Filler and Surface Treatment Method of Chip Components

A surface treatment and filler technology, applied in electrical components, electrical solid devices, semiconductor devices, etc., can solve the problems of increasing the nickel layer of the intermediate layer, difficulty, reducing the probability of tin spraying phenomenon, etc., to achieve strong hydrophobic performance, use Simple, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

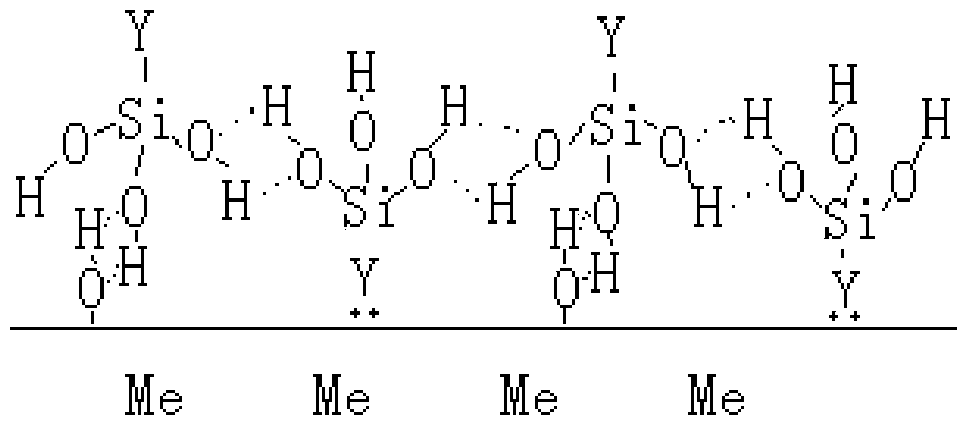

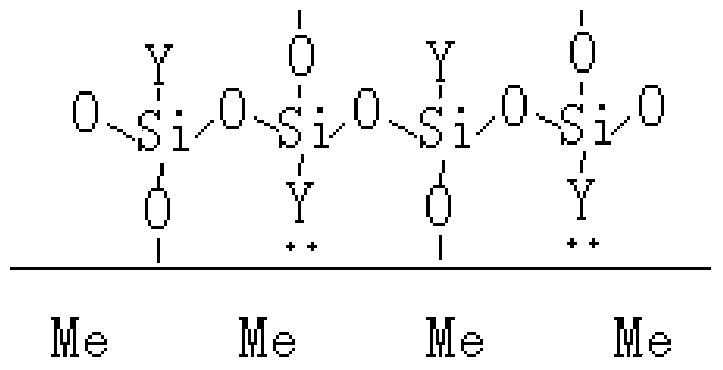

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of above-mentioned filler comprises the steps:

[0049] 60-75 parts by weight of alcohol and 5-10 parts by weight of water are prepared into an aqueous alcohol solution;

[0050] Mixing 15-30 parts by weight of vinyl silane coupling agent and alcohol aqueous solution to obtain a mixed solution;

[0051] Add 1-5 parts by weight of organic carboxylic acid to the mixed liquid.

[0052] The preparation method of the above filler is relatively simple.

