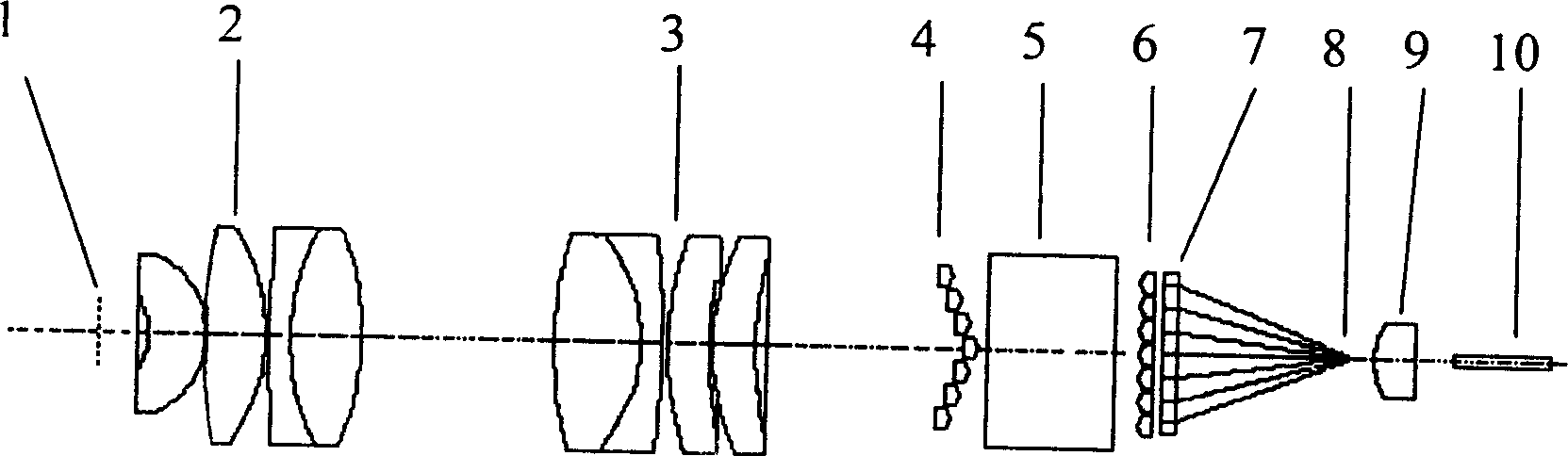

Light beam shaping device in use for semiconductor laser array in high power

A beam shaping, semiconductor technology, applied in semiconductor laser devices, laser devices, optics, etc., can solve the problems of small beam numerical aperture, achieve high numerical aperture, small beam output, high coupling efficiency, simple design and production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

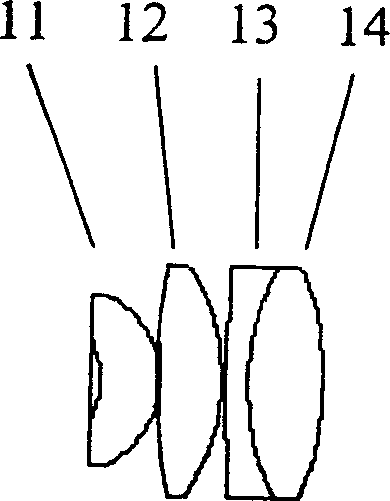

Embodiment 1

[0014] The first lens group 2 is made up of the first concave-convex lens 11, the first double-convex lens 12, the cemented lens that is the first convex-convex lens 13 and the second double-convex lens 14; 12. The cemented lens is the first concave-convex lens 13 and the second biconvex lens 14. The concave surface of the first concave-convex lens 11 is close to the output end of the laser array 1, and the convex surface of the first concave-convex lens 11 is close to the input surface of the first biconvex lens 12. The output surface of the first lenticular lens 12 is close to the convex surface of the first lenticular lens 13, the concave surface of the first lenticular lens 13 is glued together with the convex input surface of the second lenticular lens 14, and the convex output surface of the second lenticular lens 14 is close to the first lenticular lens 14. The convex input face of the three lenticular lenses 15 .

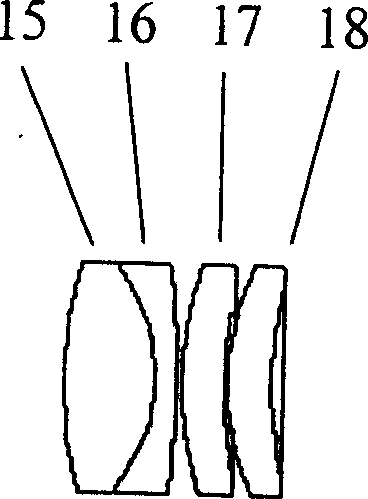

[0015] The second lens group 3 is made up of cemented ...

Embodiment 2

[0021] When the present invention is used in a high-power laser array, the laser array 1 can adopt a laser array of nineteen light-emitting units, each light-emitting unit has a strip width of 150 μm, a period of 500 μm, an area of the light-emitting area of 10 mm×0.001 mm, and continuous output at room temperature The optical power is 40W, the divergence angle perpendicular to the p-n junction direction (fast axis) of the laser array is 35°, the numerical aperture is 0.5736, and the divergence angle parallel to the p-n junction direction (slow axis) of the laser array is 7°, the value The aperture is 0.12, and other parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| divergence angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com