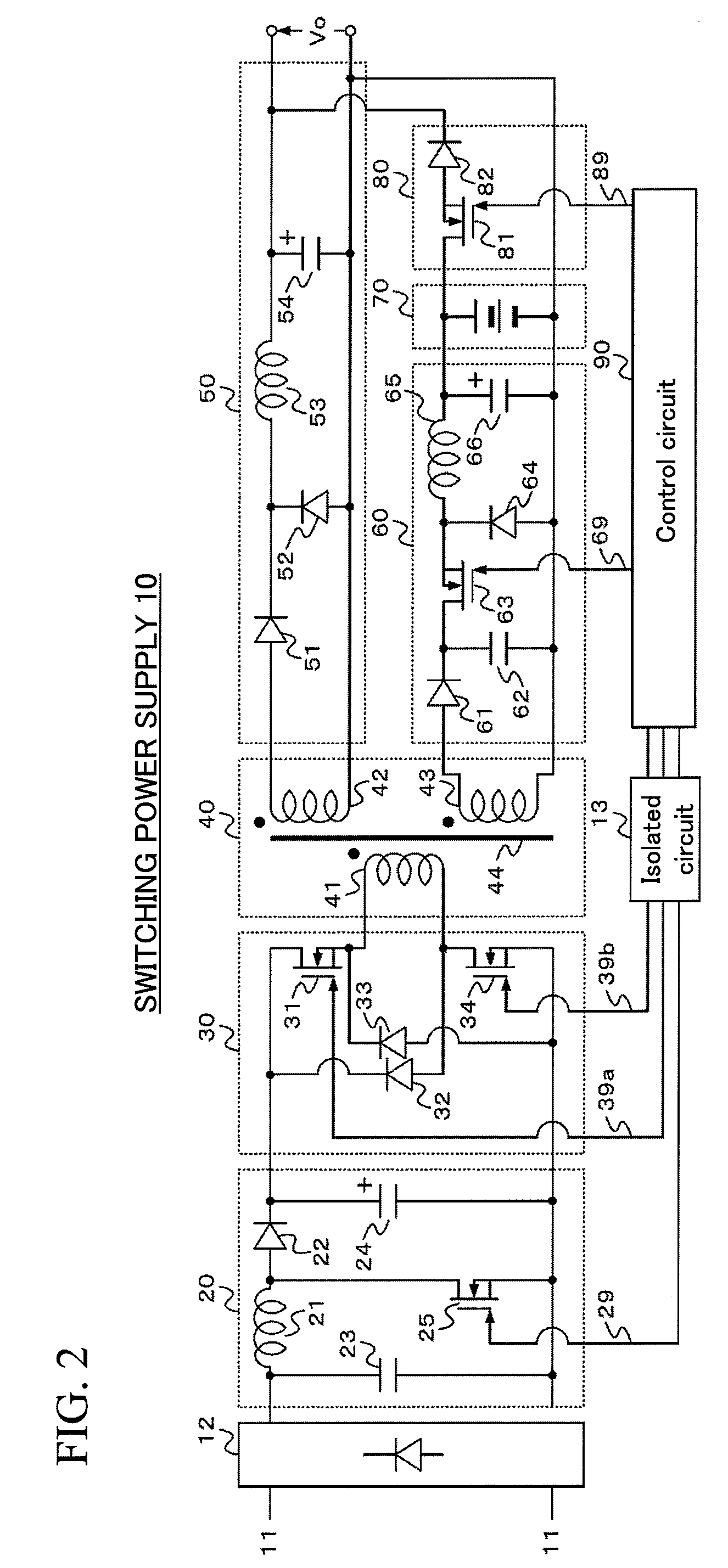

Switching power supply

InactiveUS20080174276A1Small and efficientSmaller and more efficient switching power supplyBatteries circuit arrangementsApparatus with intermediate ac conversionConductor CoilSecondary side

To provide a smaller and more efficient switching power supply 10. The switching power supply 10 according to the present invention includes: a high frequency transformer 40; a primary side switching circuit 30 adapted to switch a current flowing through a primary winding 41 of the high frequency transformer 40 to thereby generate predetermined voltages in a secondary winding 42 and an auxiliary winding 43 of the high frequency transformer 40; a secondary side rectifier 50 adapted to rectify a voltage generated in the secondary winding 42 of the high frequency transformer 40 to supply the rectified voltage to a load; a charging circuit 60 adapted to rectify a current flowing through the auxiliary winding 43 of the high frequency transformer 40 and switch the rectified current to thereby charge a secondary battery 70 at a constant current; and a switch 80 provided between the secondary battery 70 and the load, and supplies, when the voltage supplied to the load is interrupted, the voltage of the secondary battery 70 to the load without via the high frequency transformer 40.

Owner:HITACHI INFORMATION & TELECOMM ENG LTD

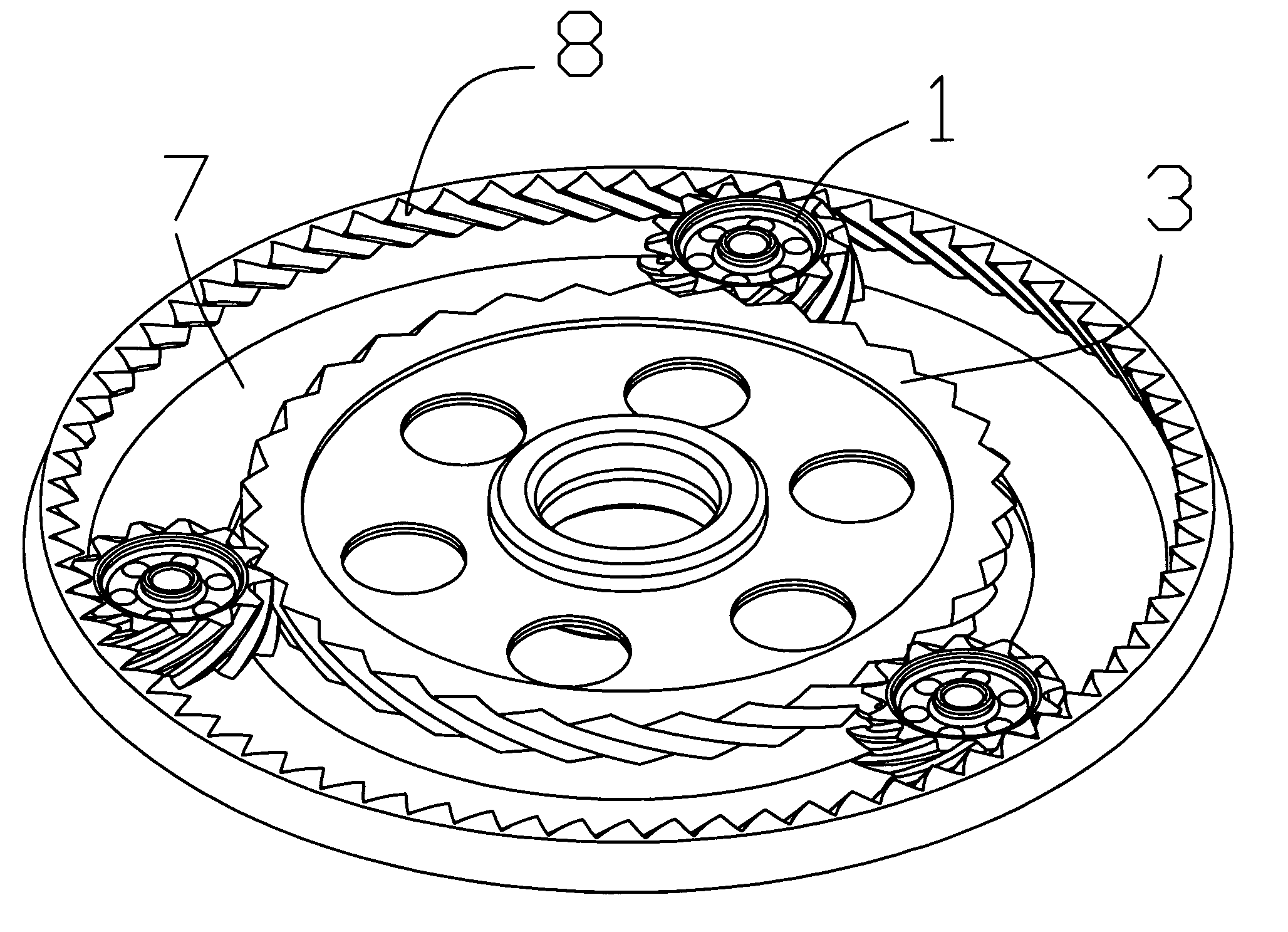

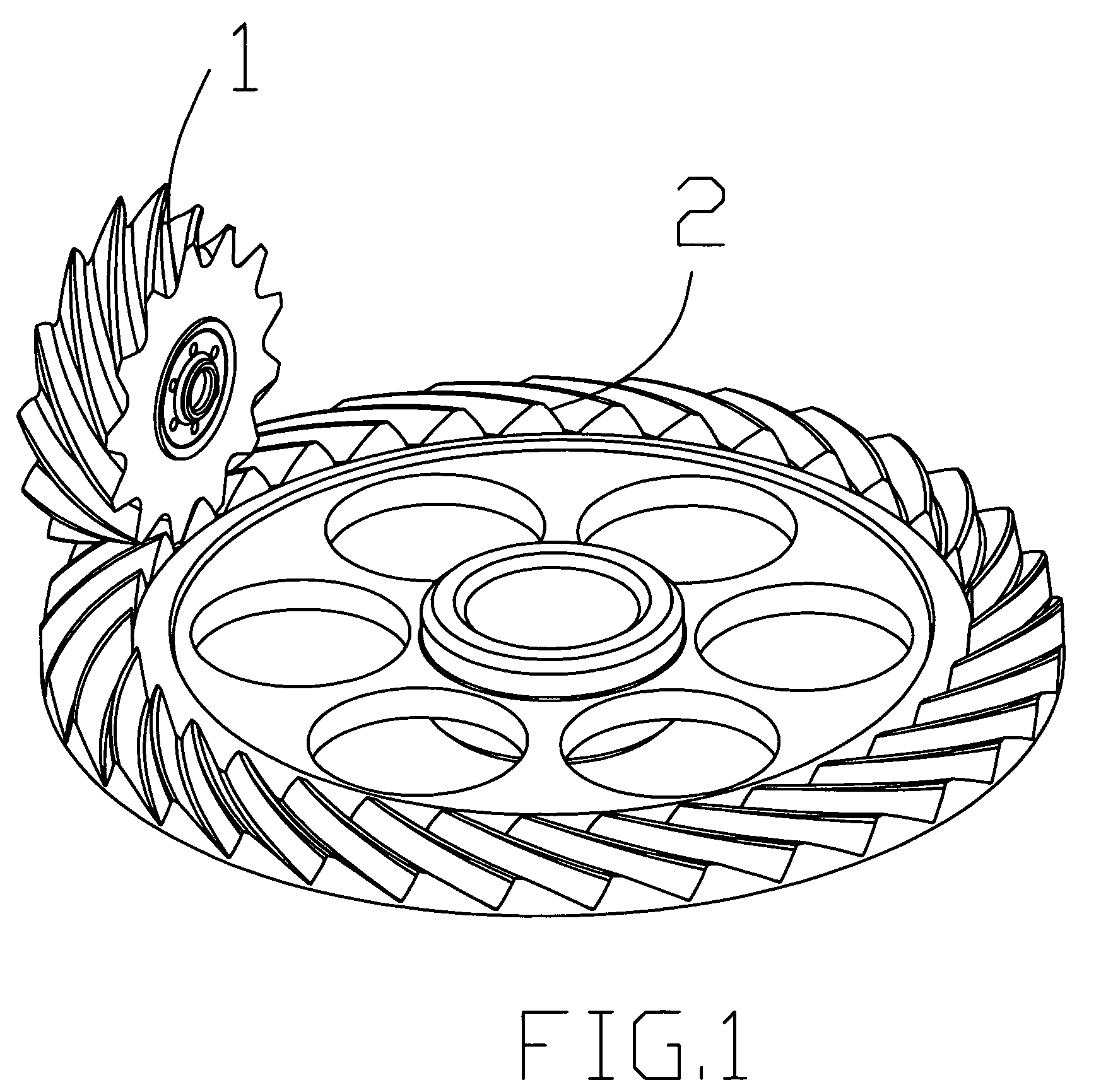

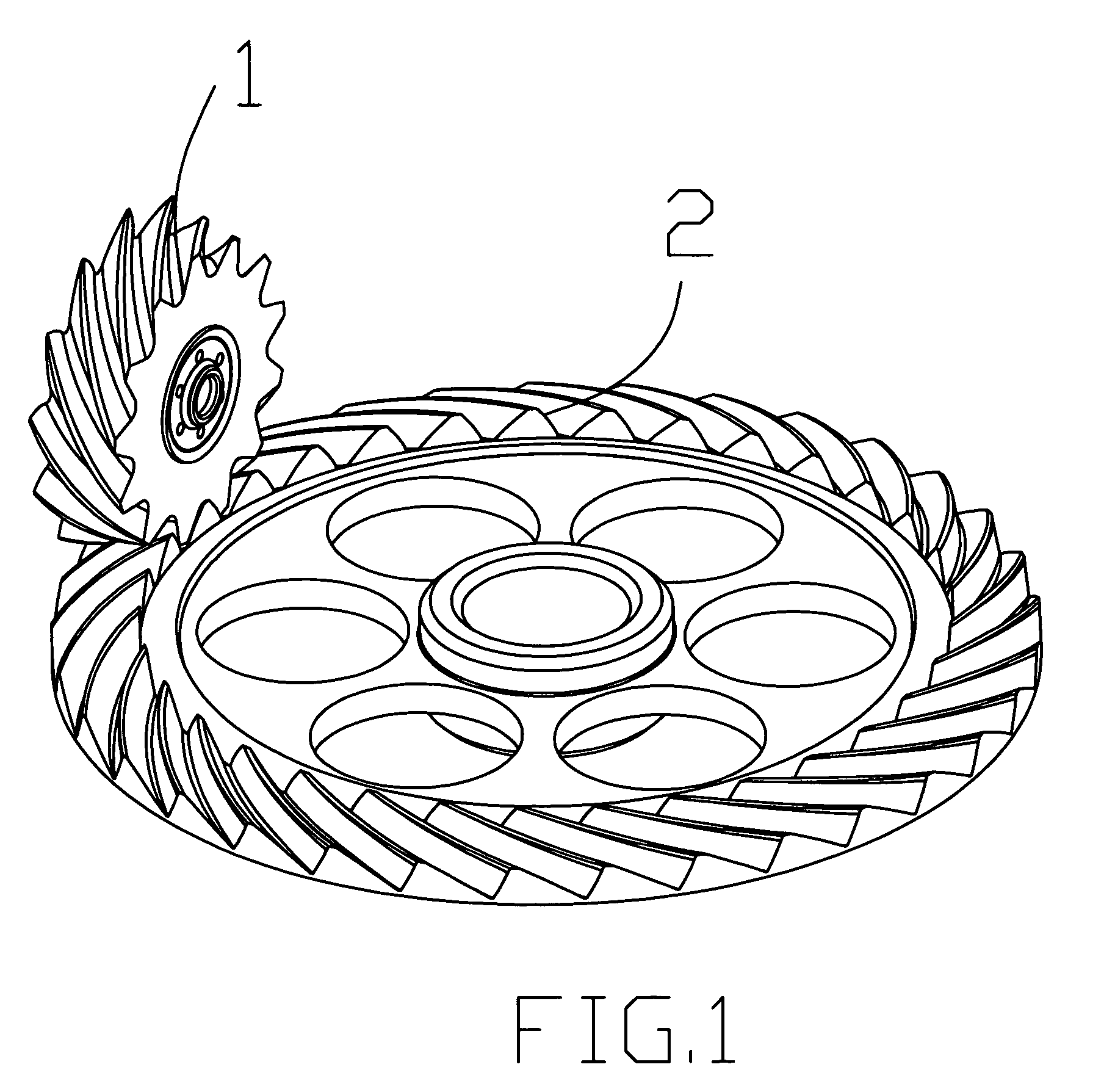

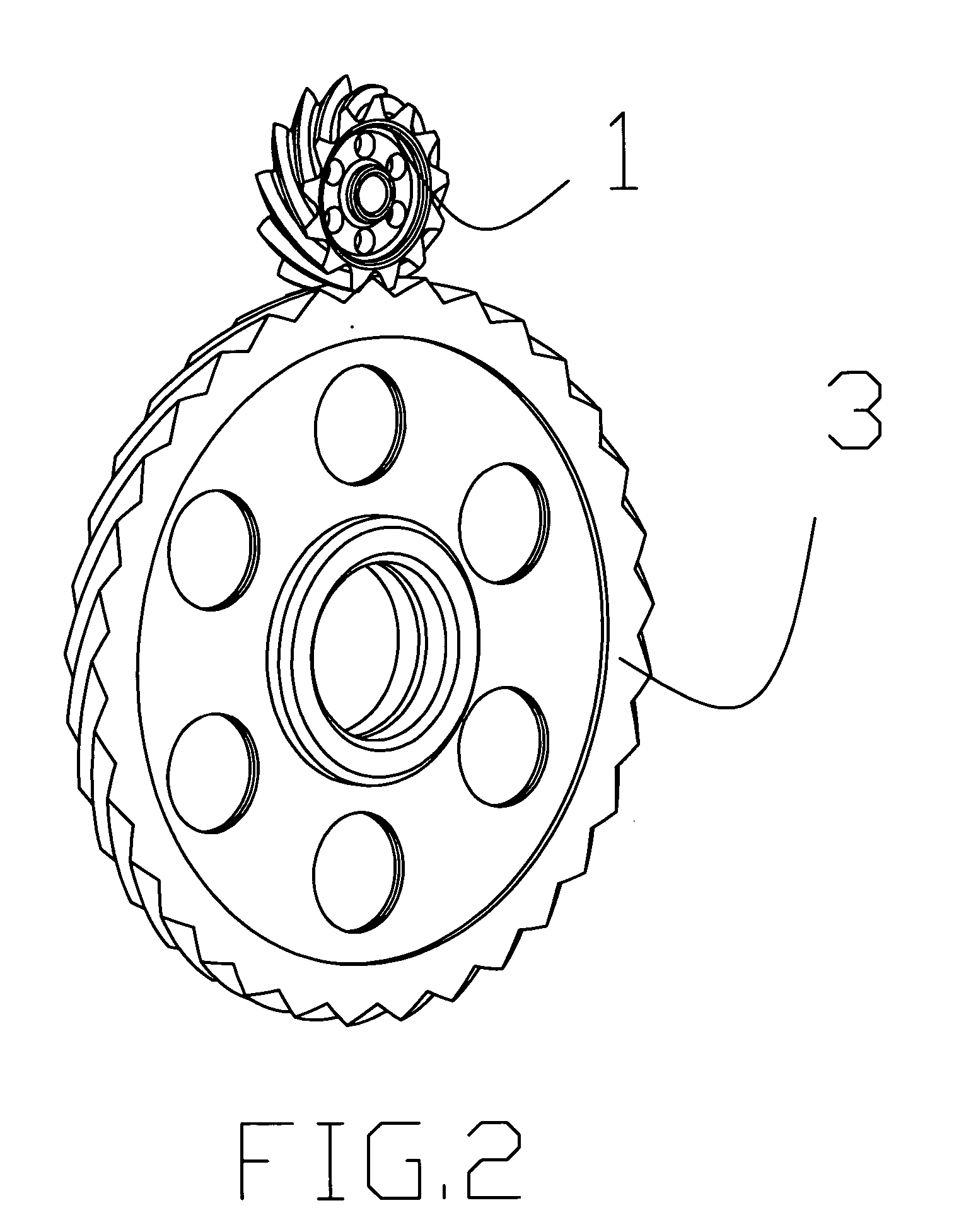

Epicyclic gear train

InactiveUS7022042B2Reduced dimensionSmall and efficientToothed gearingsGearing detailsEngineeringGear train

Owner:EDELWEISS DENTISTRY PROD

Double-Gated Transistor Memory

InactiveUS20110147806A1Small and efficientMade small and moreTransistorSolid-state devicesMemory retentionPower parameter

Memory cells are constructed from double-gated four terminal transistors having independent gate control. DRAM cells may use one, two or three transistors. Single transistor cells are constructed either with or without a bit storage capacitor, and both NAND- and NOR-type Non-Volatile NVRAM cells, as well as Ferroelectric FeRAM cells, are described. For all cells, top gates provide conventional access while independent bottom gates provide control to optimize memory retention for given speed and power parameters as well as to accommodate hardening against radiation. In a single transistor cell without a capacitor, use of the bottom gate allows packing to a density approaching 2 F2. The memory cells are compatible with SOI logic circuitry for use as embedded RAM in SOC applications.

