Method for preparing 2, 5-furandicarboxylic acid by electro-catalyzing oxidation of 5-hydroxymethylfurfural and simultaneously electrolyzing water to prepare hydrogen

A technology of hydroxymethylfurfural and electrolyzed water, which is applied in the chemical industry, can solve problems such as difficult to improve energy utilization efficiency and water molecule activation, and achieve the effects of good hydrogen production ability, high selectivity and high tolerance of water decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] The preparation method of described monolithic catalyst comprises the following steps:

[0077] S100, preparation of solution: Co(NO 3 ) 2 Mix with nitrogen and carbon compounds in a certain proportion and add water to form a solution; wherein, the Co(NO 3 ) 2 The molar ratio to nitrogen and carbon compounds is 1:1.5 to 1:5. Preferably, as an implementation manner, the nitrogen- and carbon-containing compound is one or both of urea and tetrasodium edetate.

[0078] In the present application, there is no particular limitation on the concentration of the prepared solution. In order to prepare a monolithic nitrogen-doped carbon-wrapped cobalt tetraoxide nanowire catalyst with excellent performance, enhance its catalytic stability, and prolong its service life, preferably, Co(NO 3 ) 2 The molar ratio with water is 1:600~1:1200.

[0079] S200, hydrothermal reaction: put the solution obtained in step S100 in a reaction kettle, add metal foam, carbon foam or carbon fib...

Embodiment 1

[0091] (1) Add 0.584g Co(NO 3 ) 2 ·6H 2 O, 0.6g urea, 36mL deionized water, stir well at room temperature. Among them, Co(NO 3 ) 2 The molar ratio to urea is 1:5, Co(NO 3 ) 2 The molar ratio with water is 1:1000.

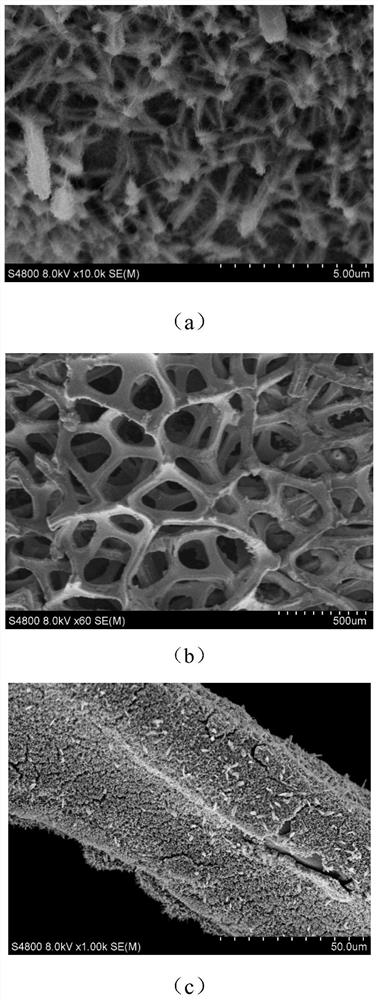

[0092] (2) Transfer the solution prepared in step (1) to a 100mL reaction kettle, add foamed nickel carrier, make it immersed in the solution, put it in an oven and react at 120°C for 8h, take it out and wash it twice with water and ethanol in turn , placed in a beaker, and dried in an oven at 60° C. for 12 hours to obtain a precursor.

