Large horizontal tunnel kiln spiral continuous dry-type anaerobic fermentation equipment

A dry anaerobic fermentation and tunnel kiln technology is applied in the field of large-scale horizontal tunnel kiln type spiral continuous dry anaerobic fermentation equipment, which can solve the problems of low reaction concentration, easy blockage of the discharge port, and scum crusting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

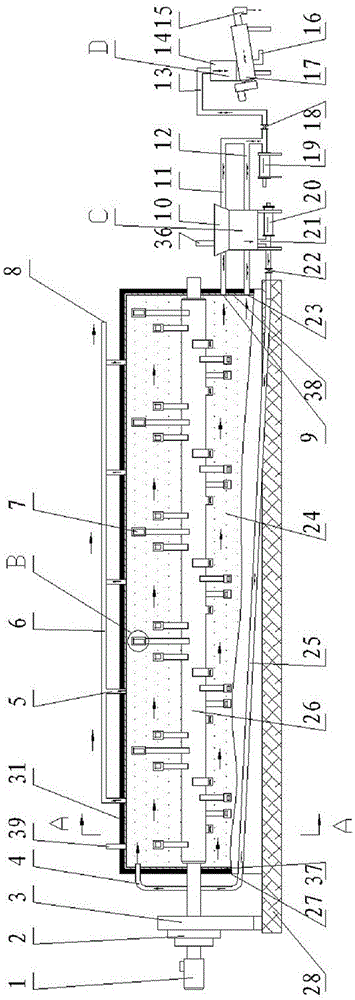

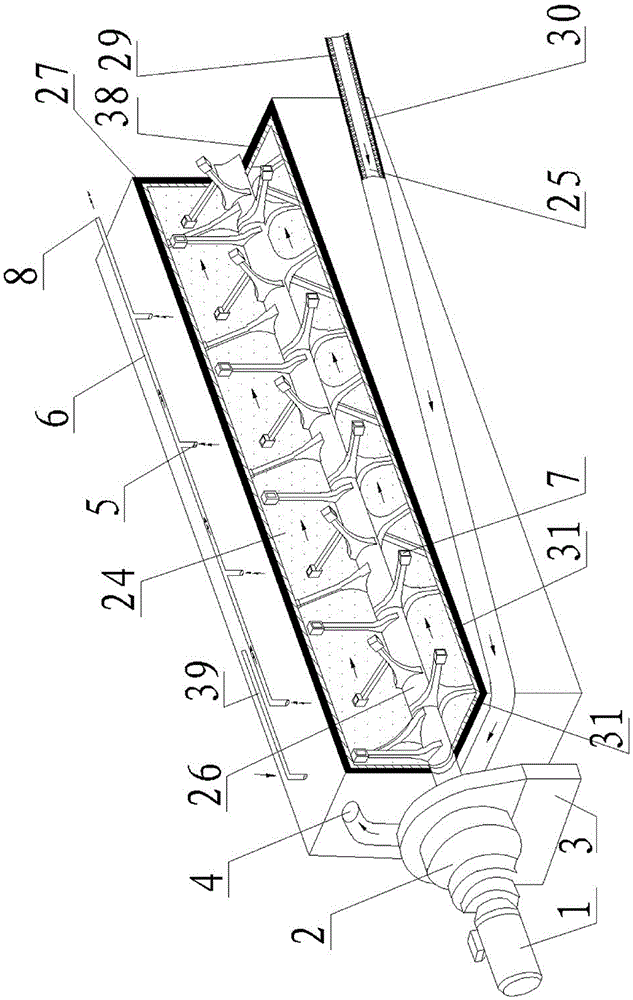

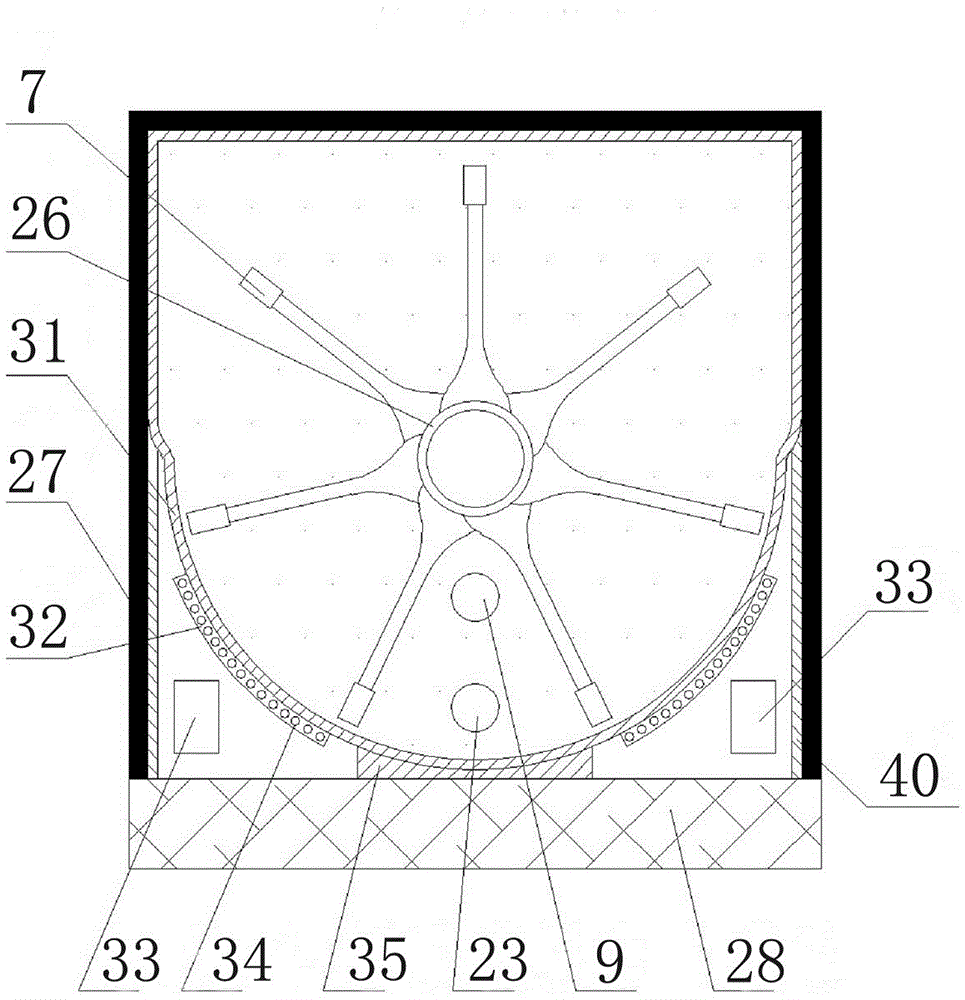

[0054] Such as figure 1 , figure 2 , image 3 As shown, the large-scale horizontal tunnel kiln type spiral continuous dry anaerobic fermentation equipment of the present invention includes the anaerobic reaction tunnel kiln installed on the equipment foundation 28, and the anaerobic reaction tunnel kiln is composed of a tunnel kiln inner cavity 31 and The front and rear end covers 37 and 38 are jointly formed to seal the front and rear ends of the tunnel kiln cavity in an airtight manner, and the lower half of the cross section of the tunnel kiln cavity 31 has a semicircular structure, and the upper half It is a rectangular structure; a row of heat exchange plates 32 with steam heating pipes 34 are respectively installed on both sides of the outer wall of the semicircular structure, so that the temperature of the reaction material 24 can be maintained at 55 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com