Owner:AMERICAN SEMICON

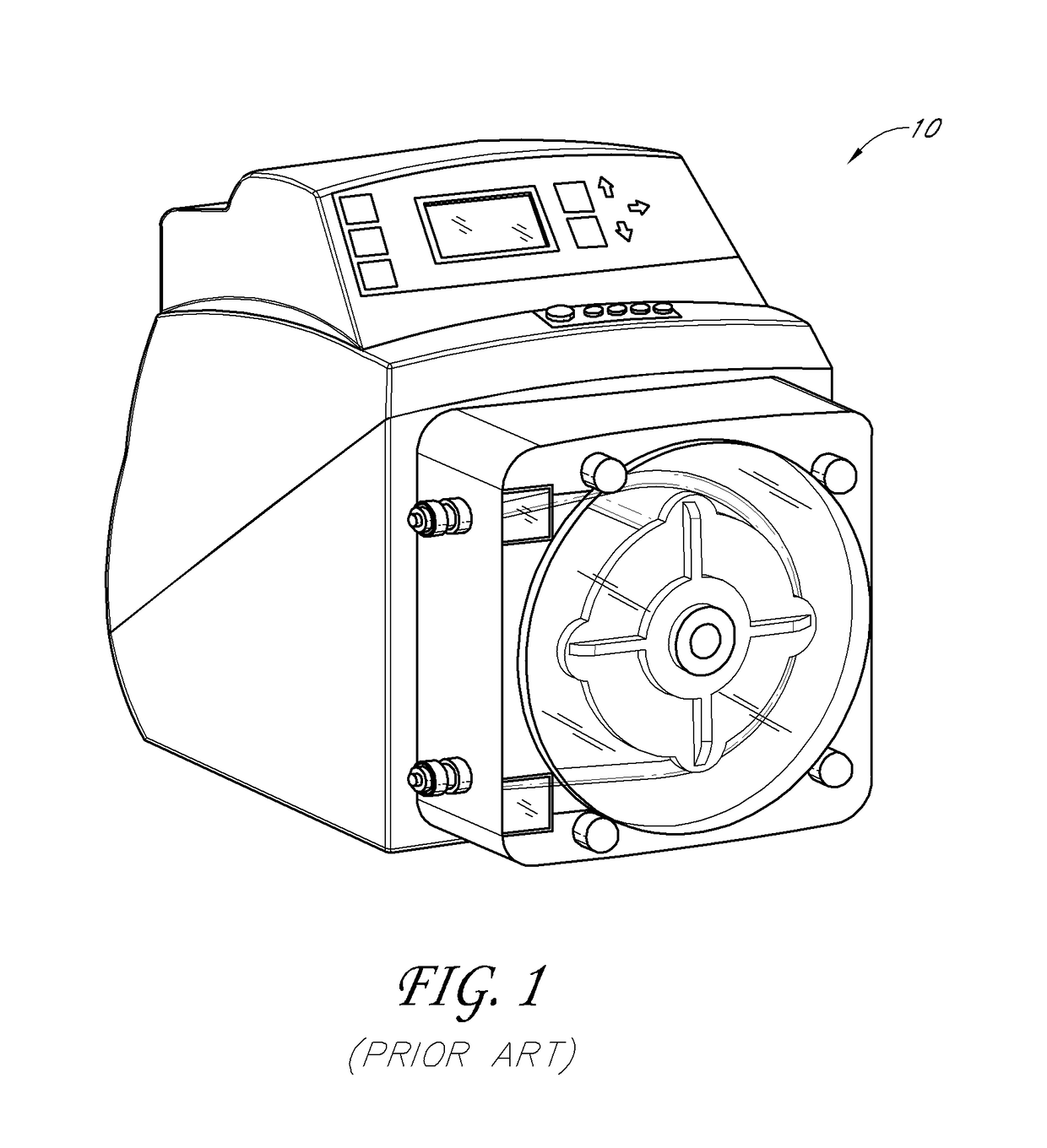

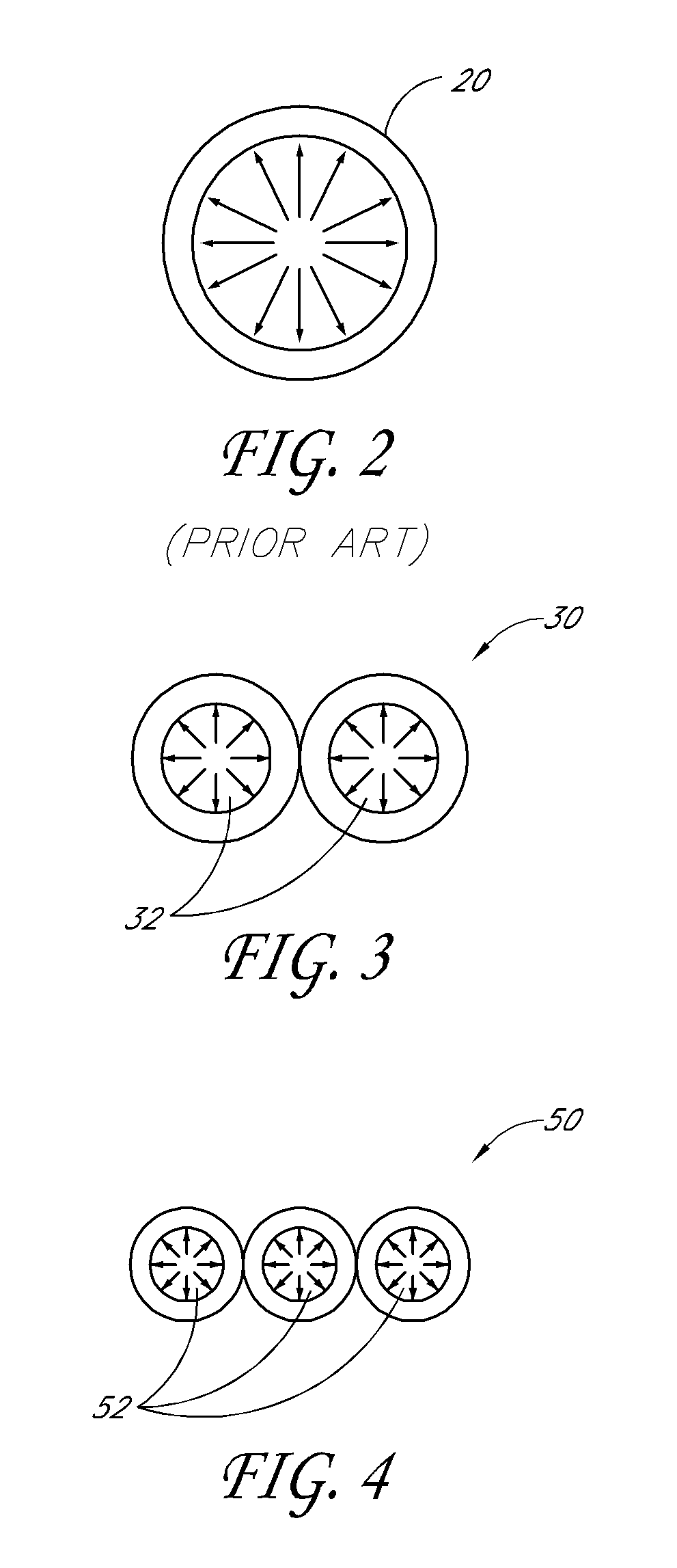

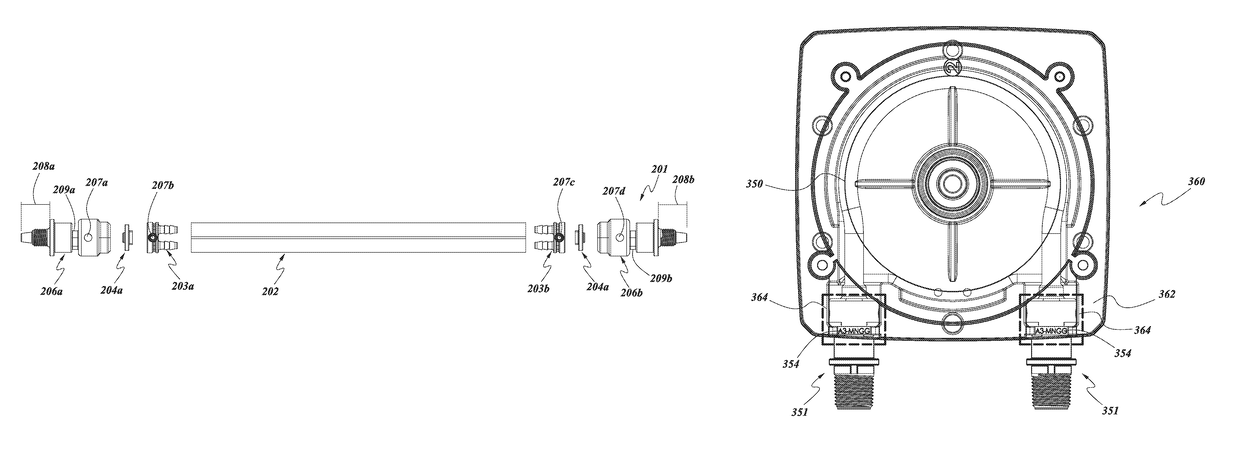

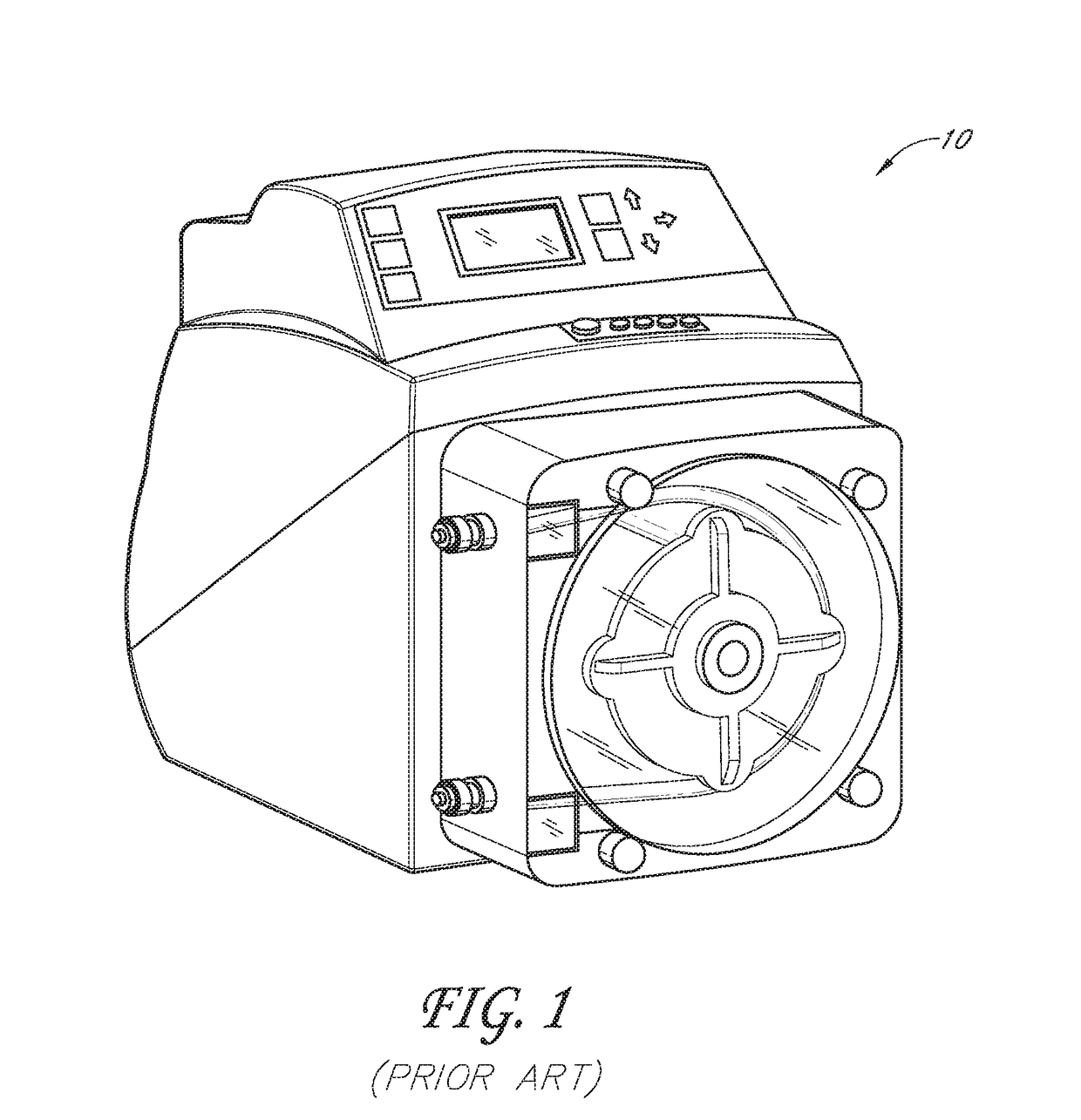

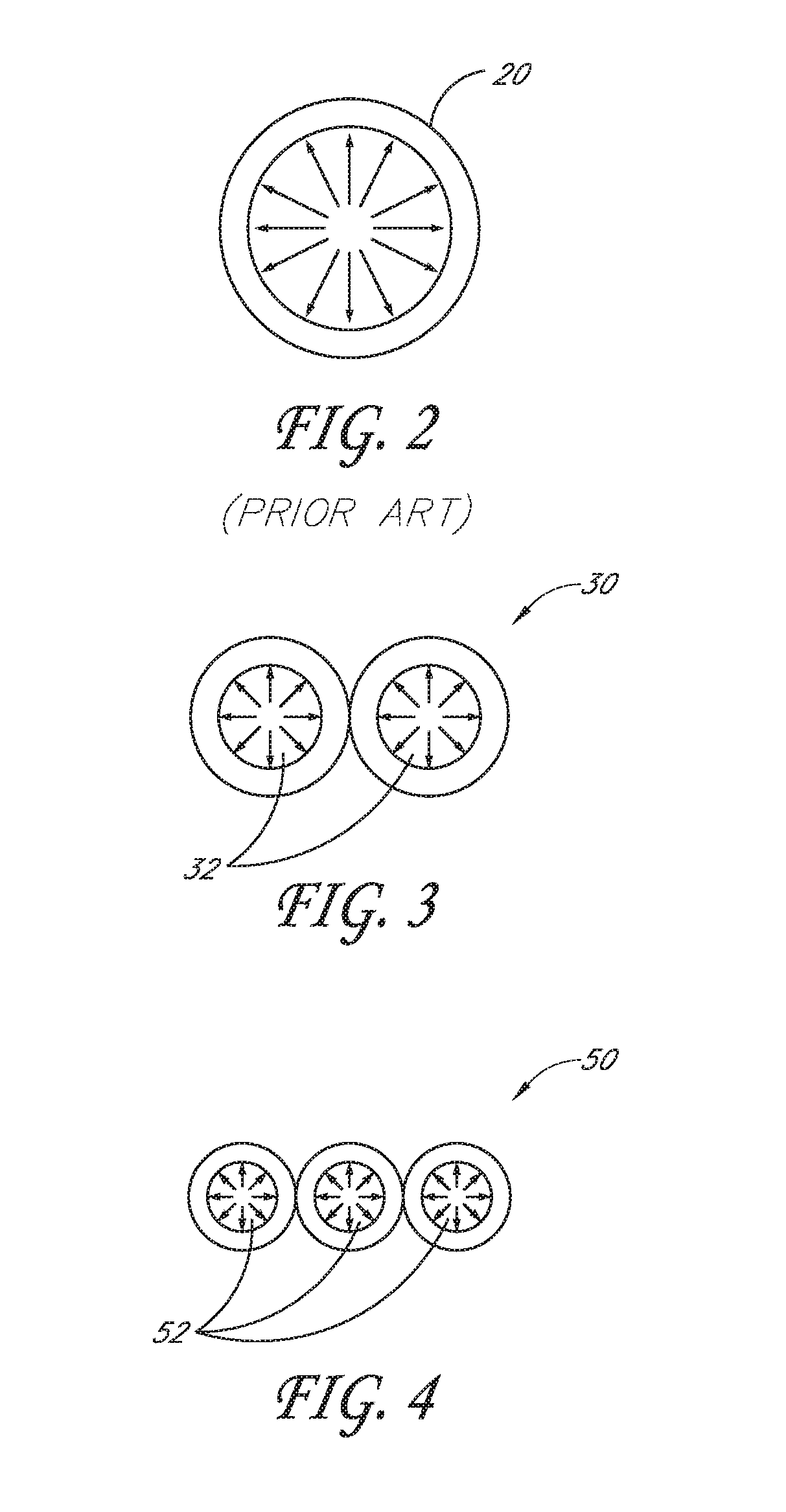

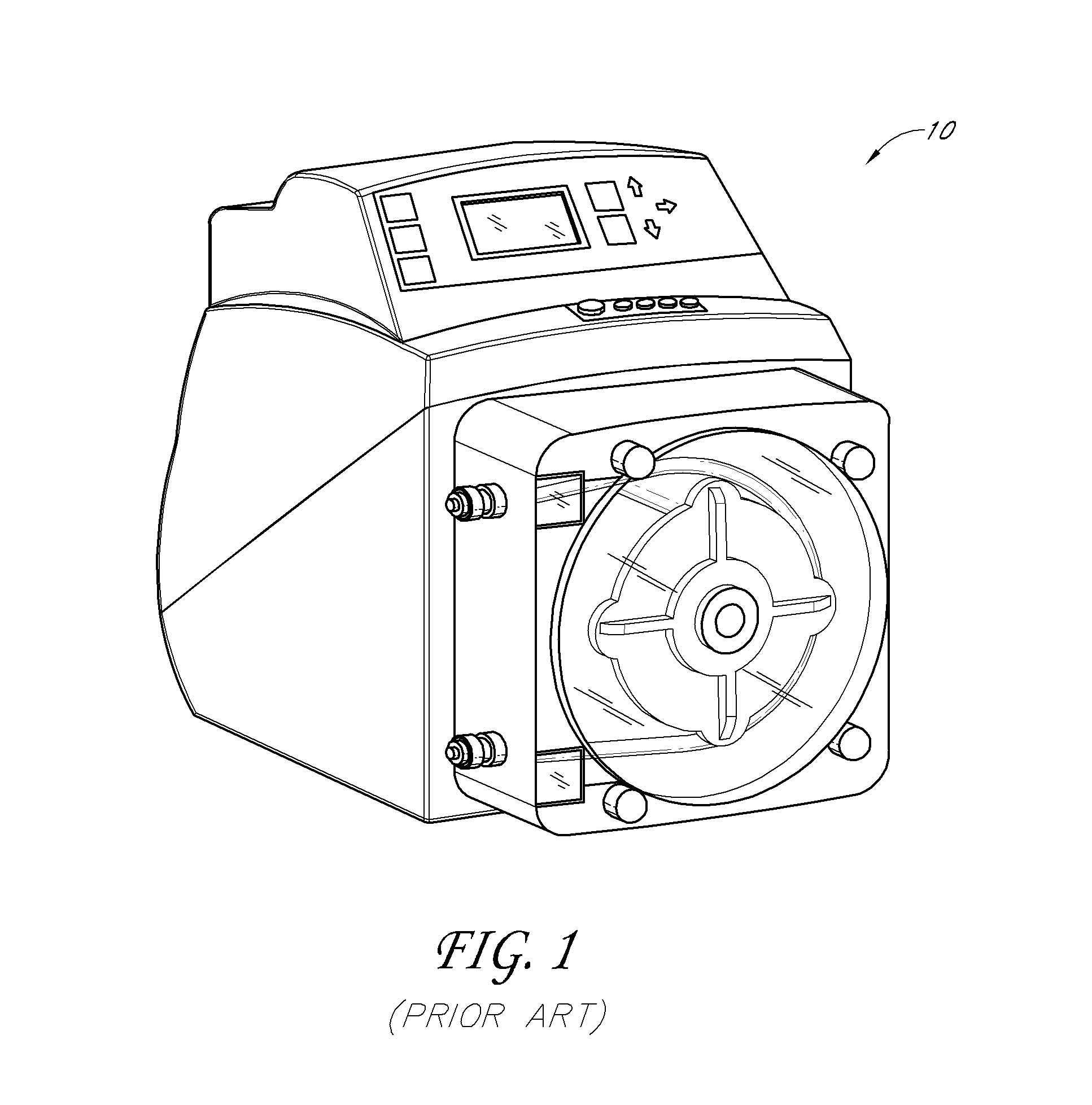

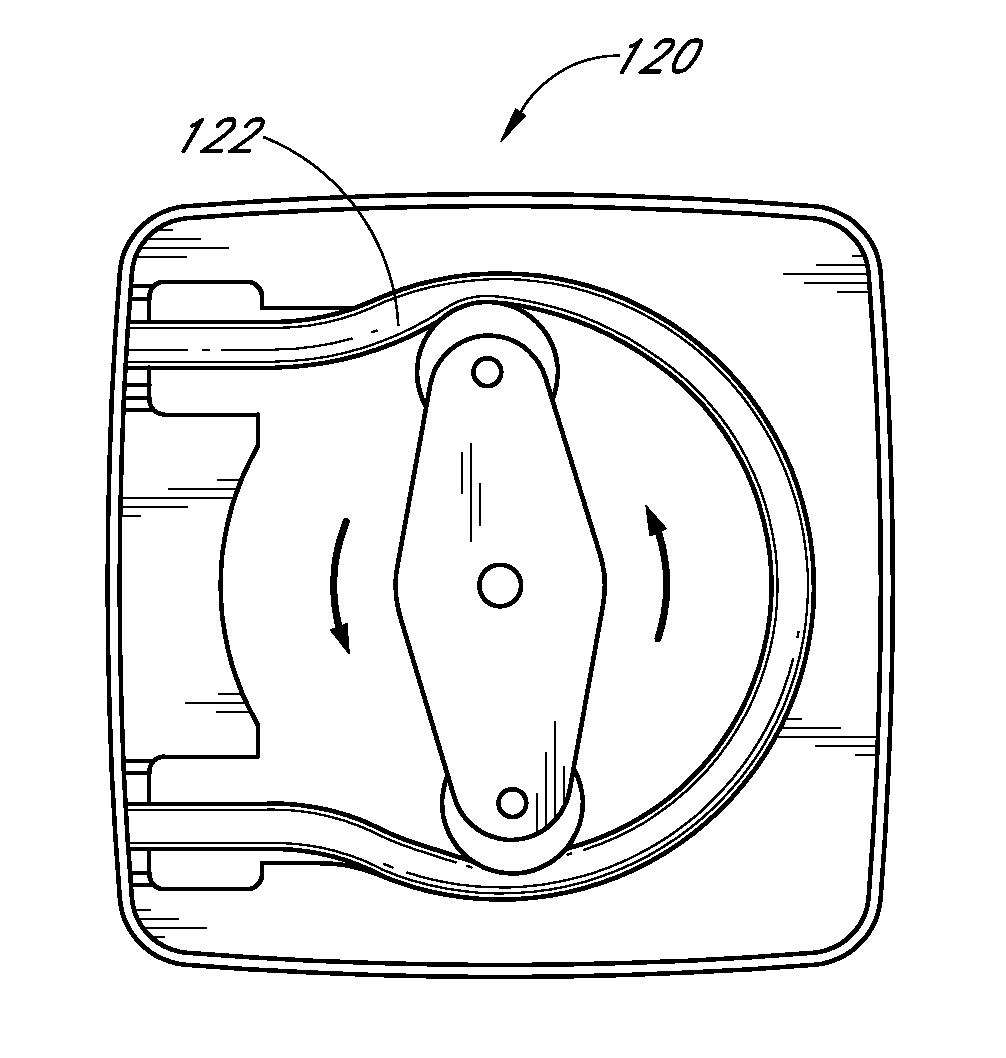

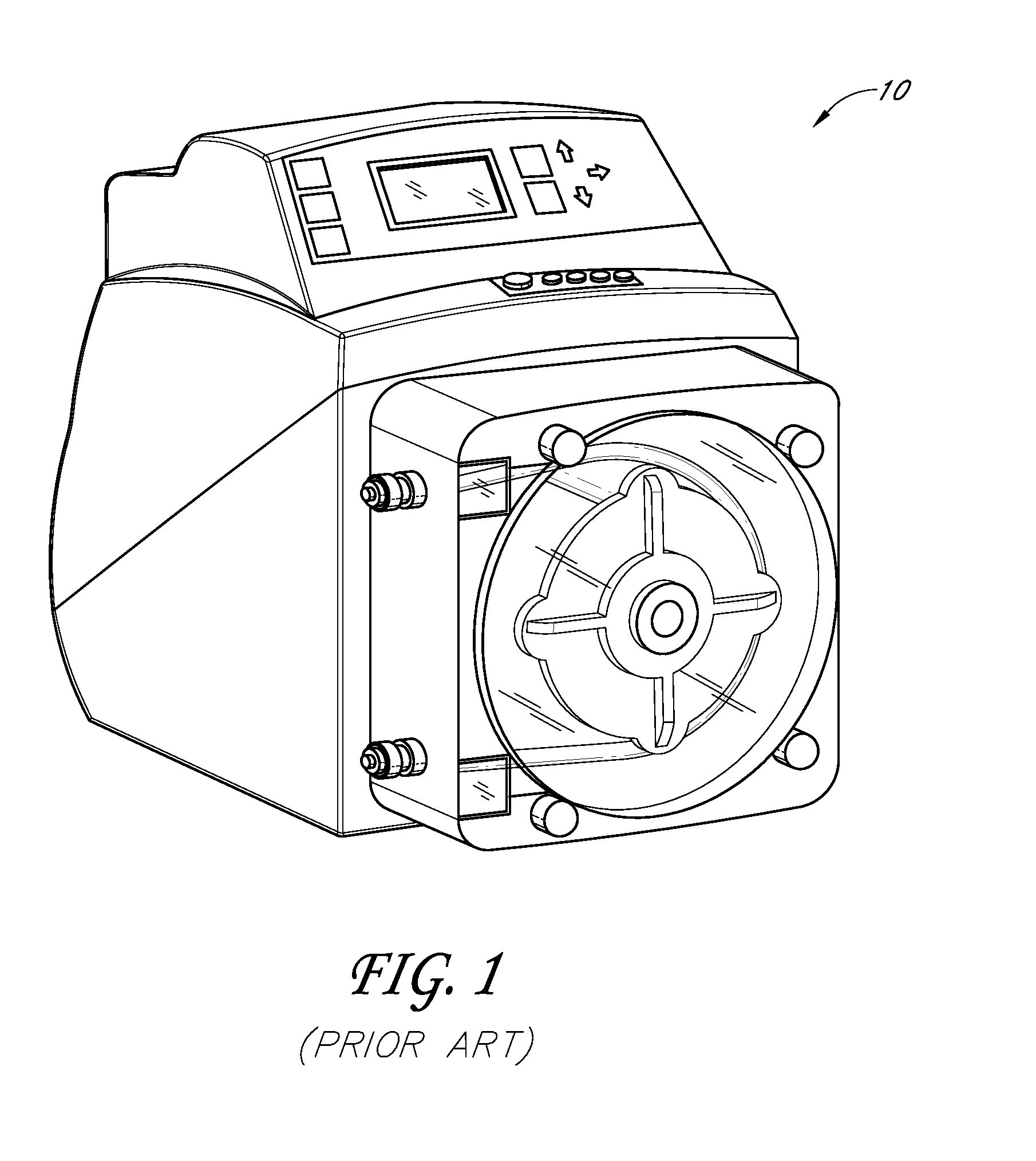

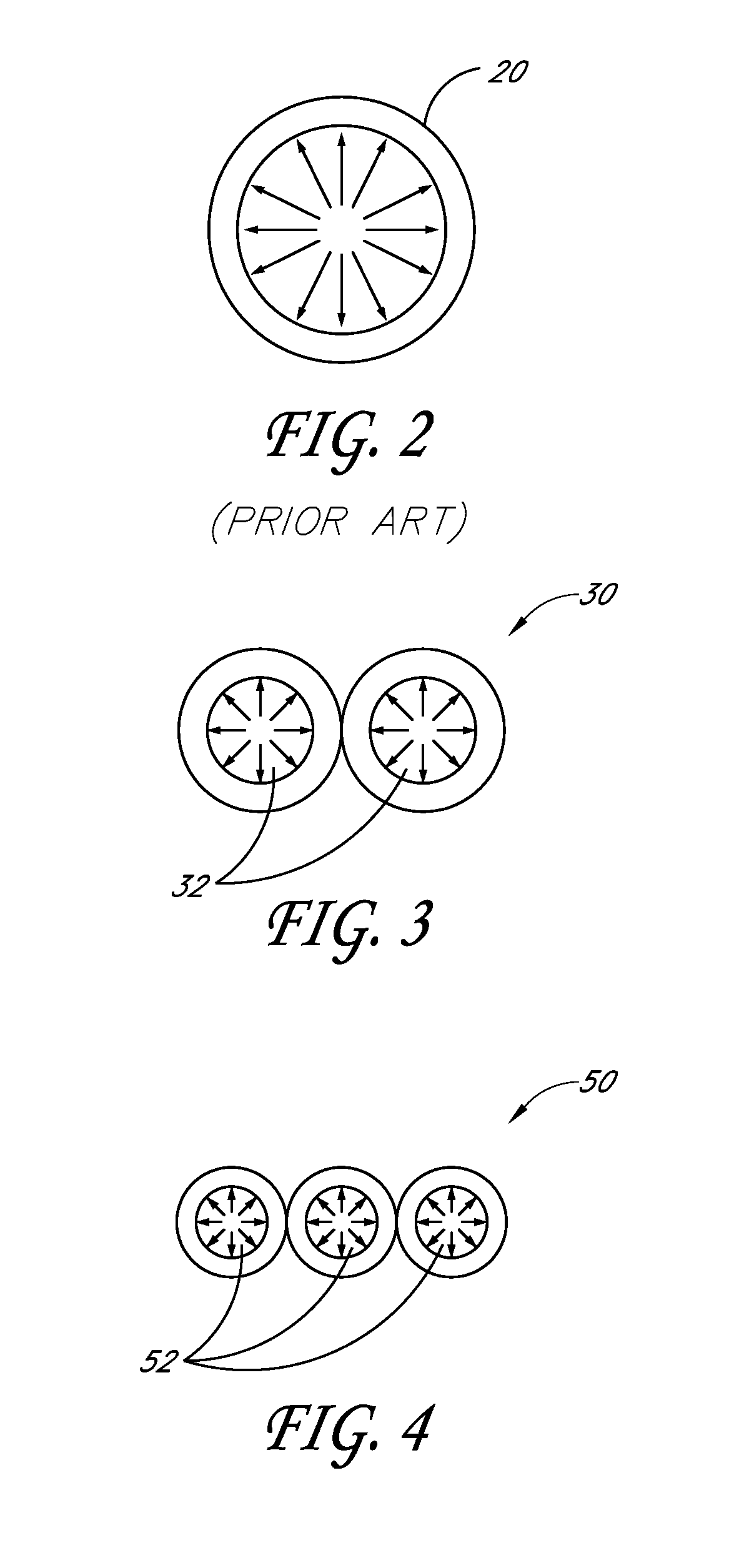

High pressure, high flow rate tubing assembly for a positive displacement pump

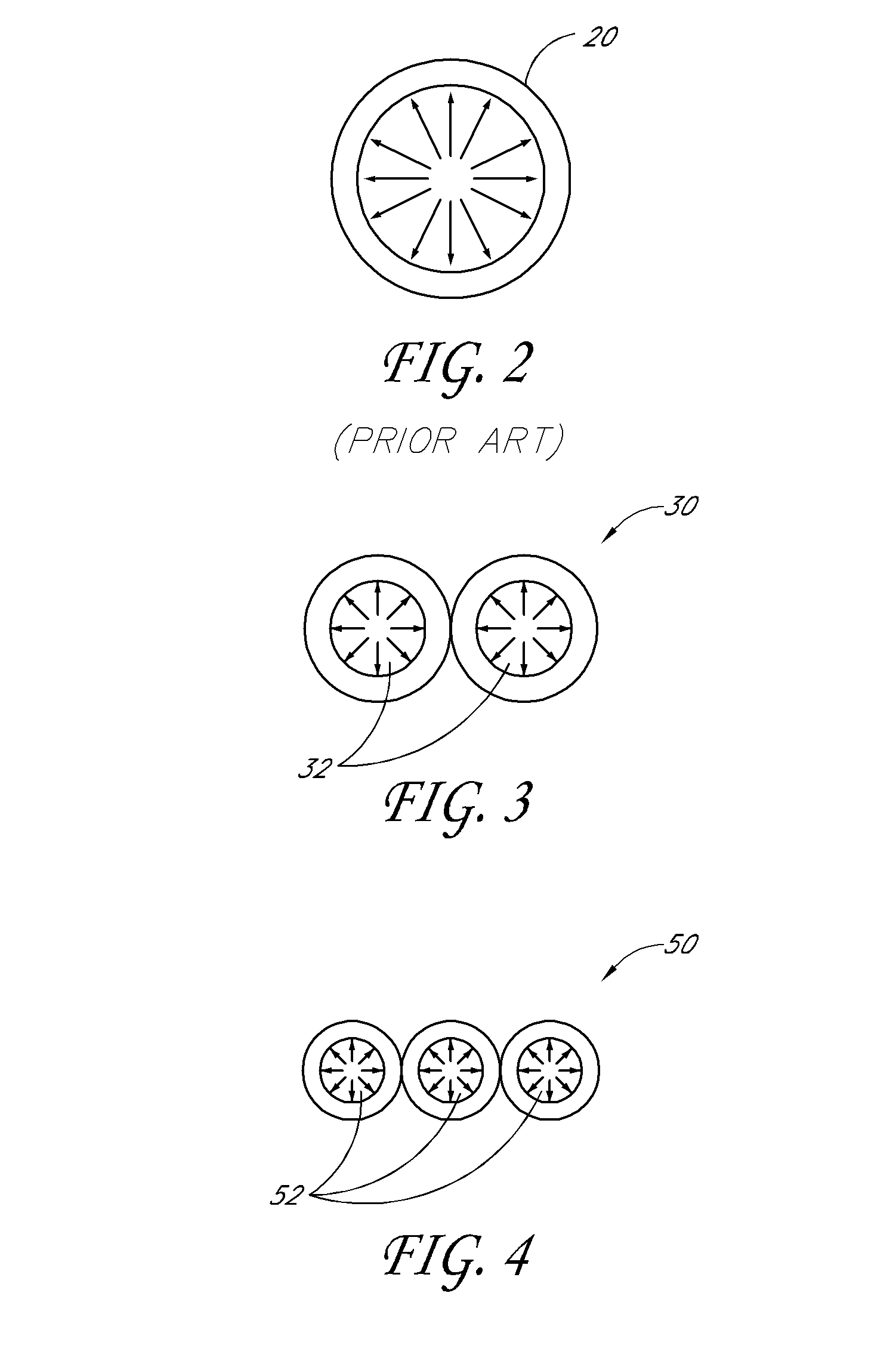

InactiveUS20110180172A1Increased tube lifeReduce replacement costsFlexible member pumpsPipe elementsPeristaltic pumpWorking life

A tubing assembly is provided that can comprise a plurality of tubes or lumens that can be disposed within a head of a peristaltic pump. The tubing assembly can provide a flow rate or volume capacity that is generally equal to or greater than that achieved with a comparable prior art tube while operating at higher pressures than that possible using the prior art tube. Further, in accordance with some embodiments, the tubing assembly can achieve a longer working life than a comparable prior art tube, and the load on the pump motor can be reduced such that the pump life is increased and / or a larger pump motor is not required to achieve such advantageous results.

Owner:BLUE WHITE INDS

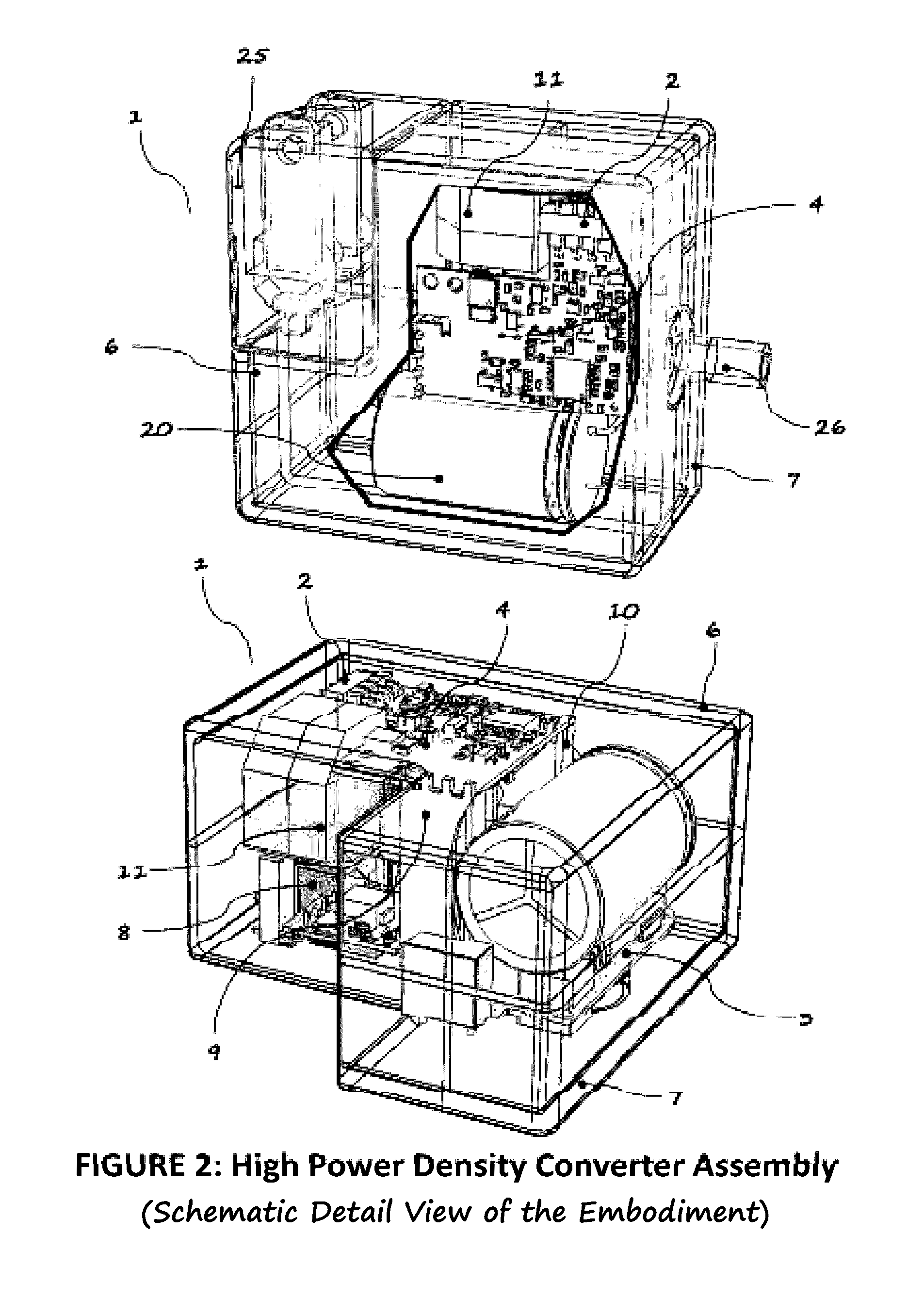

Packaging method for very high density converters

InactiveUS20160359426A1Improve power densitySmall and efficientAc-dc conversion without reversalActive shieldingAC adapterHigh density

Meeting todays requirement in power supply technology demands significant technological advancement in optimizing circuit topology, components and materials, thermal and packaging designs. These requirements are being pushed mainly by continuously increasing power density and efficiency requirements. Ultimately, these trends will come to a point whereby limitations from the above mentioned technological advancements is dependent on one of the above, which