Anaerobic digestion system capable of improving biogas production efficiency

An anaerobic digestion system and anaerobic digestion technology, applied in the field of biological fermentation, can solve the difficulty of realizing complete mixing in large and ultra-large anaerobic reactors, the negative impact of anaerobic reactor function and performance, and the concentration of anaerobic reactor materials. Low problems such as improving treatment efficiency and biogas production, preventing pipeline corrosion or damage to generator equipment, and shortening hydraulic retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

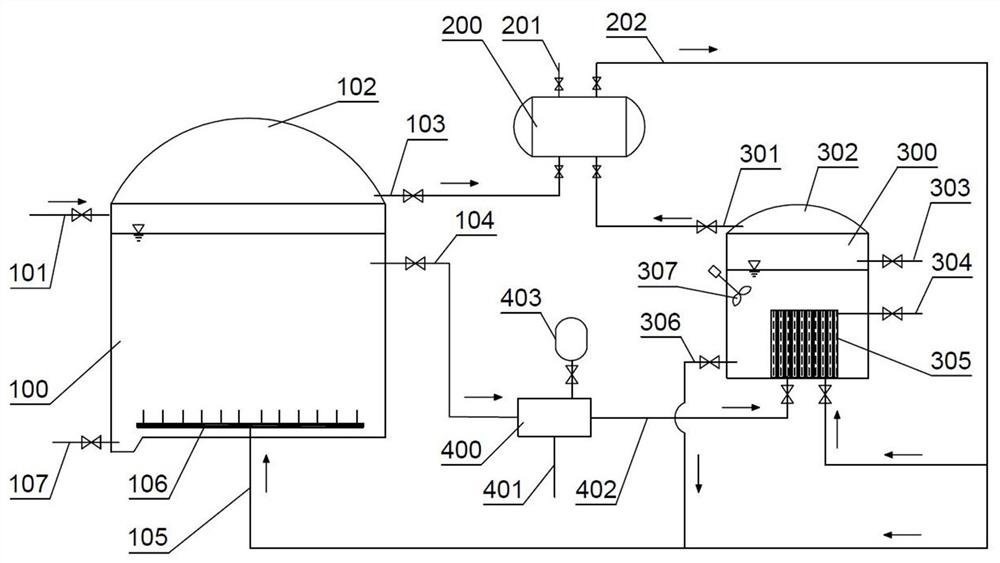

[0032] Such as figure 1As shown, an anaerobic digestion system for improving biogas production efficiency includes anaerobic digester 100, biogas surge tank 200, anaerobic membrane separator 300 and solid-liquid separator 400, and anaerobic digester 100 is connected with feed Pipe 101, digester flexible gas storage bag 102, discharge pipe 104, and distribution pipe 105, the feed pipe 101 is arranged on the upper side of the anaerobic digester 100, the C / N in the material is between 20 and 40, anaerobic The concentration of the total material inside the oxygen digester 100 is not higher than 12%. The bottom of the anaerobic digester 100 is provided with a concave slag discharge port. , the distributing device is formed by cross-connecting multiple distributing pipes with holes, the distributing device 106 is evenly laid on the bottom of the anaerobic dig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com