Biogas slurry treatment system for use in biogas project

A biogas slurry treatment and engineering technology, which is applied in the field of biogas engineering biogas slurry treatment system, can solve the problems of difficult transportation, unacceptable farmers, inability to digest biogas slurry, etc., to save investment, solve serious pollution problems, and high fermentation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

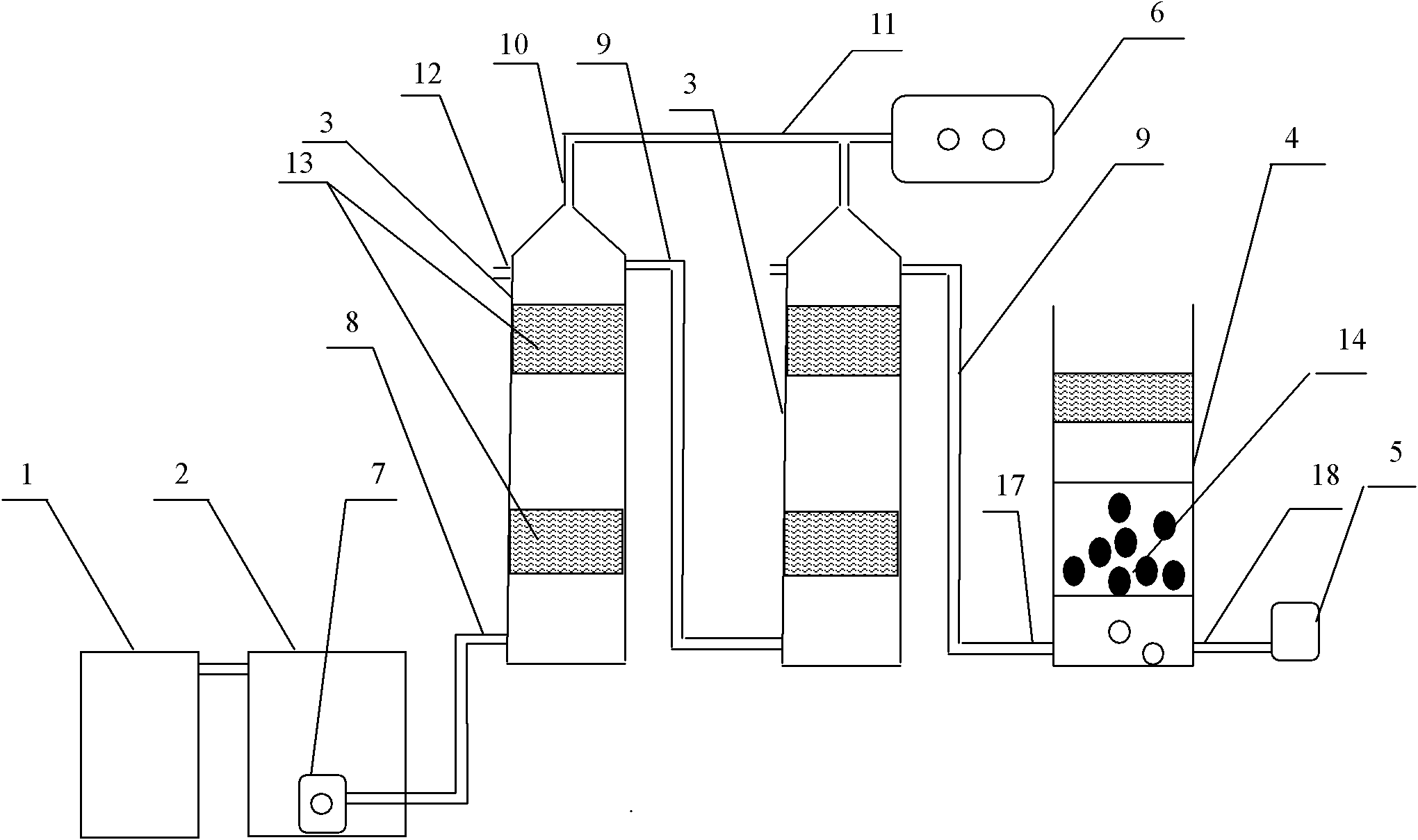

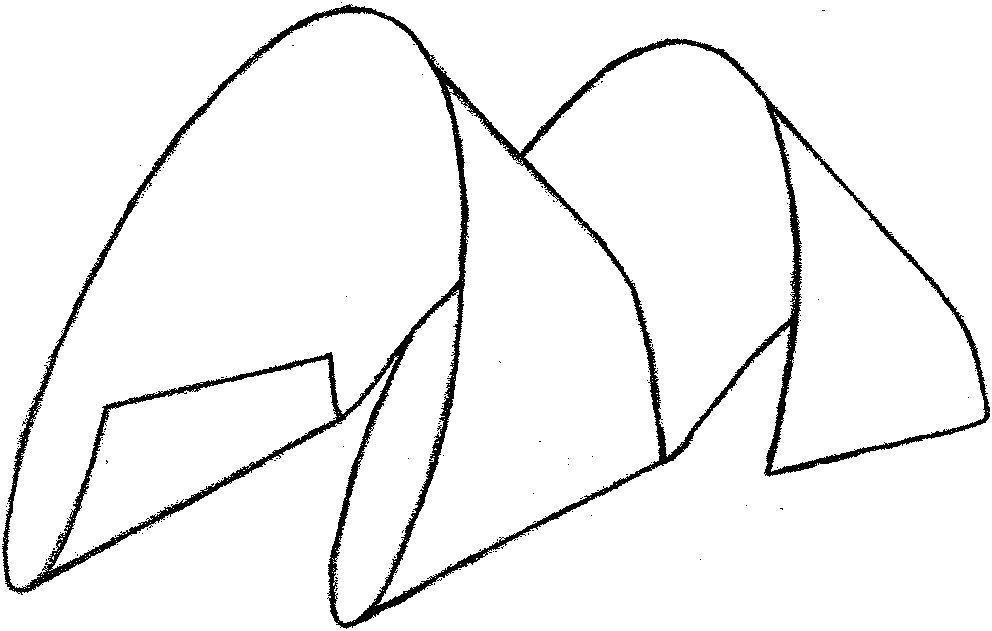

[0032] like figure 1 The biogas slurry treatment system shown in the biogas project includes a sedimentation tank 1, a regulating tank 2, an anaerobic reaction device and a biochemical ceramic post-treatment device 4, a sedimentation tank 1 and a regulating tank 2, a regulating tank 2 and an anaerobic reaction device, an anaerobic reaction device, and an anaerobic reaction device. The oxygen reaction device is connected with the biochemical ceramic post-processing device 4 in sequence, and the anaerobic reaction device is composed of two anaerobic reactors 3. The water inlet of the anaerobic reactor 3 is connected with each other; the anaerobic reactor 3 is filled with a spiral biological filler 13, the lower part of the side wall of the anaerobic reactor 3 is provided