is the packaging design. To realize this dependence, we need to look at the growing power systems for modern equipment out there. Let us enumerate some of the available AC adapters in terms of power densities of a 45 W adapter. Firstly, square type architecture introduced by Apple is about 7 W / in3, considering the packaging has a profile limitation whereby its AC plug is removable thus occupying relatively bigger chunk of the volume. The next one is by Asus of similar profile to Apple incorporating the AC Plug eliminating the socket assembly in the packaging; which packs about 9 W / in3. Lastly, the typical rectangular profile by Eos which is about 7 W / in3. As for this particular embodiment it is about 40% smaller in profile, in contrast to the 45 W Apple packaging, with increase power density of about 12 W / in3. Packaging design method plays a great role in achieving the above requirements for a very high density converters.

Owner:ROMPOWER ENERGY SYST

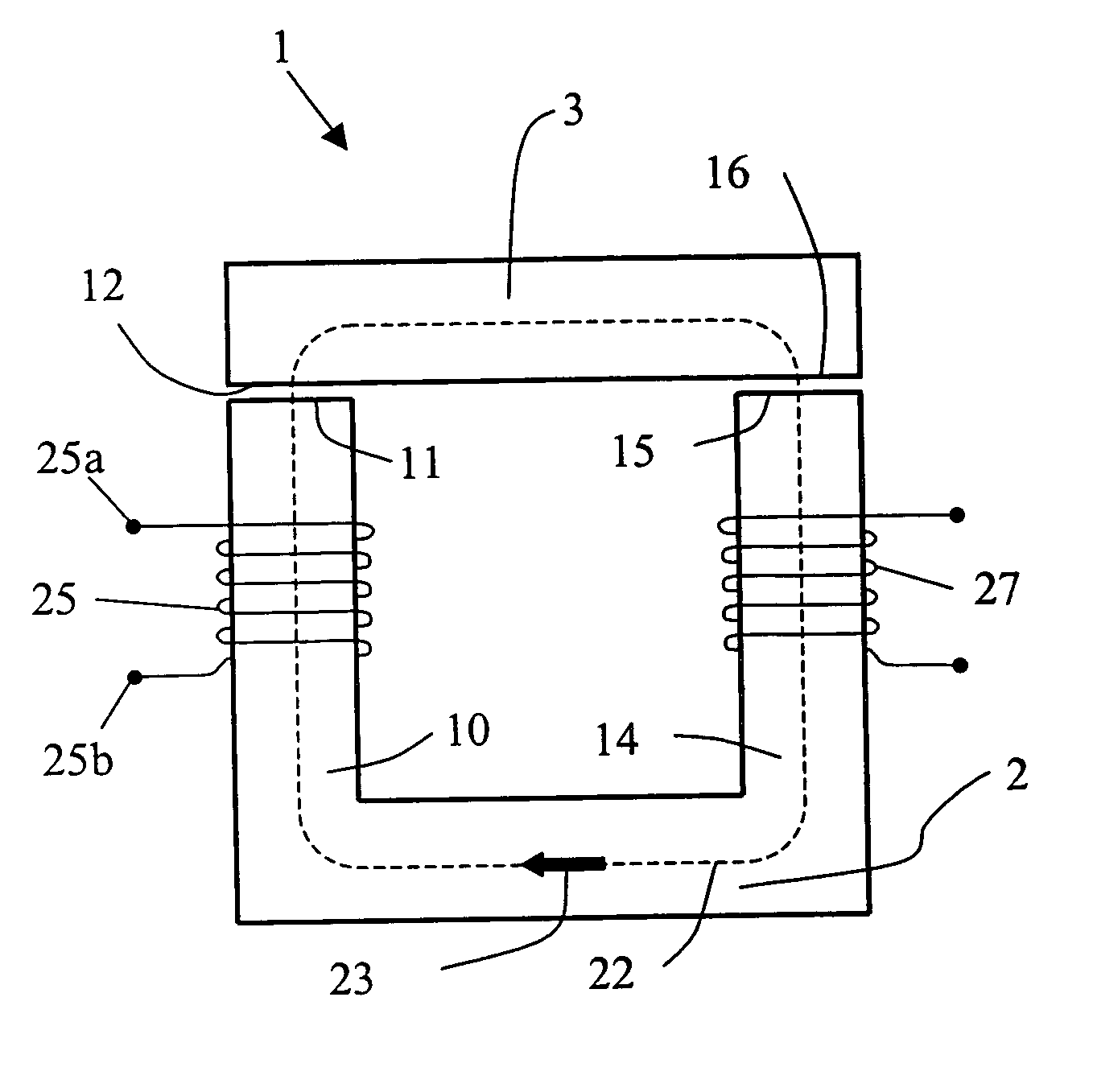

Bulk amorphous metal inductive device

InactiveUS20060066433A1Low reluctanceImprove energy storage performanceTransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerPeak value

A bulk amorphous metal inductive device includes a magnetic core having at least one low-loss bulk ferromagnetic amorphous metal magnetic component forming a magnetic circuit having an air therein. The component has a plurality of similarly shaped layers of amorphous metal strips bonded together to form a polyhedrally shaped part. The device has one or more electrical windings and is easily customized for specialized magnetic applications, e.g. for use as a transformer or inductor in power conditioning electronic circuitry employing switch-mode circuit topologies and switching frequencies ranging from 1 kHz to 200 kHz or more. The low core losses of the device, e.g. a loss of at most about 12 W / kg when excited at a frequency of 5 kHz to a peak induction level of 0.3 T, make it especially useful at frequencies of 1 kHz or more.

