High-efficiency waste water treatment system for nursery

A wastewater treatment system and farm technology, applied in animal husbandry wastewater treatment, water/sewage treatment, biological water/sewage treatment, etc. Convenience, fast response and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

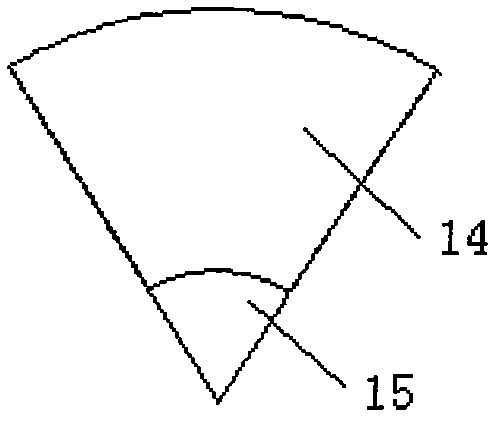

[0037] A biological nest material, which is composed of a long spiral ribbon structure formed by forward and reverse folding of an arched structure 14 in a cylindrical helicoid. The central angle 15 of the arched structure is 60 ° (as image 3 shown). Described cylindrical helicoid width is 1.5cm, and thickness is 0.15mm (as Figure 4 shown). The biological nest material is made of PVC material, and the specific surface area is 3100m 2 / m 3 , the specific gravity is 1.02.

