Methane generator for cattle farms

A biogas generator and cattle farm technology, which is applied in the fields of gas production bioreactors, biochemical instruments, biological sludge treatment, etc., can solve the problem of low energy conversion efficiency of biogas generators, achieve efficient use of energy, enhance anaerobic conditions Effects of Fermentation Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

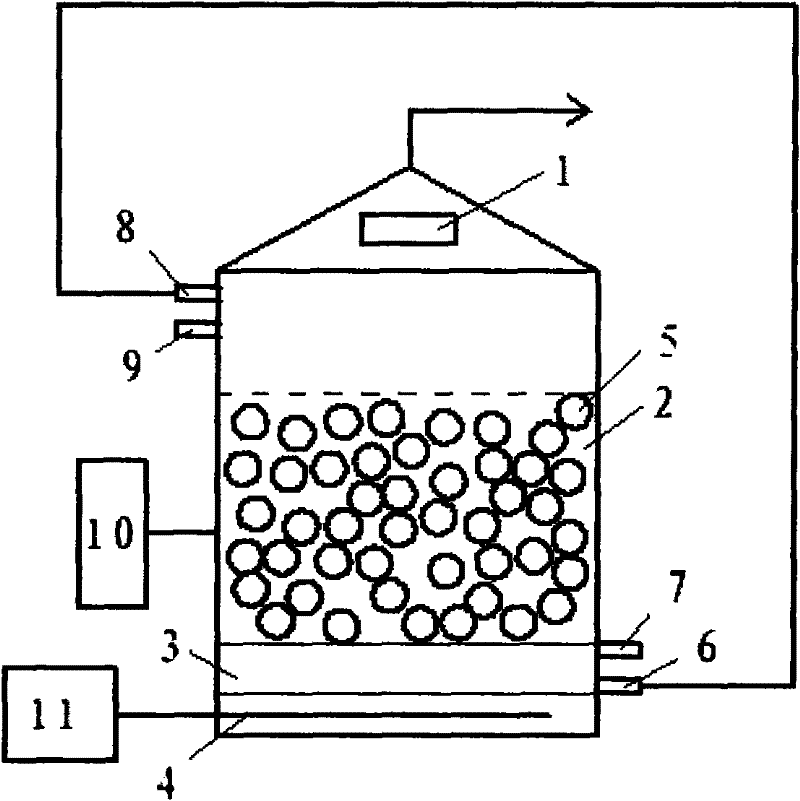

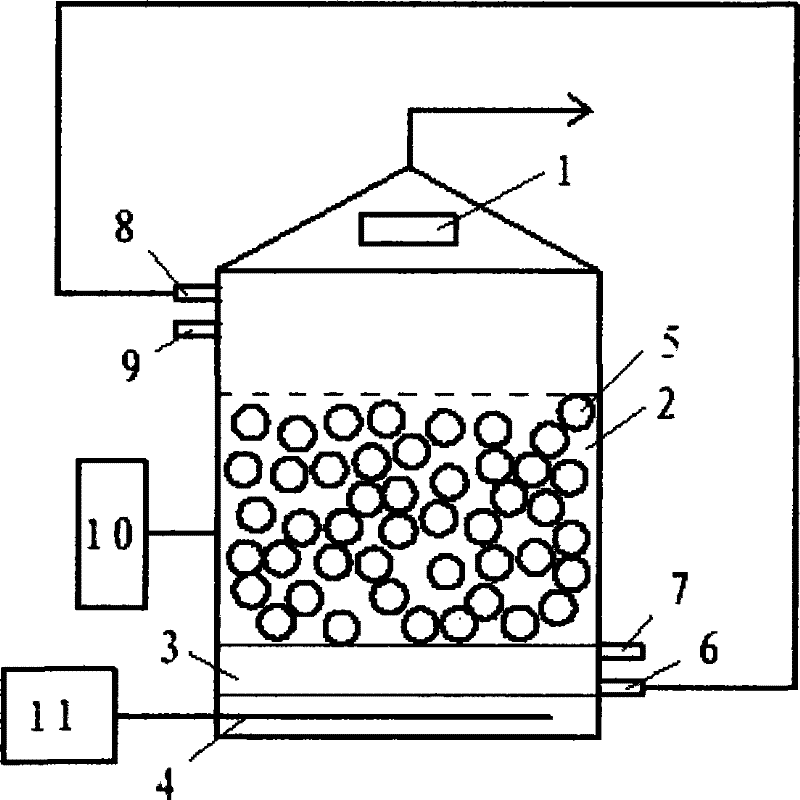

[0014] combine figure 1 As shown, a cattle farm biogas generator of the present invention includes a material inlet 1 set on the top side of the generator, a generation layer 2 in the middle of the generator, a sedimentation tank 3 at the lower part of the generation layer, and a recoil at the bottom of the sedimentation tank 3 layer, wherein the occurrence layer 2 is filled with a helically staggered material 5 .

[0015] Preferably, the generation layer 2 is also connected to a heat exchanger 10 .

[0016] Preferably, a circulation system is also provided between the precipitation tank 3 and the generation layer 2 .

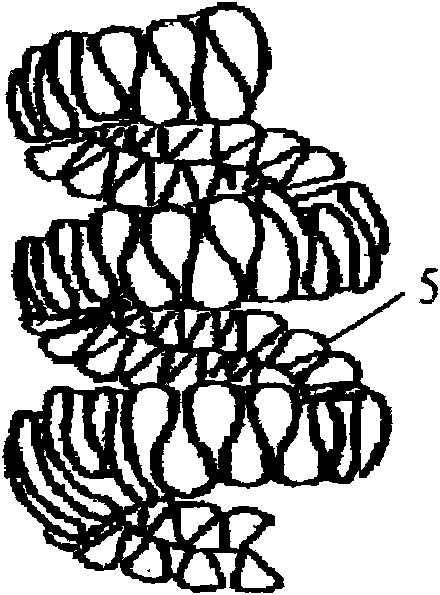

[0017] Preferably, the helically staggered filter material 5 is a spiral staggered type in which strip-shaped thin-skinned materials are wound along the wire winding direction, combined with figure 2 shown.

[0018] Preferably, the material of the helically staggered material 5 is PVC, the specific gravity of the helically staggered material is 0.074, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com