Owner:METGLAS INC

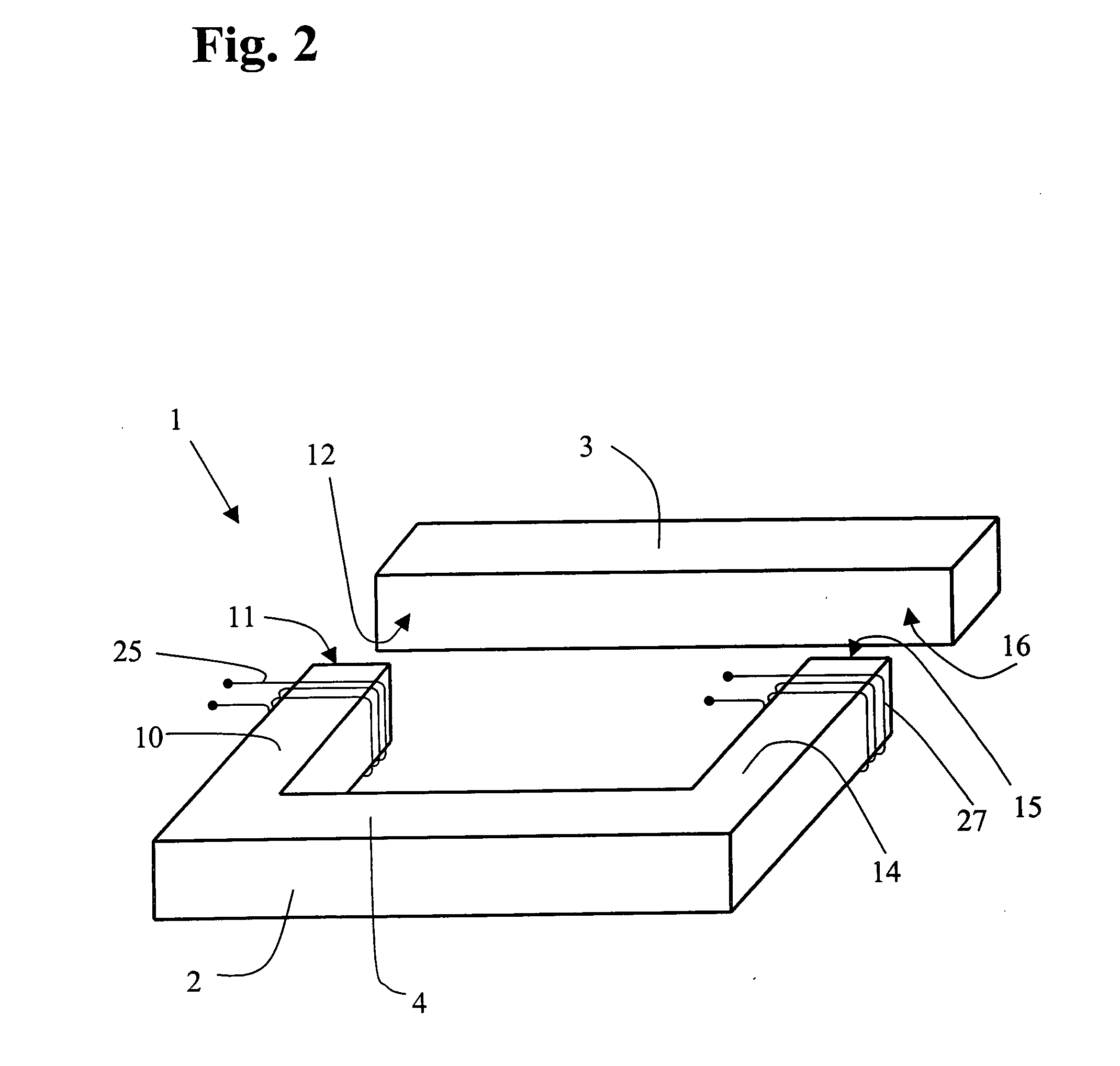

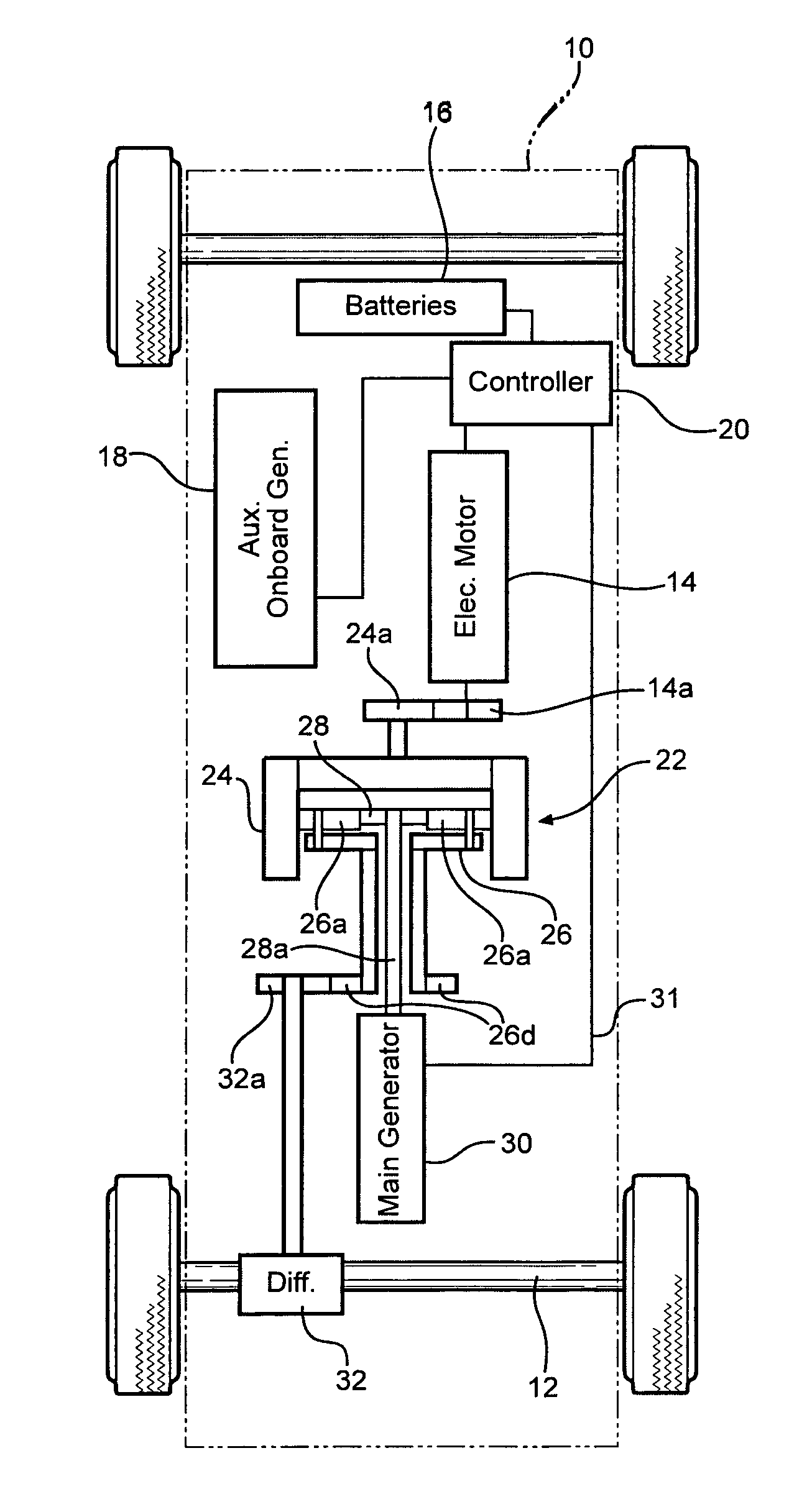

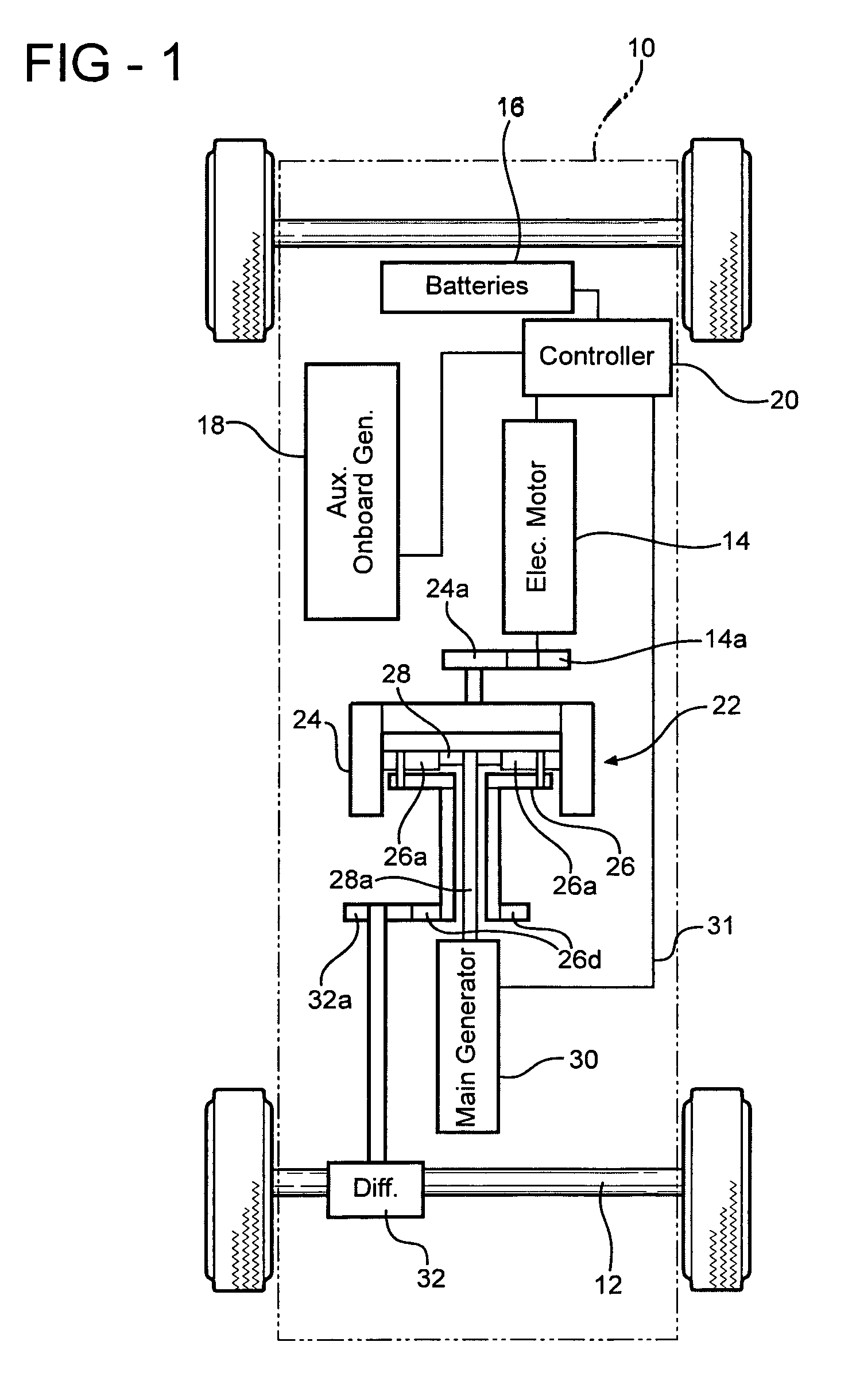

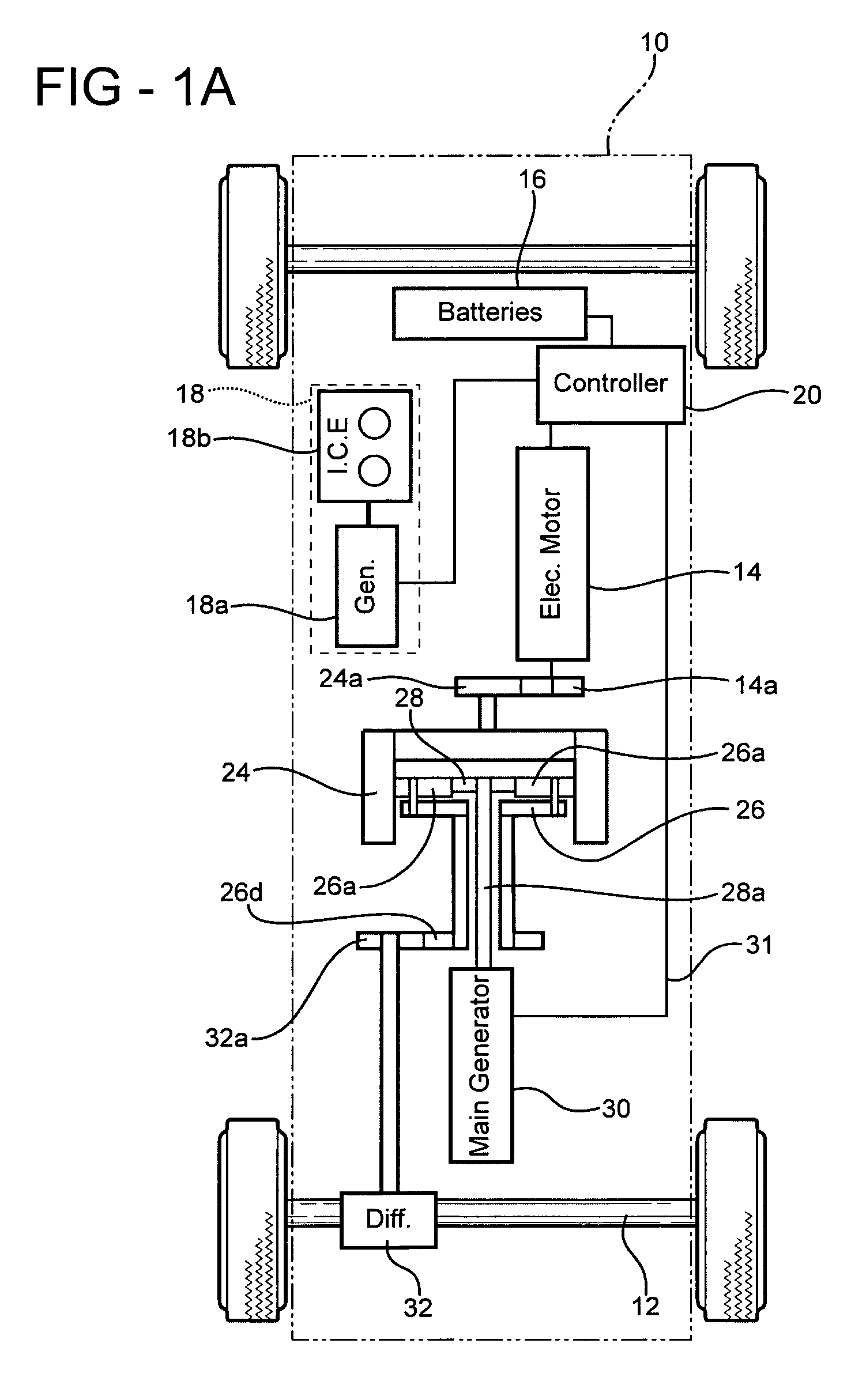

Electric vehicle reaction drive

InactiveUS7448458B2Greater vehicle drive torqueSmall and efficientAuxillary drivesDigital data processing detailsElectricityElectric drive

An electric drive for a vehicle or other machine having a rotatable drive mechanism, in which the torque output of an electric motor is coupled to drive a main generator through a planetary gear set, the electrical output of the main generator is supplied to the motor to drive the motor, and a reaction torque produced in the planetary gear set from the driving of the generator is coupled to drive the vehicle wheels or other motion means. The reaction torque produced in the planetary gear set in response to the generator torque is greater than the electric motor torque input. Start-up and make-up power for the electric motor are provided by an onboard battery recharged by an auxiliary onboard generator, or by the auxiliary onboard generator.

Owner:MEYER JOHN FRED

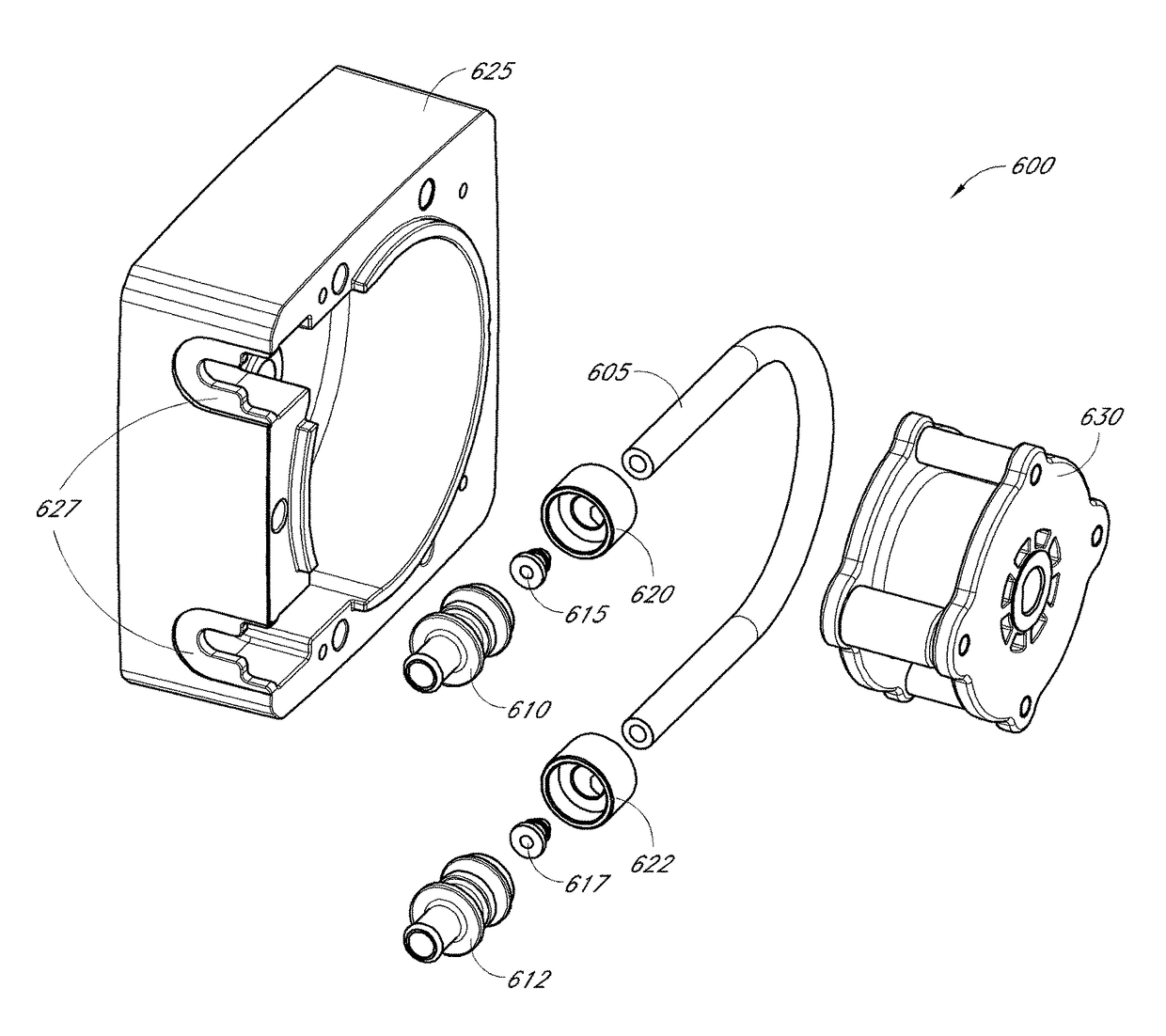

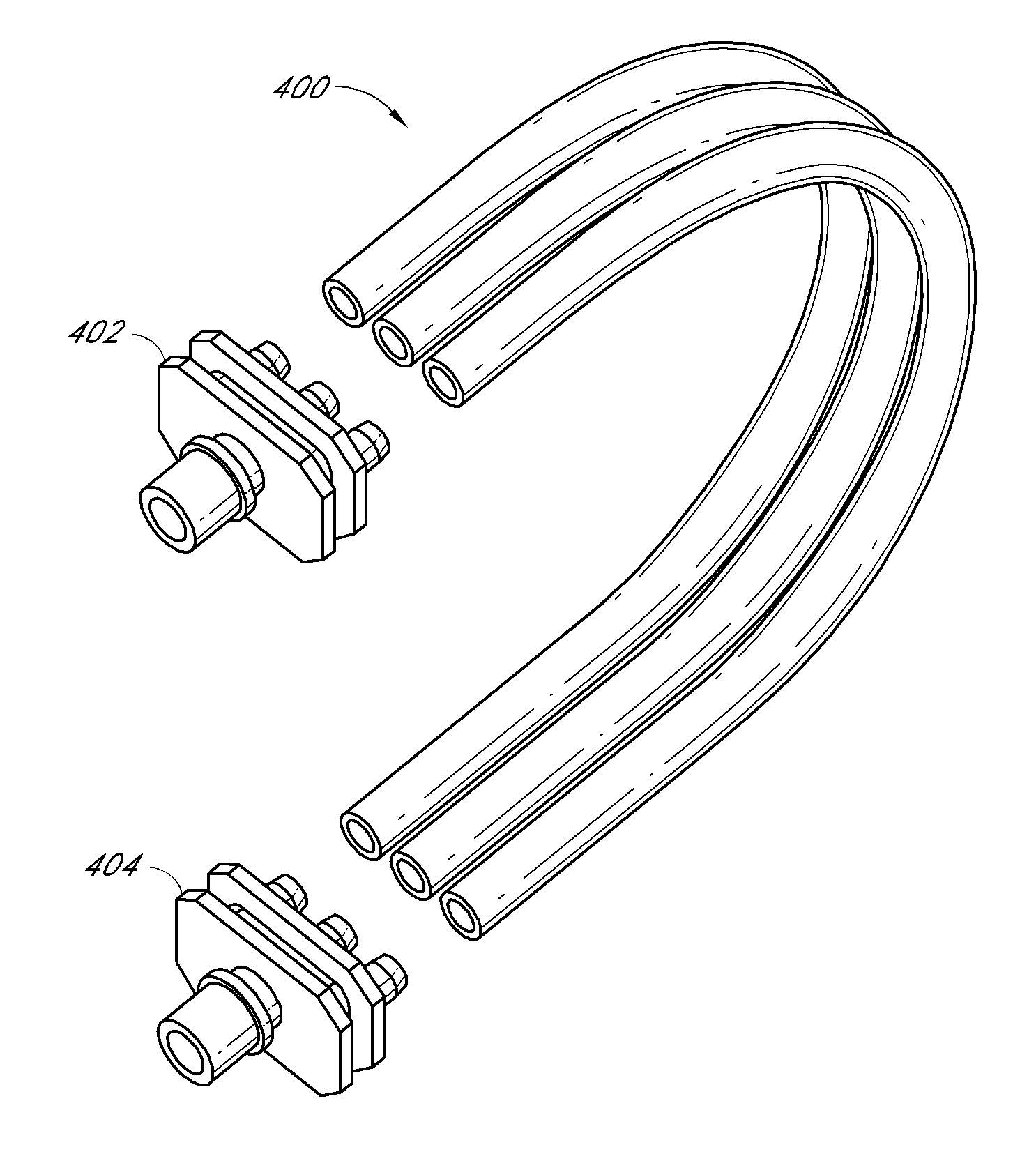

High pressure, high flow rate tubing assembly and adapter for a positive displacement pump

ActiveUS9777720B2Low costIncrease flow rateFlexible member pumpsPositive-displacement liquid enginesPeristaltic pumpWorking life

A tubing and adapter assembly is provided that can comprise a plurality of tubes or lumens that can be disposed within a head of a peristaltic pump. The tubing assembly can provide a flow rate or volume capacity that is generally equal to or greater than that achieved with a comparable prior art tube while operating at higher pressures than that possible using the prior art tube. Further, in accordance with some embodiments, the tubing assembly can achieve a longer working life than a comparable prior art tube, and the load on the pump motor can be reduced such that the pump life is increased and / or a larger pump motor is not required to achieve such advantageous results.

Owner:BLUE WHITE INDS

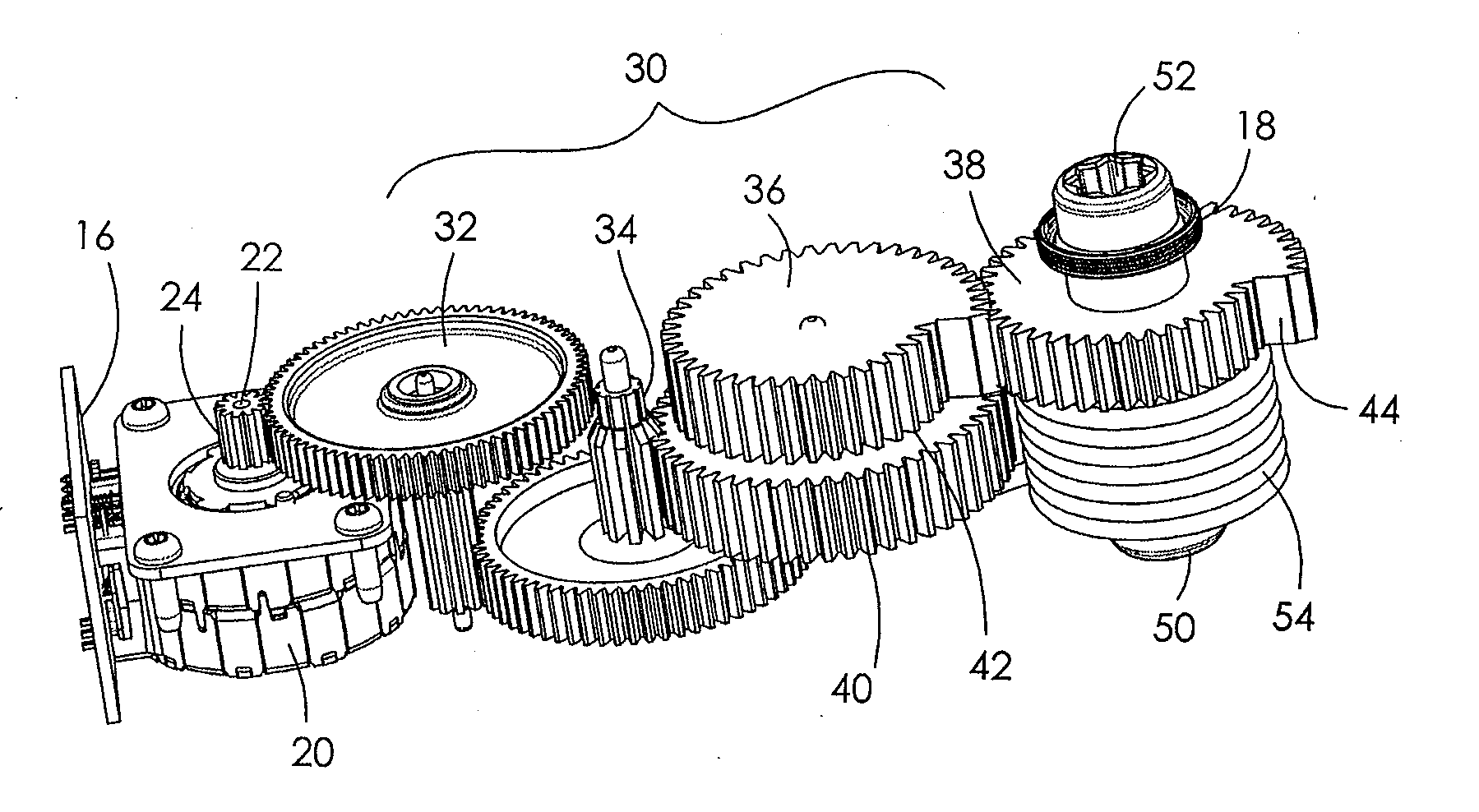

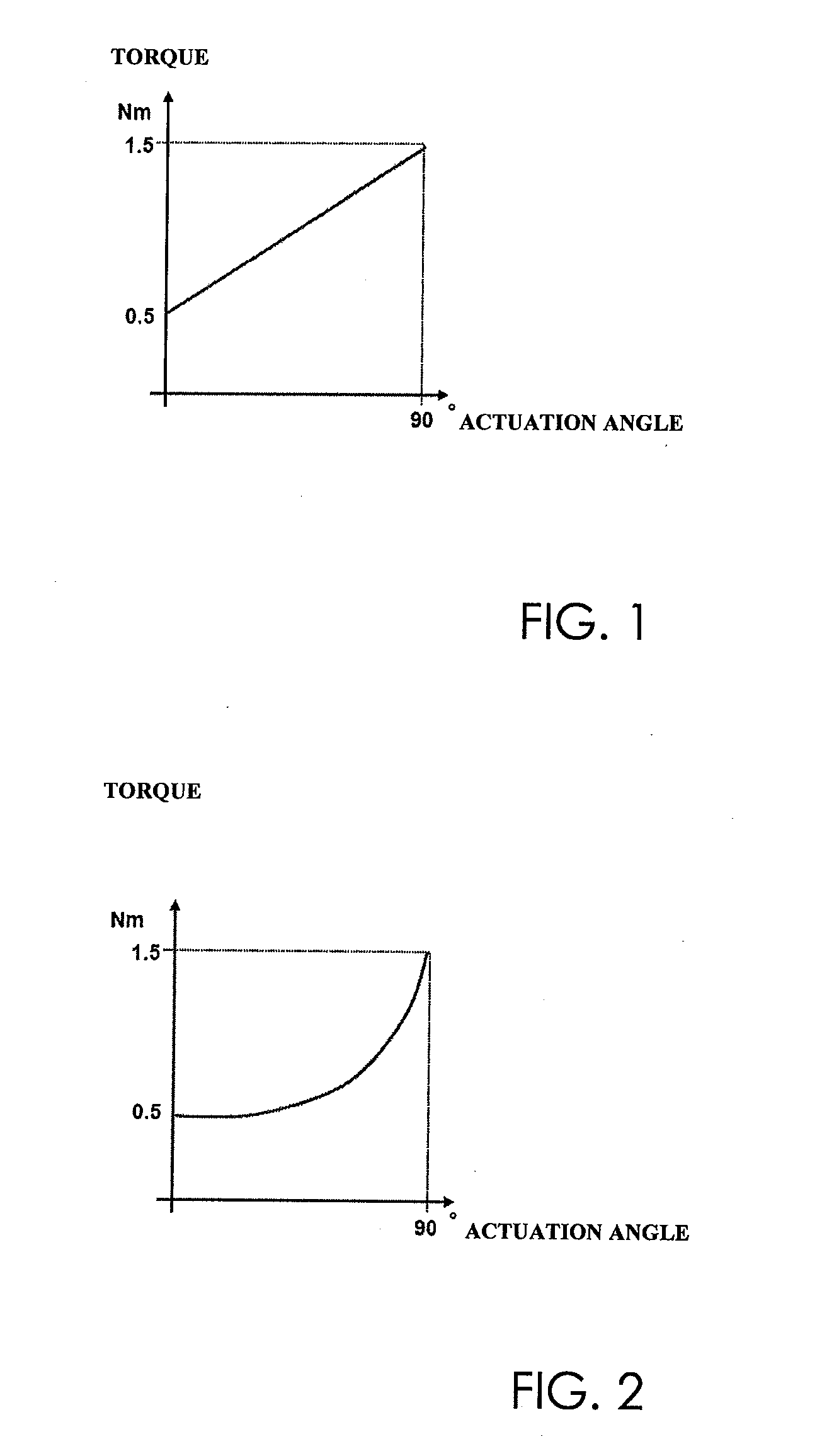

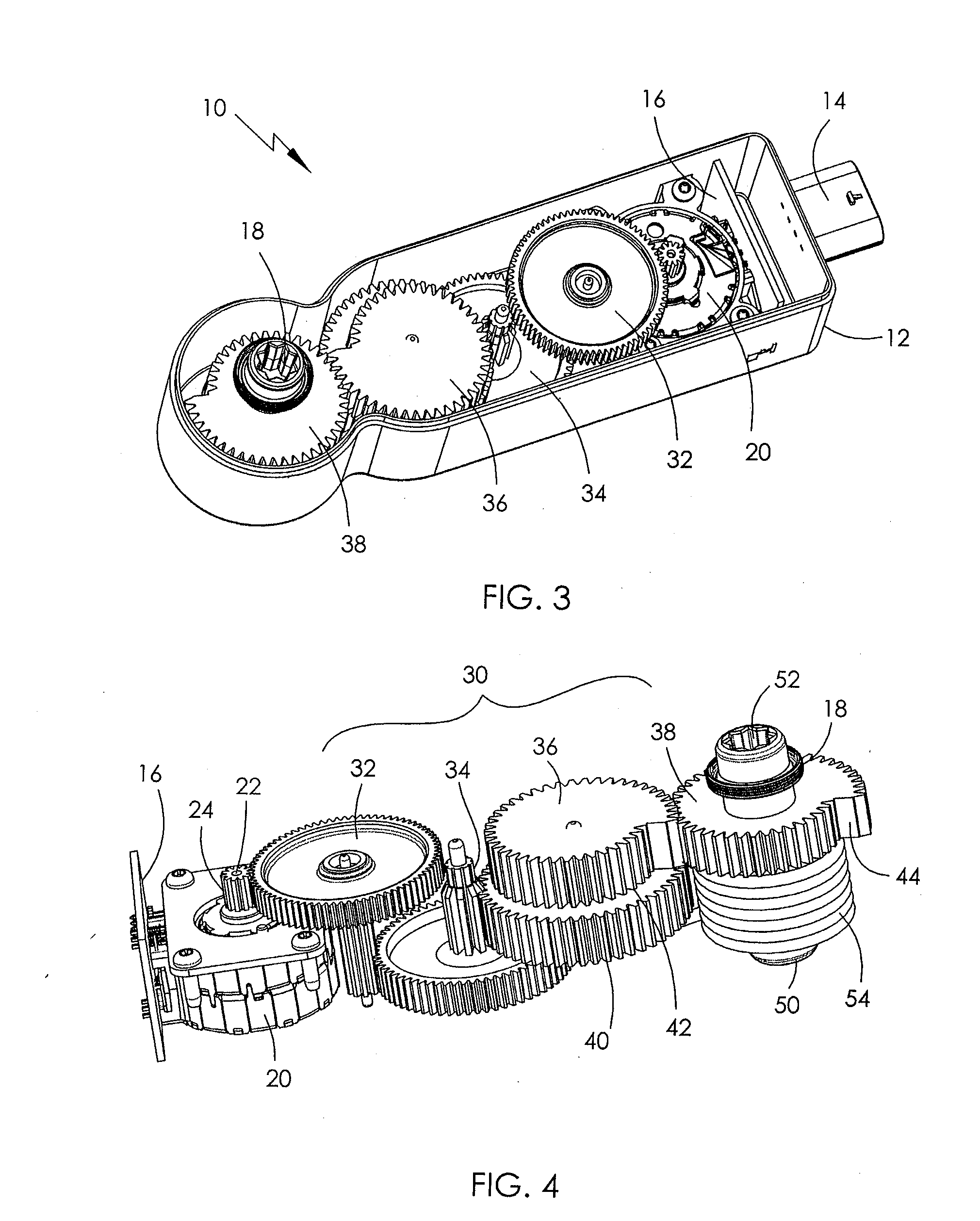

Actuator with Progressive Gear

ActiveUS20140345400A1Small and efficientReduce complexitySuperstructure subunitsComponent optimizationGear trainActuator

An actuator for a grille shutter assembly of a vehicle has a motor connected to an output via a gear train. The output has a connection for connecting to louvers of the grille shutter assembly. The gear train has a gear ratio which is variable depending on the actuation angle of the output shaft. Optionally, a return spring is arranged to resiliently return the output shaft to an initial actuation angle when the motor is not active.

