Organic waste treatment system and treatment method thereof

A technology for organic waste and treatment pools, applied in biochemical equipment and methods, fertilizers made from biological waste, organic fertilizers, etc., can solve the problems of slow reaction speed of reactors, high investment costs, large projects, etc., and achieve improvement The effect of system gas production rate, efficiency improvement and treatment efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Utilize the organic waste processing system described in the present invention to process domestic organic waste in Xianggao Village, Zhangqiu City, Shandong Province:

[0046] The village can collect an average of 0.7 tons of domestic organic waste every day. The main components of the waste are food waste and paper waste. At the same time, there is a small pig farm near the village, which can produce 0.2 tons of solid waste every day, with a total of 1 ton of raw materials.

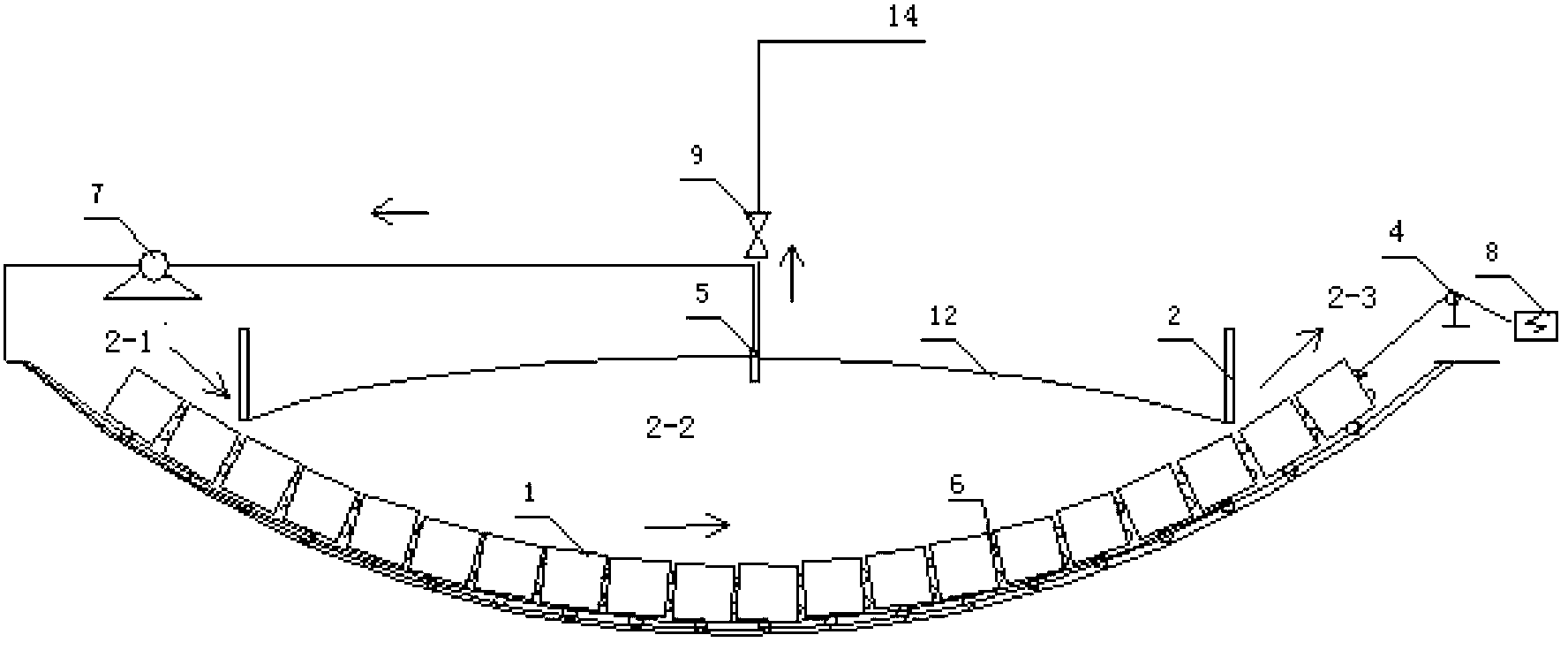

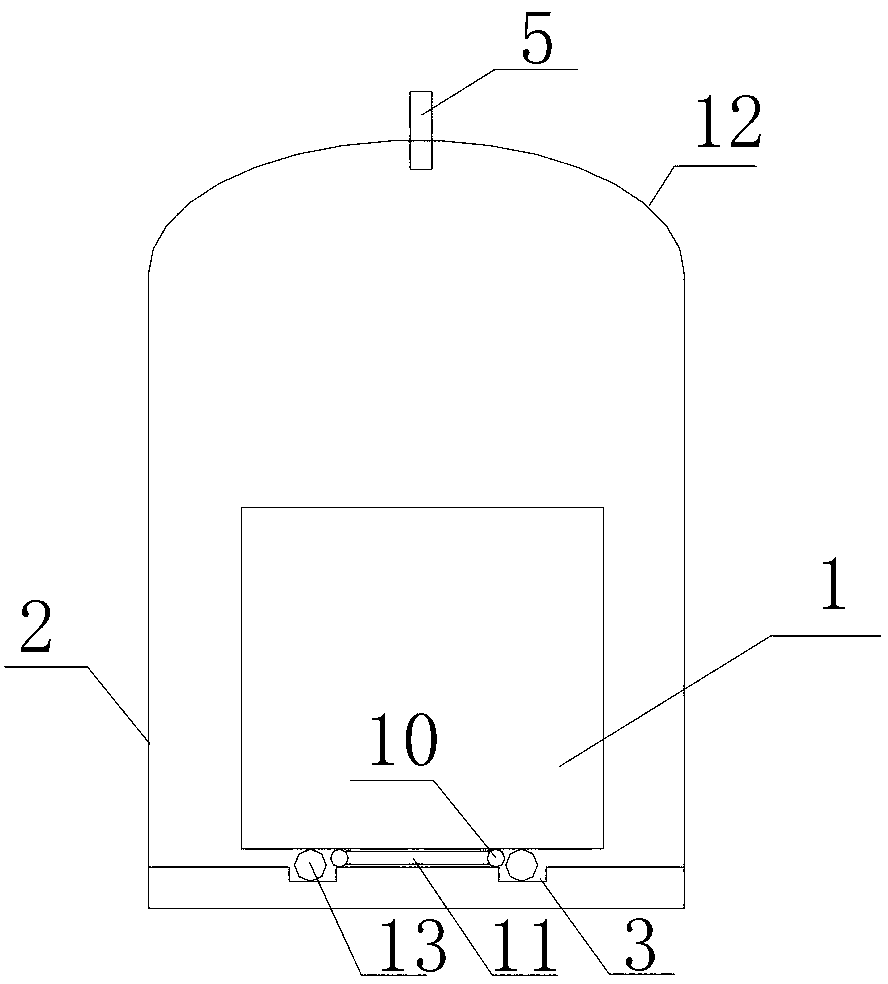

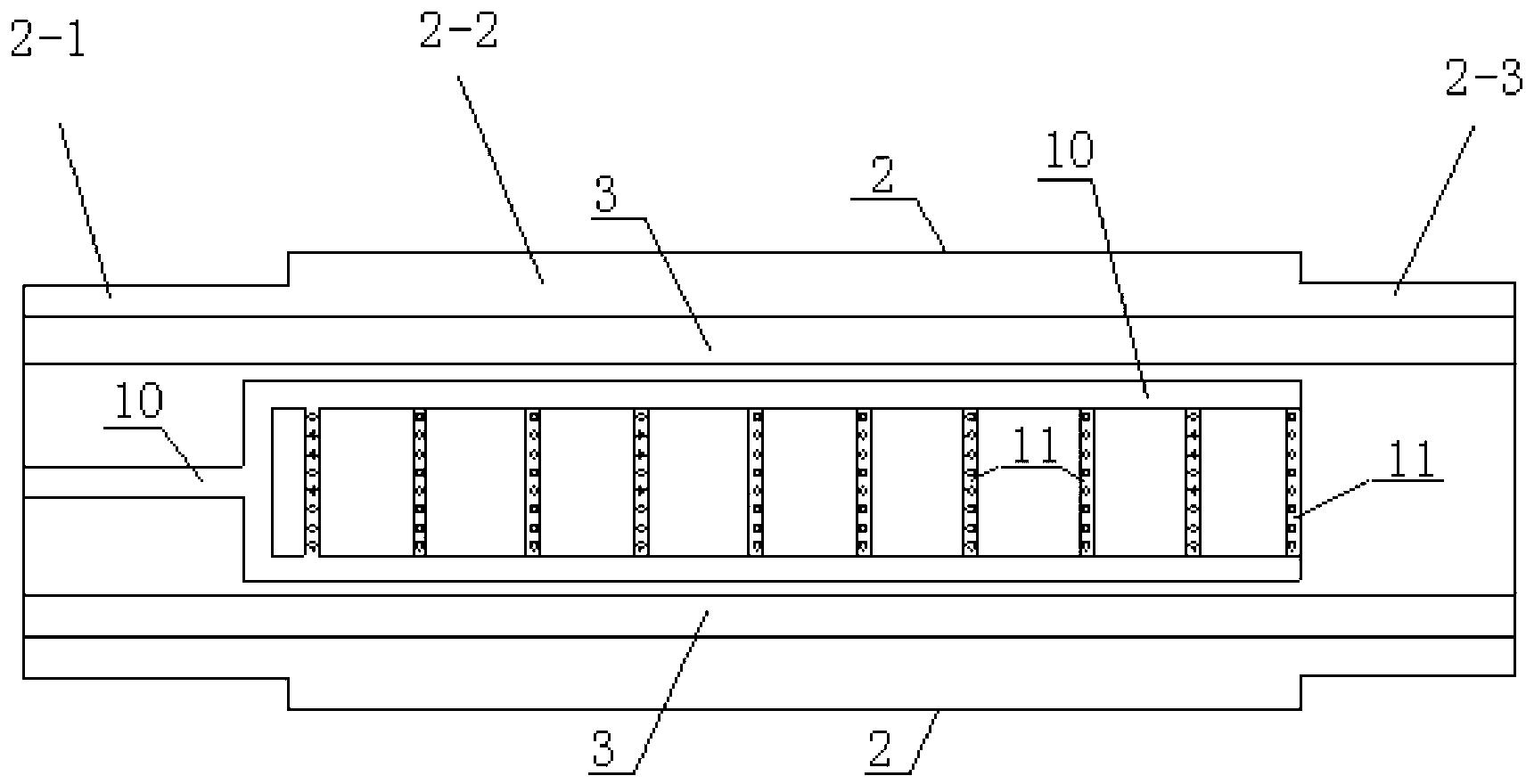

