High-temperature oil-proof high numerical aperture optical fiber and preparation method thereof

A numerical aperture and oil-resistant technology, used in cladding optical fibers, glass optical fibers, glass manufacturing equipment, etc., can solve the problems that temperature-measuring optical fibers cannot meet large numerical values, high temperature resistance, oil resistance, and cannot meet the temperature measurement requirements of transformer windings at the same time. , to achieve the effect of blocking corrosion, stable performance and enhancing high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

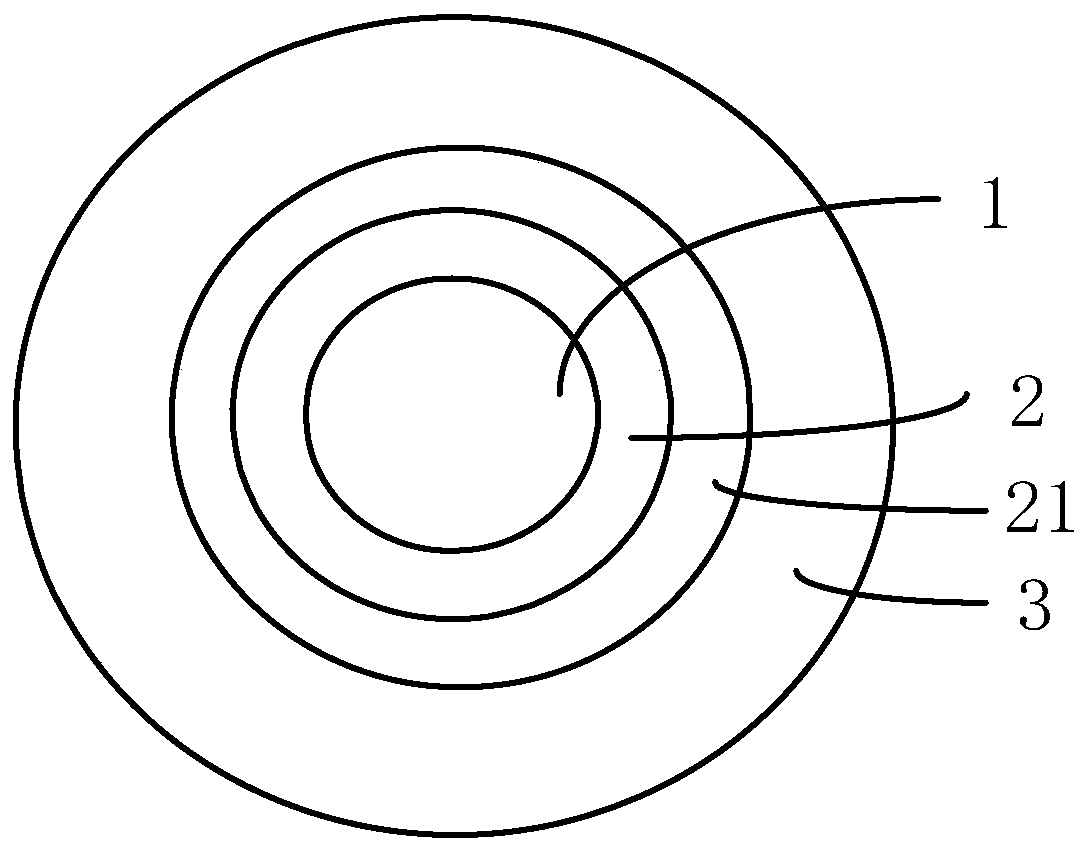

[0022] The structure of traditional optical fiber is a three-layer structure, namely core layer, cladding layer and coating layer, and the numerical aperture is usually NA=0.22. Polyimide coating is usually used for high temperature resistant optical fiber coating. In order to improve the coupling efficiency of optical fiber coupling and increase the numerical aperture of the optical fiber, the present invention proposes a two-layer optical fiber preparation scheme, coating one or two layers of high-temperature-resistant new low-refraction coating on the pure silica core layer, and the numerical aperture can be increased. As large as NA=0.46. In addition, in order to meet the oil resistance performance of transformer temperature measurement in the power industry, a PFA oil-resistant sheath is added to the outside of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com