Owner:JOHNSON ELECTRIC SA

Overmolded tubing assembly and adapter for a positive displacement pump

ActiveUS9909579B2Low costIncrease flow rateFlexible member pumpsPipe elementsPeristaltic pumpState of art

A tubing assembly is provided that can comprise a plurality of tubes or lumens that can be disposed within a head of a peristaltic pump. The tubing assembly can provide a flow rate or volume capacity that is generally equal to or greater than that achieved with a comparable prior art tube while operating at higher pressures than that possible using the prior art tube. Further, in accordance with some embodiments, the tubing assembly can achieve a longer working life than a comparable prior art tube, and the load on the pump motor can be reduced such that the pump life is increased and / or a larger pump motor is not required to achieve such advantageous results.

Owner:BLUE WHITE INDS

High pressure, high flow rate tubing assembly and adapter for a positive displacement pump

ActiveUS20140271293A1Increased tube lifeReduce replacement costsFlexible member pumpsPositive-displacement liquid enginesState of artPeristaltic pump

A tubing assembly is provided that can comprise a plurality of tubes or lumens that can be disposed within a head of a peristaltic pump. The tubing assembly can provide a flow rate or volume capacity that is generally equal to or greater than that achieved with a comparable prior art tube while operating at higher pressures than that possible using the prior art tube. Further, in accordance with some embodiments, the tubing assembly can achieve a longer working life than a comparable prior art tube, and the load on the pump motor can be reduced such that the pump life is increased and / or a larger pump motor is not required to achieve such advantageous results.

Owner:BLUE WHITE INDS

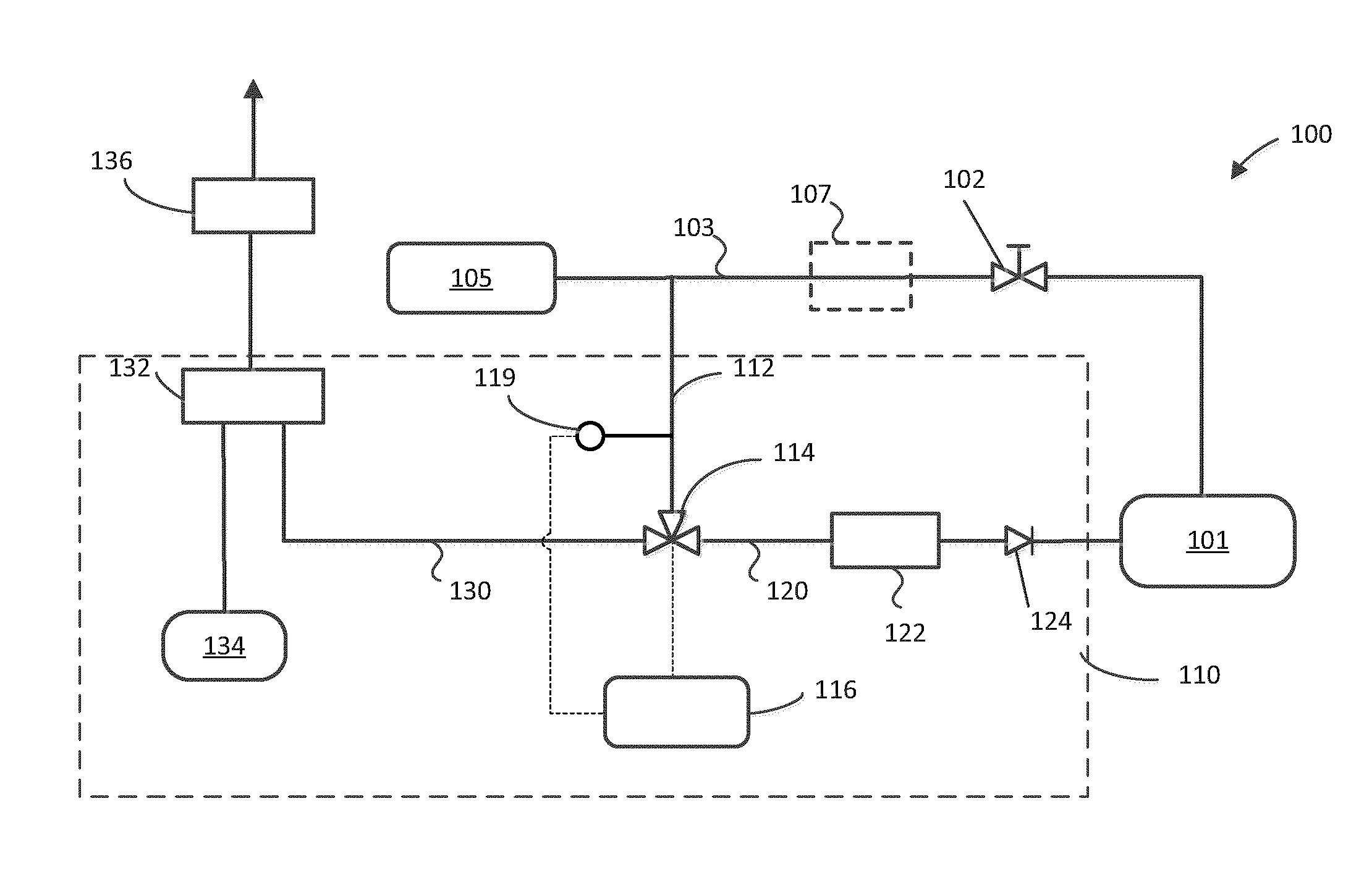

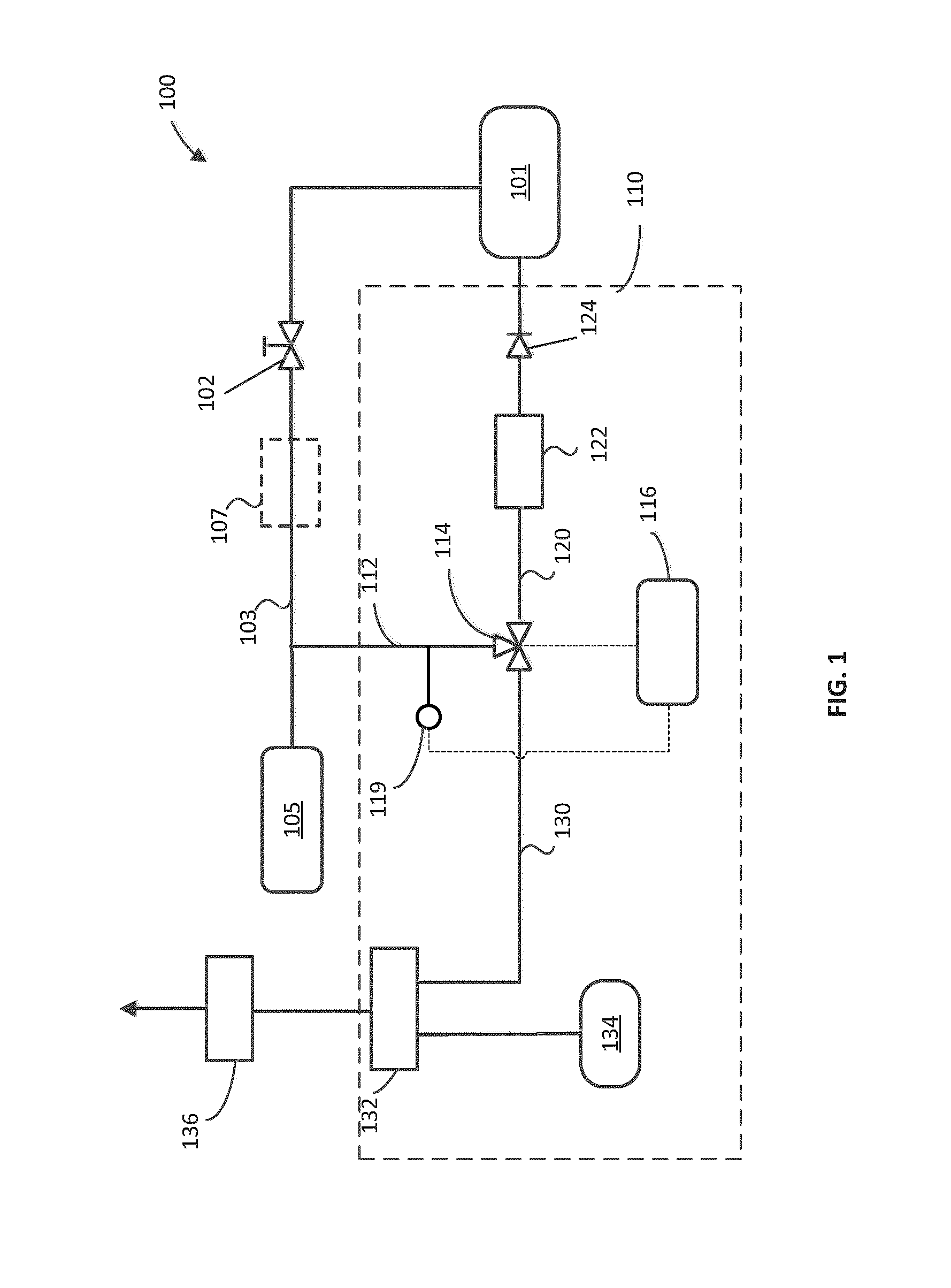

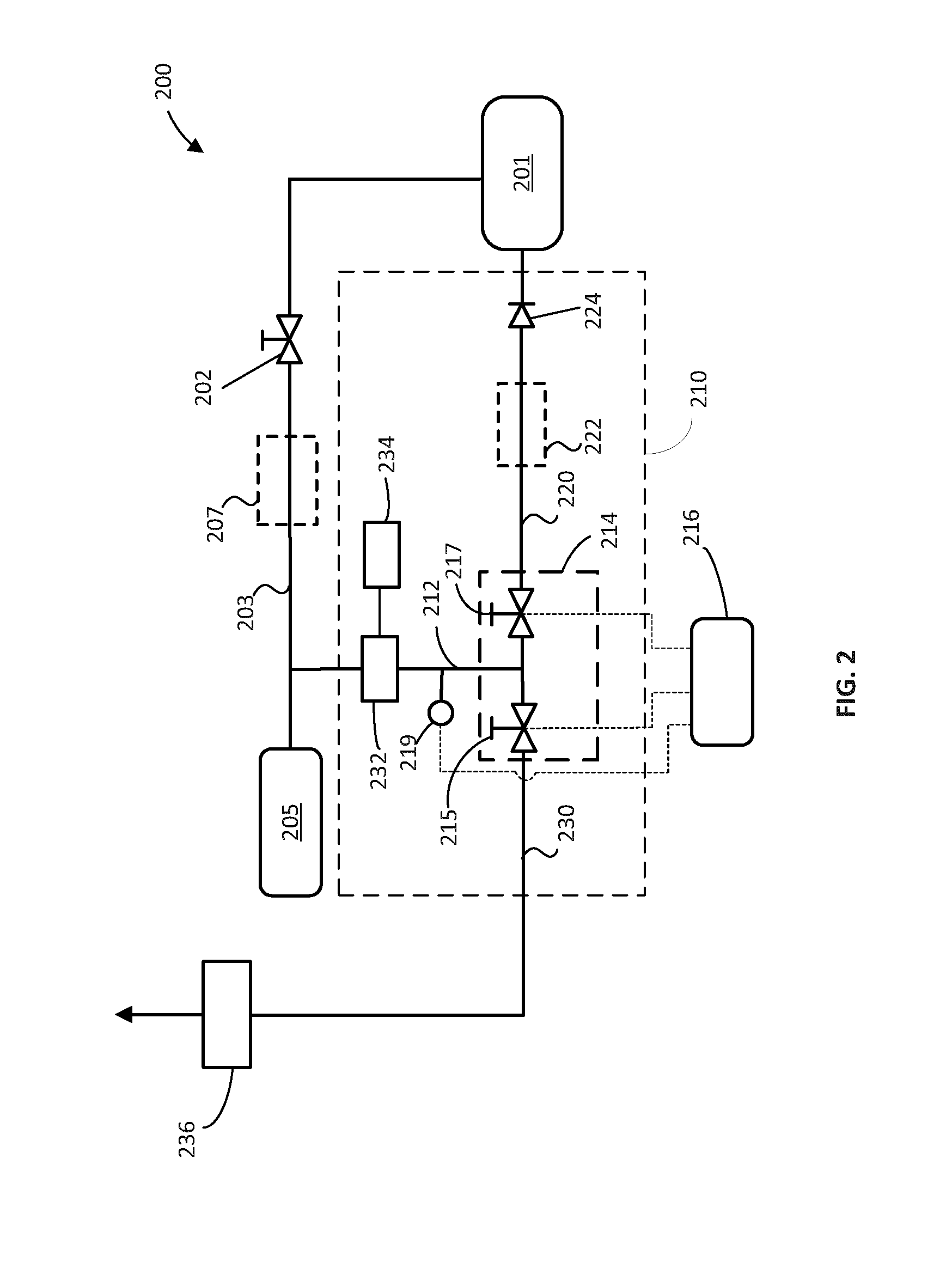

System and method for delivering a fluid stored in liquefied form to an end user in gaseous form

ActiveUS20160265478A1Reduce amountSmall and efficientInternal combustion piston enginesGas handling applicationsEngineering

A system and method is disclosed for storing a fluid in a storage vessel in liquefied form and delivering it in gaseous form to an end user through a supply line. The system comprises a pressure relief circuit for returning the fluid from the supply line to the vessel when predetermined conditions are met. The pressure relief circuit comprises a return line connected to the supply line and the storage vessel, a diversion line to divert the fluid elsewhere and a switching device operable to direct the fluid to either one of the lines, as a function of predetermined conditions.

Owner:WESTPORT FUEL SYST CANADA INC

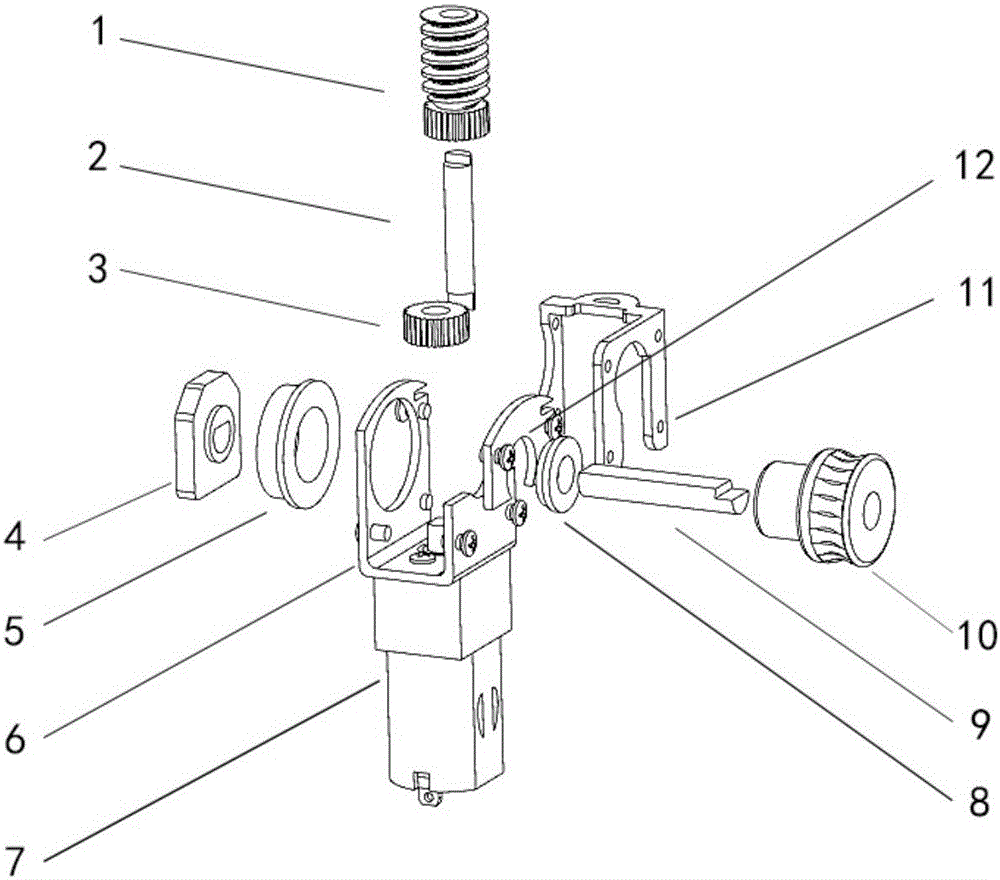

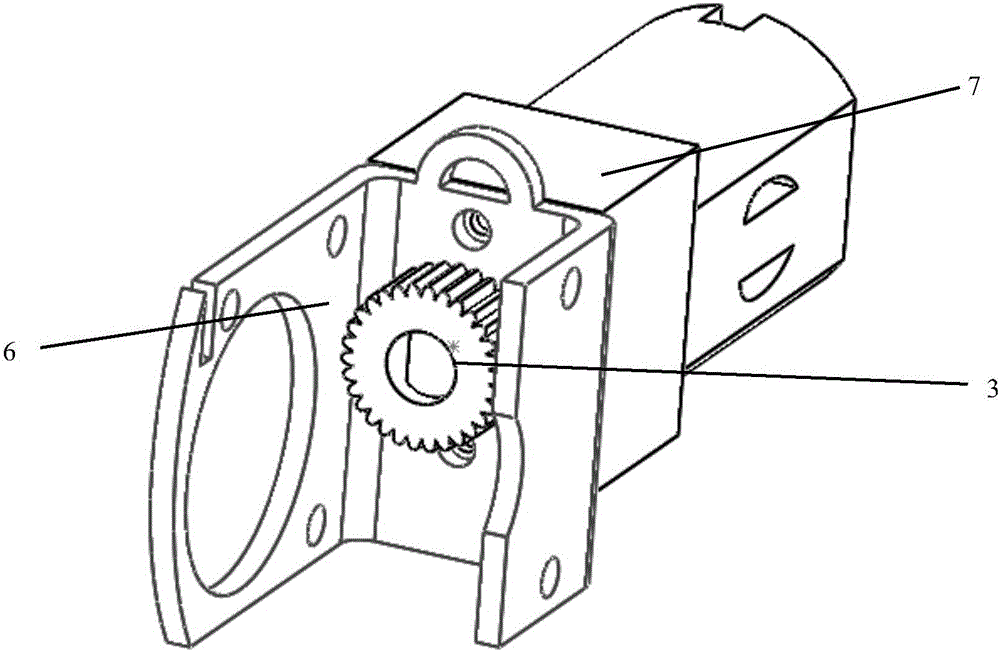

Knuckle movement module of five-finger dextrous hande based on worm wheel and worm mechanism

InactiveCN105881536AMechanically compactLightweightProgramme-controlled manipulatorGripping headsGear wheelSpatial structure

The invention designs a knuckle movement module of a five-finger dextrous hand based on the structural features and kinetic characteristics of a worm wheel and worm mechanism. Movement functions of all fingers are satisfied, additionally, the space structure of knuckles can be optimized to the maximum, the used worm wheel and worm mechanism has a self-locking function, and therefore, the designed knuckle movement module of the five-finger dextrous hand can achieve the poweroff self-locking function, so that the grasping ability of the dextrous hand is increased, and the movement and grasping requirements of the five-finger dextrous hand are satisfied. A worm wheel and worm speed reducer which is used as a driving unit of the knuckle module is mainly composed of a worm wheel, a worm, a gear, a shaft, a bearing, a box body and accessories and can be divided into three basic structures including the box body, a worm wheel and worm gear set and the combination of the bearing and the shaft, wherein the box body is a base of all parts in the worm wheel and worm mechanism and is an important part for supporting and fixing shaft components, guaranteeing correct positions of all transmission parts and supporting loads which act on the speed reducer; the worm wheel and worm gear set is used for transferring output power of a motor and changing the direction of the output power; the combination of the bearing and the shaft is mainly used for transferring power, supporting operation and improving the efficiency.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

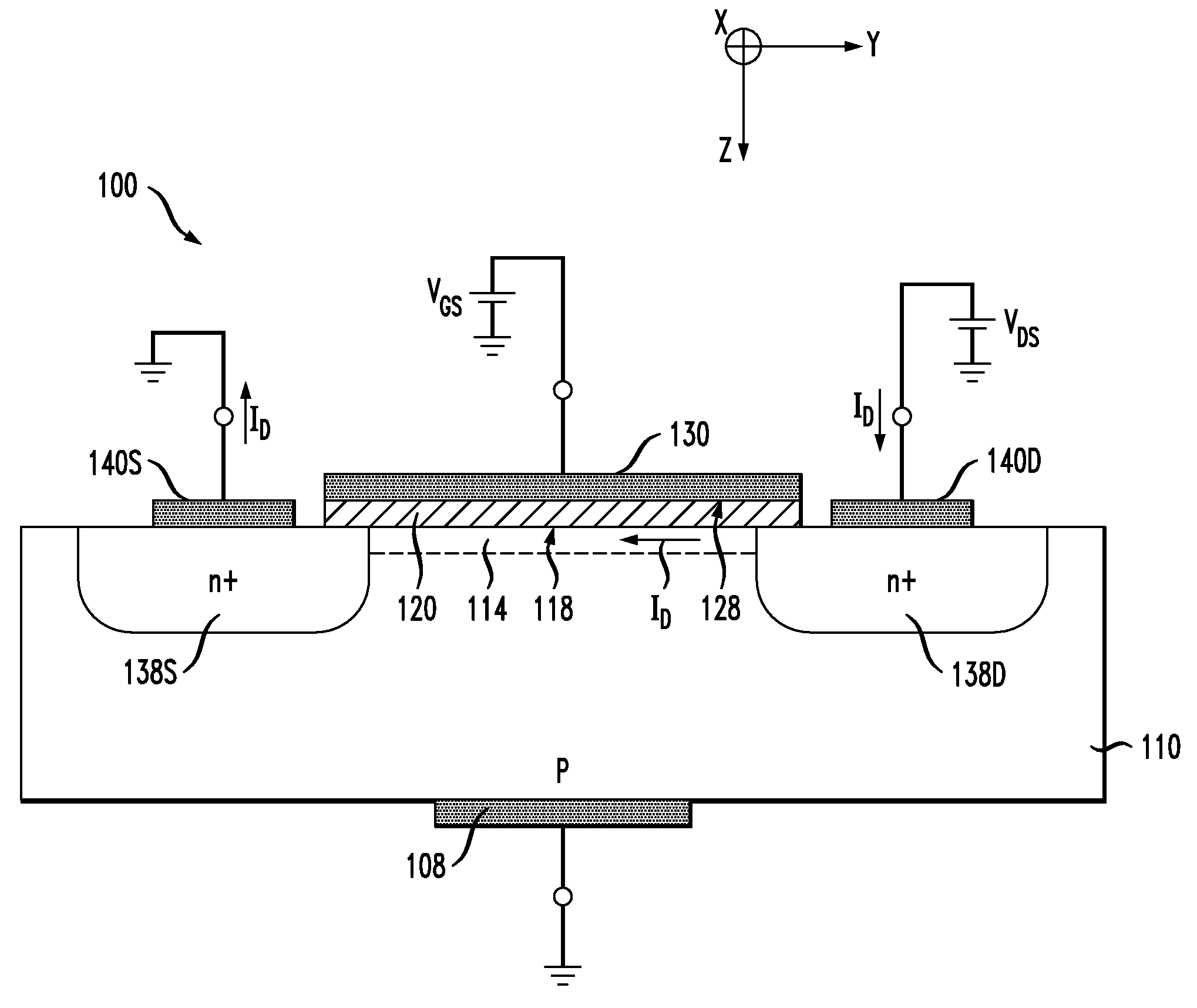

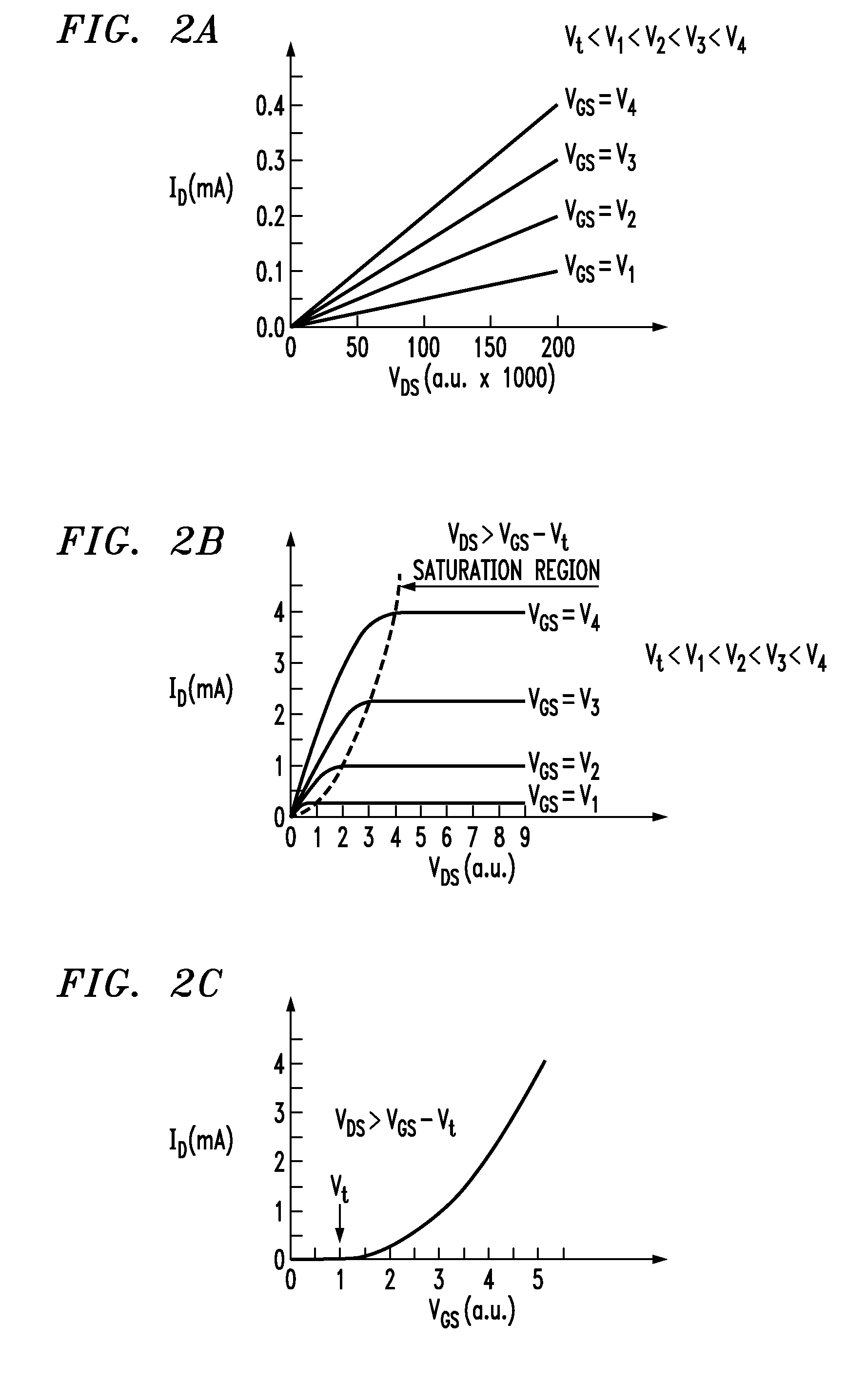

Surface-plasmon detector based on a field-effect transistor

ActiveUS20090243589A1Small and efficientResistance/reactance/impedenceVoltage-current phase angleElectricitySurface plasmon

According to one embodiment, a surface-plasmon (SP) beam generated by an SP source and directed via an SP waveguide is applied to a gate node of a field-effect transistor (FET). The FET also has a source node and a drain node. In a representative configuration, the gate, source, and drain nodes are electrically biased to pass an electrical current between the source and drain nodes in a manner that makes the electrical current responsive to the intensity of the SP beam.