with a water inlet pipe 8, and the upper part of the side wall of the anaerobic reactor 3 is provided with a sampling port 12, The top of the anaerobic reactor 3 is provided with a gas outlet 10; the biogas gene...

Embodiment 2

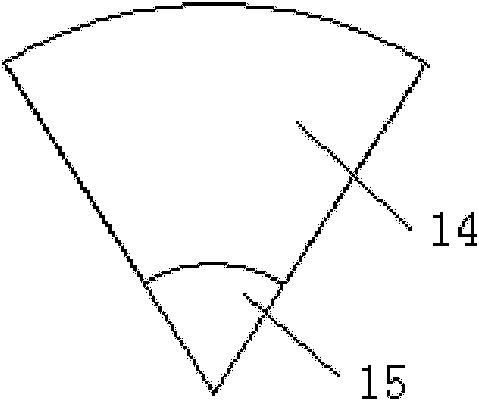

[0044] The biogas engineering biogas slurry treatment system as described in embodiment 1, the difference is that the central angle 15 of the arched structure 14 is 75 ° (such as image 3 shown). The width of the cylindrical helicoid is 1.8cm, and the thickness is 0.15mm.

[0045] The above-mentioned biogas project biogas slurry treatment system aims at producing 200m 3 The relevant design parameters of biogas slurry as raw material of cow dung are as follows:

[0046] The amount of biogas slurry that needs to be treated every day is 200m 3 , the specific device design dimensions are as follows:

[0047] (1) Sedimentation tank 1 is made of brick concrete with a volume of 300m 3 , the size is length × width × height = 10.0m × 6.0m × 5.0m;

[0048] (2) The adjustment pool 2 is made of brick concrete, with a volume of 240m 3 , the size is length × width × height = 10.0m × 4.0m × 6.0m;

[0049] (3) Anaerobic reactor 3 is that the design hydraulic retention time is 20h, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com