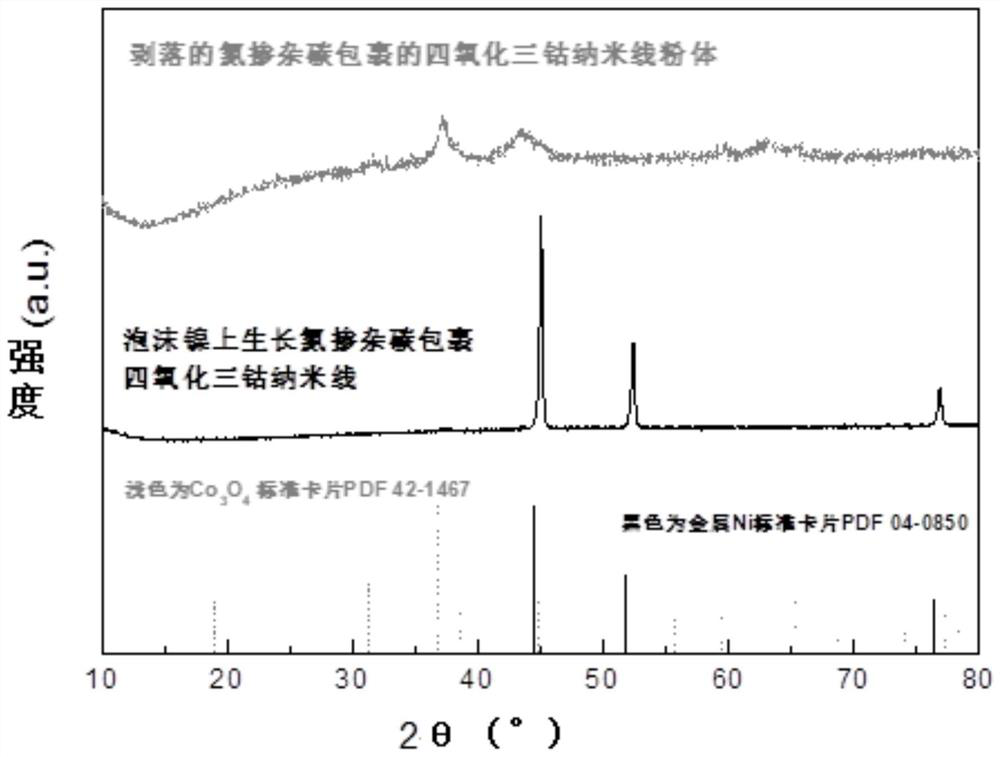

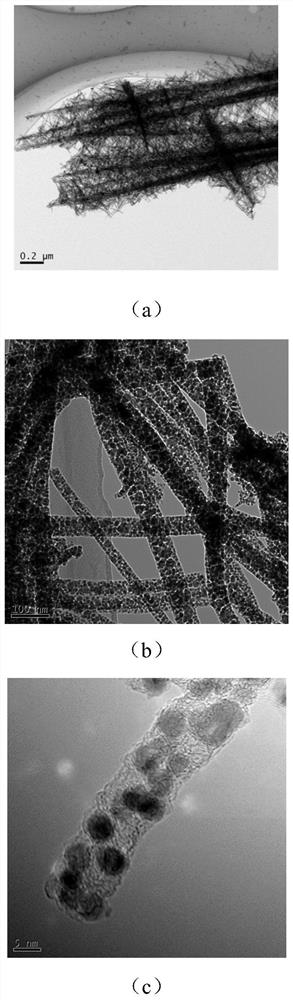

[0093] (3) Place the precursor obtained in step (2) in the quartz boat of the tube furnace, seal it and pass high-purity nitrogen gas as the whole process protective gas, wherein the flow rate of nitrogen gas is 150mL / min; The temperature was raised to 350°C at a speed of 1 min, and after holding for 0.5h, it was cooled to room temperature at a speed of 3°C / min. The obtained product was a monolithic nitrogen-doped carbon-wra...

Embodiment 2

[0095] (1) Add 0.584g Co(NO 3 ) 2 ·6H2 O, 0.2g urea, 36mL deionized water, stir well at room temperature. Among them, Co(NO 3 ) 2 The molar ratio to urea is 1:1.67, Co(NO 3 ) 2 The molar ratio with water is 1:1000.

[0096] (2) with embodiment 1

[0097] (3) Same as Example 1, the obtained sample is designated as sample 2.

[0098] Compared with Example 1, the quality of urea in the raw materials used in this example has changed, and the rest of the preparation conditions have not changed. As the quality of urea decreases, the nitrogen-doped carbon coating of the catalyst finally obtained becomes thinner, The amount of nitrogen doping is reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com