Owner:ALCATEL LUCENT SAS

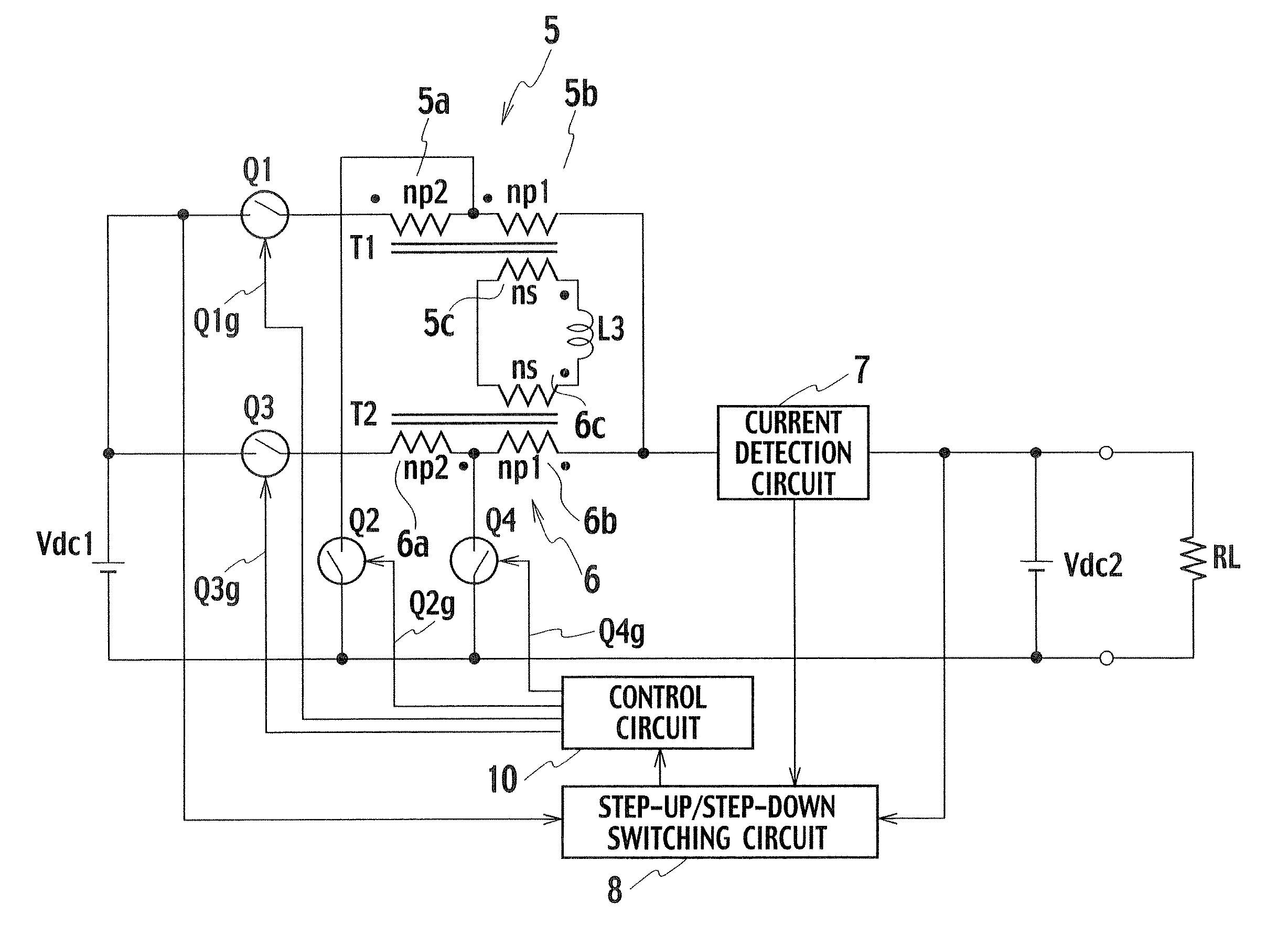

Dc/dc converter

InactiveUS20070046270A1Small and efficientIncrease heightEfficient power electronics conversionDc-dc conversionPhase differenceTransformer

A DC / DC converter includes a first transformer and a second transformer each having primary windings and secondary windings respectively having first windings and second windings, a second switch connected to both ends of a first series circuit, a fourth switch connected to both ends of a second series circuit, a third series circuit being connected to both ends of the second switch and having the second winding and a second DC power supply, a fourth series circuit being connected to both ends of the fourth switch and having the second winding and the second DC power supply, a reactor connected to both ends of a series circuit having the secondary windings, and a control circuit turning ON / OFF the first and third switches with a phase difference of a half cycle and turning ON / OFF the second and fourth switches with a phase difference of a half cycle.

Owner:SANKEN ELECTRIC CO LTD

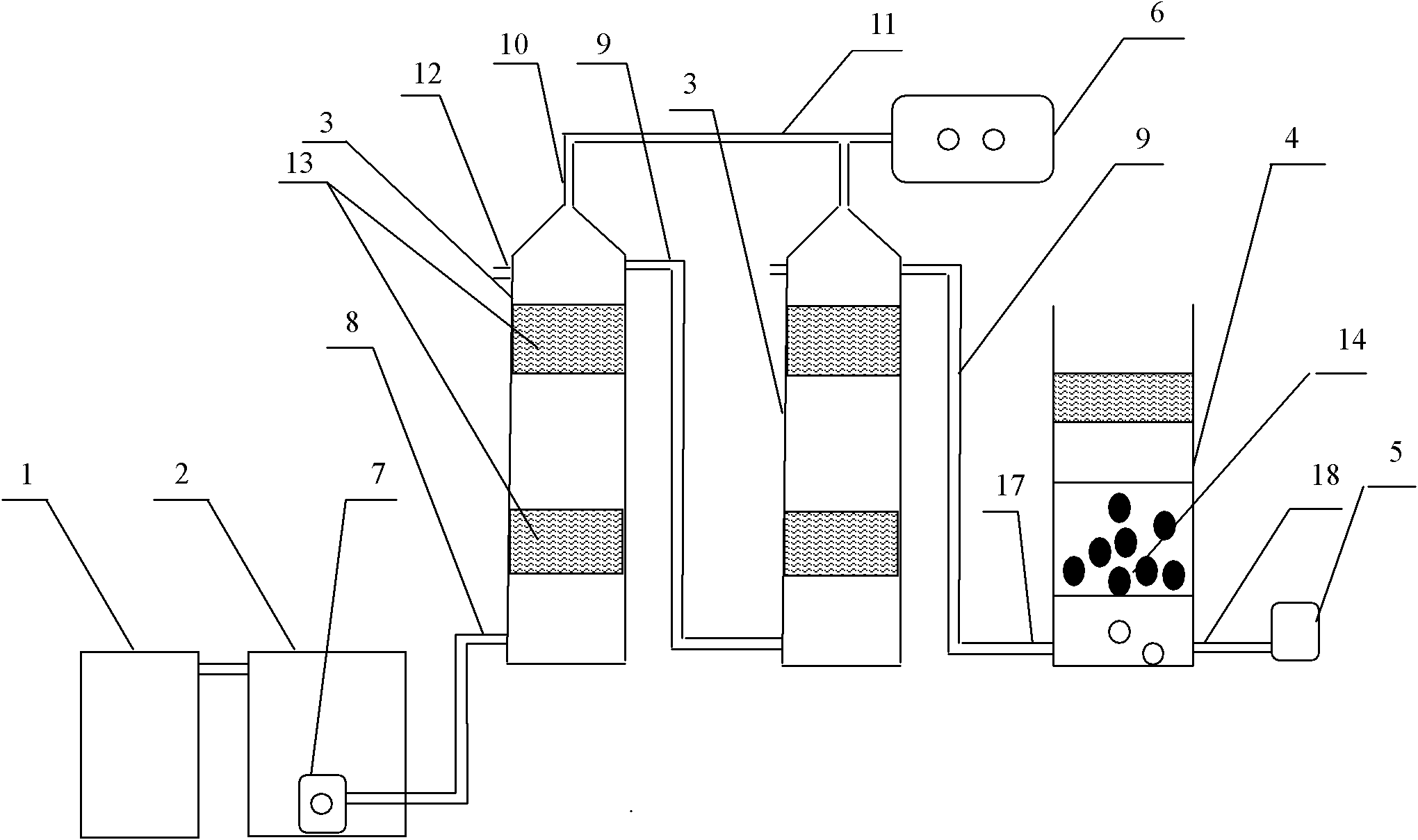

Biogas slurry treatment system for use in biogas project

ActiveCN102101744AIncrease surface areaIncrease microbial biomass and microbial activityMultistage water/sewage treatmentBiogasSmall footprint

The invention relates to a biogas slurry treatment system for use in a biogas project and belongs to the technical field of wastewater treatment. The biogas slurry treatment system for use in the biogas project comprises a settling pool, a regulating pool and an anaerobic reaction device, wherein the settling pool, the regulating pool and the anaerobic reaction device are connected in turn. The invention is characterized in that: the system also has a biochemical ceramic post-treatment device which is connected with the anaerobic reaction device; the anaerobic reaction device consist of an anaerobic reactor in which a spiral biological filler is arranged; the spiral biological filler is fixed by a polyvinyl chloride (PVC) plate with a hole; a water inlet is formed on the lower part of the side wall of the anaerobic reactor; a water outlet and a sampling opening are formed on the upper part of the side wall; and an exhaust hole is formed on the top part. The system has the characteristics of high treatment efficiency, small floor area, low price, convenience for maintenance and use, and the like.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

DC-DC converter

InactiveUS8203322B2Small and efficientSmall sizeEfficient power electronics conversionDc-dc conversionCapacitanceSoft switching

A small and efficient DC-DC converter is provided. In this DC-DC converter, passive elements such as an inductor and a capacitor can be reduced in size by reducing switching loss by a soft switching technology and increasing the drive frequency of a switching element. The DC-DC converter has a main switching element, a main diode and an auxiliary circuit that discharges the electric charges of the capacitance between the ends of the main switching element. The DC-DC converter includes an auxiliary inductor magnetically coupled with the main inductor, an auxiliary switching element that stores energy in the auxiliary inductor, and an auxiliary diode that discharges energy stored in the auxiliary inductor to the direct-current power source or the output side. The auxiliary inductor is coupled with the main inductor in the direction in which backward voltage is applied to the auxiliary diode when the main inductor discharges energy.

Owner:HITACHI LTD

Epicyclic gear train

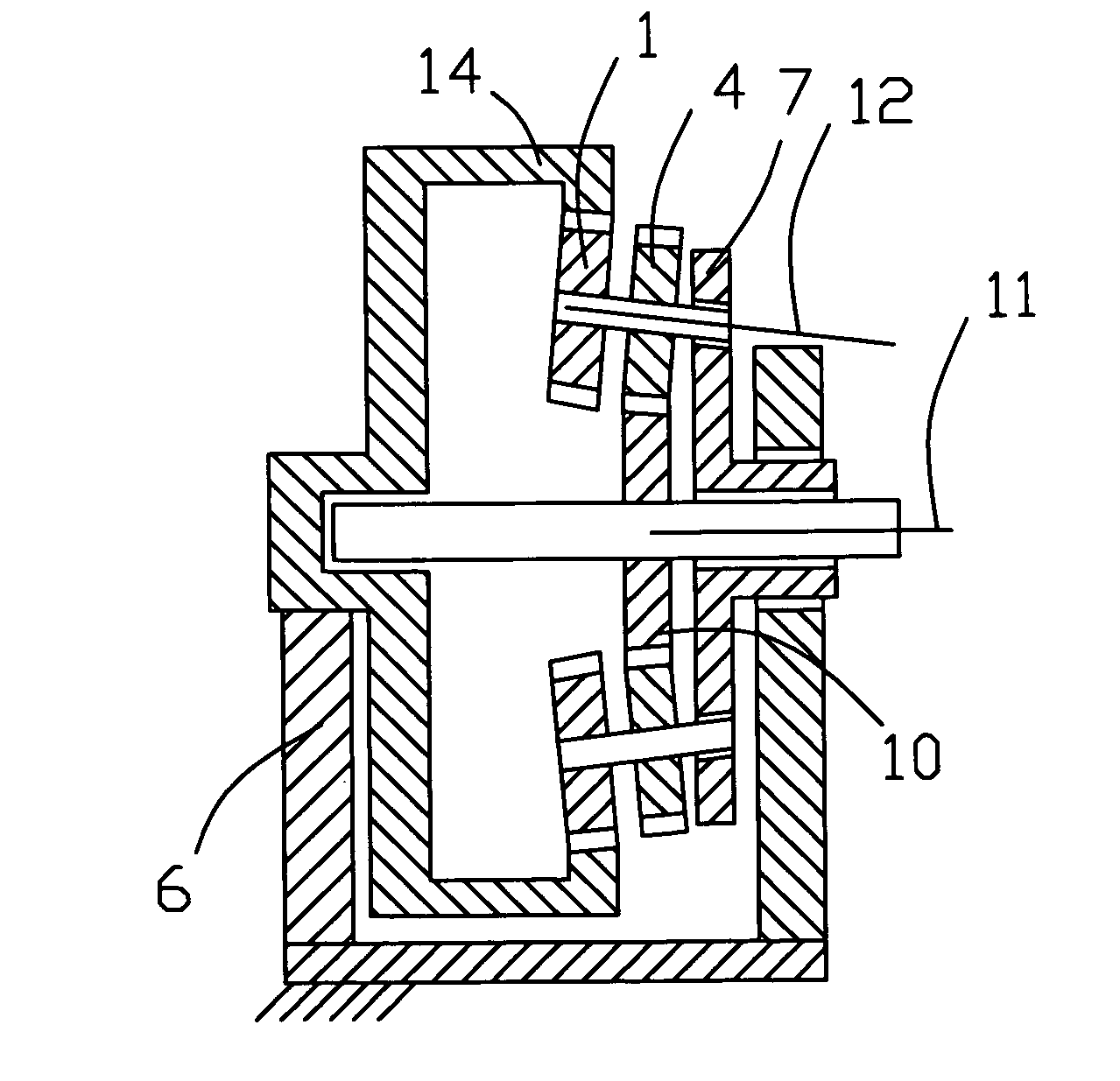

InactiveUS20050164824A1Reduced dimensionSmall and efficientToothed gearingsGearing detailsEngineeringGear train

Epicyclic gear train is comprised of a first gear coaxial to second gear and a satellite gear in a mesh with first and second gears. Satellite gear is an enveloping worm and is placed on a rotating carrier for supporting said satellite where carrier is coaxial to first and second gears. Axis of enveloping worm and axis of first and second matting gears are parallel, intersection or crossing. Epicyclic gear train could also be comprised of the first gear coaxial to the second gear and two coaxial enveloping worms attached to each other to rotate together in mesh with first and second gears. Enveloping worms are placed on a rotating carrier for supporting said satellites where carrier is coaxial to first and second gears. Axis of enveloping worms and axis of first and second matting gears are parallel or intersected.

Owner:EDELWEISS DENTISTRY PROD

Overmolded tubing assembly and adapter for a positive displacement pump

ActiveUS20150354555A1Increased tube lifeReduce replacement costsPositive displacement pump componentsFlexible member pumpsPeristaltic pumpState of art

A tubing assembly is provided that can comprise a plurality of tubes or lumens that can be disposed within a head of a peristaltic pump. The tubing assembly can provide a flow rate or volume capacity that is generally equal to or greater than that achieved with a comparable prior art tube while operating at higher pressures than that possible using the prior art tube. Further, in accordance with some embodiments, the tubing assembly can achieve a longer working life than a comparable prior art tube, and the load on the pump motor can be reduced such that the pump life is increased and / or a larger pump motor is not required to achieve such advantageous results.