[0047] The above-mentioned system for processing organic waste includes an arc-shaped treatment pool 2 and a material cage 1, and the arc-shaped treatment pool 2 includes an inlet aerobic zone 2-1, an anaerobic zone 2-2 and an outlet aerobic zone 2-3 ; The anaerobic zone 2-2 is located at the bottom position of the arc-shaped treatment pool 2, and the two sides of the anaerobic zone 2-2 are respectively symmetrically provided with an inlet aerobic zone 2-1 and an outlet aerobic zone 2-3 and The a...

Embodiment 2

[0061] A method of utilizing the system as described in embodiment 1 to process organic wastes, comprising the following steps:

[0062] (1) Put the organic waste into the material cage;

[0063] (2) Place the material cage along the track in the aerobic zone at the entrance;

[0064] (3) Inject water into the arc-shaped reaction tank, and all the water injected does not pass through the anaerobic zone;

[0065] (4) Detain the material net cage in the aerobic zone at the entrance for 2 days, then slide into the anaerobic zone along the track and stay in the anaerobic zone for 21 days;

[0066] (5) Push the material net cage into the export good breeding area and stay there for 2 days; follow steps (1)-(2) to add new material net cages in turn, and fill the arc-shaped treatment pool with water at any time to maintain the arc-shaped treatment The water in the pool is submerged in the anaerobic zone;

[0067] (6) The biogas generated in step (4) flows back to the bottom of the...

Embodiment 3

[0075] Utilize the processing organic waste system described in the present invention to process litter excrement of Shandong Qingyun Duck Farm:

[0076] The duck farm produces an average of 9 cubic meters of waste per day. The main components of the farm waste are rice husk, sawdust and duck manure, with a moisture content of 35%.

[0077] The system for treating organic waste as described in Example 1, the difference is that the vault height of the vault is 3 / 4 of the width of the anaerobic zone.

[0078] The gas booster pump is a 100w biogas booster pump produced by Hebei Longfeiteng Biogas Equipment Co., Ltd., with an output pressure of 80kpa.

[0079] Evenly distributed on the stainless steel box wall is provided with through holes with a diameter of 2cm, the spacing between adjacent through holes is 3cm, and the inner side of the stainless steel box wall is provided with a mesh of 10 meshes. Purpose mesh sheet, the diameter of the mesh wire is 0.5mm.

[0080] The gas r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com