Embodiment 2

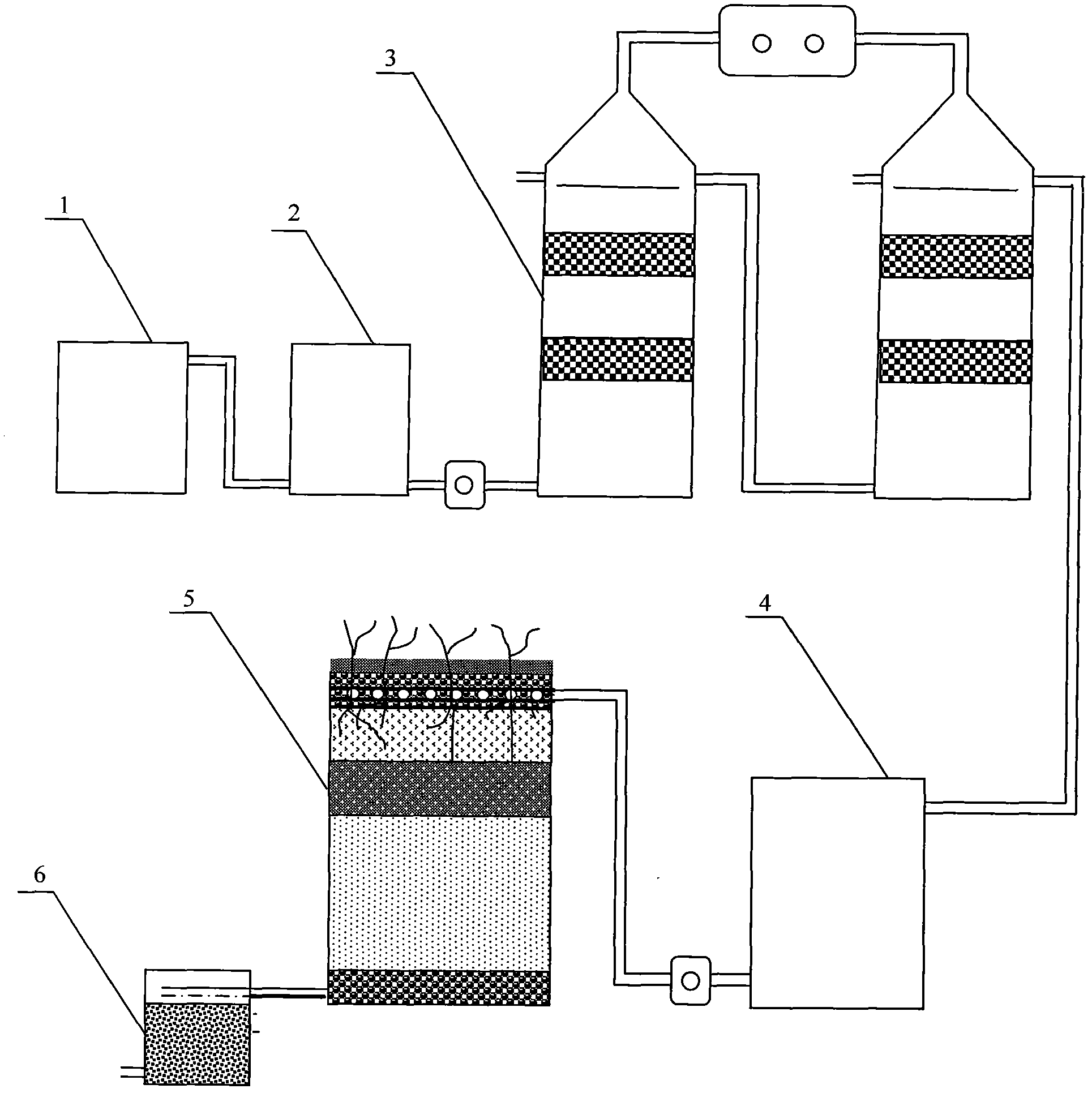

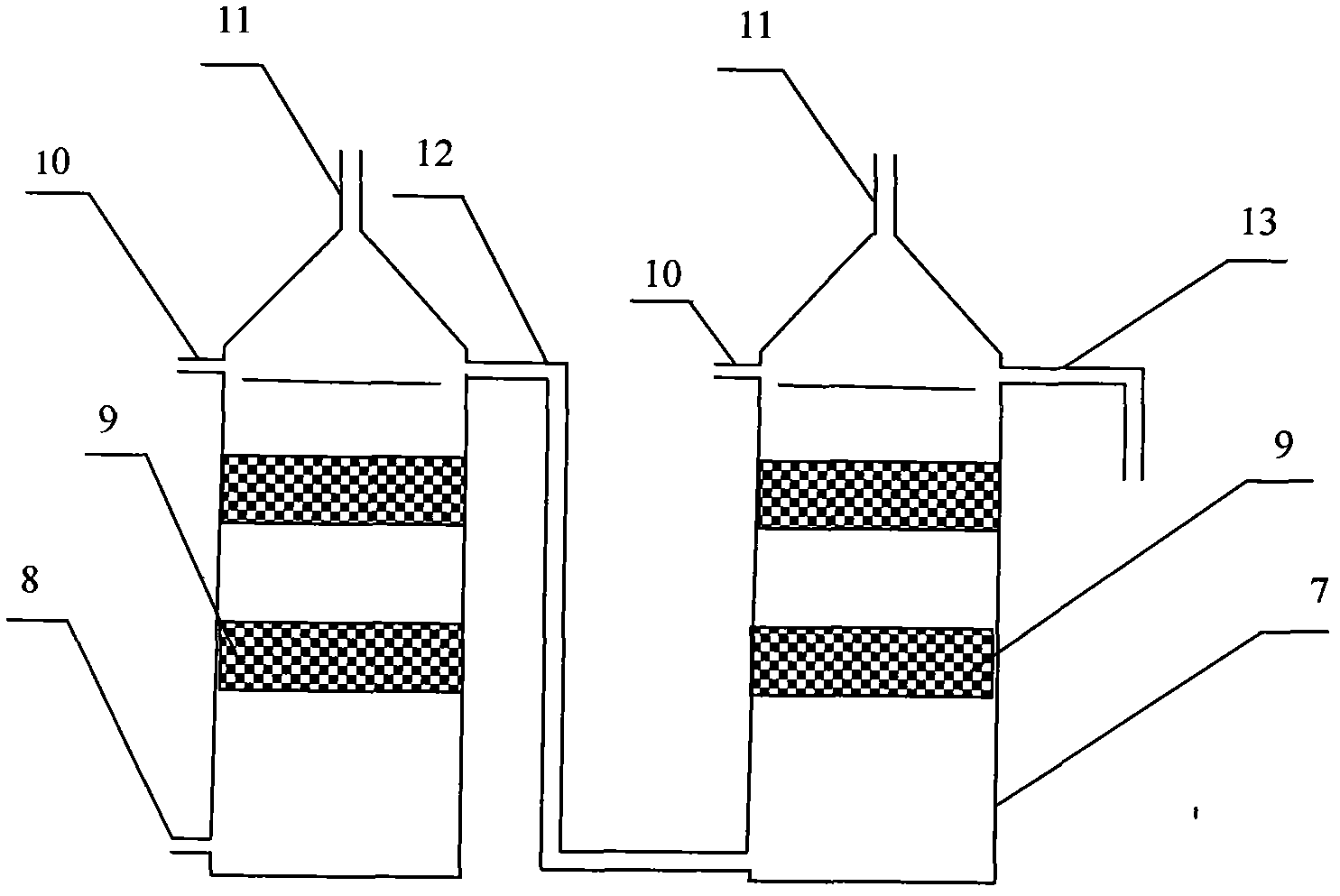

[0039] like figure 1Shown, a kind of livestock and poultry farm wastewater treatment system, it comprises sedimentation tank 1, regulating tank 2, anaerobic reactor 3, effluent collection tank 4, sand type effluent treatment tank 5 and follow-up treatment tank 6, sedimentation tank 1 and Regulating tank 2, regulating tank 2 and anaerobic reactor 3, anaerobic reactor and effluent collection tank 4, effluent collecting tank 4 and sand-type effluent treatment tank 5, sand-type effluent treatment tank 5 and subsequent treatment tank 6 are connected in sequence , the anaerobic reactor is made up of two biological nest anaerobic reactors 3, and the water outlet 13 of the previous biological nest anaerobic reactor communicates with the water inlet 10 of the latter biological nest anaerobic reactor through the connecting pipe 12, as figure 2 Shown; Biological nest anaerobic reactor 3 comprises main body anaerobic fermentation tank 7 and biological nest device 9, two biological nest d...

Embodiment 3

[0051] Wastewater treatment of 2,000 pig farms:

[0052] As the livestock and poultry farm waste water treatment system described in embodiment 2, the difference is:

[0053] A farm with 2,000 pigs in stock produces 14m of pen flushing water and pig urine every day 3 , the specific device design and method are as follows:

[0054] (1) Sedimentation tank 1 is made of brick concrete with a volume of 8m 3 , the size is length × width × height = 2.0m × 2.0m × 2.0m;

[0055] (2) The adjustment pool 2 is made of brick concrete with a volume of 15m 3 , the size is length × width × height = 2.0m × 3.0m × 2.5m;

[0056] (3) The biological nest anaerobic reactor is a glass fiber reinforced plastic structure, the design hydraulic retention time is 15h, and the design volume of each reactor is 4.5m 3 ;

[0057] (4) According to the amount of treated wastewater, the effluent of the bio-nest anaerobic reactor is 13m per day 3 , the volume of the water collection tank 4 is designed to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com