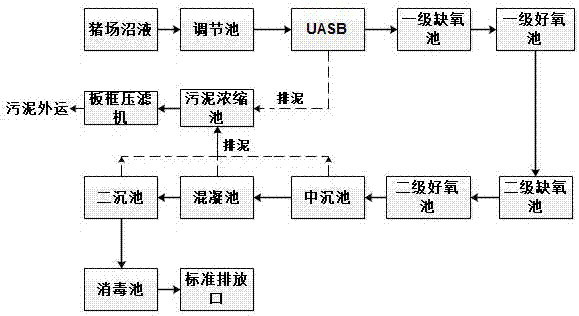

UASB-two stage A/O-coagulation process for treatment of pig farm biogas slurry

A biogas slurry and process technology, applied in the field of environmental protection water treatment, can solve the problems of high operating cost, excessive energy consumption, lack of economic rationality, etc., and achieve the effects of low operating cost, lightening treatment load, and prolonging sludge age.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The processing capacity is 100m 3 / d pig farm biogas slurry, biogas slurry water quality: CODCr 2850 ~ 3000mg / L, NH 3 -N 750~850mg / L, TP 30~40mg / L, SS 950~1300mg / L. The pig farm biogas slurry enters the adjustment pond after passing through the coarse screen, and the water quality and water quantity are adjusted. Then the wastewater is lifted by the lift pump to the UASB reactor for anaerobic treatment, and the biogas slurry undergoes secondary hydrolysis and acidification to greatly reduce the concentration of organic matter. UASB reactor effluent CODCr 700~800mg / L, NH 3 -N 1100~1200mg / L, TP 25~30mg / L, SS 300~350mg / L. Secondly, the wastewater flows into the two-stage A / O biological treatment system under the action of gravity. The two-stage A / O process is connected in series, and the mixed liquid in the aerobic section is partially returned to the anoxic section. The first-stage A / O adopts the activated sludge method, which promotes the growth of phosphorus-accumul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com