Molten metal compatible with stainless steel and capable of controlling oxygen activity to be 200-300 degrees and technology thereof

A liquid metal and stainless steel technology, applied in the alloy field, can solve problems such as pipe cracking and heat transfer system failure, and achieve the effect of fast dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The invention relates to a liquid metal compatible with stainless steel whose oxygen activity is controlled at 200-300 degrees and its technology. In terms of weight percentage, the alloy composition is Ga: 0.5wt.%, In: 2.1wt.%, Pb: 4.5wt.%, Zn: 10.8wt.%, Bi: 4.0wt.%, Cd: 3.2wt.% , Sb: 5.0wt.%, the balance is tin; the oxide composition for controlling oxygen activity is PbO: 24.0wt.%, MnO: 3.2wt.%, MgO: 12.0wt.%, In 2 o 3 : 4.5wt.%, CuO: 3.2wt.%, the balance is Fe 2 o 3 .

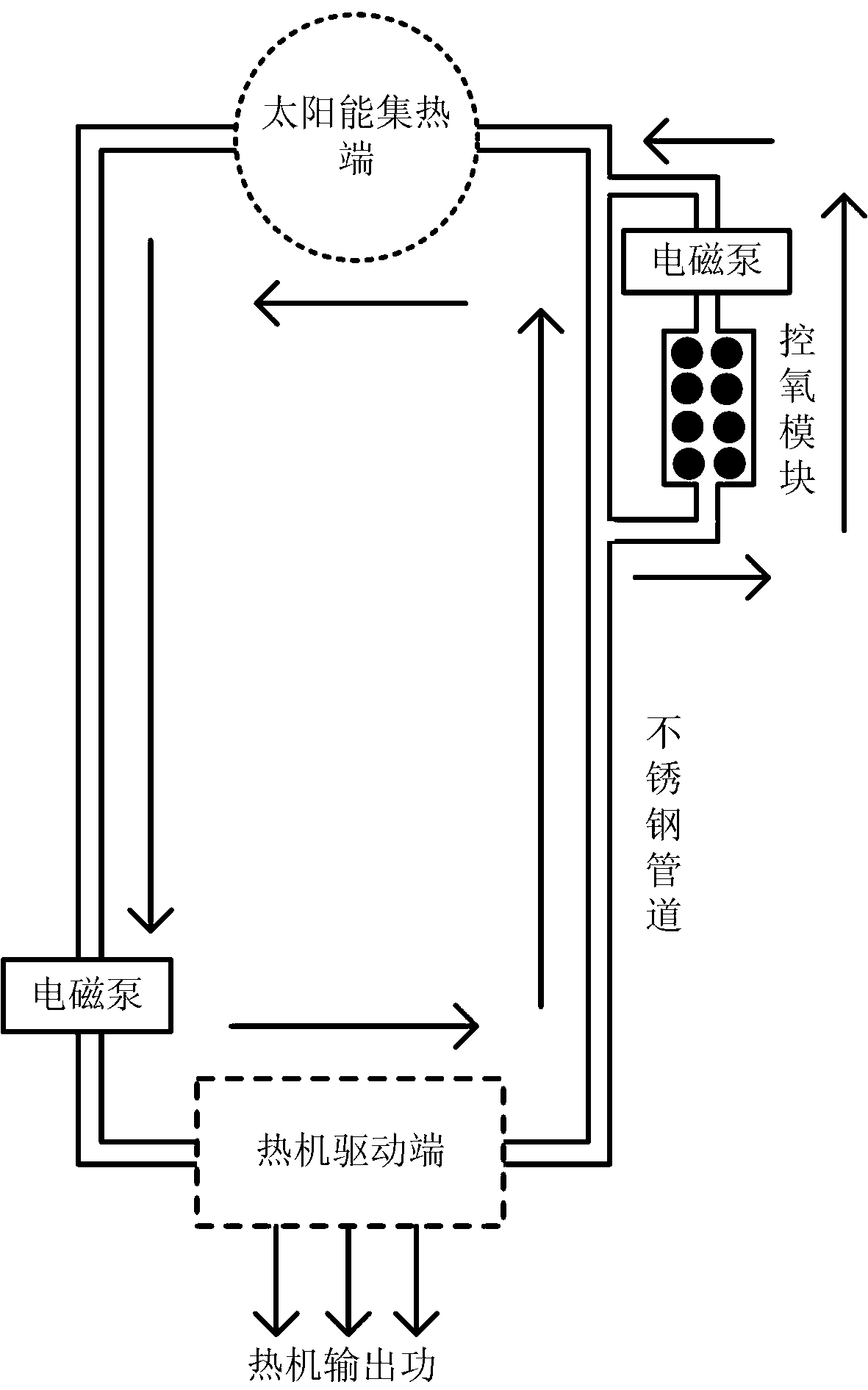

[0020] The above-mentioned liquid metal whose oxygen activity is controlled at 200-300 degrees and is compatible with stainless steel and its technology include the following processing and use steps: (a) After the alloy is configured according to the required composition, it is placed in an induction furnace for Melting, and using graphite crucible for smelting under the protection of argon; heat preservation at 200 degrees for 10 minutes, use electromagnetic stirring to fully stir the alloy mel...

Embodiment 2

[0023] The invention relates to a liquid metal compatible with stainless steel whose oxygen activity is controlled at 200-300 degrees and its technology. In terms of weight percentage, the alloy composition is Ga: 0.7wt.%, In: 2.9wt.%, Pb: 5.6t.%, Zn: 18.0wt.%, Bi: 5.0wt.%, Cd: 4.8wt.% , Sb: 7.2wt.%, the balance is tin; the oxide composition for controlling oxygen activity is PbO: 28.0wt.%, MnO: 4.5wt.%, MgO: 16.0wt.%, In 2 o 3 :5.2wt.%, CuO: 4.1wt.%, the balance is Fe 2 o 3 .

[0024] The above-mentioned liquid metal whose oxygen activity is controlled at 200-300 degrees and is compatible with stainless steel and its technology include the following processing and use steps: (a) After the alloy is configured according to the required composition, it is placed in an induction furnace for Melting, and using a graphite crucible for smelting under the protection of argon; heat the alloy at 290 degrees for 10 minutes and use electromagnetic stirring to fully stir the alloy mel...

Embodiment 3

[0027] The invention relates to a liquid metal compatible with stainless steel whose oxygen activity is controlled at 200-300 degrees and its technology. In terms of weight percentage, the alloy composition is Ga: 0.6wt.%, In: 2.4wt.%, Pb: 5.1wt.%, Zn: 14.0wt.%, Bi: 4.8wt.%, Cd: 3.2wt.% , Sb: 6.0wt.%, the balance is tin; the oxide composition for controlling oxygen activity is PbO: 24.0wt.%, MnO: 3.2wt.%, MgO: 18.0wt.%, In 2 o 3 :5.0wt.%, CuO: 4.0wt.%, the balance is Fe 2 o 3 .

[0028] The above-mentioned liquid metal whose oxygen activity is controlled at 200-300 degrees and is compatible with stainless steel and its technology include the following processing and use steps: (a) After the alloy is configured according to the required composition, it is placed in an induction furnace for Melting, and using a graphite crucible for melting under the protection of argon; heat the alloy at 240 degrees for 10 minutes and use electromagnetic stirring to fully stir the alloy mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com