Owner:BLUE WHITE INDS

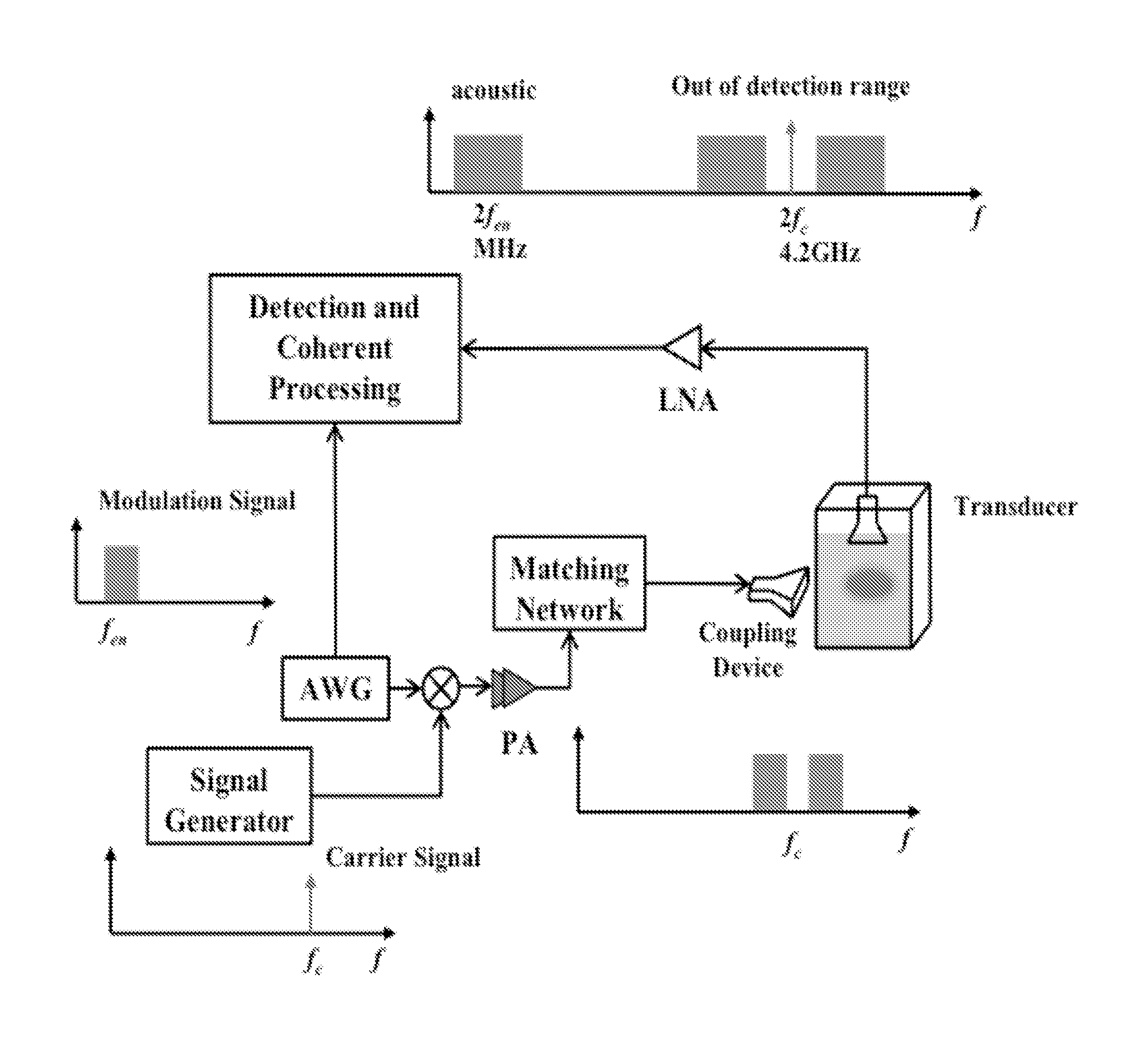

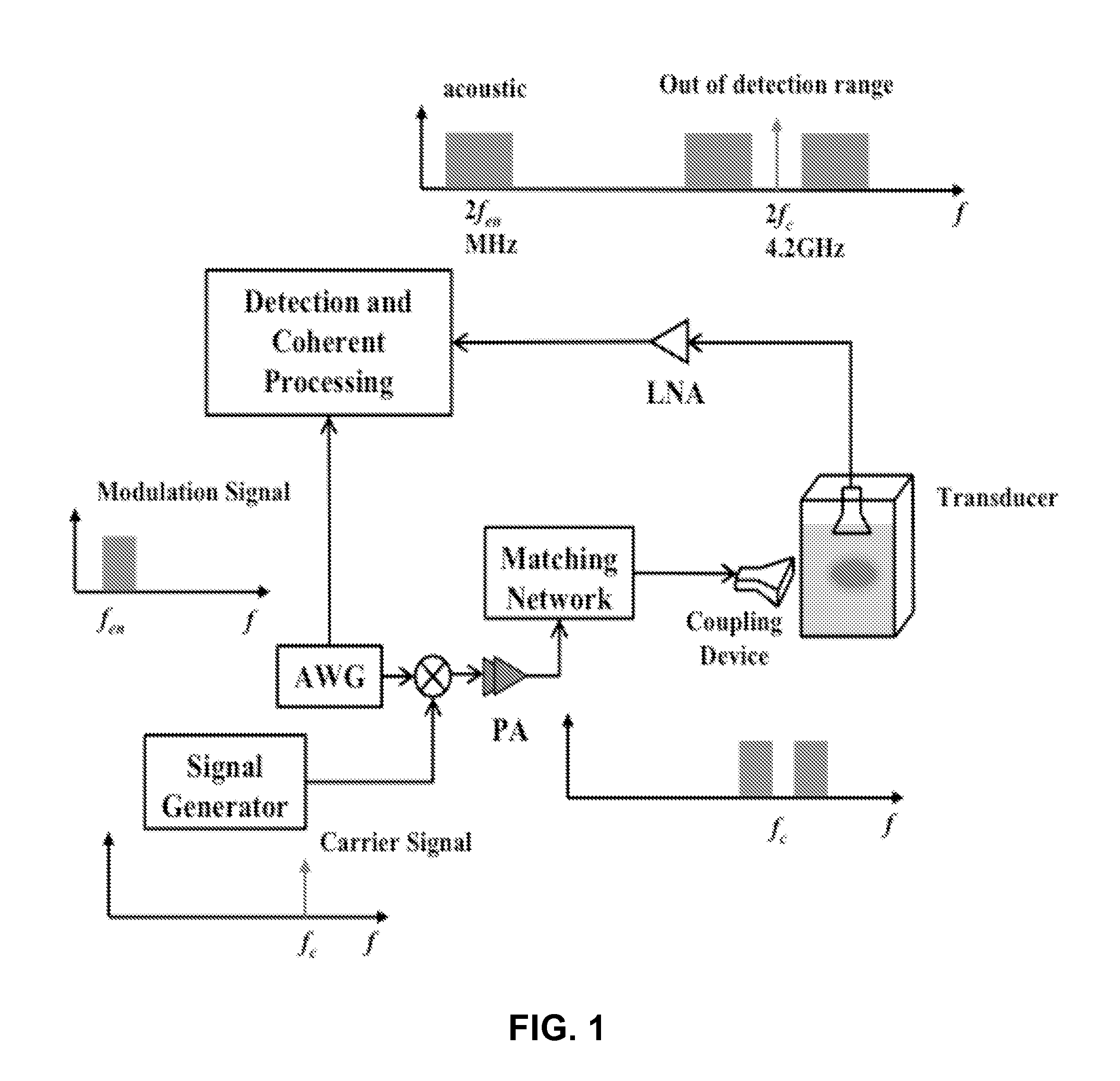

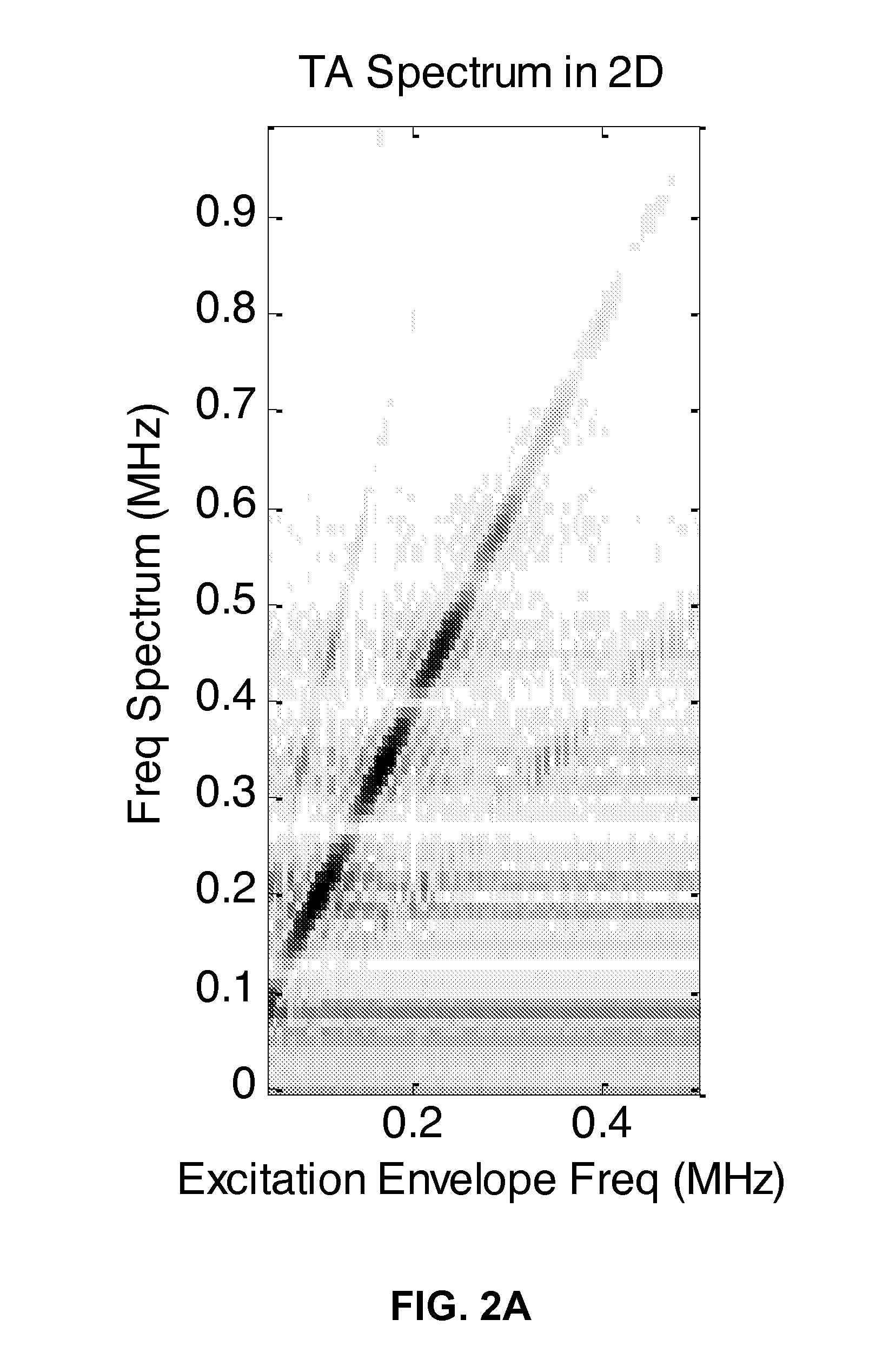

Coherent Frequency-Domain Microwave-Induced ThermoAcoustic Imaging

ActiveUS20160007859A1Significant signal-to-noise (SNR) improvementReduce required peak RF power levelMedical imagingDiagnostic recording/measuringSignal-to-noise ratio (imaging)Continuous wave

A thermoacoustic imaging device is provided having a transmitter configured to provide an electromagnetic transmit signal (e.g. a continuous sinusoidal signal) to an object being imaged. The transmit signal is a modulated continuous-wave signal based on a carrier frequency signal fc modulated at a modulation frequency at or near fm. The detector is further configured to receive an acoustic signal from the object being imaged, and is responsive to acoustic frequencies at or near 2fm. A non-linear thermoacoustic effect in the object being imaged generates the acoustic signal from the object being imaged. Spectroscopic maps could be generated and imaged object could be analyzed. The device enhances signal-to-noise ratio of the reconstructed image and reduces the requirement of peak power in thermoacoustic imaging systems. In addition, the generated pressure of the imaged object is separated from microwave leakage and feedthrough in frequency through the nonlinear thermoacoustic effect.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Surface-plasmon detector based on a field-effect transistor

ActiveUS8344750B2Small and efficientResistance/reactance/impedenceVoltage-current phase angleElectricityPhase detector

According to one embodiment, a surface-plasmon (SP) beam generated by an SP source and directed via an SP waveguide is applied to a gate node of a field-effect transistor (FET). The FET also has a source node and a drain node. In a representative configuration, the gate, source, and drain nodes are electrically biased to pass an electrical current between the source and drain nodes in a manner that makes the electrical current responsive to the intensity of the SP beam.

