Method for comprehensively treating and utilizing cassava vinasse waste water and industrial sludge

A technology for cassava distiller's grains and industrial sludge, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc., can solve problems such as deficiencies, reduce production costs and simplify production processes , the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

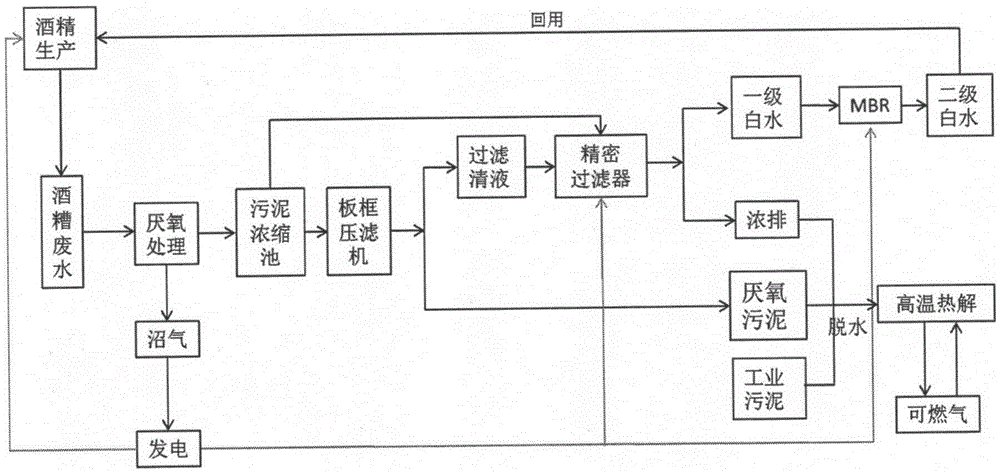

[0036] Such as figure 2 Shown, a kind of comprehensive treatment and utilization method of cassava distiller's grain wastewater and industrial sludge, concrete steps are:

[0037] Step 1: Pump the cassava distiller's grain wastewater stock solution into an anaerobic fermentation tank for high-temperature anaerobic treatment of the whole grain (Class I CSTR anaerobic fermentation), the fermentation temperature is 60°C, and biogas is generated;

[0038] The second step: the sludge with a water content of 90% discharged from the anaerobic fermentation tank is separated from the sludge and water through the sludge concentration tank to obtain the concentrated sludge and the clear liquid of the sludge concentration tank, and the obtained concentrated sludge is sent to the plate and frame press filter, using a plate and frame filter press to filter to obtain anaerobic sludge and filtered clear liquid; the third step: the clear liquid in the sludge concentration tank obtained in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com