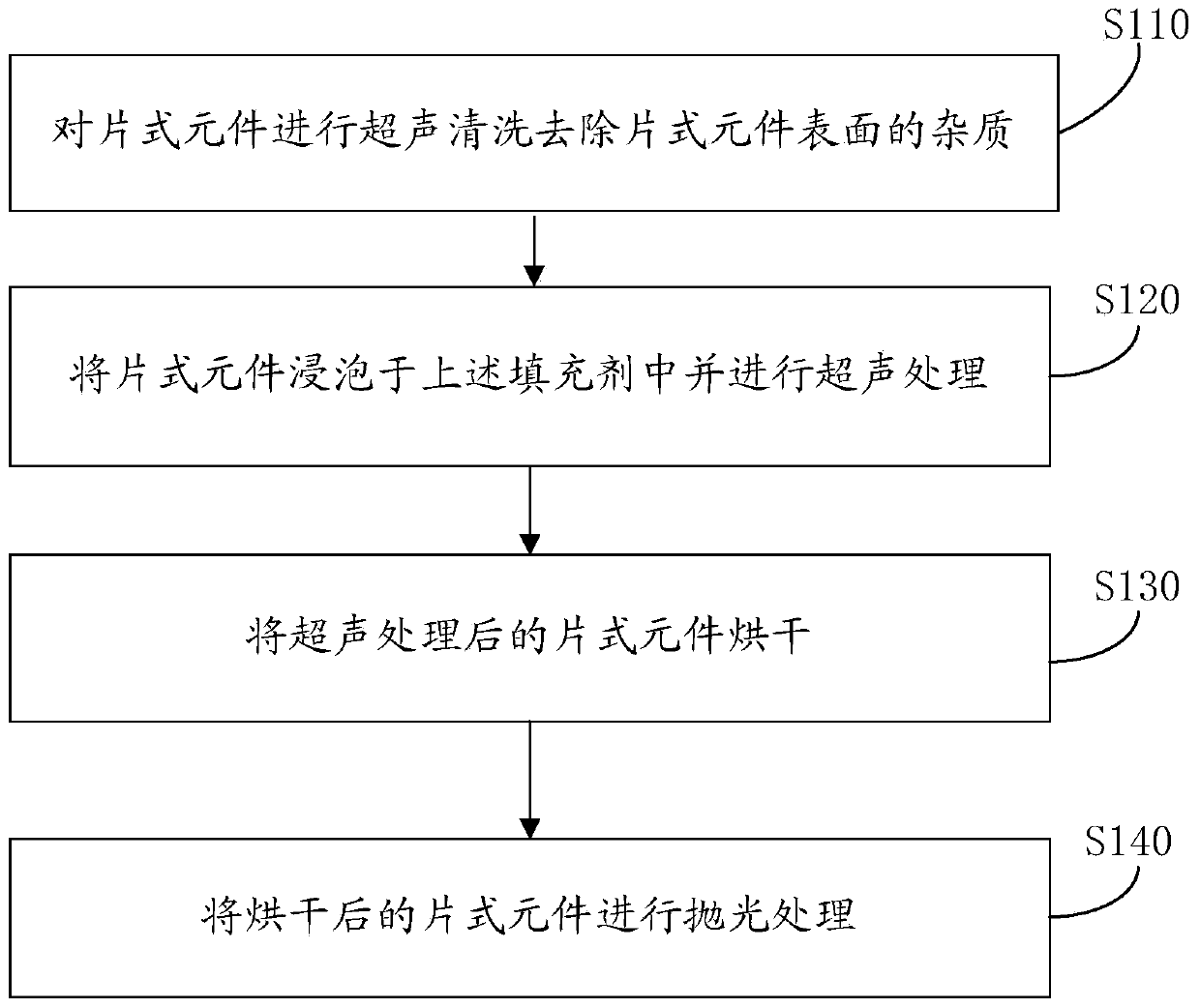

[0053] The surface treatment method of the chip component using the above-mentioned filler in one embodiment includes the following steps:

[0054] Step S110, performing ultrasonic cleaning on the chip component to remove impurities on the surface of the chip component.

[0055] The chip components involved in this embodiment are chip components in laminated inductors, capacitors, and resistors. The terminal electrodes generally adopt three-layer electrode technology, which is composed of three-layer e...

Embodiment 1

[0072] 1. Take the end-capped and sintered multilayer chip inductor (silver end), ultrasonically clean it in deionized water for 7 minutes, remove surface impurities, and then dry it.

[0073] 2. Soak the cleaned and dried chip inductor at room temperature in the filler for ultrasonic treatment for 8 minutes.

[0074] The composition of the filler is: in parts by mass, 20 parts of vinyltriethoxysilane, 70 parts of ethanol, 8 parts of water, 2 parts of acetic acid, and the pH value is 5.0.

[0075] 3. Dry the soaked chip inductor at 110°C for 70 minutes.

[0076] 4. Polish the dried chip inductor for 30 minutes.

Embodiment 2

[0078] 1. Take the capped and sintered chip inductor (silver terminal), ultrasonically clean it in deionized water for 6 minutes, remove surface impurities, and then dry it.

[0079] 2. Soak the cleaned and dried chip inductor at room temperature in the above-mentioned filler for ultrasonic treatment for 10 minutes.

[0080] The composition of the filler is: in parts by mass, 15 parts of vinyltriethoxysilane, 75 parts of ethanol, 5 parts of water, 5 parts of acetic acid, and the pH value is 4.0.

[0081] 3. Dry the soaked chip inductor at 120°C for 60 minutes.

[0082] 4. Polish the dried chip inductor for 25 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com