Owner:ALCATEL LUCENT SAS

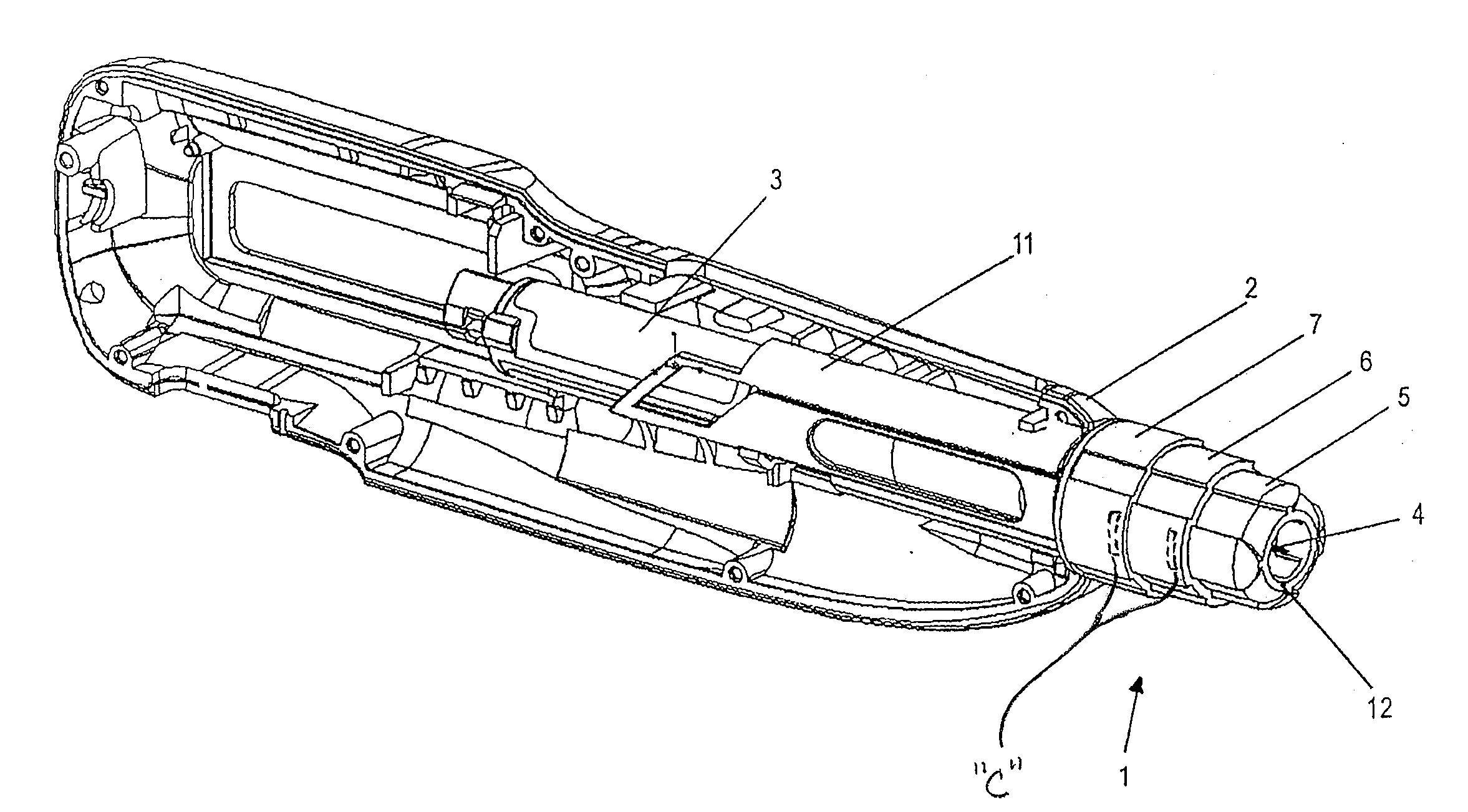

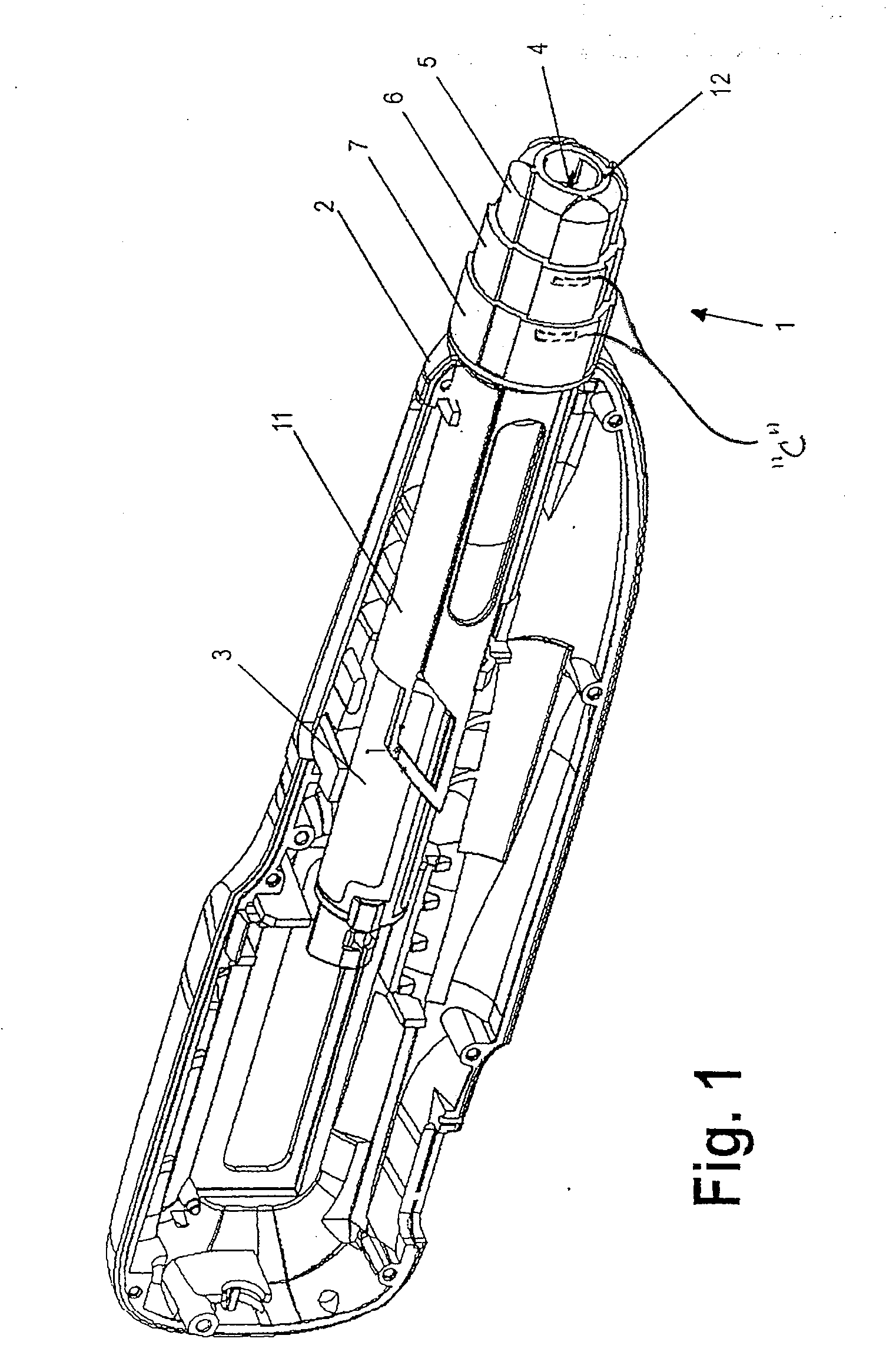

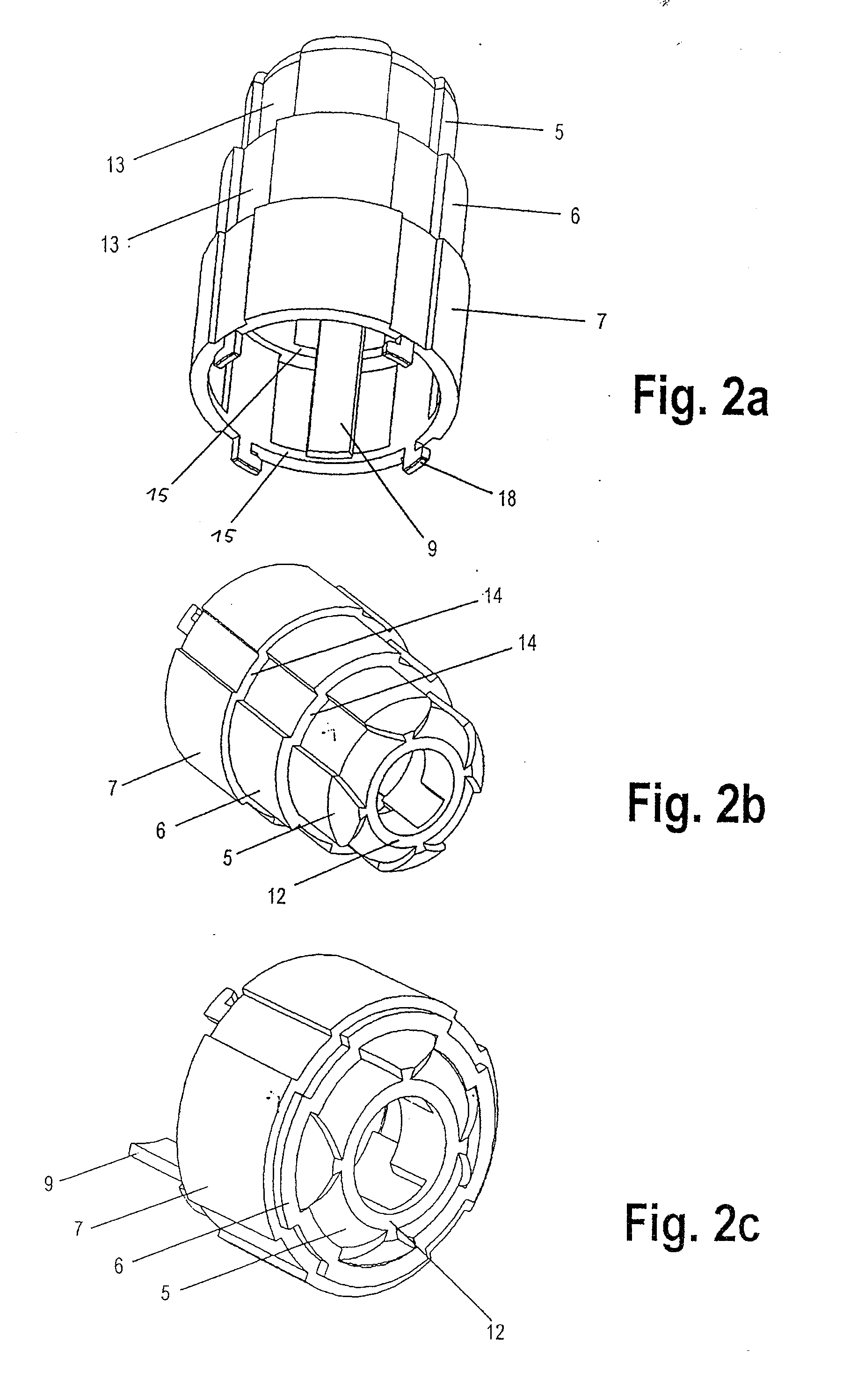

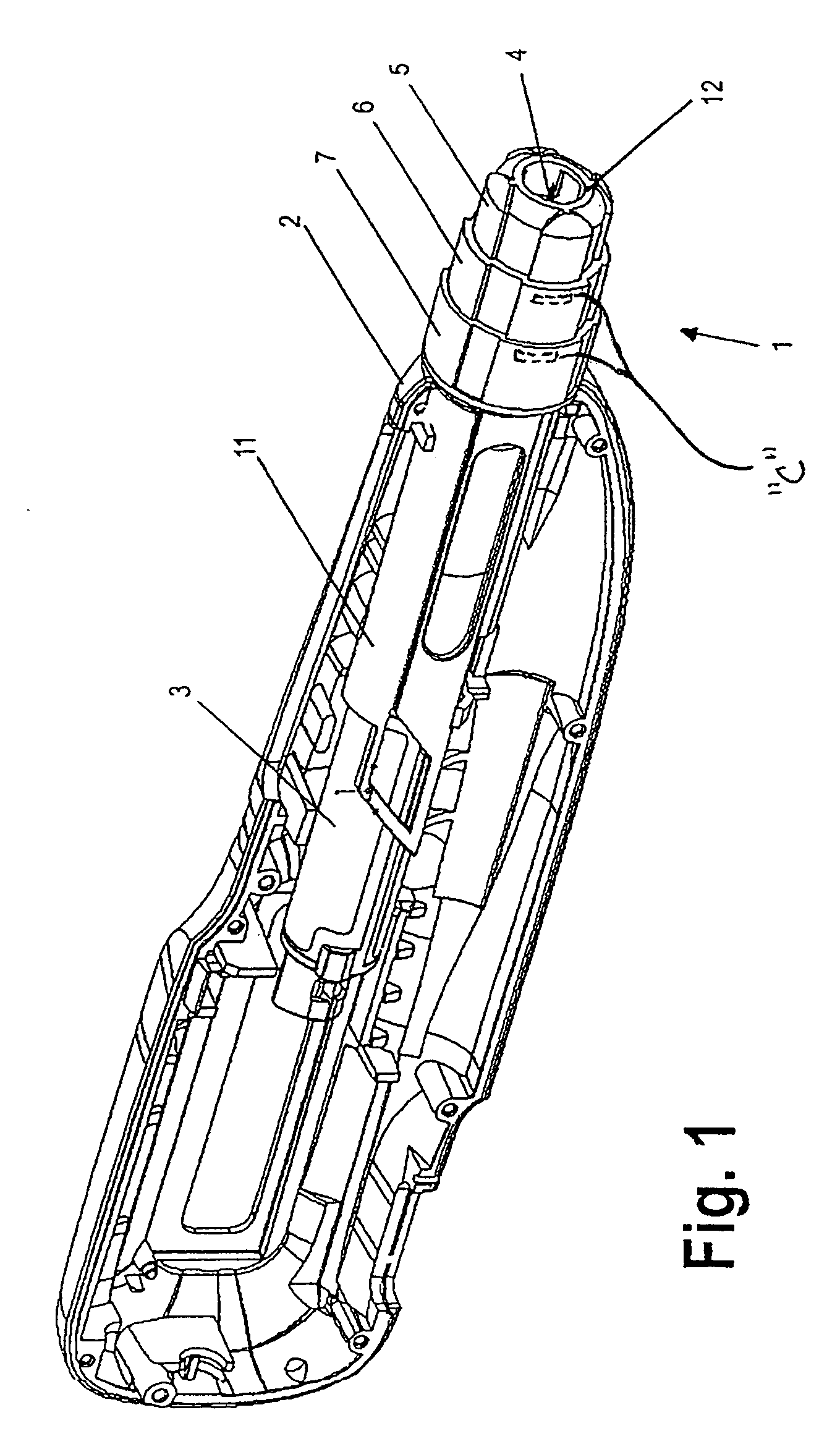

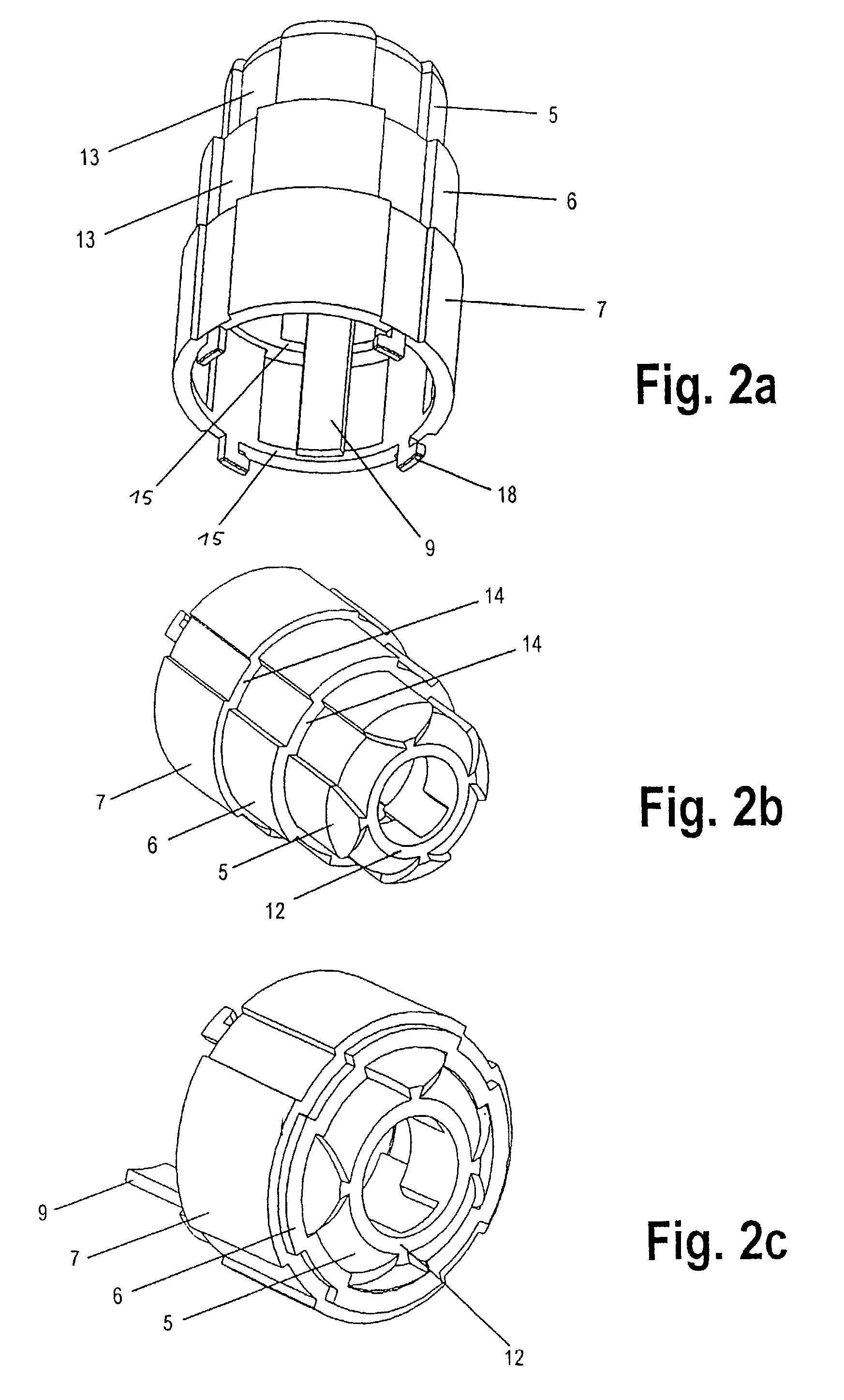

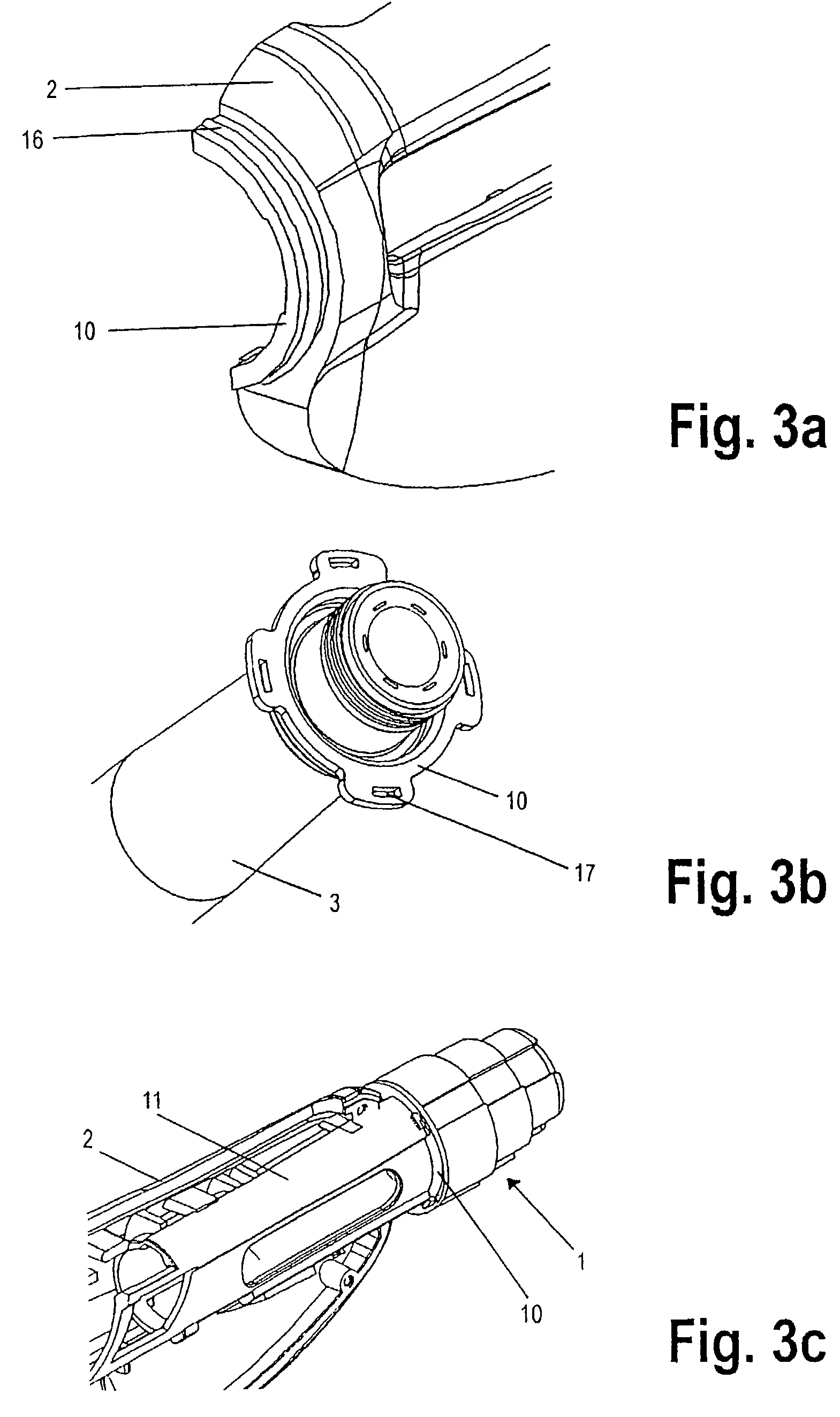

Variable-length needle covering device of an injection device

InactiveUS20070293824A1Simple operationSecure operationAutomatic syringesMedical devicesInjections needleVariable length

The invention relates to a needle covering device of an injection device, the injection device including a casing comprising a reservoir, in particular an ampoule, for a product fluid to be administered, and an injection needle for injecting the product fluid from the reservoir, wherein the device surrounds the injection needle in an extended position and exposes the injection needle in a retracted position. The device comprises a passage for the injection needle, a front section via which the device is placed on an injection point, and another section which is nearer to the casing than the front section is, at least in the extended position. The sections can be moved axially relative to the casing and relative to each other, such that the device is variable in its length, the front section being guided in a straight line on the casing.

Owner:TECPHARMA LICENSING AG

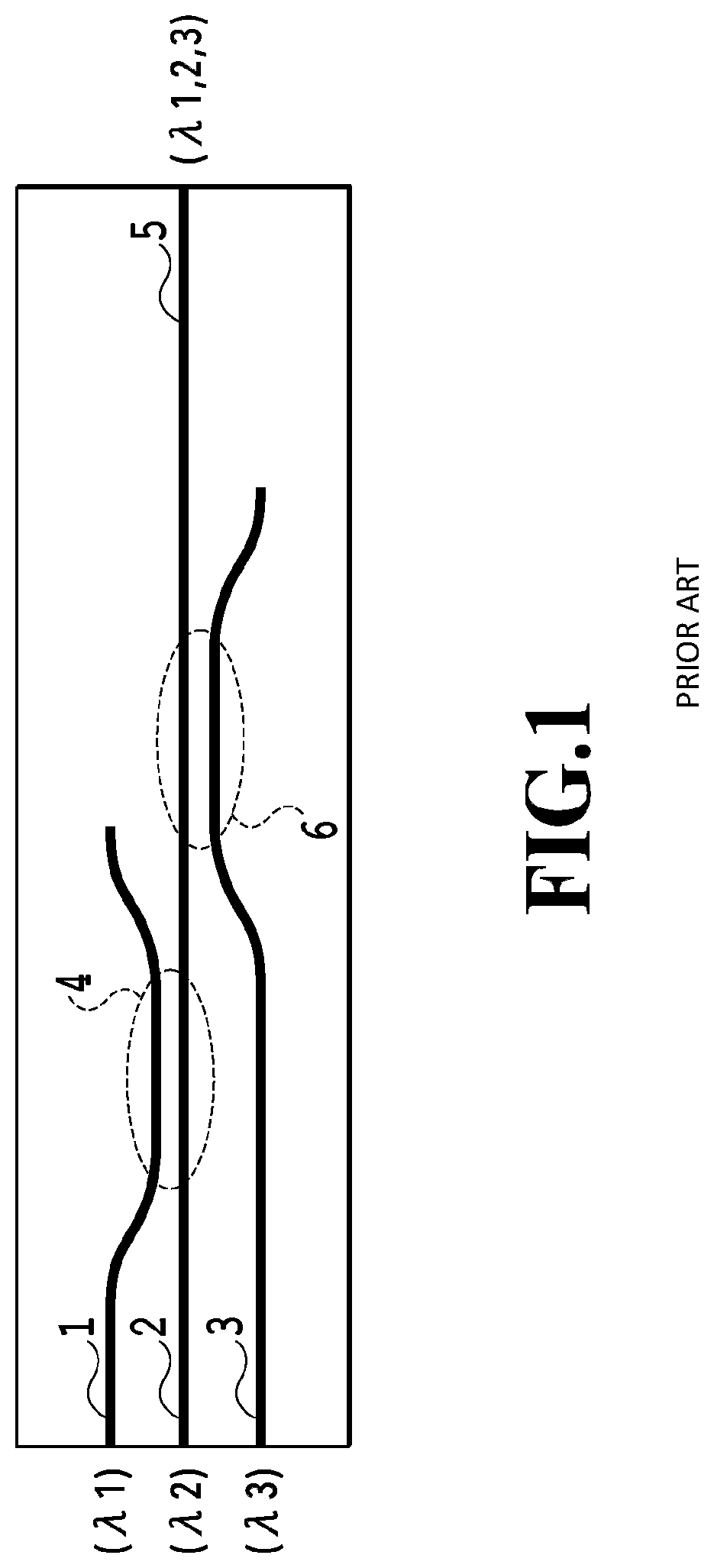

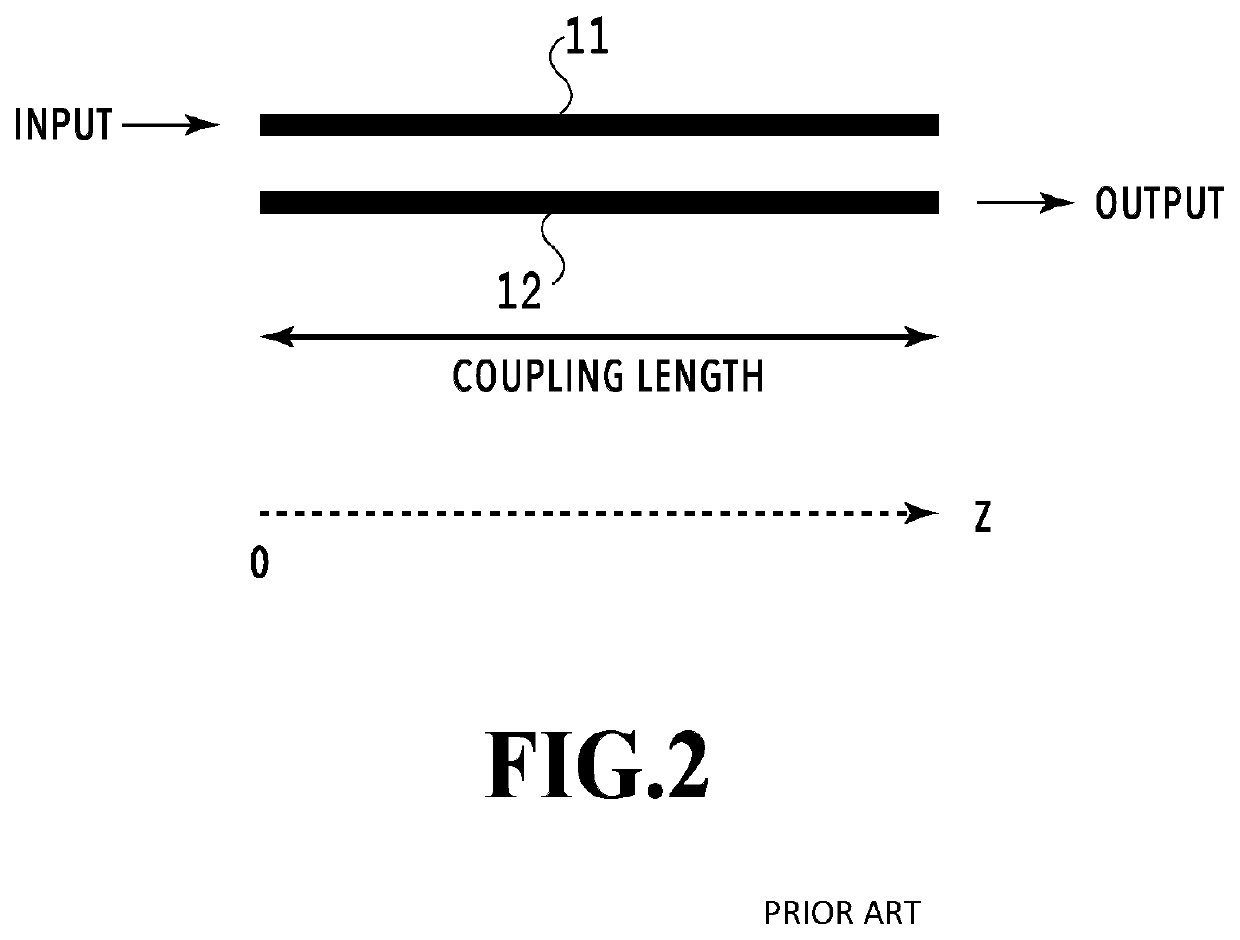

Optical multiplexing circuit

ActiveUS10649144B2Suppress couplingShorten the lengthOptical waveguide light guideLight beamHemt circuits

Provided is an optical multiplexing circuit. The waveguide width of each waveguide is set such that the effective refractive index of a first optical waveguide with a first light beam in the 0-th order mode is equal to the effective refractive index of a MM conversion waveguide with the first light beam in the higher order mode and that the effective refractive indexes of the MM conversion waveguide with second and third light beams in the higher order mode are not equal to the effective refractive indexes of a second optical waveguide with the second and third light beams in the 0-th order mode.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

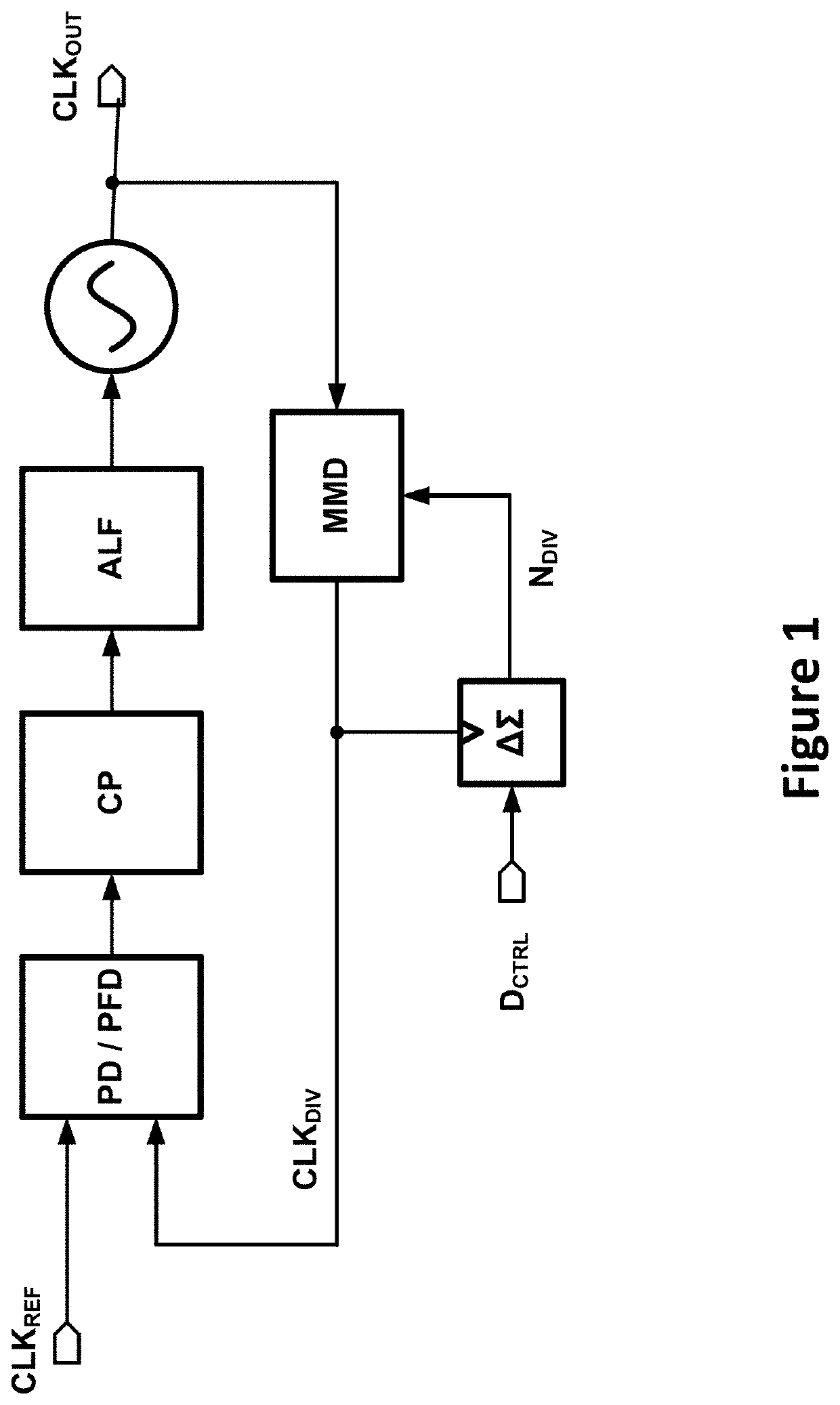

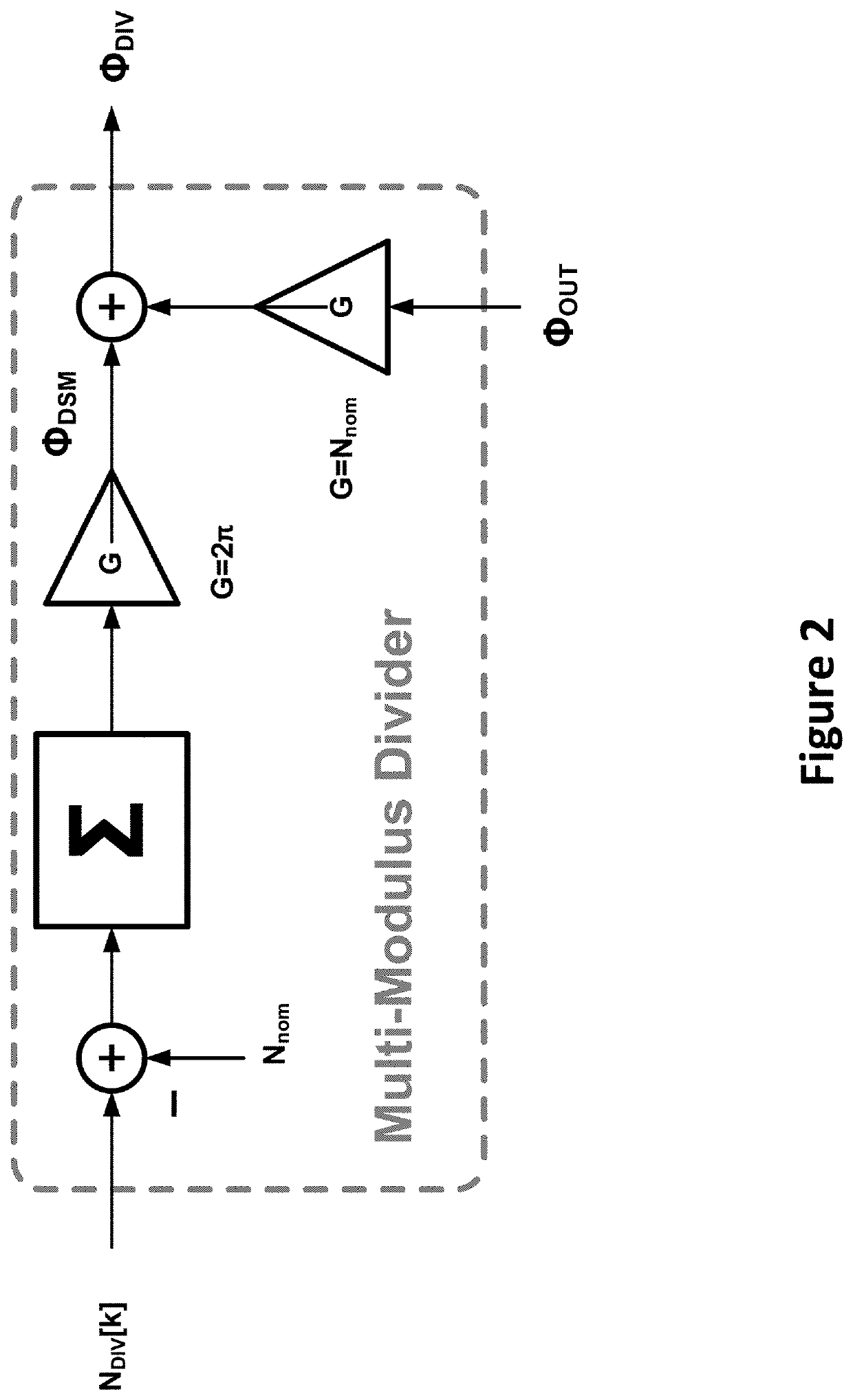

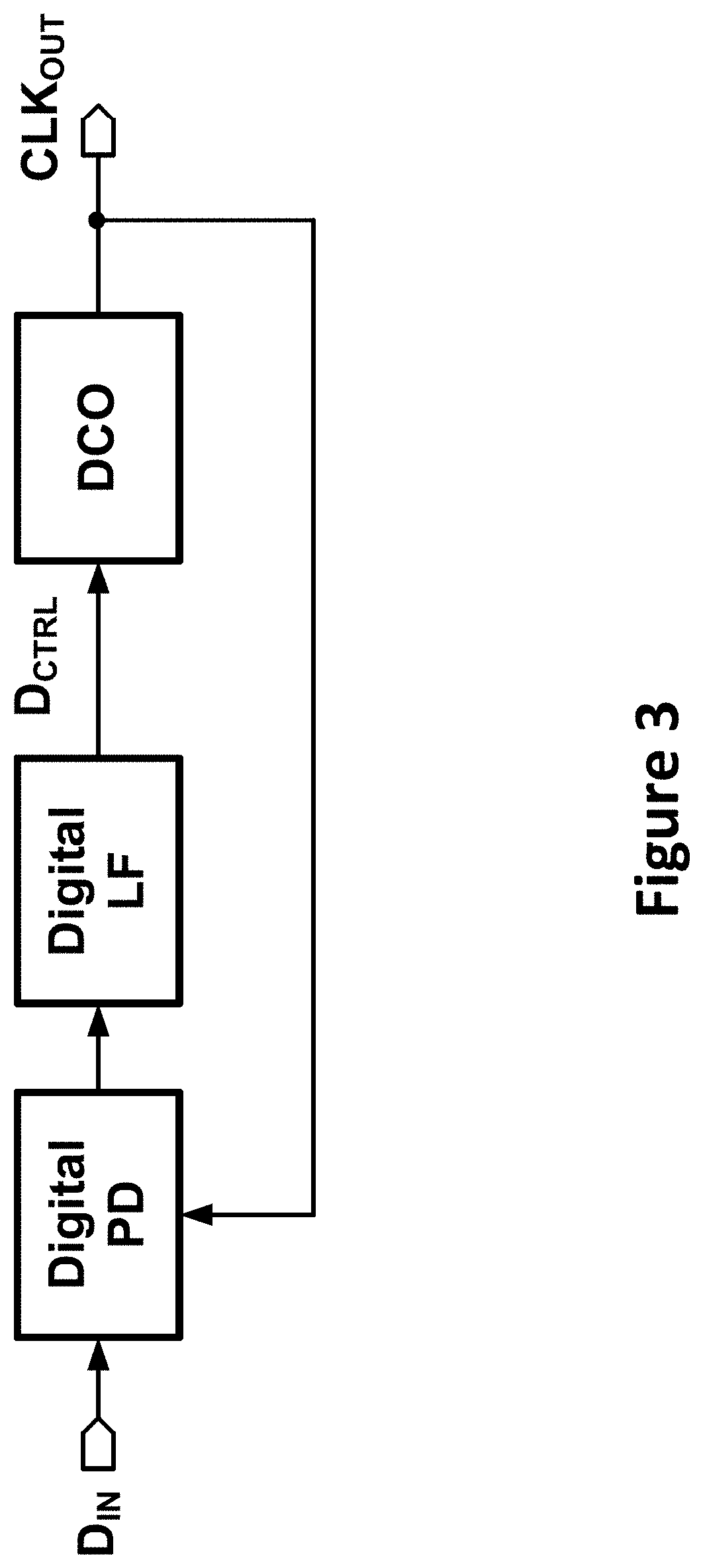

Clock and data recovery devices with fractional-N PLL

ActiveUS10804913B1Improve immunitySmall and efficientPulse automatic controlPulse techniqueLoop filterPhase detector

The present invention relates to data communication and electrical circuits. More specifically, embodiments of the present invention provide a clock and data recovery (CDR) architecture implementation for high data rate wireline communication links. In an embodiment, a CDR device includes a phase detector, a loop filter, and a fractional-N PLL. The fractional-N PLL generates output clock signal based on output of the loop filter. There are other embodiments as well.

Owner:MARVELL ASIA PTE LTD

Variable-length needle covering device of an injection device

InactiveUS7326185B2Operational securityEasy to operateAutomatic syringesMedical devicesInjection pointVariable length

The invention relates to a needle covering device of an injection device, the injection device including a casing comprising a reservoir, in particular an ampoule, for a product fluid to be administered, and an injection needle for injecting the product fluid from the reservoir, wherein the device surrounds the injection needle in an extended position and exposes the injection needle in a retracted position. The device comprises a passage for the injection needle, a front section via which the device is placed on an injection point, and another section which is nearer to the casing than the front section is, at least in the extended position. The sections can be moved axially relative to the casing and relative to each other, such that the device is variable in its length, the front section being guided in a straight line on the casing.

Owner:TECPHARMA LICENSING AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com